Translucent ceramics and methods of making the same

A translucent and ceramic technology, applied in the field of ceramic processing, can solve the problems of not being effectively used, occupying land resources, dust pollution, etc., and achieve the effect of improving optical properties and ornamental properties, simple preparation process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

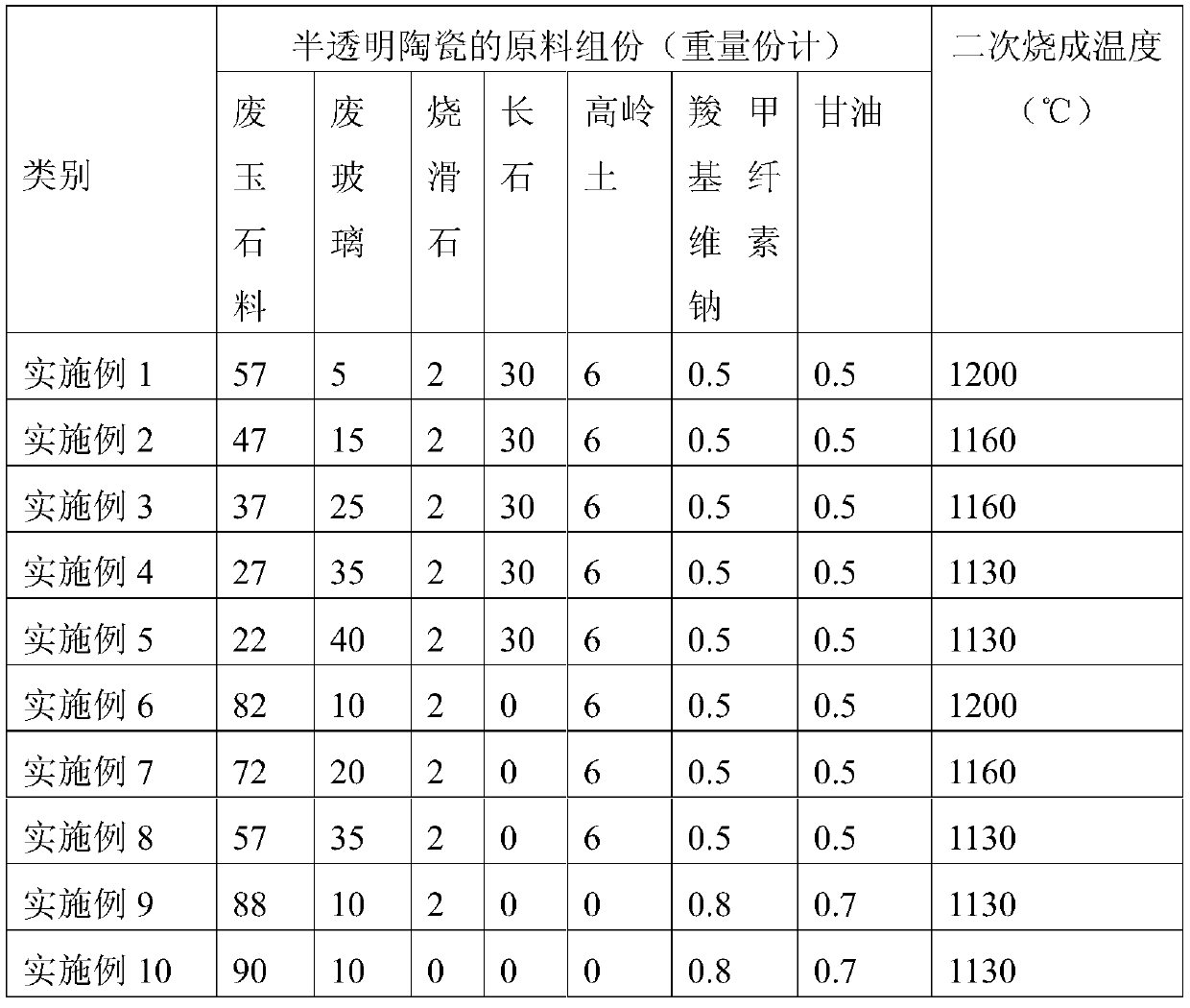

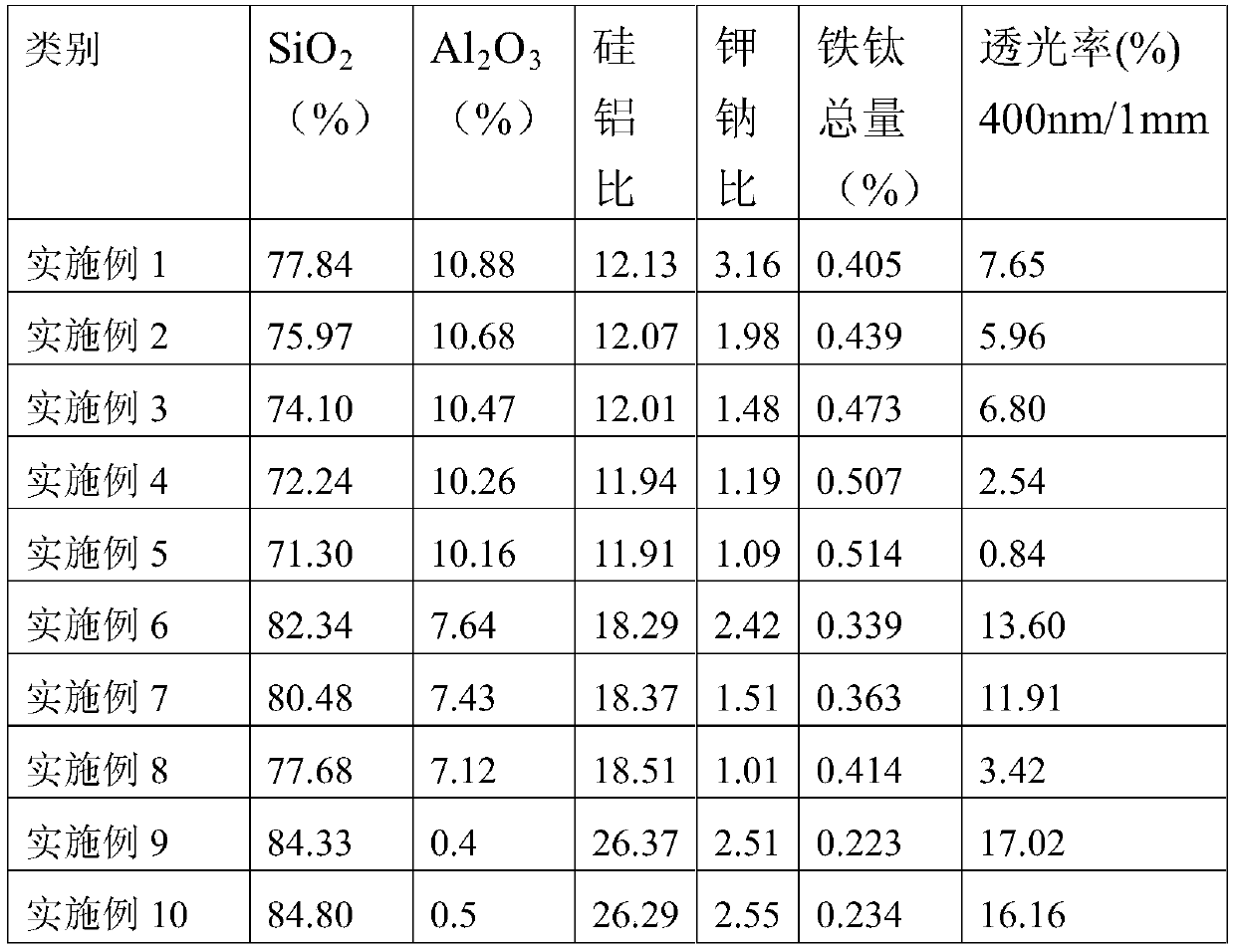

Examples

Embodiment 1

[0027] A kind of preparation method of translucent ceramic comprises the steps:

[0028] 1) Crushing, sorting, grinding waste jade, waste glass, burnt talc, feldspar and kaolin in the required raw materials, passing through a 100-mesh sieve, drying, and then weighing each raw material according to the required ratio and mixing , to obtain raw material powder after stirring evenly;

[0029] 2) Weigh the sodium carboxymethyl cellulose according to the required ratio, add water and stir quickly, dissolve the sodium carboxymethyl cellulose in water completely and then add it to the raw material powder mixed uniformly in step 1), and use a fast grinder to Add water and wet mill for 30 minutes; then add glycerin and mix evenly to obtain a mixture;

[0030] 3) Pass the mixture in step 2) through sieves of 120 mesh, 160 mesh, and 200 mesh respectively, and use a 1T-type iron remover to remove iron, and then use a gypsum mold to dehydrate the raw materials after iron removal by the ir...

Embodiment 2

[0034] 1) Crushing, sorting, grinding waste jade, waste glass, burnt talc, feldspar and kaolin in the required raw materials, passing through a 100-mesh sieve, drying, and then weighing each raw material according to the required ratio and mixing , to obtain raw material powder after stirring evenly;

[0035] 2) Weigh the sodium carboxymethyl cellulose according to the required ratio, add water and stir quickly, dissolve the sodium carboxymethyl cellulose in water completely and then add it to the raw material powder mixed uniformly in step 1), and use a fast grinder to Add water and wet mill for 40 minutes; then add glycerin and mix evenly to obtain a mixture;

[0036] 3) Pass the mixture in step 2) through sieves of 120 mesh, 160 mesh, and 200 mesh respectively, and use a 1T-type iron remover to remove iron, and then use a gypsum mold to dehydrate the raw materials after iron removal by the iron remover to a moisture content of 20 %, moisturizing stale for 4 days, get mud; ...

Embodiment 3

[0040] 1) Crushing, sorting, grinding waste jade, waste glass, burnt talc, feldspar and kaolin in the required raw materials, passing through a 100-mesh sieve, drying, and then weighing each raw material according to the required ratio and mixing , to obtain raw material powder after stirring evenly;

[0041]2) Weigh the sodium carboxymethyl cellulose according to the required ratio, add water and stir quickly, dissolve the sodium carboxymethyl cellulose in water completely and then add it to the raw material powder mixed uniformly in step 1), and use a fast grinder to Add water and wet mill for 60 minutes; then add glycerin and mix evenly to obtain a mixture;

[0042] 3) Pass the mixture in step 2) through sieves of 120 mesh, 160 mesh, and 200 mesh respectively, and use a 1T type iron remover to remove iron, and then use a gypsum mold to dehydrate the raw materials after iron removal by the iron remover to a moisture content of 25 %, moisturizing stale for 5 days, get mud; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com