Ceramic manufacturing method using quartz as matrix material and product

A technology of matrix material and production method, which is applied in the field of daily-use ceramics, can solve the problems of lack of high-quality clay resources, and achieve the effects of abundant reserves, high strength, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

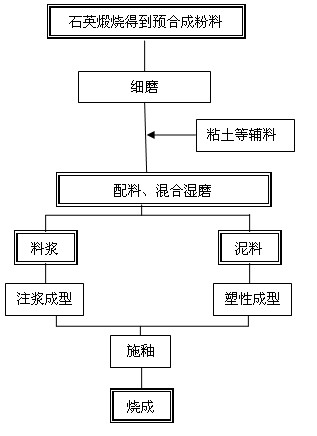

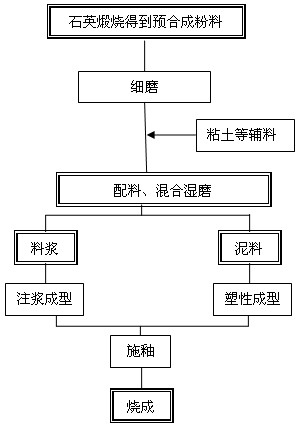

Method used

Image

Examples

Embodiment 1

[0028] A ceramic production method using quartz as the base material, using quartz (silicon dioxide) as the base material, and using alumina, basic oxide and magnesia as auxiliary materials; this embodiment uses the following raw material composition (mass percentage):

[0029] Silica 93-94%

[0030] Alumina 5%

[0034] The remainder is impurity

[0035] First calcining the silicon dioxide raw material at 500-700°C, during the calcining process, β-quartz is transformed into α-quartz through crystal transformation to obtain a pre-synthesized powder, and then finely grind the obtained pre-synthesized powder. The raw materials with a particle size of less than 5 microns in the ground pre-synthesized powder account for 25% of the total amount of silica raw materials, and the rest are raw materials with a particle size greater than 5 microns. The pre-synthesized powder and other auxiliary m...

Embodiment 2

[0042] A ceramic production method using quartz as the base material, using quartz (silicon dioxide) as the base material, and using alumina, basic oxide and magnesia as auxiliary materials; this embodiment uses the following raw material composition (mass percentage):

[0043] Silica 90-92%

[0044] Alumina 3-4%

[0045] Calcium Oxide 0.2-0.3%

[0046] Potassium oxide 0.3-0.5%

[0047] Magnesium Oxide 0.2-0.5%

[0048] The remainder is impurity

[0049] First calcining the silicon dioxide raw material at 600-650°C, during the calcining process, β-quartz is transformed into α-quartz through crystal transformation to obtain a pre-synthesized powder, and then the obtained pre-synthesized powder is finely ground, finely The raw materials with a particle size of less than 5 microns in the ground pre-synthesized powder account for 25% of the total amount of silica raw materials, and the rest are raw materials with a particle size greater than 5 microns. The pre-synthesized pow...

Embodiment 3

[0055] A ceramic production method using quartz as the base material, using quartz (silicon dioxide) as the base material, and using alumina, basic oxide and magnesia as auxiliary materials; this embodiment adopts the following raw material composition (mass percentage):

[0056] Silica 92-93%

[0057] Alumina 4-5%

[0058] Calcium Oxide 0.6-0.7%

[0059] Potassium oxide 0.6-0.7%

[0060] Magnesium Oxide 0.6-1%

[0061] The remainder is impurity

[0062] Firstly, the silicon dioxide raw material is calcined at 500-700°C to convert β-quartz to α-quartz to obtain a pre-synthesized powder, and then the obtained pre-synthesized powder is finely ground, and the particle size of the pre-synthesized powder after fine grinding is Raw materials smaller than 5 microns account for 25% of the total amount of silica raw materials, and the remainder is raw materials with a particle size larger than 5 microns. Pre-synthesized powder, clay, potassium feldspar, talc and wollastonite are w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com