Bone-green porcelain

A technology of bone powder and porcelain powder, applied in the field of bone emerald china, can solve the problems of inability to form a production scale, poor quality of Lu celadon porcelain, restricted product development, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

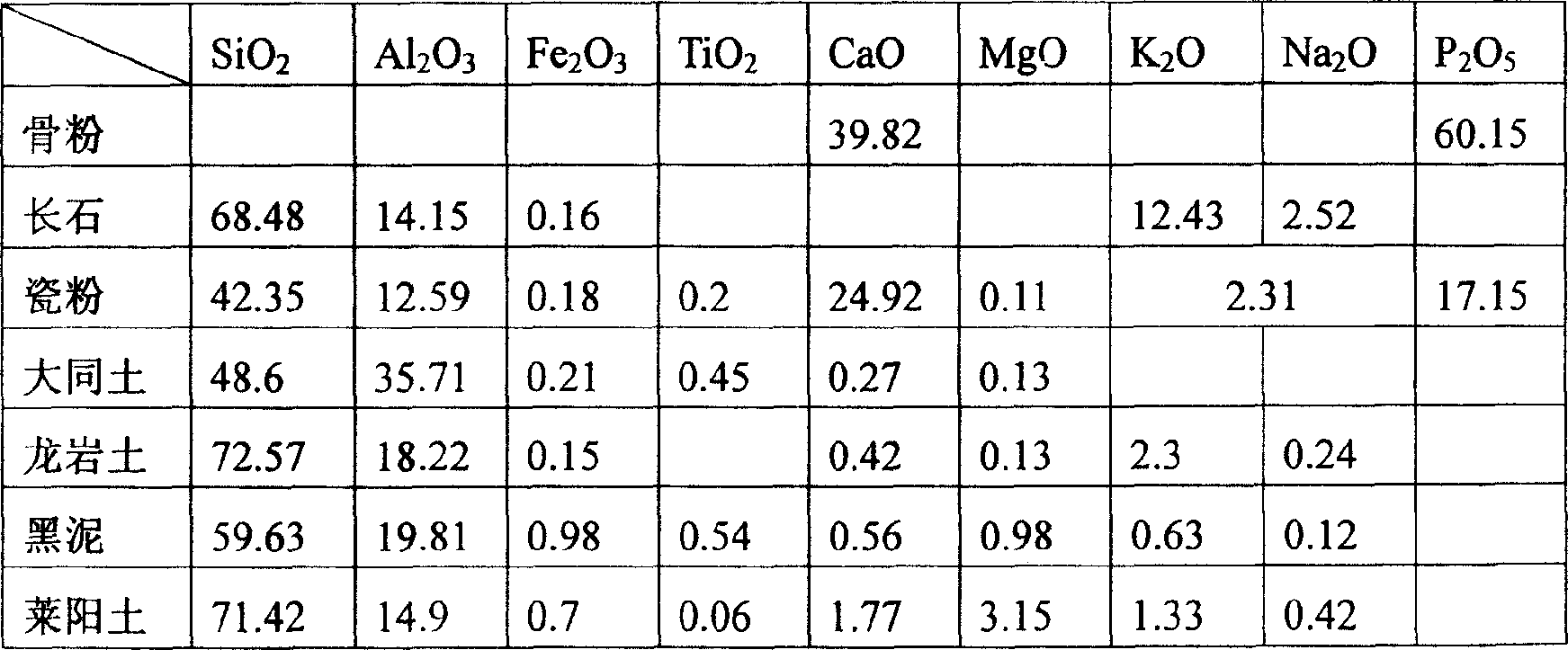

Method used

Image

Examples

Embodiment 1

[0023] Bone emerald porcelain of the present invention, batching weight percent is composed of:

[0024] 33% bone meal, 9% feldspar, 16% porcelain powder, 26% Datong, 8% Longyan soil, 6% black mud and 2% Laiyang soil, plus 0.10% copper oxide and 0.15% iron oxide.

[0025] Put the above-mentioned ingredients into a ball mill according to the conventional method, then press filter, and then use a vacuum mud trainer to refine the filter cake into a mud bar with a water content of 21%, and roll it into a 6-inch flat disc with a rolling machine, at 1270 ± 5 Bisque firing at a temperature of ℃, and then apply lead-free frit glaze (the weight percentage of lead-free glaze is composed of: SiO 2 55%, AI 2 o 3 10%, KNaO10%, Li 2 O1%, BaO10%, ZnO5%, B 2 o 3 9%), firing at a temperature of 1170±10° C. to obtain the emerald-green bone emerald china of the present invention.

Embodiment 2

[0027] Bone emerald porcelain of the present invention, batching weight percent is composed of:

[0028] Bone powder 35%, feldspar 10%, porcelain powder 18%, Datong 22%, Longyan soil 8%, black mud 6%, Laiyang soil 1%, plus copper oxide 0.13% and iron oxide 0.14%.

[0029] Put the above-mentioned ingredients into a ball mill according to the conventional method, then press filter, and then use a vacuum mud refiner to refine the filter cake into a mud bar with a water content of 21%, and use a rolling machine to press the flat plate. Bisque firing, then apply lead-free frit glaze (the weight percentage of lead-free glaze is composed of: SiO 2 55%, AI 2 o 3 10%, KNaO10%, Li 2 O1%, BaO10%, ZnO5%, B 2 o 3 9%), firing at a temperature of 1170±10° C. to obtain the emerald green bone emerald china of the present invention.

Embodiment 3

[0031] Bone emerald porcelain of the present invention, batching weight percent is composed of:

[0032] 32% bone meal, 9% feldspar, 18% porcelain powder, 25% Datong, 9% Longyan soil, 5% black mud and 2% Laiyang soil, plus 0.13% copper oxide and 0.14% iron oxide.

[0033] Put the above-mentioned ingredients into a ball mill according to the conventional method, then press filter, and then use a vacuum mud refiner to refine the filter cake into a mud bar with a moisture content of 22%, and press a 5-inch bowl with a rolling machine. Under biscuit firing, then apply lead-free frit glaze (the weight percentage of lead-free glaze is composed of: SiO 2 55%, AI 2 o 3 10%, KNaO10%, Li 2 O1%, BaO10%, ZnO5%, B 2 o 3 9%), firing at a temperature of 1160±10° C. to obtain the emerald green bone emerald china of the present invention.

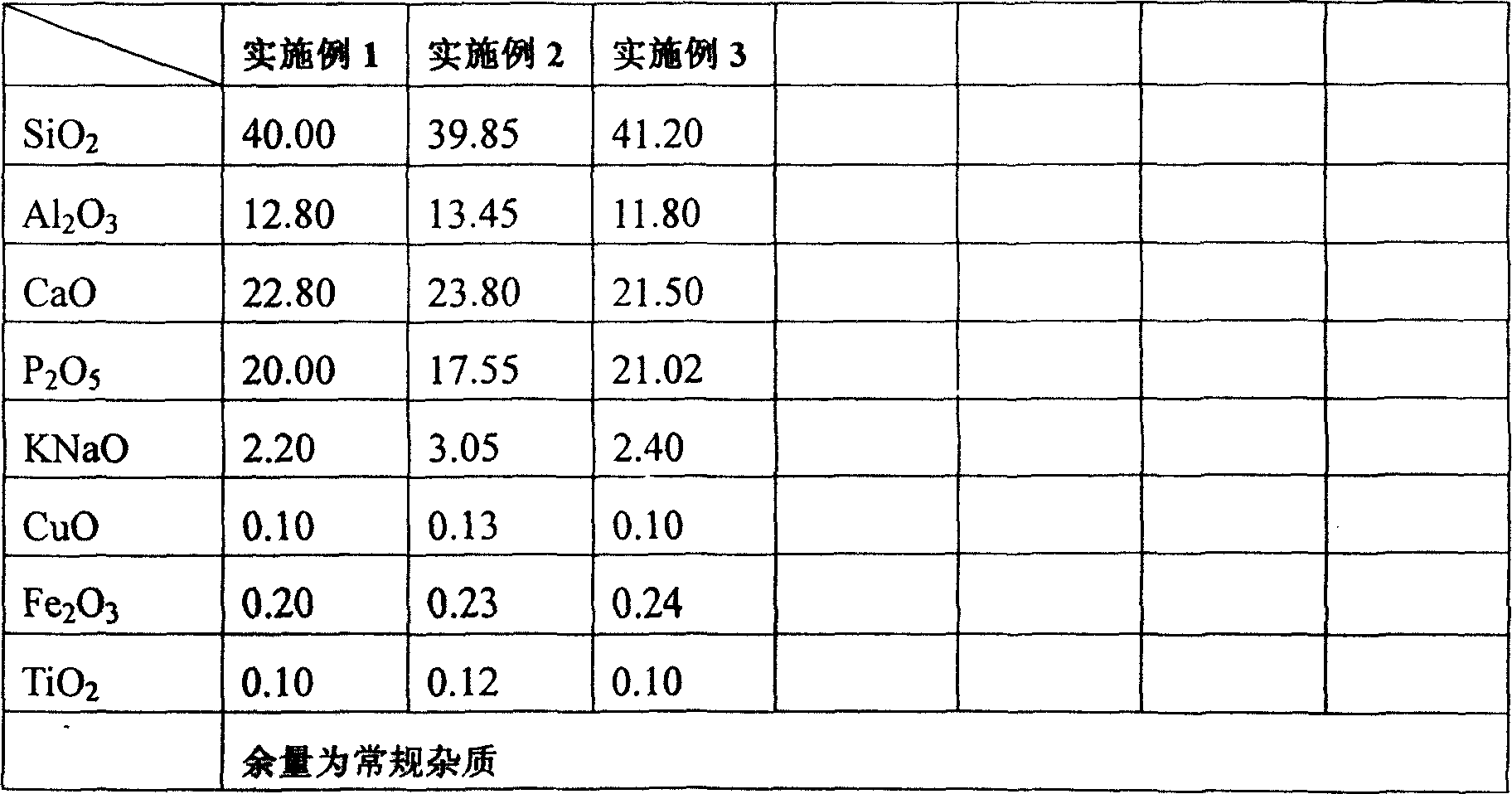

[0034] The chemical weight percentage compositions corresponding to each embodiment are shown in Table 2.

[0035] Table 2, the chemical weight perc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com