Plasticization process of bone porcelain pug

A technology of bone china and clay, applied to clay products, other household utensils, household utensils, etc., can solve the problems of high price and high cost, eliminate negative effects, reduce energy consumption, improve whiteness and The effect of translucency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below with a specific embodiment:

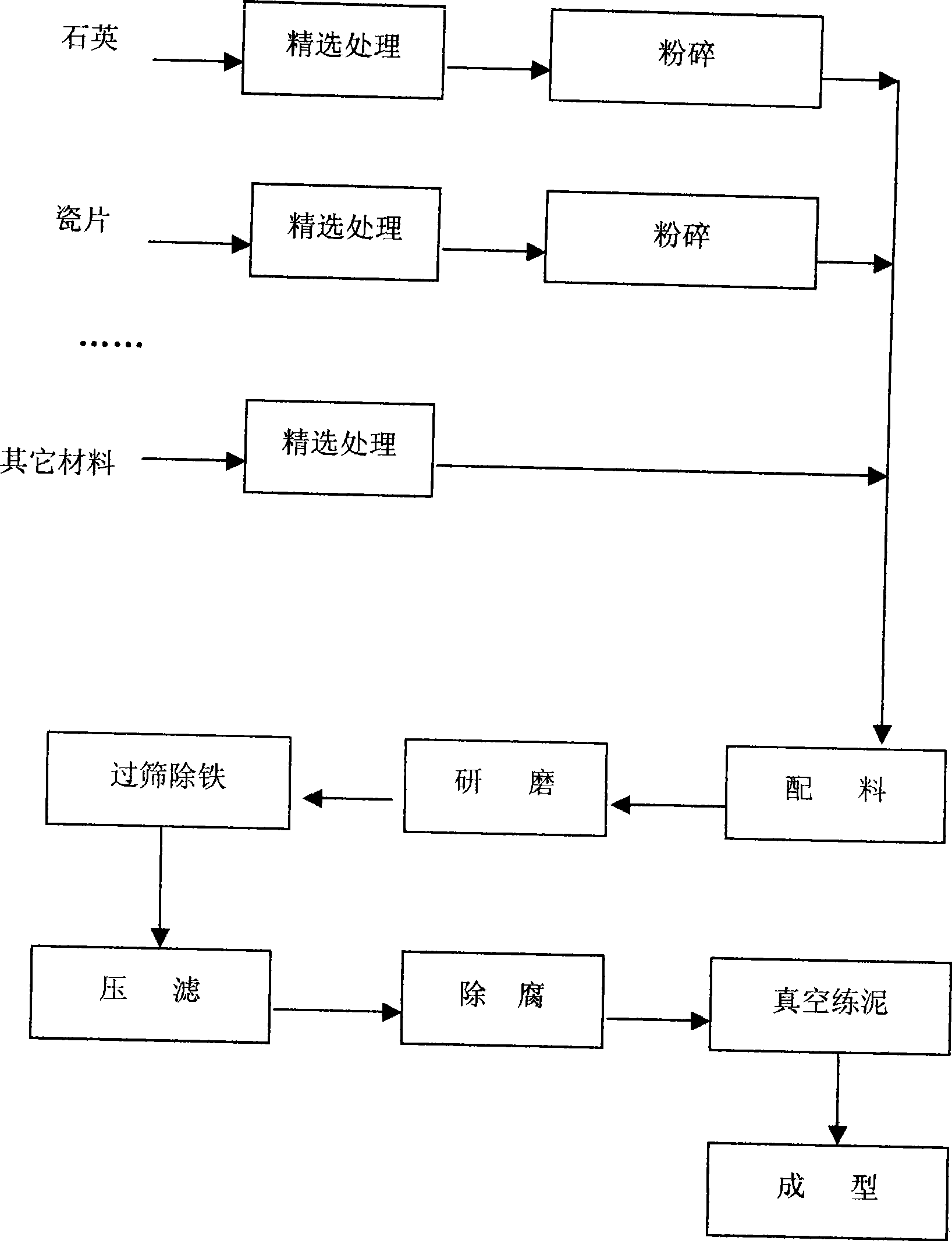

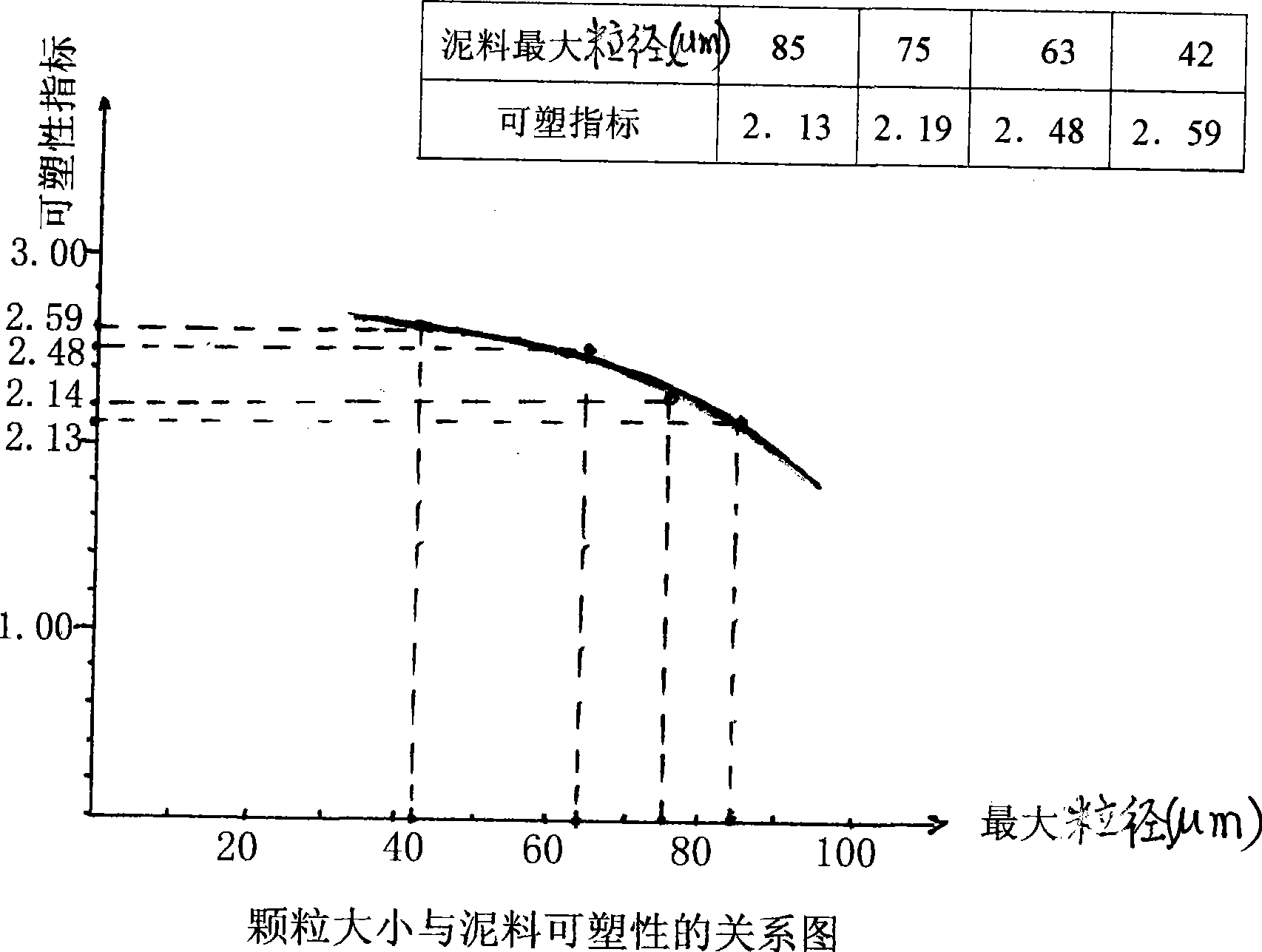

[0013] refer to figure 1 , a plasticizing process for bone china mud, including hard raw material crushing → batching → grinding → sieving to remove iron → press filtration → stale → vacuum mud refining and other processes. In this embodiment, the raw materials include quartz, For hard raw materials such as ceramic chips, the hard raw materials such as quartz and ceramic chips are crushed in advance until the maximum particle size of the material is <42μm, and these pulverized hard raw materials are mixed with other raw materials according to the formula, and then the mixture is placed in a ball mill. Grind until the maximum particle size of the material is <42μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com