Diatom-containing ecological brick and production method thereof

A production method and technology for ecological bricks, applied in the field of decorative materials, can solve the problems of long construction period, high construction skill requirements, and high construction cost, and achieve the effects of low cost, improved antibacterial and mildew resistance, and reduced firing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

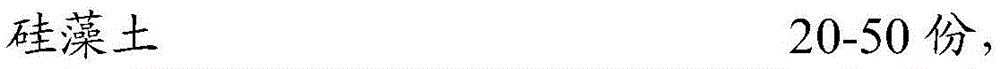

[0033] Raw material components:

[0034]

[0035]

[0036] Preparation:

[0037] The components (except 30% sodium silicate aqueous solution binder and water) were measured according to the above-mentioned parts by weight, added to the mixer for dry mixing for 30 minutes, and 17 parts of 30% sodium silicate aqueous solution binder was added to 7 Part of water, stir evenly, add to the dry material, continue to stir for 30 minutes, to obtain the wet material.

[0038] Add the wet material into the hopper of the granulator, and granulate to obtain wet granules (moisture content 15.8%).

[0039] Put the wet granules into a tray, put them into a blast drying oven, dry them at 50°C for 40 minutes, then mature them in a closed container for 24 hours, and pass through a 30-mesh vibrating sieve to obtain dry granules (moisture content 12%, bulk density 0.55 g / cm 3 ).

[0040] The dry pellets are sent into a press, pressed for 1 minute at a pressure of 30Mpa, and pressed into ...

Embodiment 2

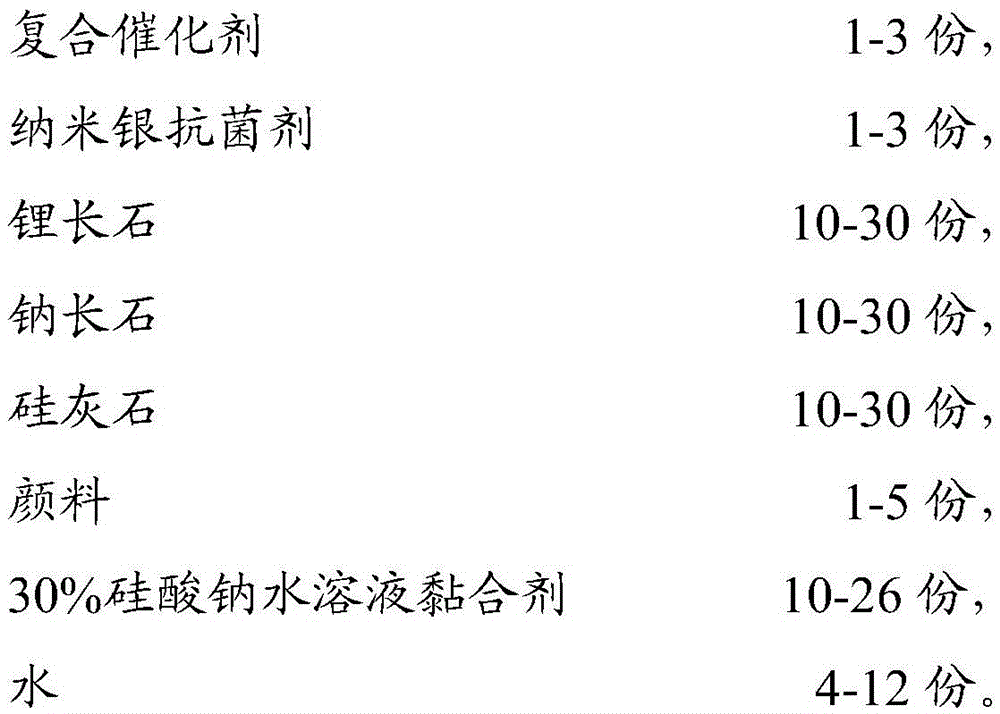

[0045] Raw material components:

[0046]

[0047]

[0048] Preparation:

[0049] The components (except 30% sodium silicate aqueous solution binder and water) were measured according to the above-mentioned parts by weight and added to the mixer for dry mixing for 45 minutes. 26 parts of 30% sodium silicate aqueous solution binder were added to 12 Part of water, stir evenly, add to the dry material, and continue to stir for 60 minutes to obtain the wet material.

[0050] Add the wet material into the hopper of the granulator, and granulate to obtain wet granules (moisture content 16.0%).

[0051] Put the wet pellets into a tray, put them in a blast drying oven, dry them at 50°C for 20 minutes, and then mature them in a closed container for 24 hours, and pass through a 30-mesh vibrating screen to obtain dry pellets (moisture content 12%, bulk density 0.54 g / cm 3 ).

[0052]The dry granules are sent into a press, pressed for 1 minute with a pressure of 40Mpa, and presse...

Embodiment 3

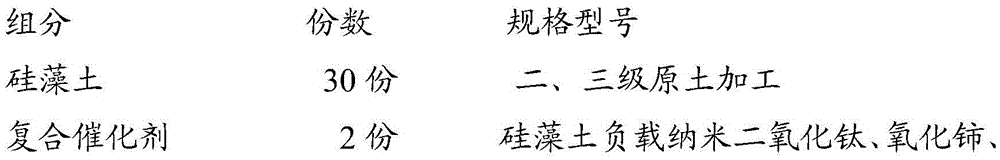

[0057] Raw material components:

[0058]

[0059]

[0060] Preparation:

[0061] The components (except 30% sodium silicate aqueous solution binder and water) were measured according to the above-mentioned parts by weight, added to the mixer for dry mixing for 30 minutes, and 10 parts of 30% sodium silicate aqueous solution binder was added to 4 part of water, stir evenly, add to the dry ingredients, and continue to stir for 30 minutes to obtain wet ingredients;

[0062] The wet material is added into the hopper of the granulator, and granulated to obtain wet granules (moisture content 16.4%).

[0063] Put the wet granules into a tray, put them in a blast drying oven, dry them at 50°C for 60 minutes, then mature them in a closed container for 24 hours, and pass through a 20-mesh vibrating sieve to obtain dry granules (moisture content 12%, bulk density 0.53 g / cm 3 ).

[0064] The dry pellets are sent into a press, pressed for 1 minute at a pressure of 30Mpa, and pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com