Patents

Literature

30 results about "Diesel spray" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

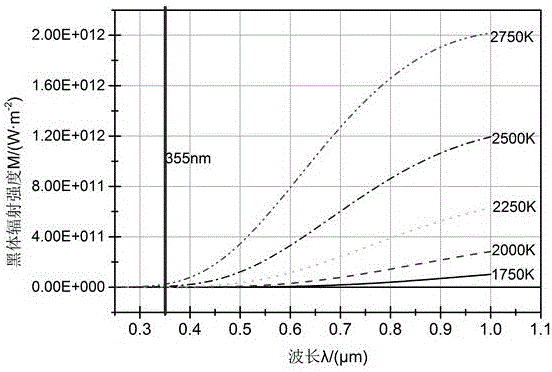

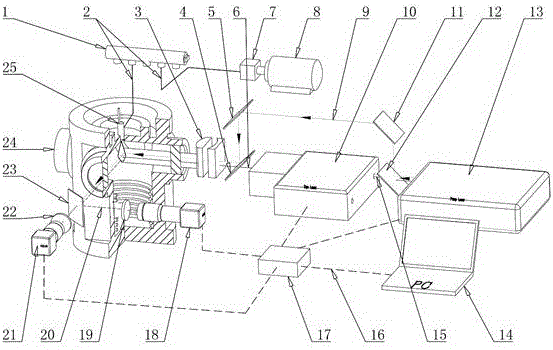

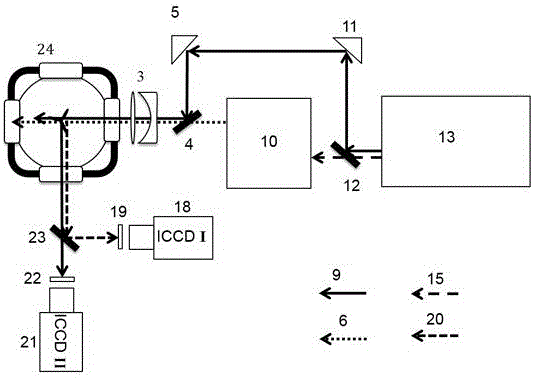

Apparatus capable of simultaneously measuring diesel spray structure and combustion characteristic and method thereof

ActiveCN106404410AReduce radiation interferenceAchieve resolutionInternal-combustion engine testingDiesel sprayDiesel combustion

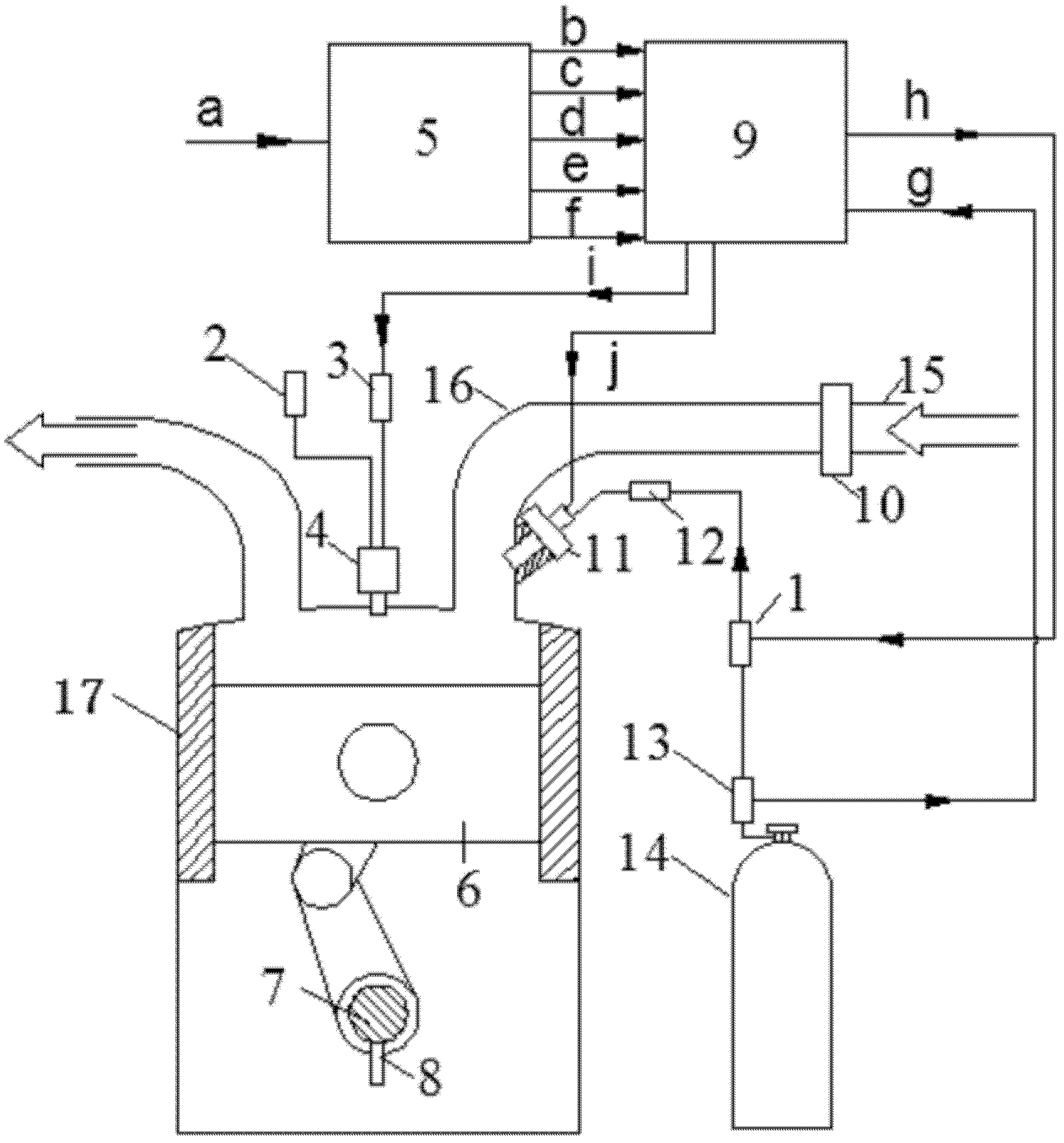

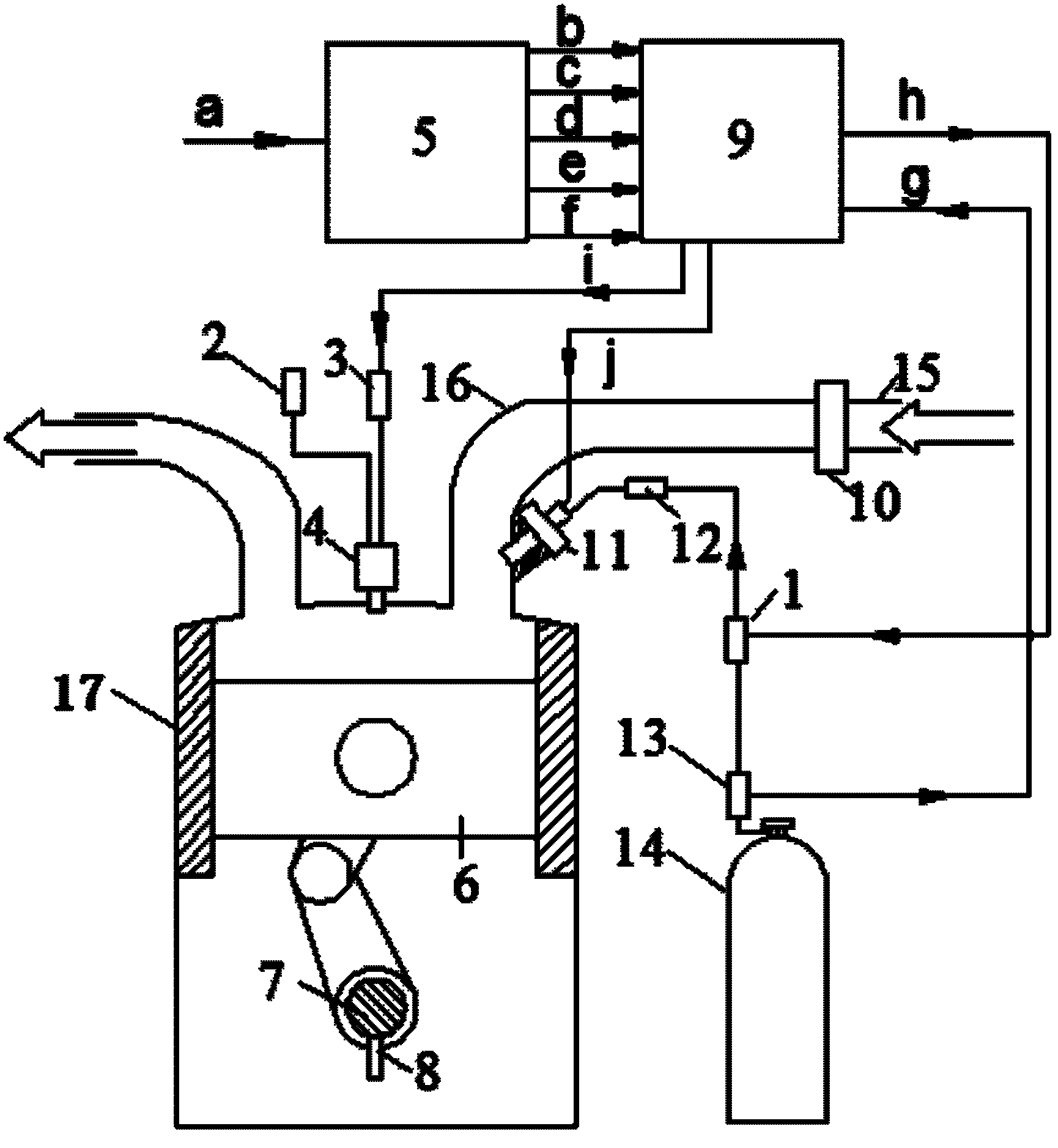

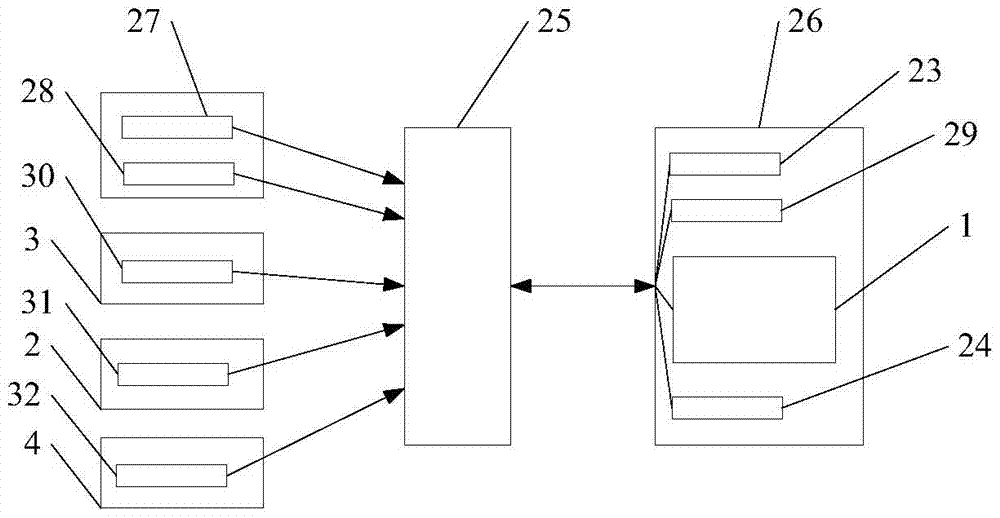

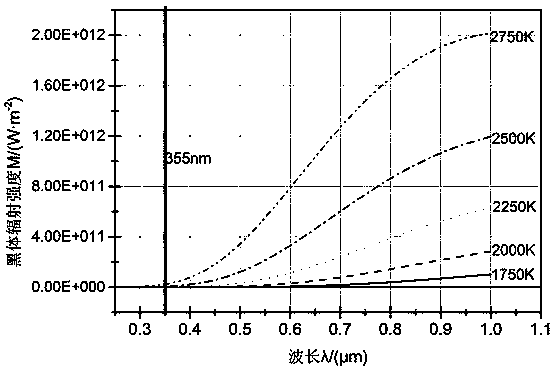

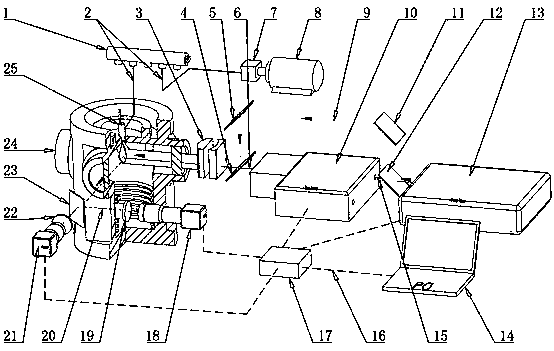

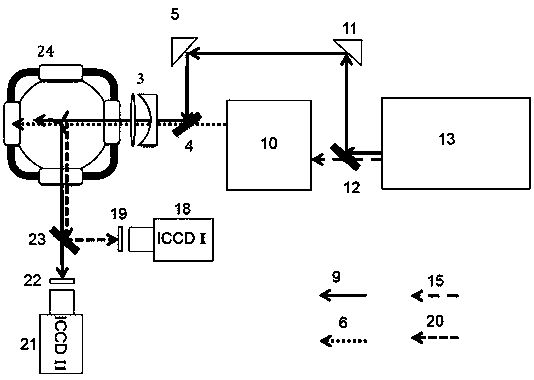

The invention belongs to the diesel spray and combustion visualization research field and discloses a measurement apparatus capable of simultaneously measuring a diesel spray structure and a combustion characteristic based on a laser diagnosis technology and a method thereof. In the past, test researches of a diesel spray characteristic and the combustion characteristic can not be performed simultaneously. In the invention, through using a Mie scattering technology of a laser and a laser induced fluorescence technology (OH-PLIF), the spray structure and the combustion characteristic during diesel combustion can be simultaneously measured and researched. The corresponding apparatus comprises a laser system, a constant volume combustion bomb system, a fuel oil supply system, a signal synchronization system and a signal acquisition system. The test apparatus can simultaneously carry out test researches of a liquid phase length of diesel spray and OH-PLIF distribution under a combustion condition, simultaneously can indicate a liquid phase area in a diesel combustion OH-PLIF distribution map and solves an interference problem of a liquid phase signal to a laser-induced fluorescence signal.

Owner:JIANGSU UNIV

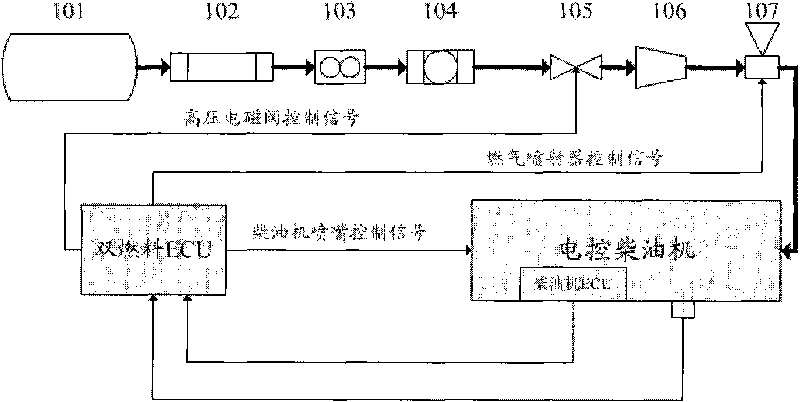

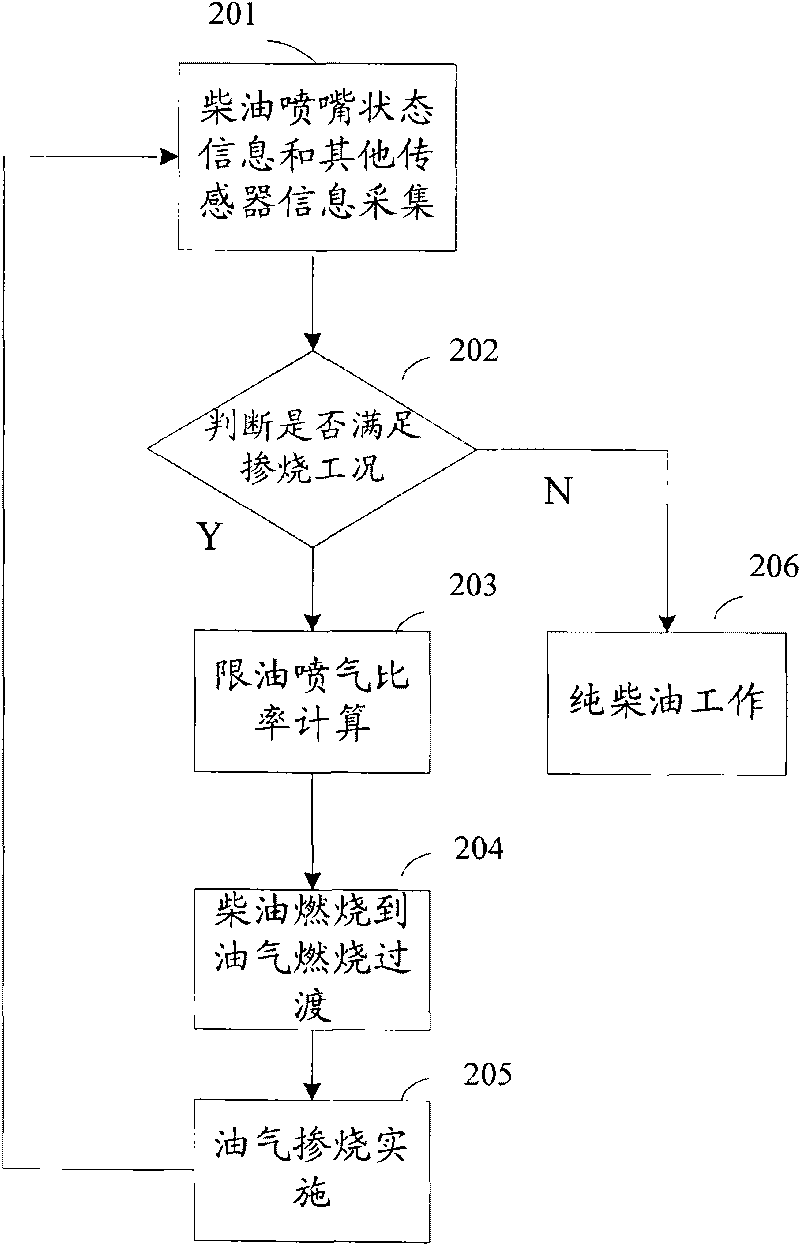

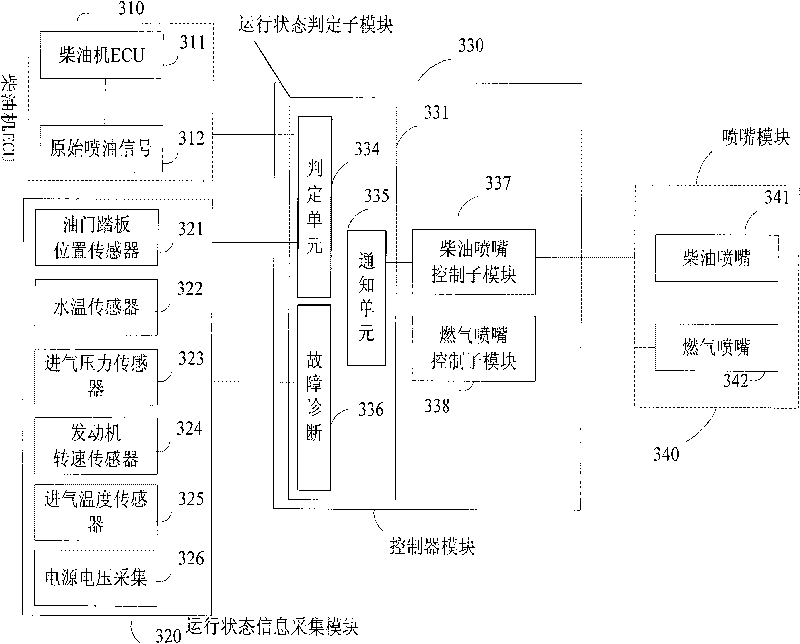

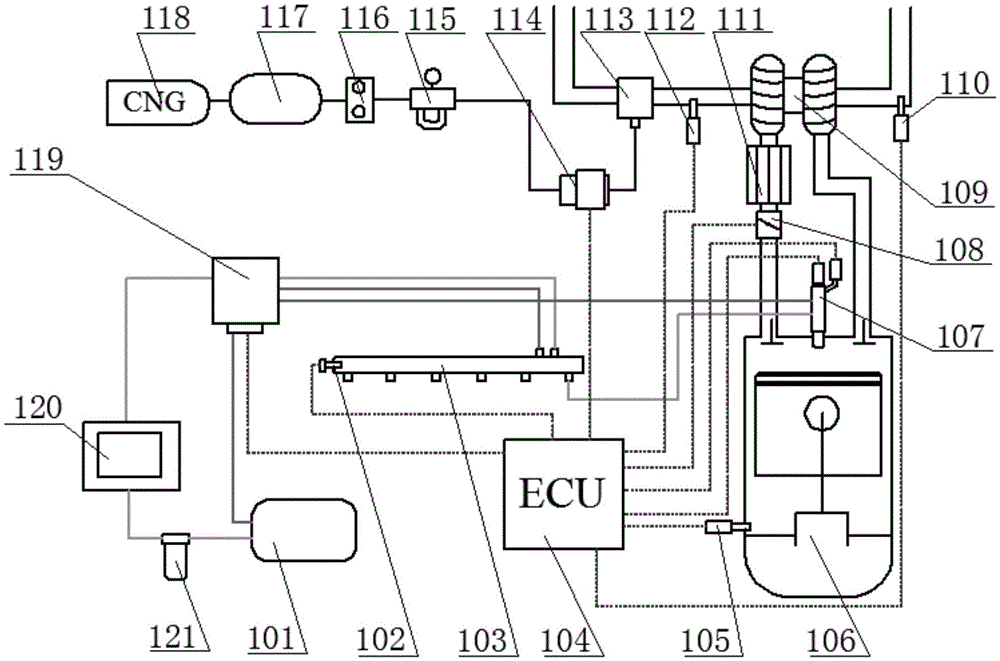

Method and device for controlling blending gas of electric-control diesel engine

InactiveCN101761406AEmission reductionReduce consumption rateElectrical controlMachines/enginesMicrocontrollerDiesel spray

The invention relates to a method and a device for controlling blending gas of an electric-control diesel engine. The invention can judge the running state of the engine according to rotation speed signals, throttle pedal signals, original diesel spraying pulse width signals and the like, and reasonably set the blending ratio to enable the diesel and gas ratio to achieve the optimum proportion state, therefore the diesel consumption rate and waste gas exhaust are reduced on the premise of ensuring the dynamic property of the engine. The method for controlling blending gas of an electric-control diesel engine comprises a quick and moderate control method for diesel and gas switching, a real-time accurate control method for gas amount and diesel amount, a self-learning control method for bad working conditions and a fault diagnosis function with fault diagnosis and alarming. The device for controlling blending gas of an electric-control diesel engine comprises a signal acquisition module, a diesel spraying amount acquisition and control module, a natural gas supply control module, a microcontroller, a CAN communication module and a serial communication module.

Owner:BAZHOU HUAWEI ENGINE TECH +2

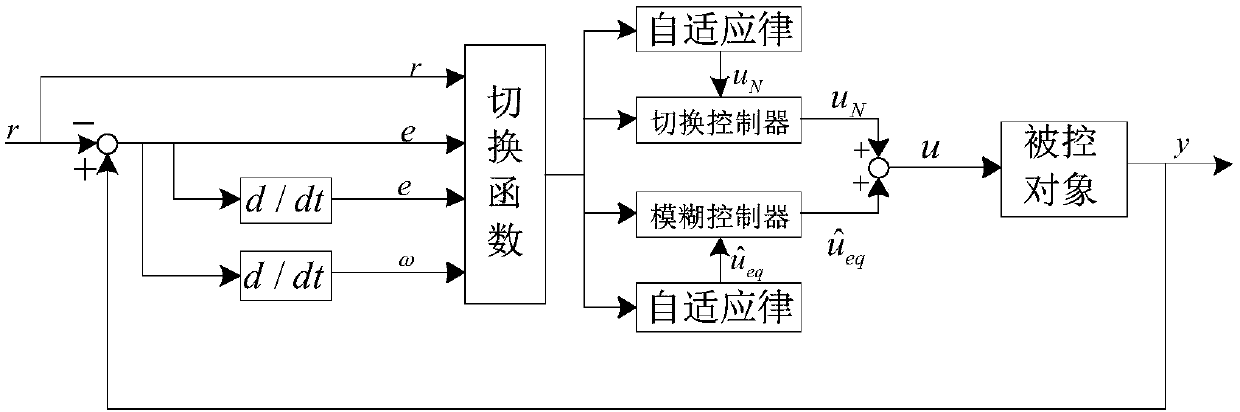

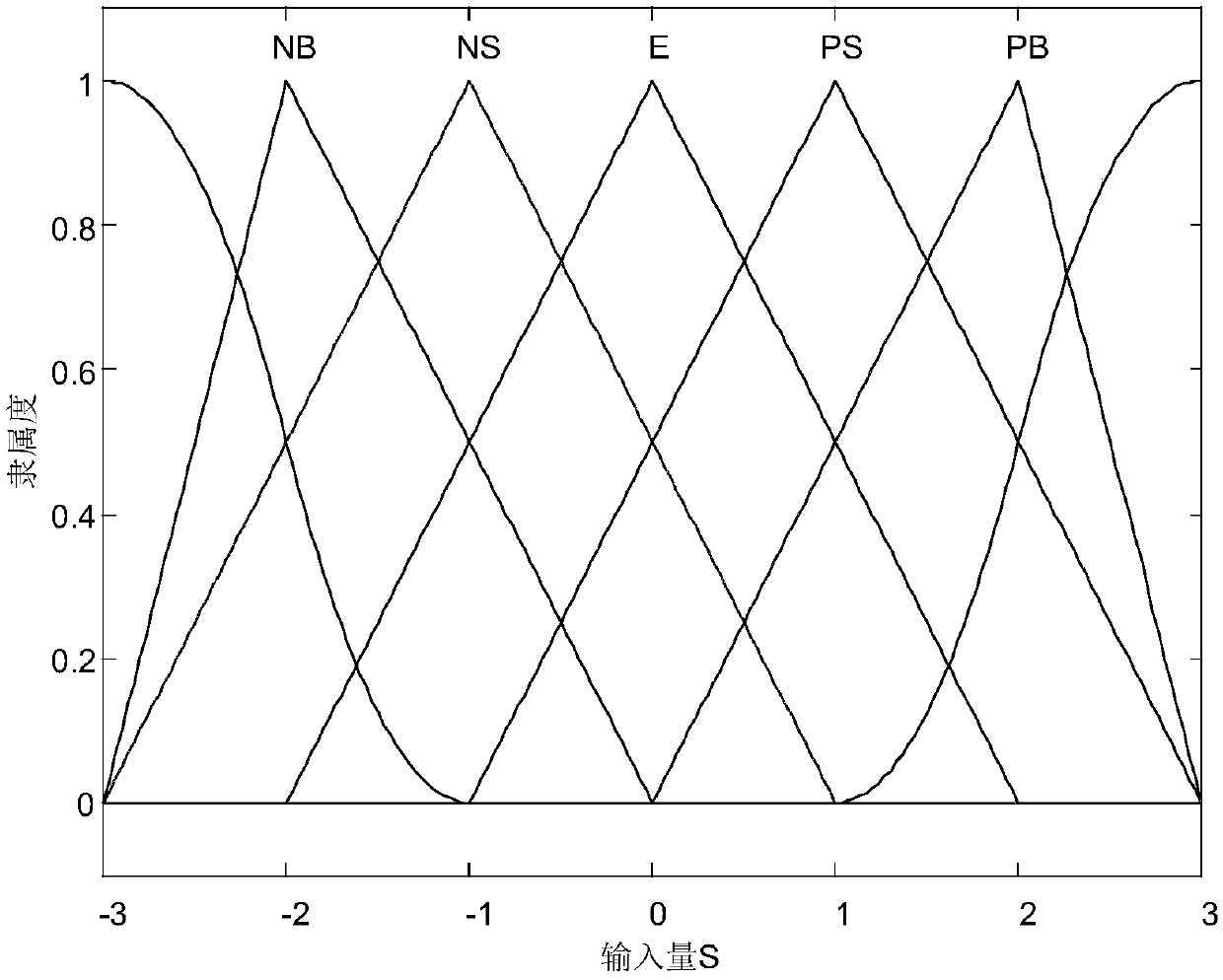

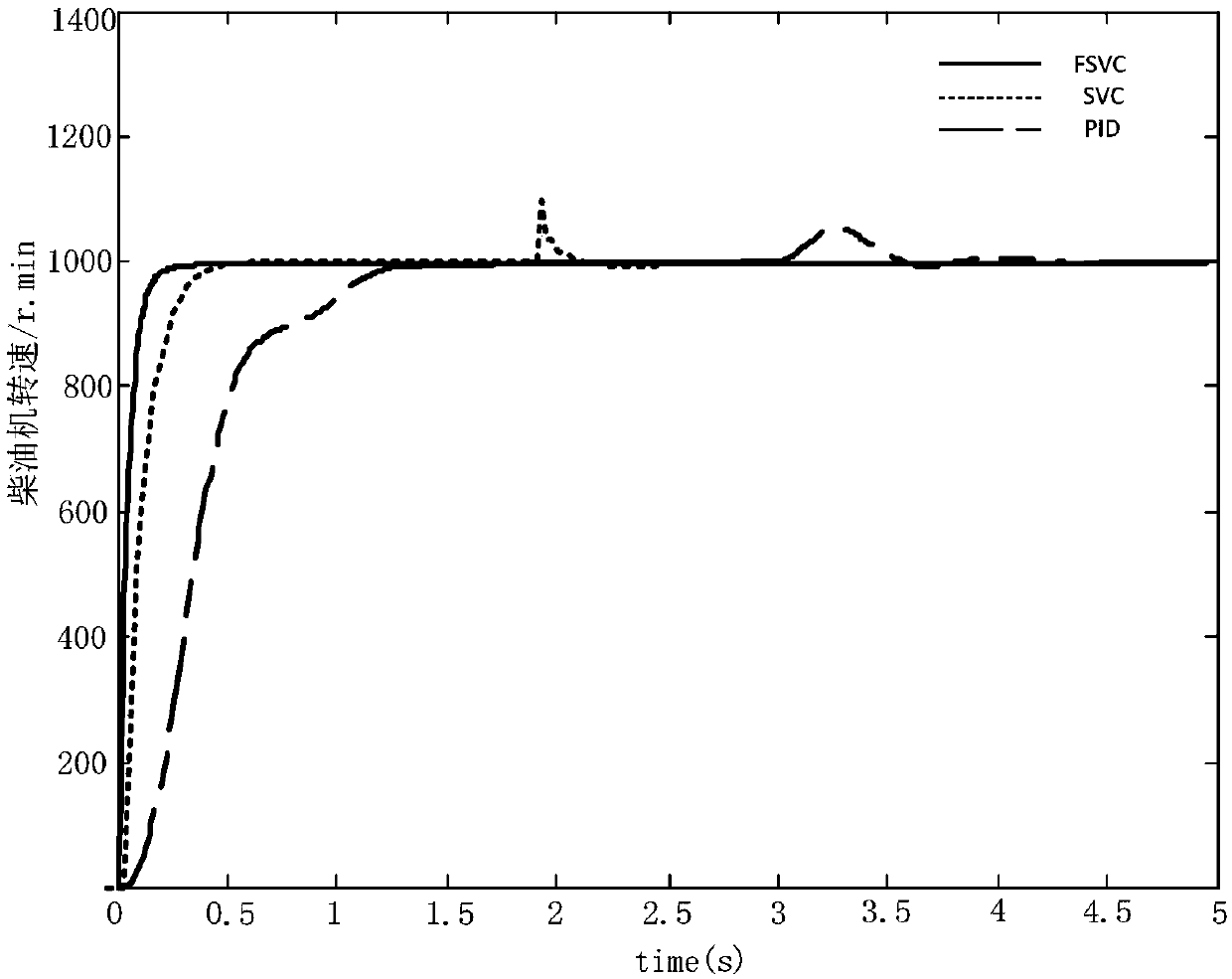

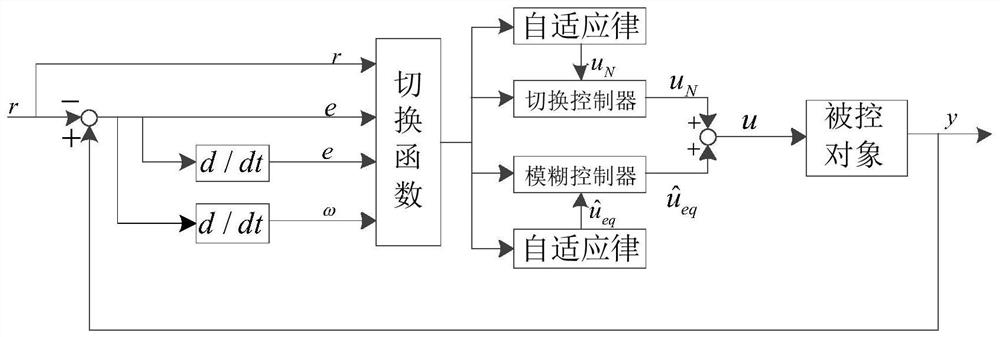

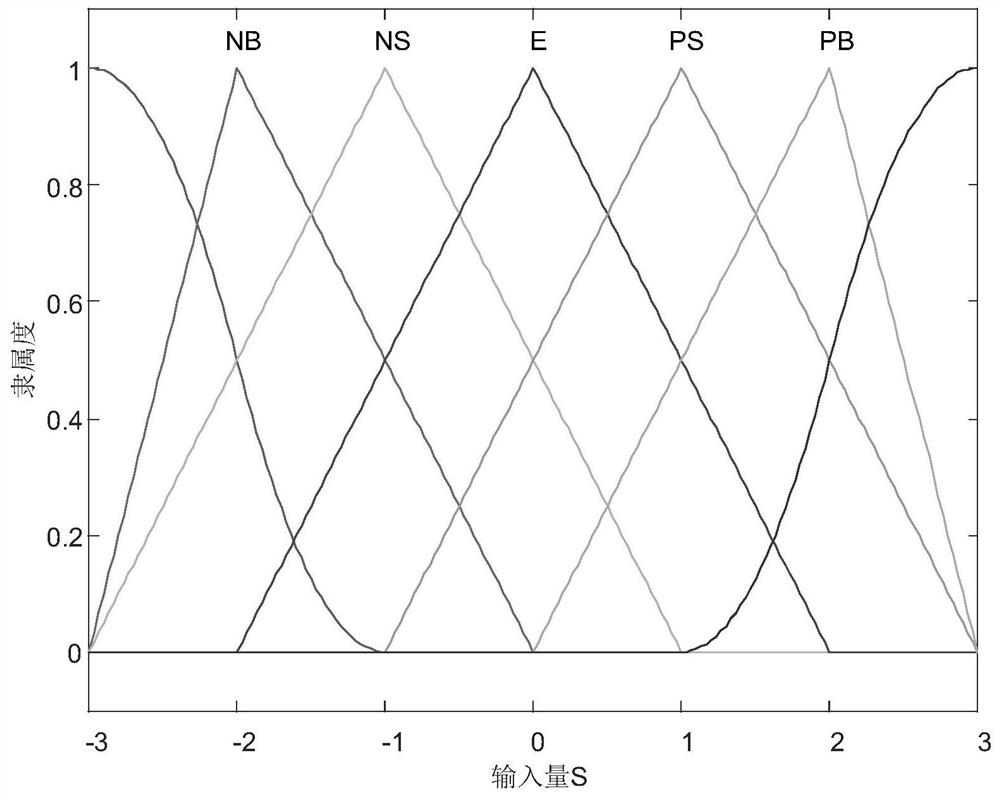

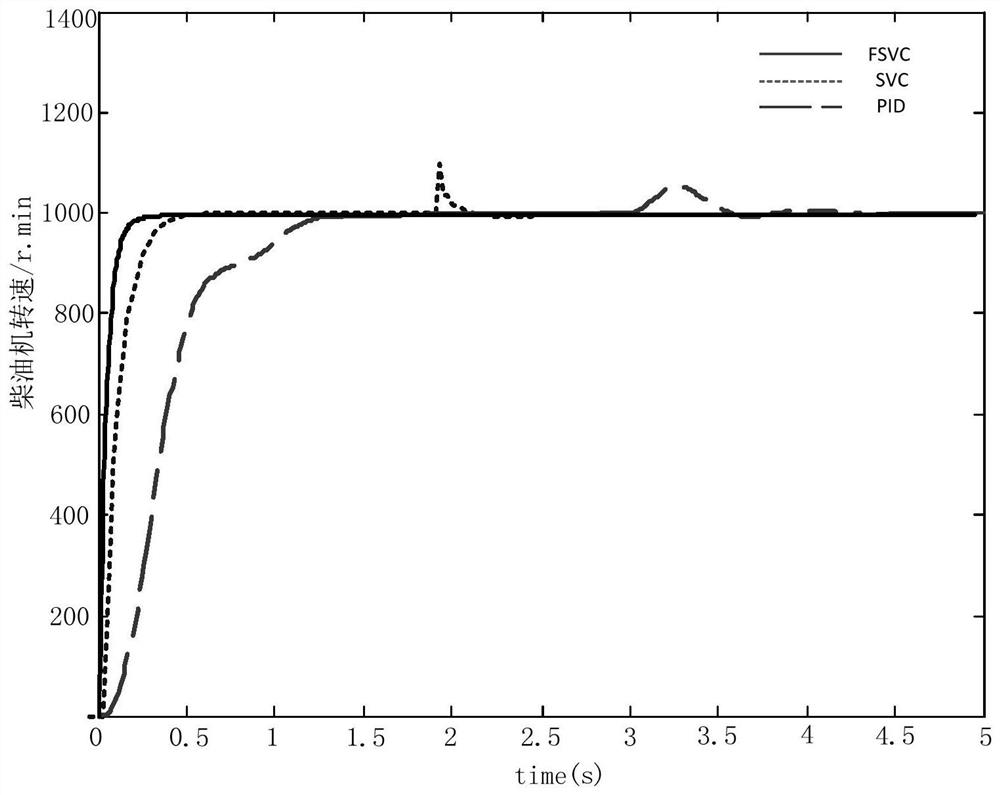

Diesel engine electronic-control speed adjusting and testing method based on fuzzy variable structure

ActiveCN108757192AGood control effectEasy to controlElectrical controlSpeed sensing governorsDiesel sprayEngineering

The invention provides a diesel engine electronic-control speed adjusting and testing method based on a fuzzy variable structure. An electronic-control speed adjusting system algorithm of a diesel engine is optimally designed. A nonlinear object dynamic model and an executer of the diesel engine are subjected to modeling, and a diesel spraying system of the diesel engine is controlled through thefuzzy variable structure; then discontinuous control conditions are deduced through the Lyapunov function, and it is proved that a system has the capacity of stability adaptive adjusting under uncertain interference; and finally, the diesel engine speed-adjusting system is subjected to a Matlab / Simulink simulation experiment. Control over accuracy of the rotating speed of the diesel engine by thediesel engine electronic-control speed adjusting system can be improved to a great extent under the uncertain interference, and the good effect under various uncertain interference backgrounds such asstarting, idling, working condition sudden increasing and reducing is achieved so that the method can meet the situation that the good control effect is achieved on the diesel engine in the practicalworking process.

Owner:HANGZHOU DIANZI UNIV

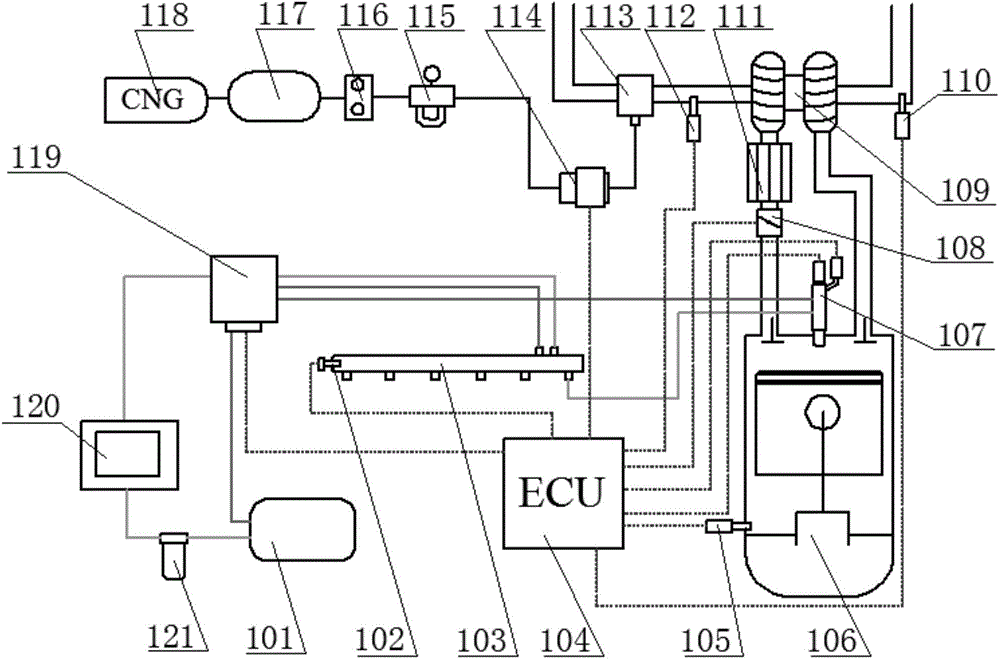

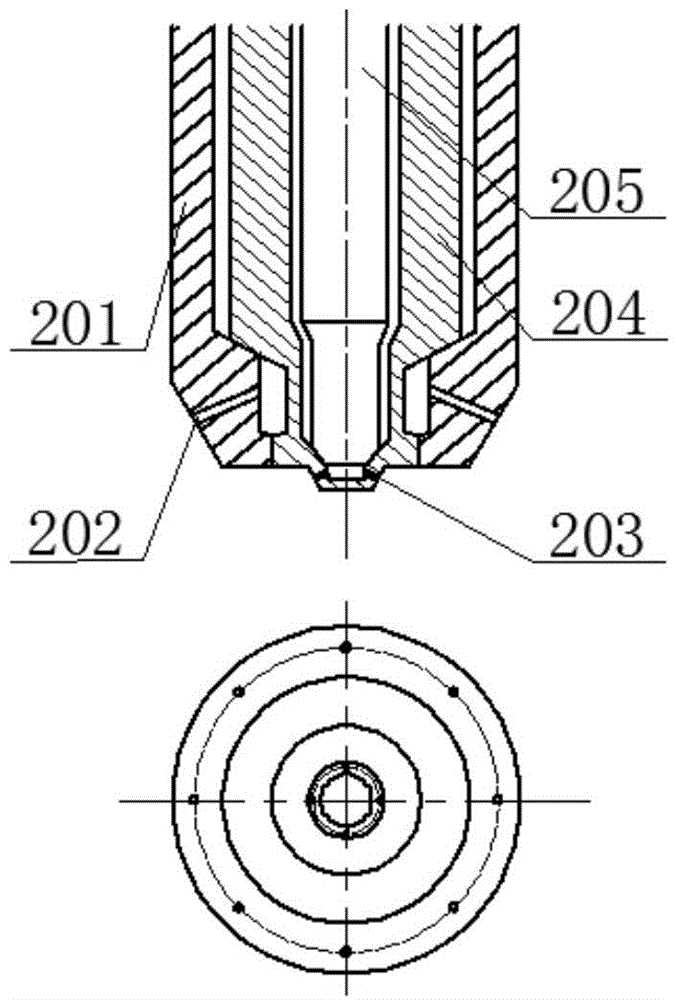

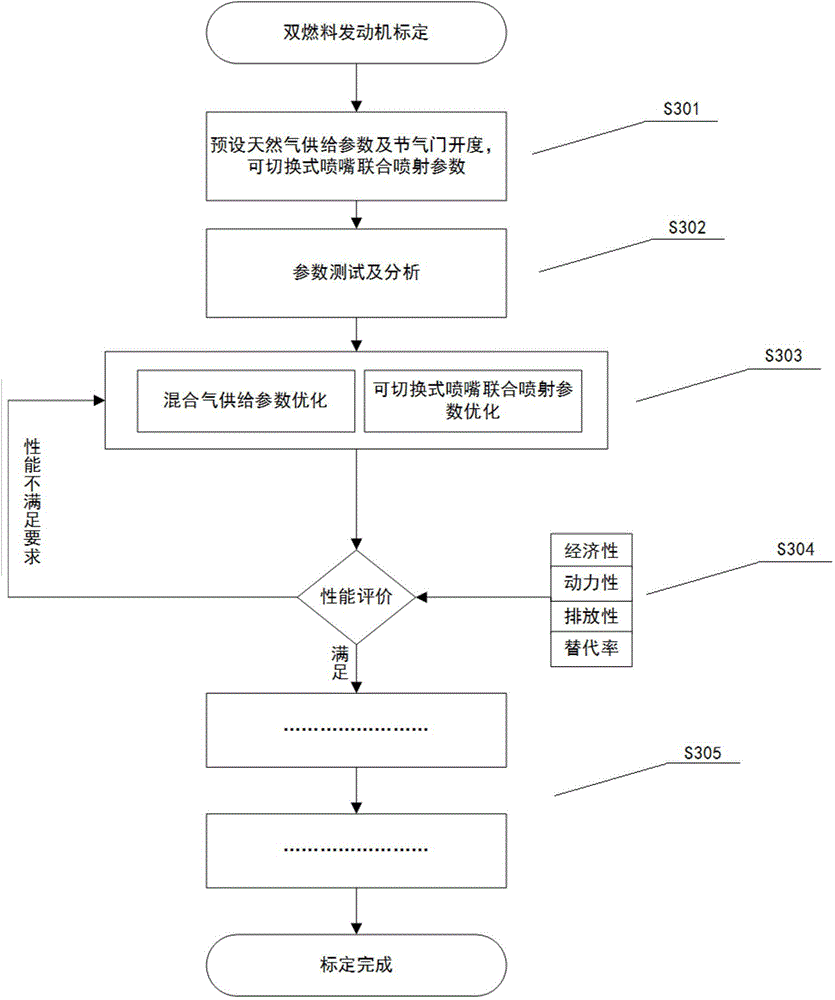

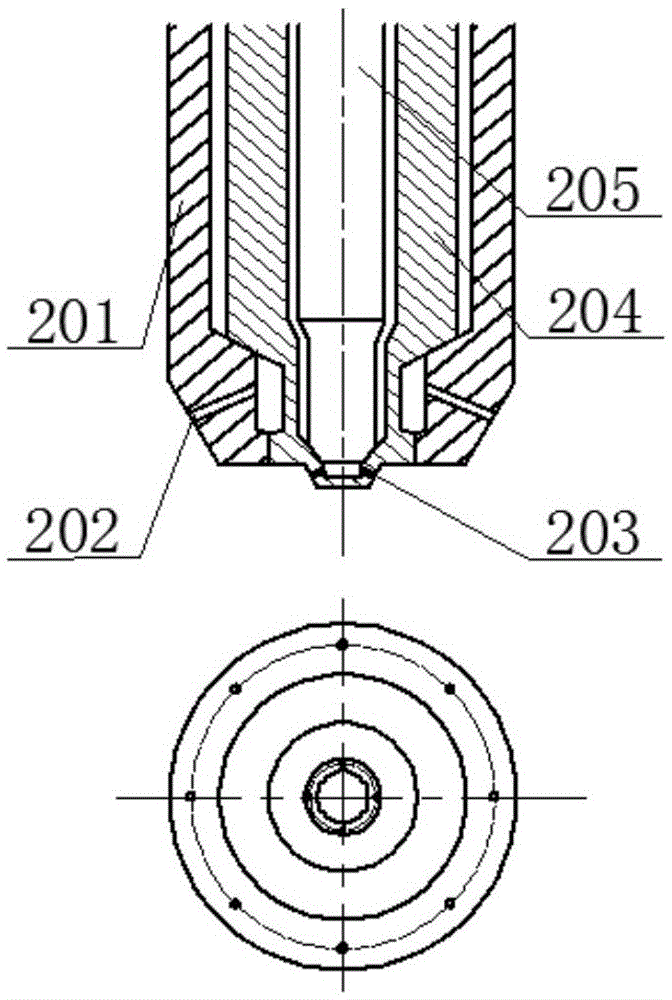

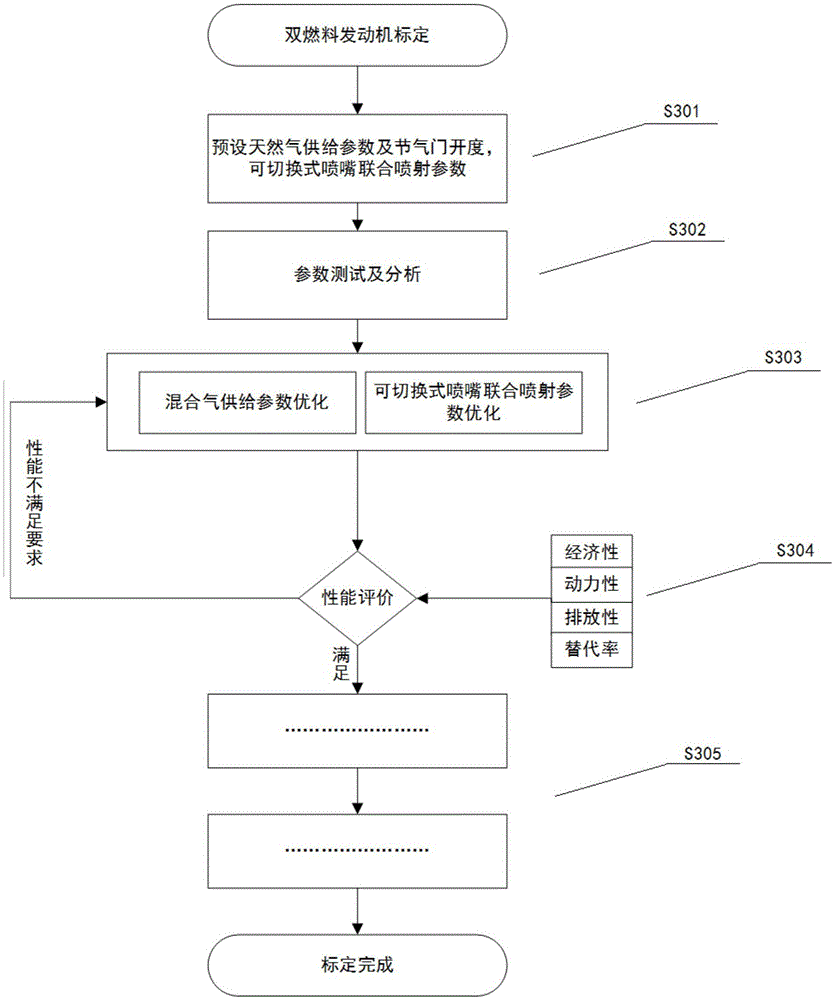

Dual-fuel engine combustion system and method based on switchable type oil sprayer

InactiveCN104533639AImprove jet atomization qualityImprove performanceElectrical controlInternal combustion piston enginesDiesel sprayCombustion system

The invention discloses a dual-fuel engine combustion system and method based on a switchable type oil sprayer. The dual-fuel engine combustion system is characterized in that an electronic control common-rail diesel supply device, a premix natural gas supply device and the switchable type oil sprayer are connected with an electronic control system ECU, and the switchable type oil sprayer is installed on a dual-fuel engine and further connected with the electronic control common-rail diesel supply device. The dual-fuel engine combustion system and method have the advantages that the mixed gas flow, the mixed gas concentration, the diesel supply pressure and spraying timing of two spraying nozzles are controlled through an electronic control system, the sprayer covers the whole substitution rate range of the dual-fuel engine, the diesel spraying atomization quality of the dual-fuel engine is improved, and the overall performance of the dual-fuel engine is optimized.

Owner:SHANDONG UNIV

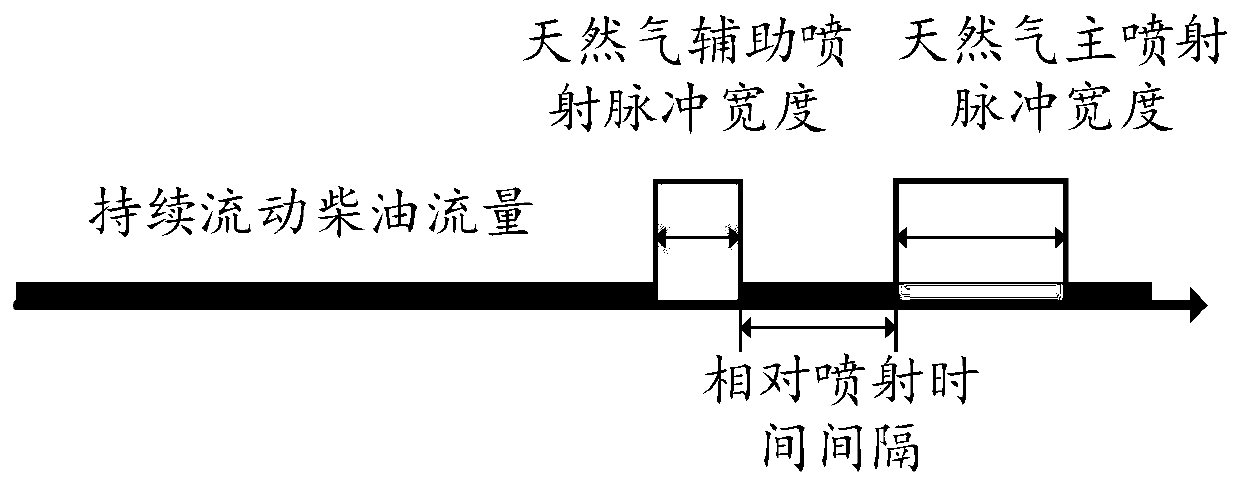

Diesel engine system capable of being powered by mixed DME (dimethyl ether) gas and control method

InactiveCN102562328AEmission reductionImprove economyEngine controllersMachines/enginesDiesel sprayWhole body

The invention relates to a compression ignition type diesel engine system capable of being powered by mixed DME (dimethyl ether) gas and a control method. On the basis that a total body and a control system of an original engine are kept, the diesel engine system is additionally provided with a mixed fuel electronic control unit, a DME storage tank, a DME pipeline pressure sensor, a DME pipeline electromagnetic valve and a DME spray nozzle. The DME fuel electronic control unit can respectively control start and stop of a diesel spray nozzle and start and stop of the DME spray nozzle by means of receiving an original engine sensor signal and a DME gas pipeline pressure signal. The DME electronic control unit judges working conditions of the engine according to obtained rotation speed and pedal plate position signals when the DME electronic control unit is communicated with an electronic control unit of the original engine, then the DME electronic control unit transmits signals so as to respectively control a jetting time interval and a pulse width of the diesel spray nozzle of the original engine and a jetting time interval and a pulse width of the DME spray nozzle, and the compression ignition type diesel engine system realizes combustion modes including that pure DME cold start is carried out, diesel is mixed with DME under small load, pure diesel start is carried out under large load. Accordingly, HC, CO and particle emission in a cold start process of the diesel engine is greatly reduced, and thermal efficiency and emission level of the engine under a steady work condition are improved.

Owner:BEIJING UNIV OF TECH

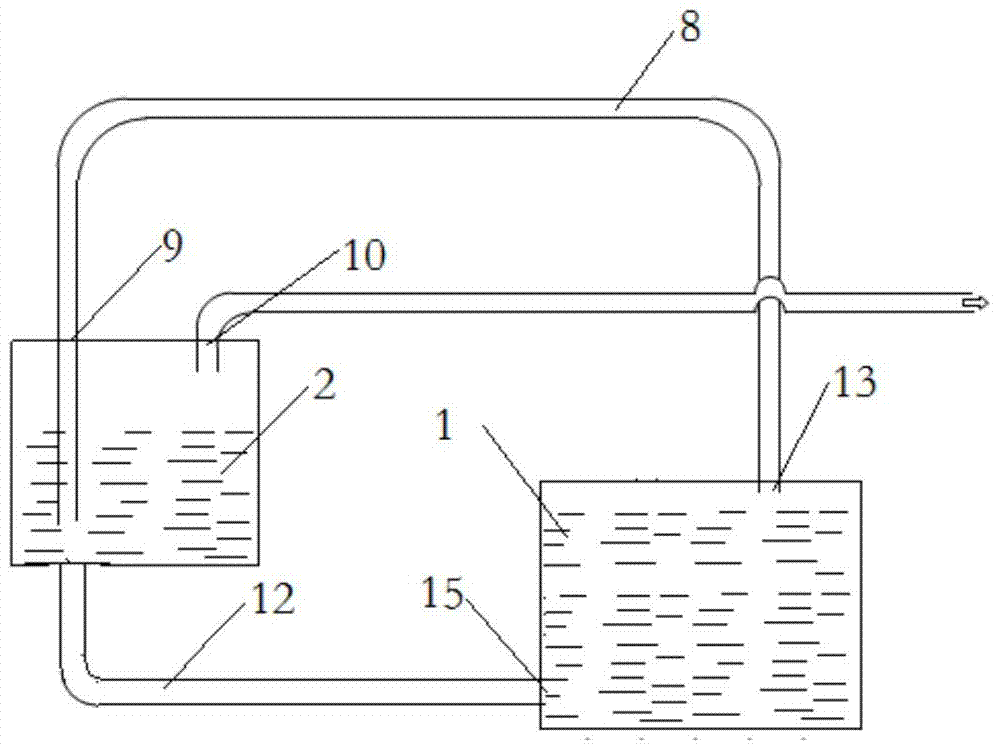

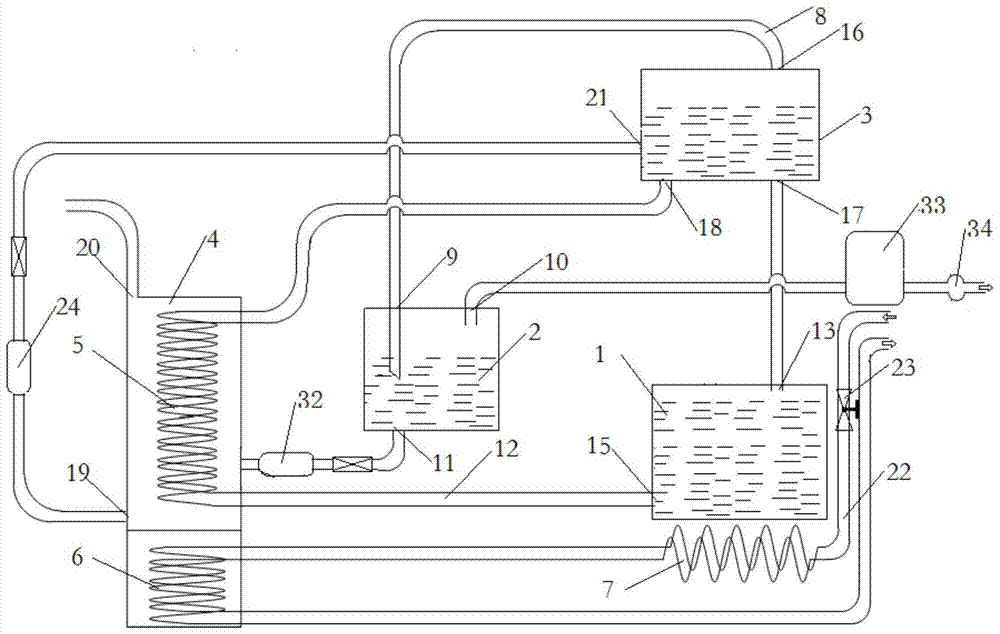

Auxiliary oil-saving environmental protection device of diesel internal combustion engine

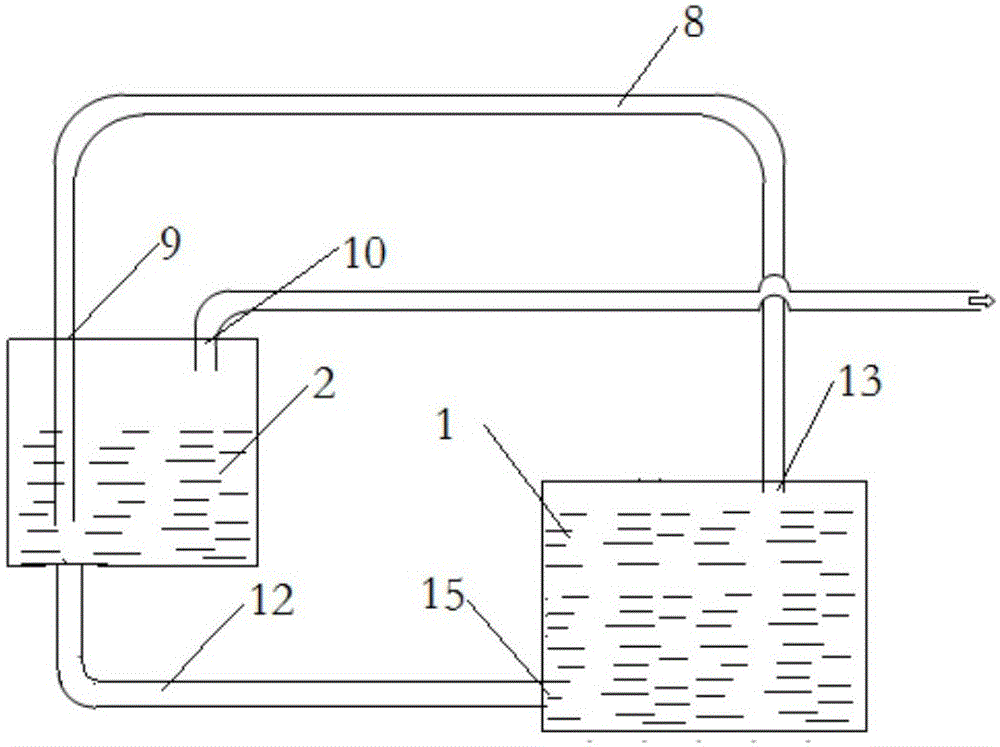

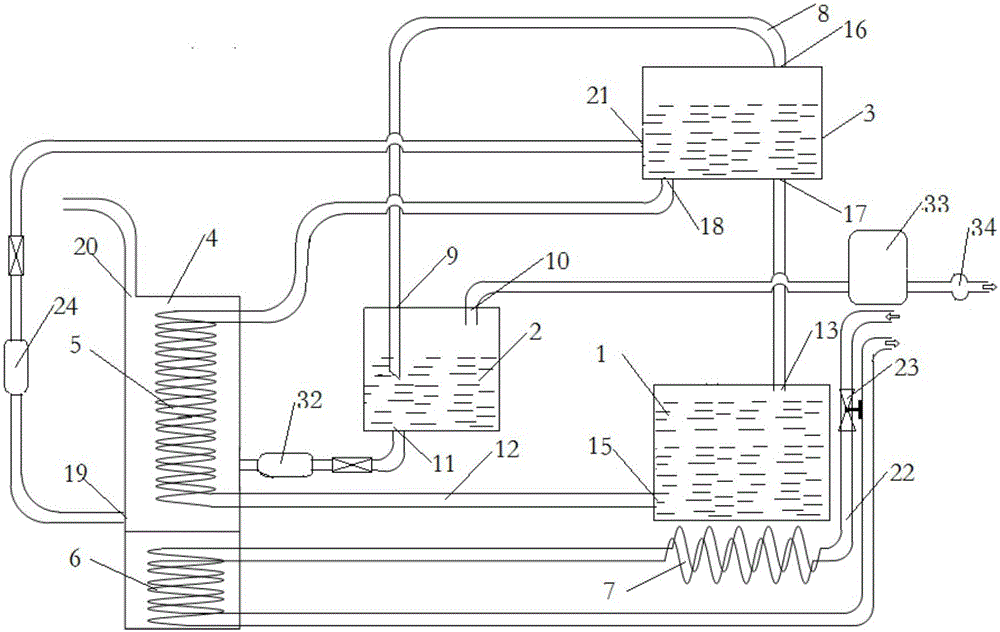

InactiveCN105020061ABurn fullyReduce usageInternal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineInternal combustion engine

The invention discloses an auxiliary oil-saving environmental protection device of a diesel internal combustion engine. The auxiliary oil-saving environmental protection device of the diesel internal combustion engine is communicated with a cylinder of the diesel internal combustion engine through a pipeline. Hydrogen and oxygen mixed gas is led into the cylinder and is mixed with diesel spray for combustion. The auxiliary oil-saving environmental protection device comprises a circulating gas supply device, a separating and filtering device and a circuit control system. The circulating gas supply device comprises a hydrogen an oxygen generator. A gas inlet of the separating and filtering device and a gas outlet of the hydrogen and oxygen generator are communicated through a first pipeline. A gas outlet of the separating and filtering device is communicated with a gas supply pipeline of the diesel internal combustion engine. Electrolytic gas is led in through the gas supply pipeline of the diesel internal combustion engine. The separating and filtering device is communicated with the hydrogen and oxygen generator through a second pipeline so that an electrolyte solution of the hydrogen and oxygen generator can be recycled. The circuit control system is electrically connected with the hydrogen and oxygen generator and the separating and filtering device. The auxiliary oil-saving environmental protection device can promote sufficient combustion of diesel oil in the diesel internal combustion engine, increase the combustion rate and the utilization rate of the diesel and effectively reduce the content of pollutants in exhausted tail gas, and therefore the comprehensive benefits of saving energy, reducing emission and protect the environment are achieved.

Owner:江苏博润通科技有限公司

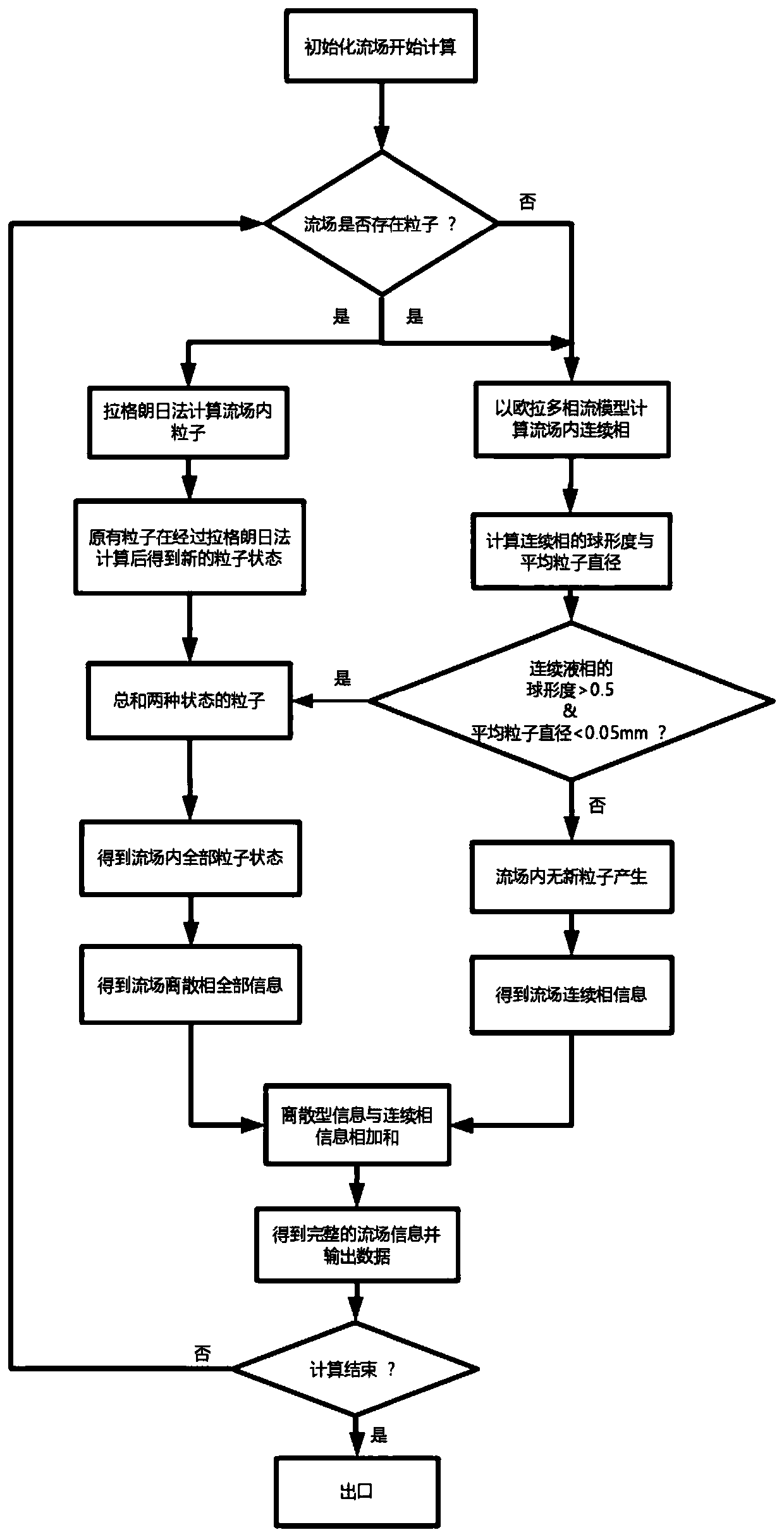

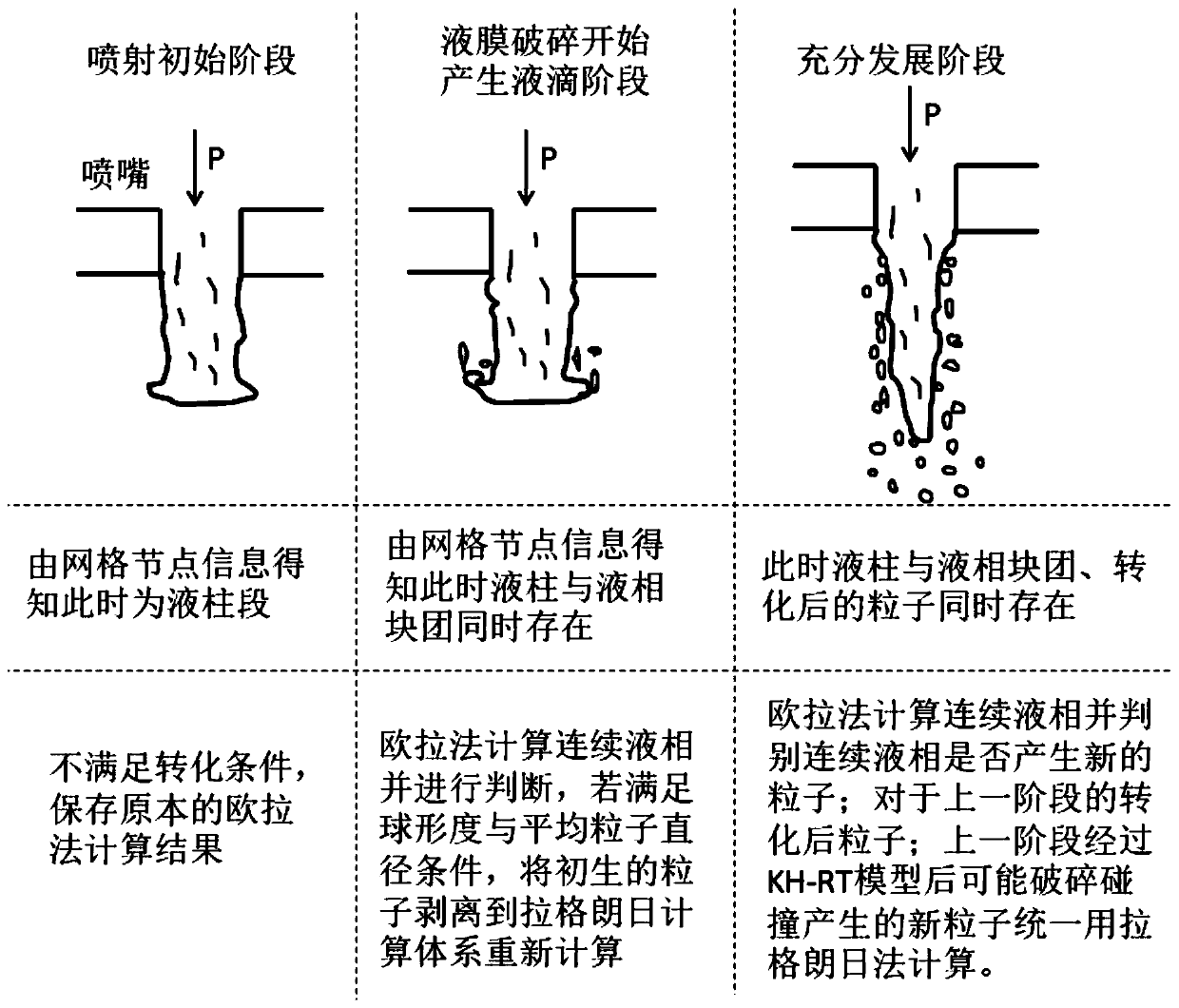

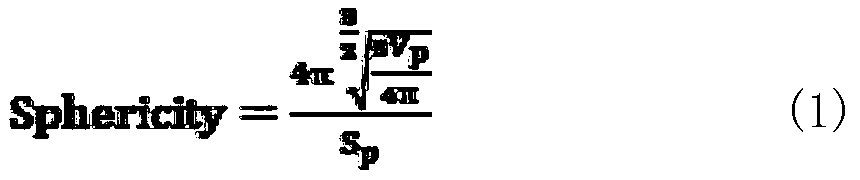

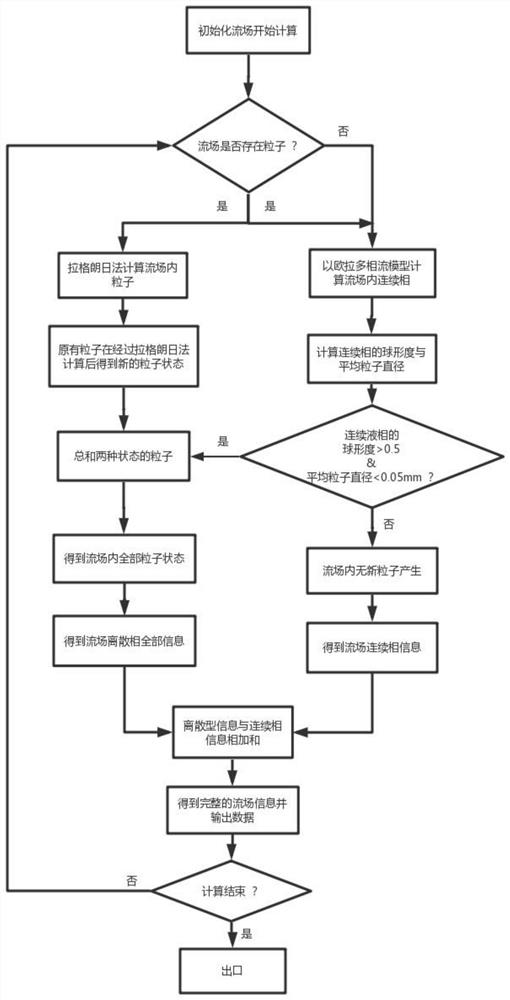

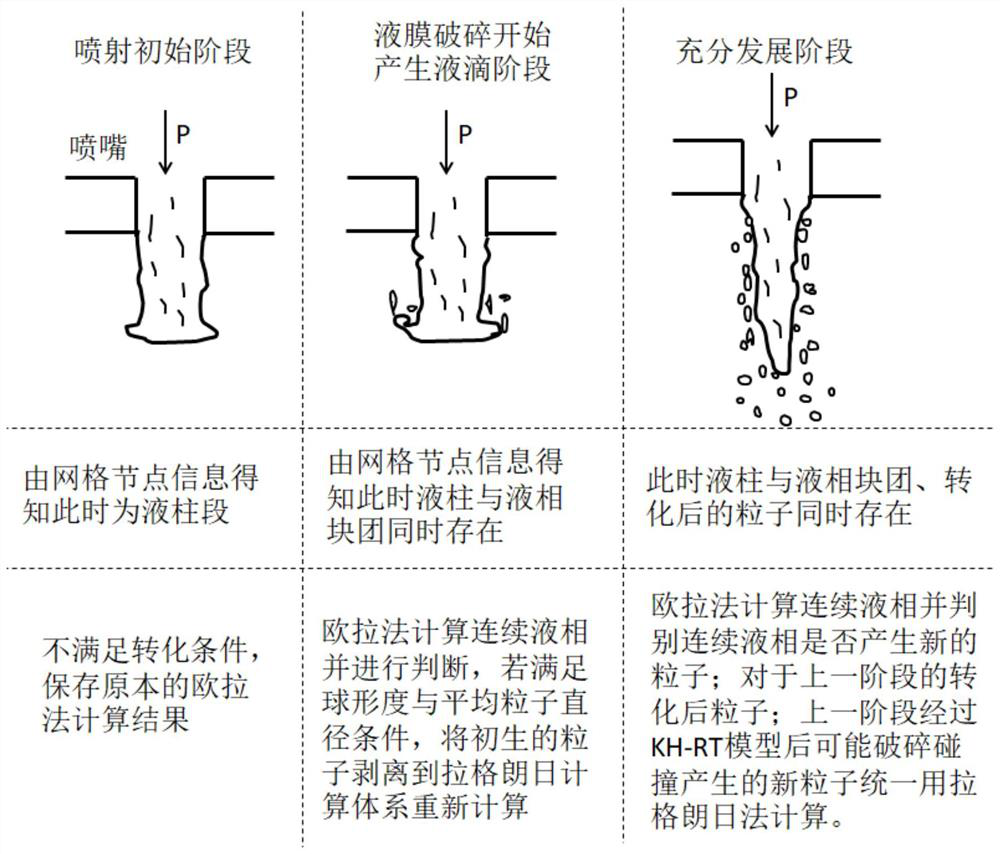

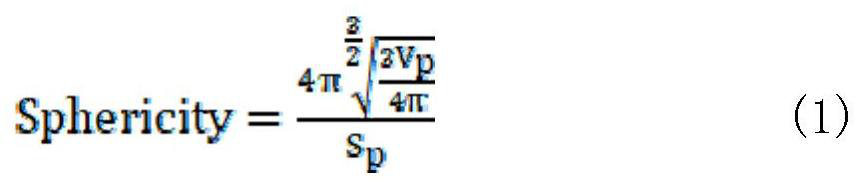

Method for automatically identifying diesel spray crushing process and automatically realizing spray continuous calculation

The invention discloses a method for automatically identifying a diesel spray crushing process and automatically realizing the spray continuous calculation. The method automatically judges the processthat a liquid film is crushed into liquid drops in the diesel injection process, and realizes a SD-ELSA algorithm of the spray continuous calculation. The SD-ELSA algorithm is characterized in that the sphericity degree and the average particle diameter of liquid phases in grids are calculated and taken as judgment bases, the information of particles in a flow field are calculated through a Lagrangian method, the information of the grids belonging to continuous liquid phases in the grid node information in the full-flow field is calculated by using an Euler model, and Euler block masses meeting two bases for determination are converted into particles and re-calculated through the Lagrangian method. According to the method, dynamic converting coupling of the Euler-Lagrangian model is realized, the complete information of discrete phases and continuous phases in the flow field can be automatically obtained and subjected to iterative computation, three stages of a liquid column, primarycrushing and secondary crushing of the diesel injection are obtained, and the diesel spray process is completely represented.

Owner:BEIJING UNIV OF TECH

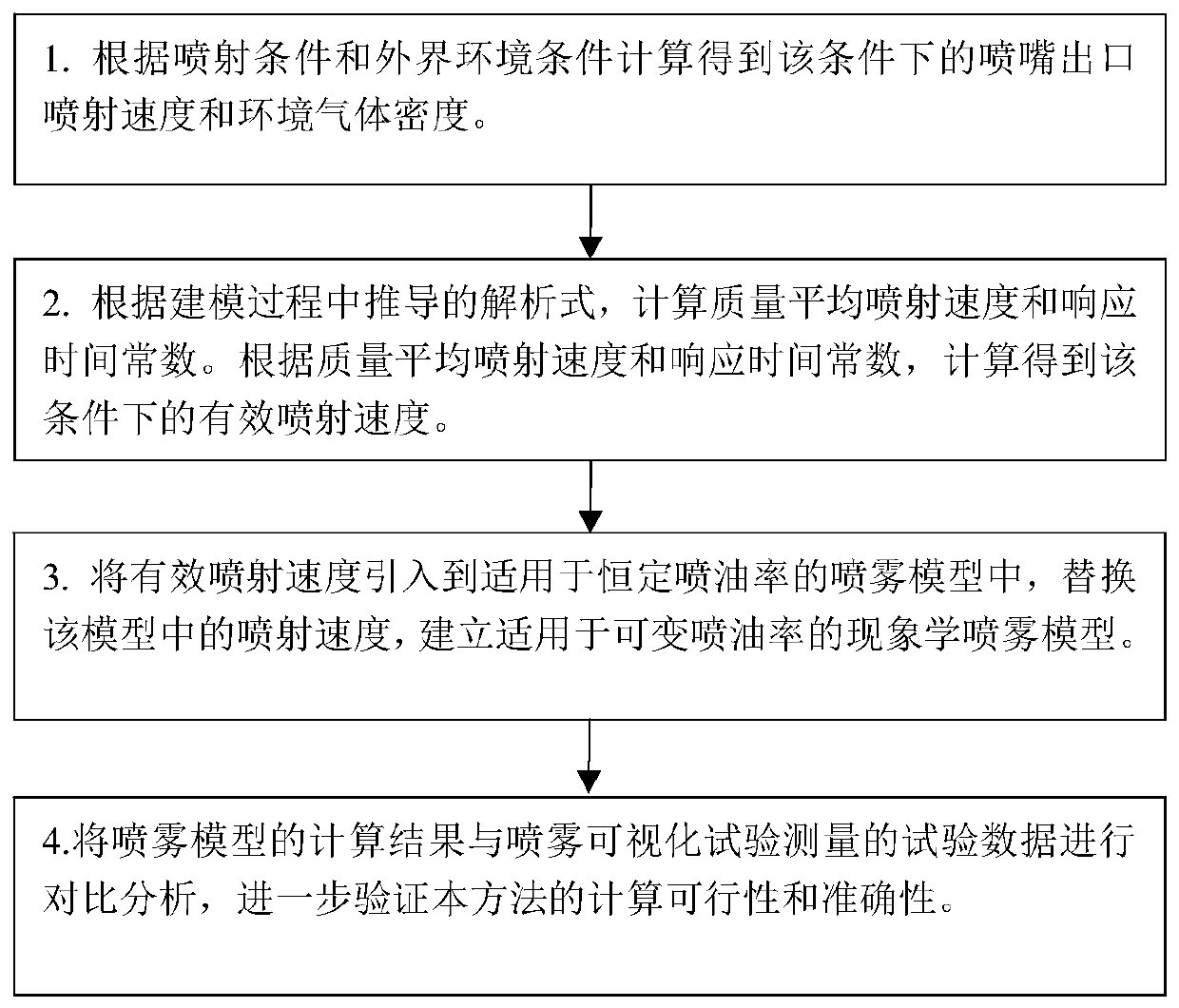

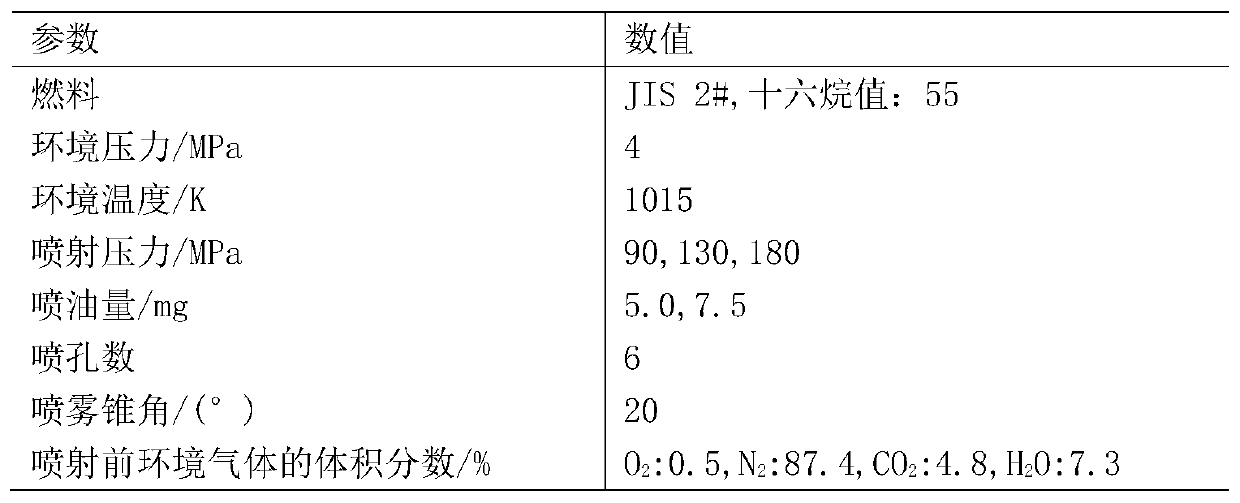

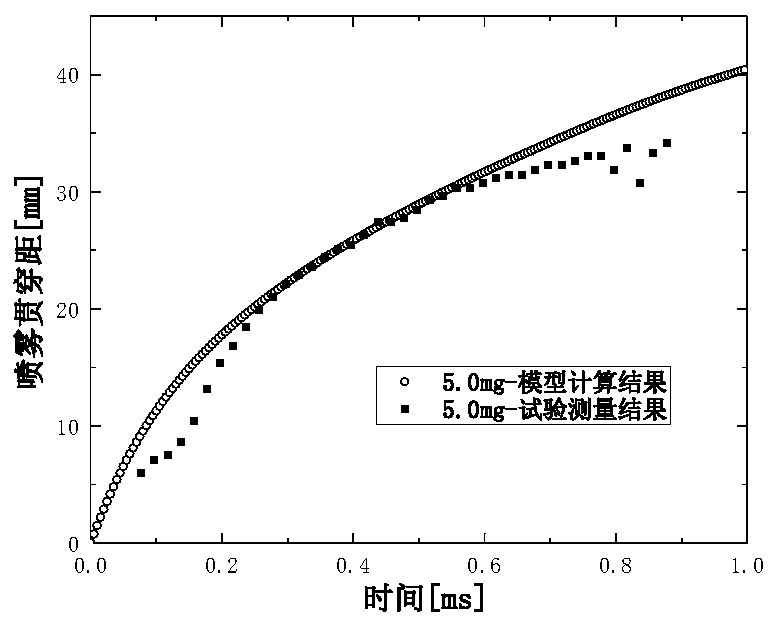

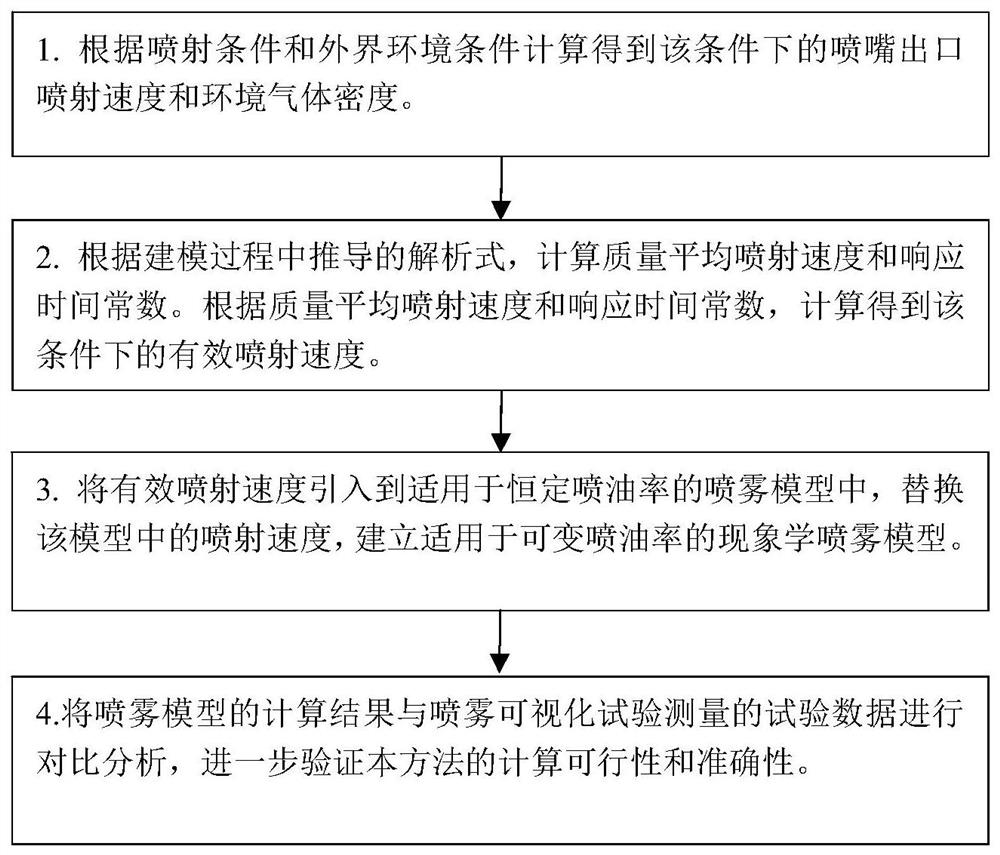

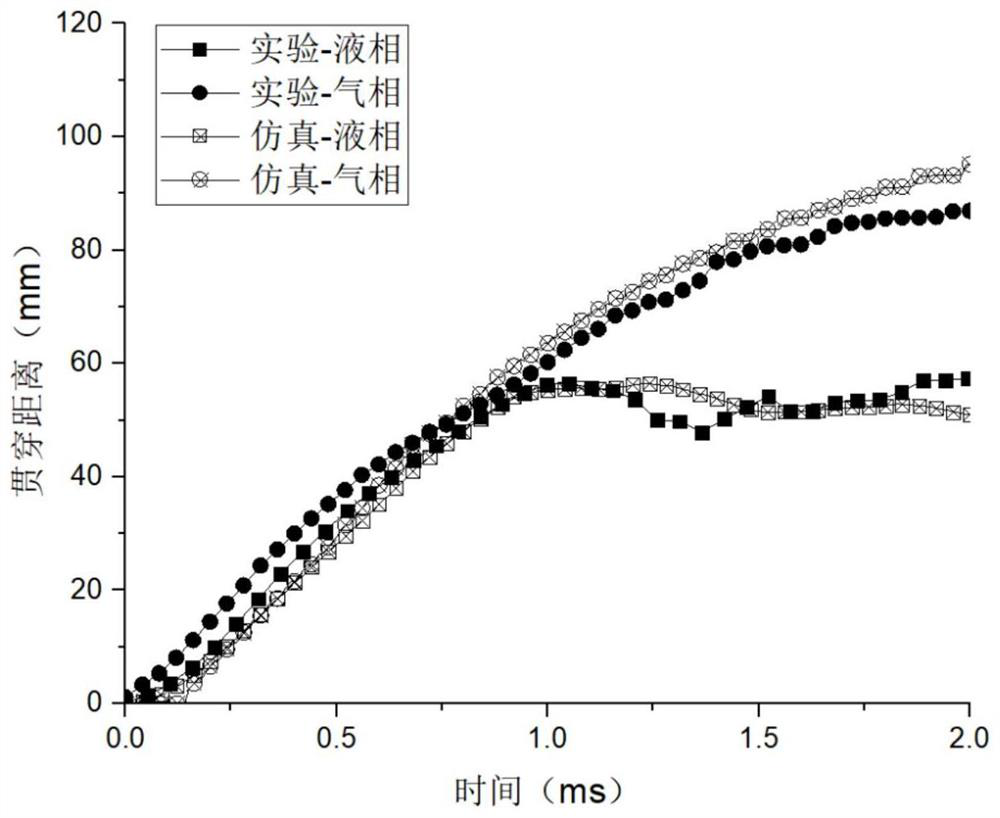

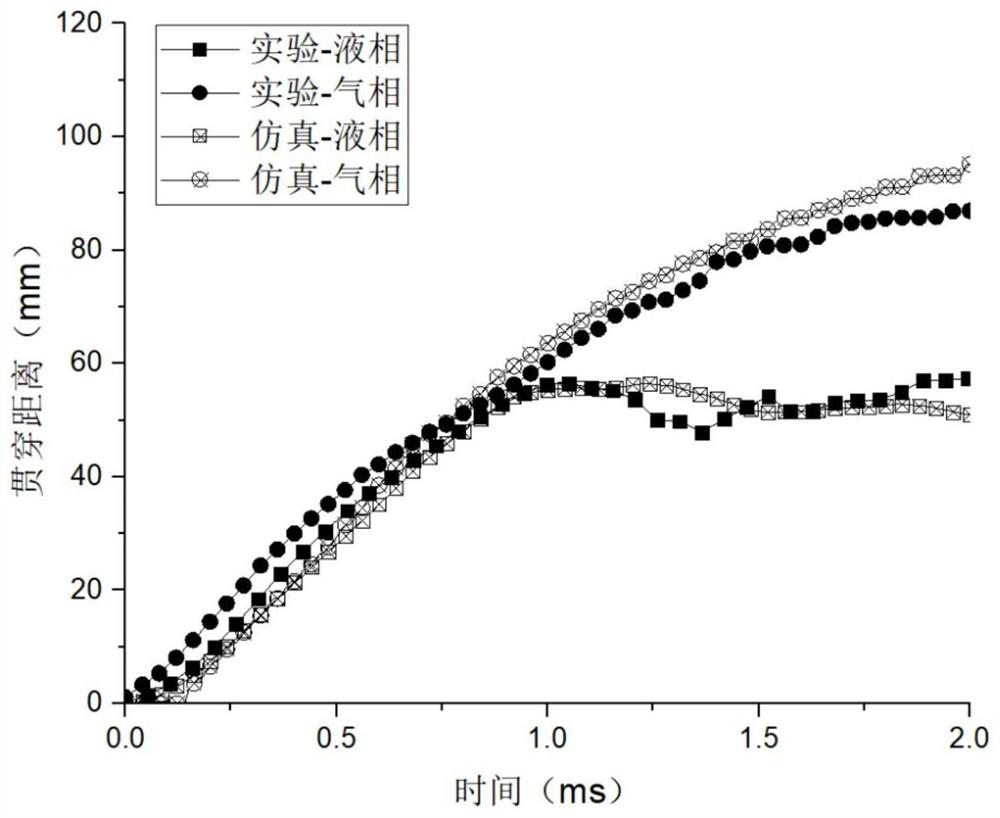

Diesel spray penetration distance prediction method with variable fuel injection rate

The invention aims to provide a diesel spray penetration distance prediction method with a variable fuel injection rate. The method is suitable for predicting the diesel spray penetration distance with the variable fuel injection rate, and belongs to an iconography modeling method. The method mainly comprises the following steps: based on the jet flow mechanics theory, an analytic expression of the change of the effective injection speed along with the injection speed is established, the effective injection speed replaces the injection speed and is introduced into a spray model suitable for constant oil injection rate calculation, and the spray model suitable for the variable oil injection rate is obtained and is used for prediction of the penetration distance. The established spray modelhas a reliable theoretical basis, the modeling method has high attribute description capability, the model is simple, parameterized research is easy, and the spray penetration distance of the variableoil injection rate can be predicted.

Owner:HARBIN ENG UNIV

Dual fuel engine combustion system and method based on switchable fuel injector

InactiveCN104533639BImprove jet atomization qualityImprove performanceElectrical controlInternal combustion piston enginesDiesel sprayCombustion system

The invention discloses a dual-fuel engine combustion system and method based on a switchable type oil sprayer. The dual-fuel engine combustion system is characterized in that an electronic control common-rail diesel supply device, a premix natural gas supply device and the switchable type oil sprayer are connected with an electronic control system ECU, and the switchable type oil sprayer is installed on a dual-fuel engine and further connected with the electronic control common-rail diesel supply device. The dual-fuel engine combustion system and method have the advantages that the mixed gas flow, the mixed gas concentration, the diesel supply pressure and spraying timing of two spraying nozzles are controlled through an electronic control system, the sprayer covers the whole substitution rate range of the dual-fuel engine, the diesel spraying atomization quality of the dual-fuel engine is improved, and the overall performance of the dual-fuel engine is optimized.

Owner:SHANDONG UNIV

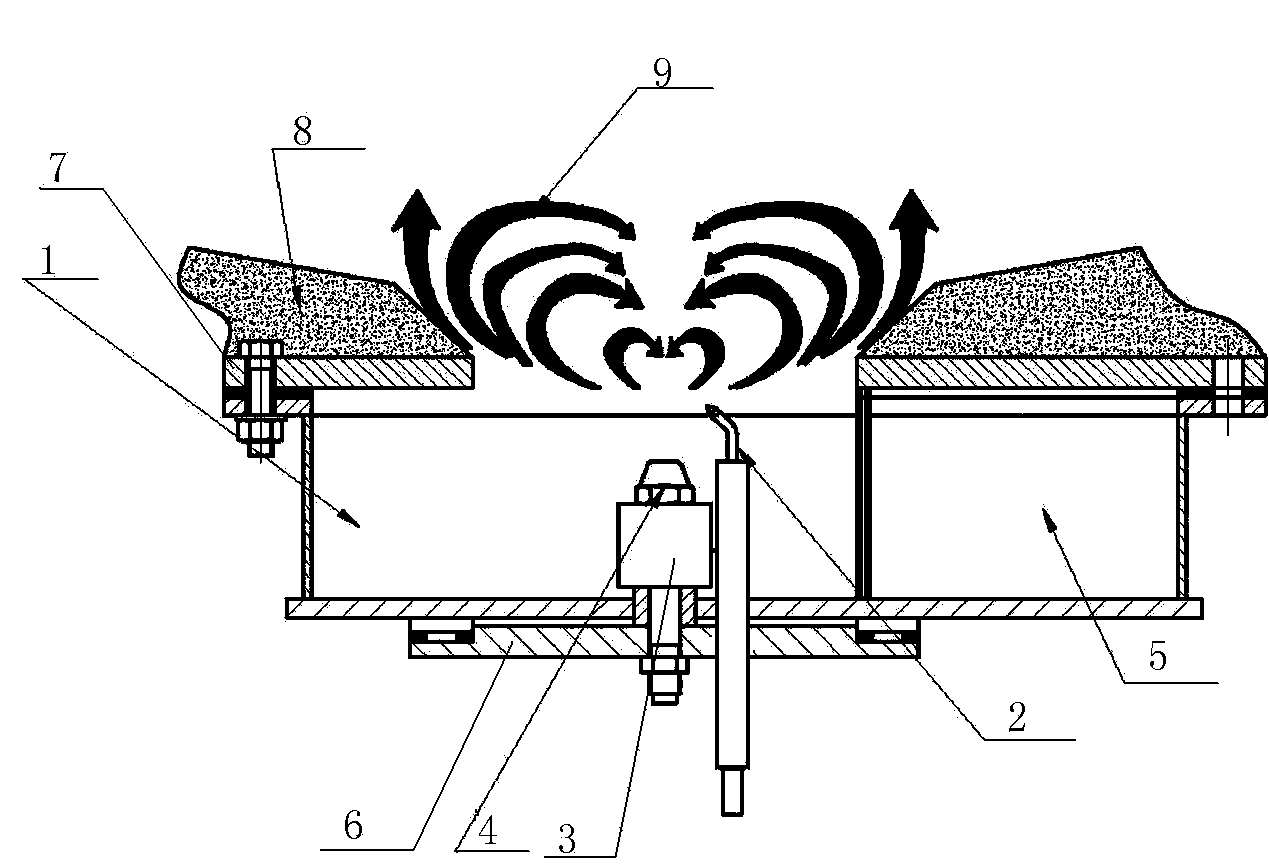

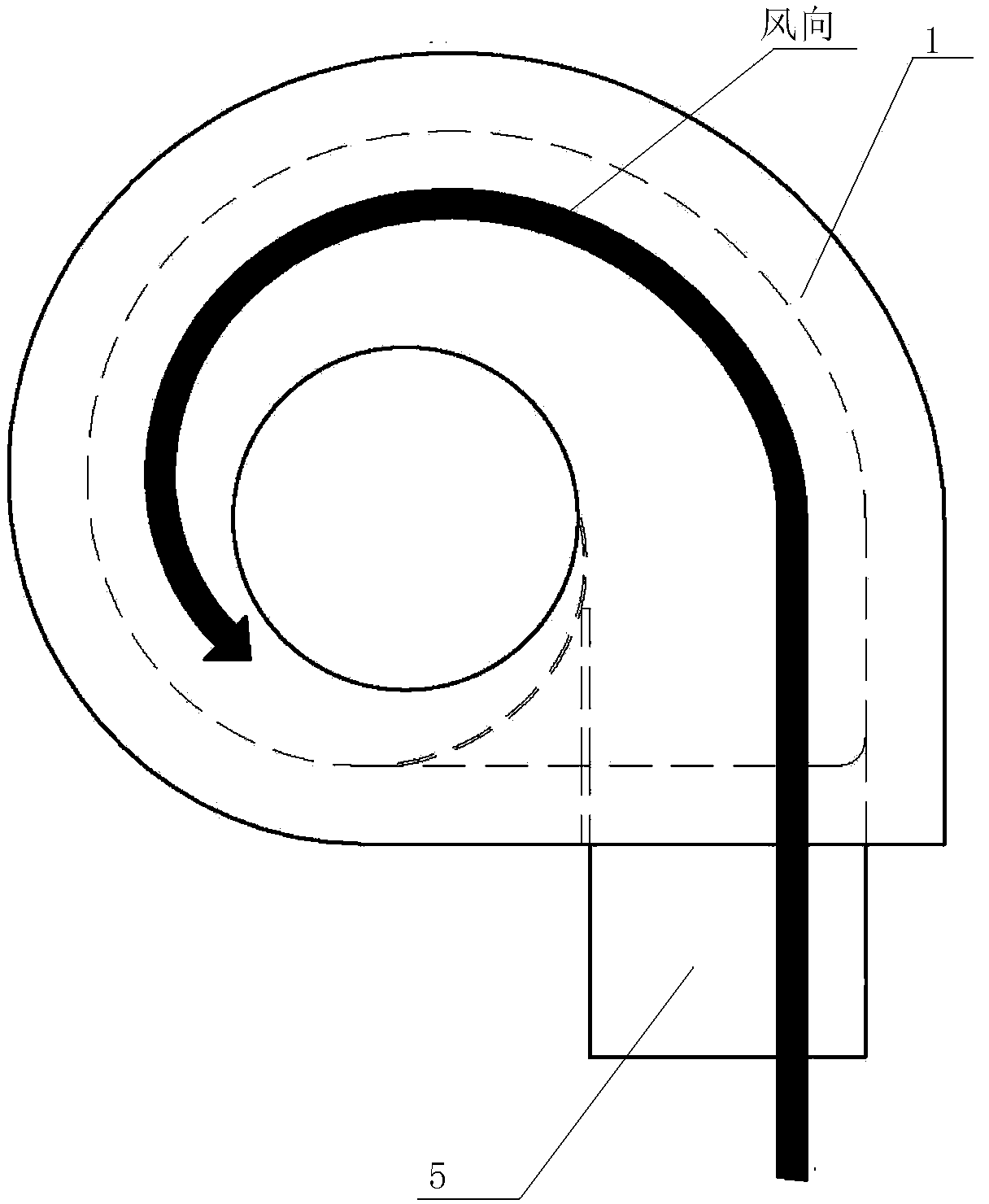

Short-flame and large-diameter diesel burner

The invention relates to a burner, in particular to a short-flame and large-diameter diesel burner. The short-flame and large-diameter diesel burner comprises a burner shell, an ignition rod and a diesel sprayer, wherein the ignition rod and the diesel sprayer are arranged in the burner shell. The burner shell is a spiral volute, an air inlet is formed in one side of an outer ring of the volute, an air outlet is formed in an inner ring of the volute, the direction of the air inlet is coincident with the tangent direction of the volute, the position of a diesel spraying nozzle of the diesel sprayer corresponds to the position of the air outlet of the volute, and the ignition position of the ignition rod is located above the diesel spraying nozzle and the air outlet. According to the short-flame and large-diameter diesel burner, the burner shell is designed into the volute, air enters the burner in the tangent direction of the volute, the air and diesel are mixed and burnt through centrifugal force, the structure is simple and attractive, the air and the atomized diesel can be more sufficiently mixed, losses of the atomized diesel can be reduced, the diameter of a hearth can be reduced, the size of a boiler can be reduced, and the burning cost can be reduced.

Owner:LIJU THERMAL EQUIP TECH

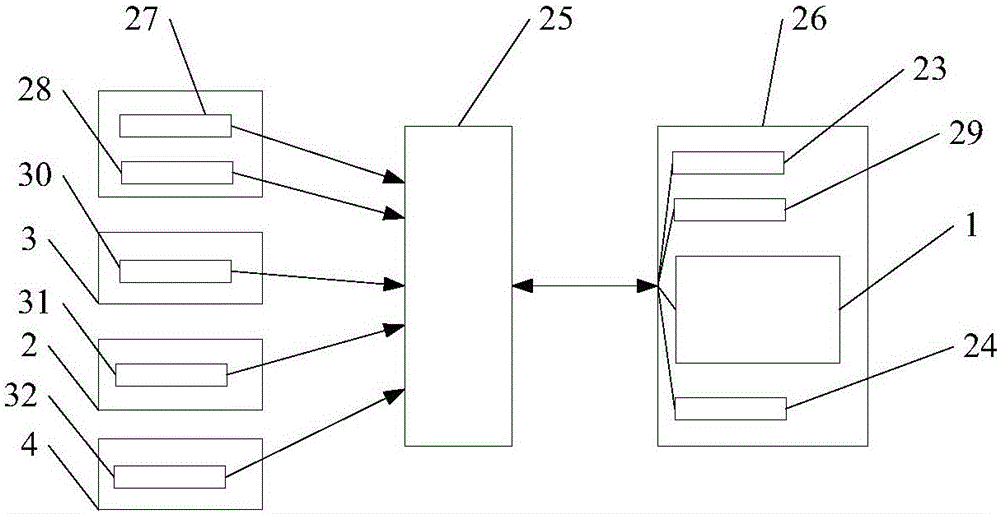

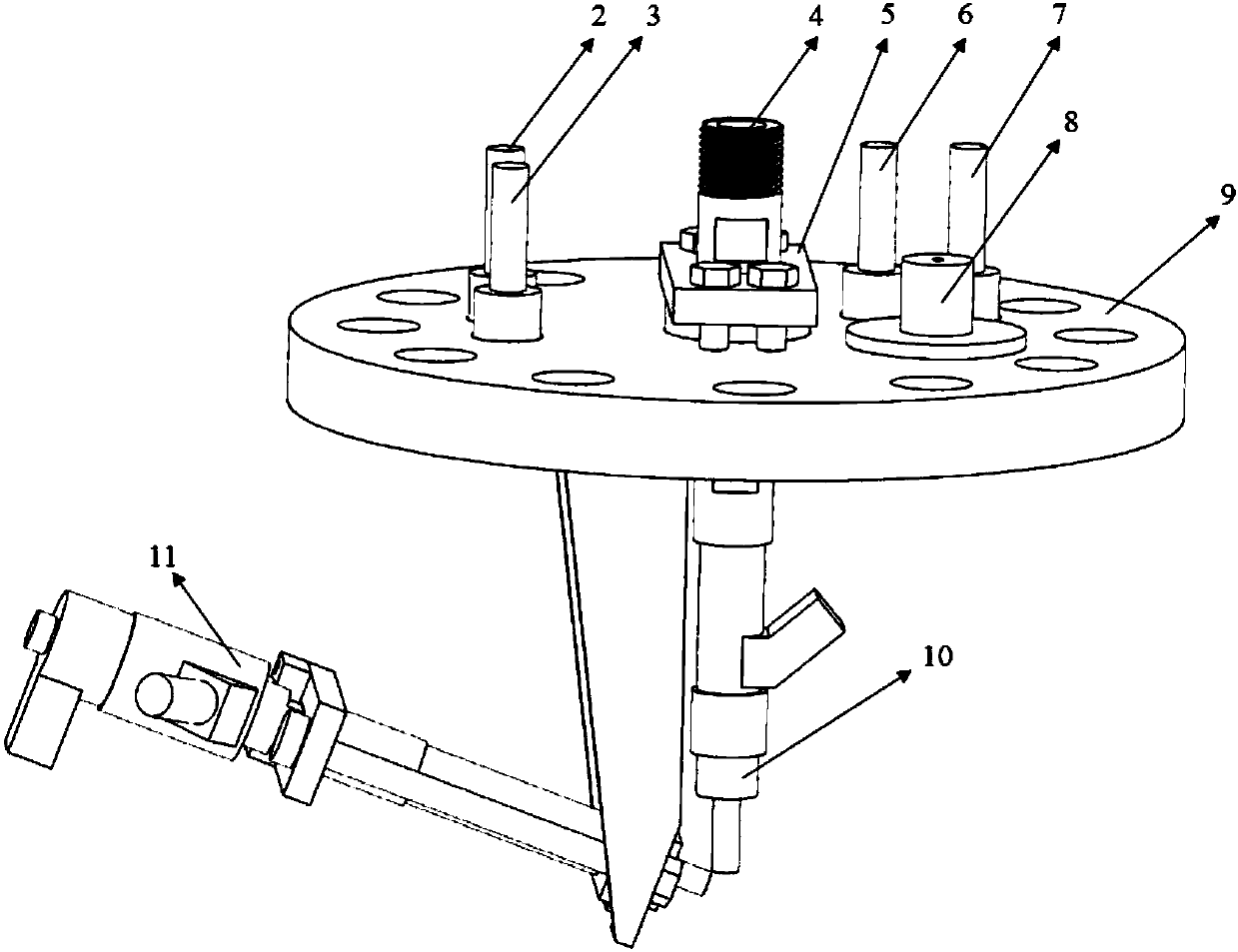

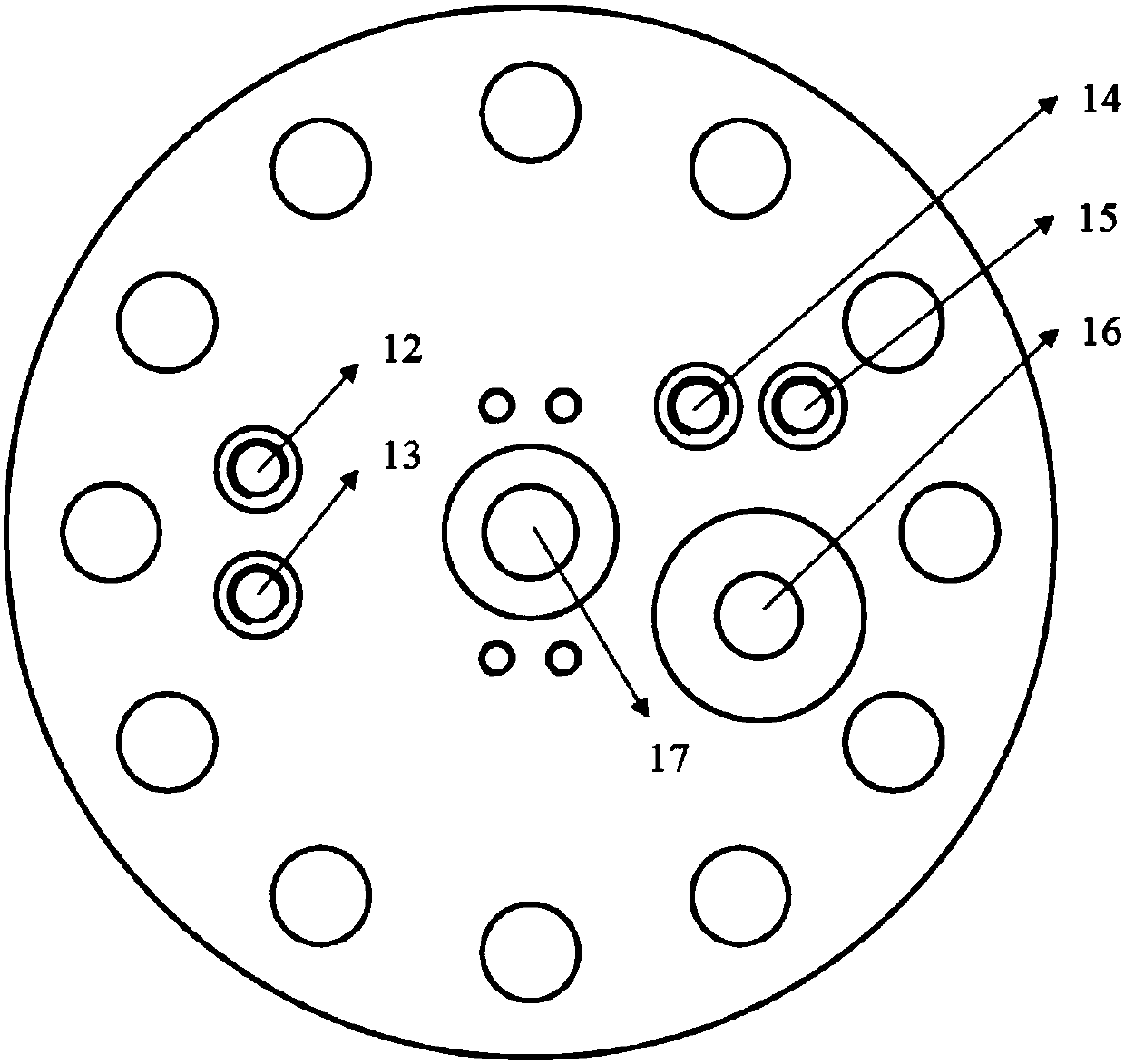

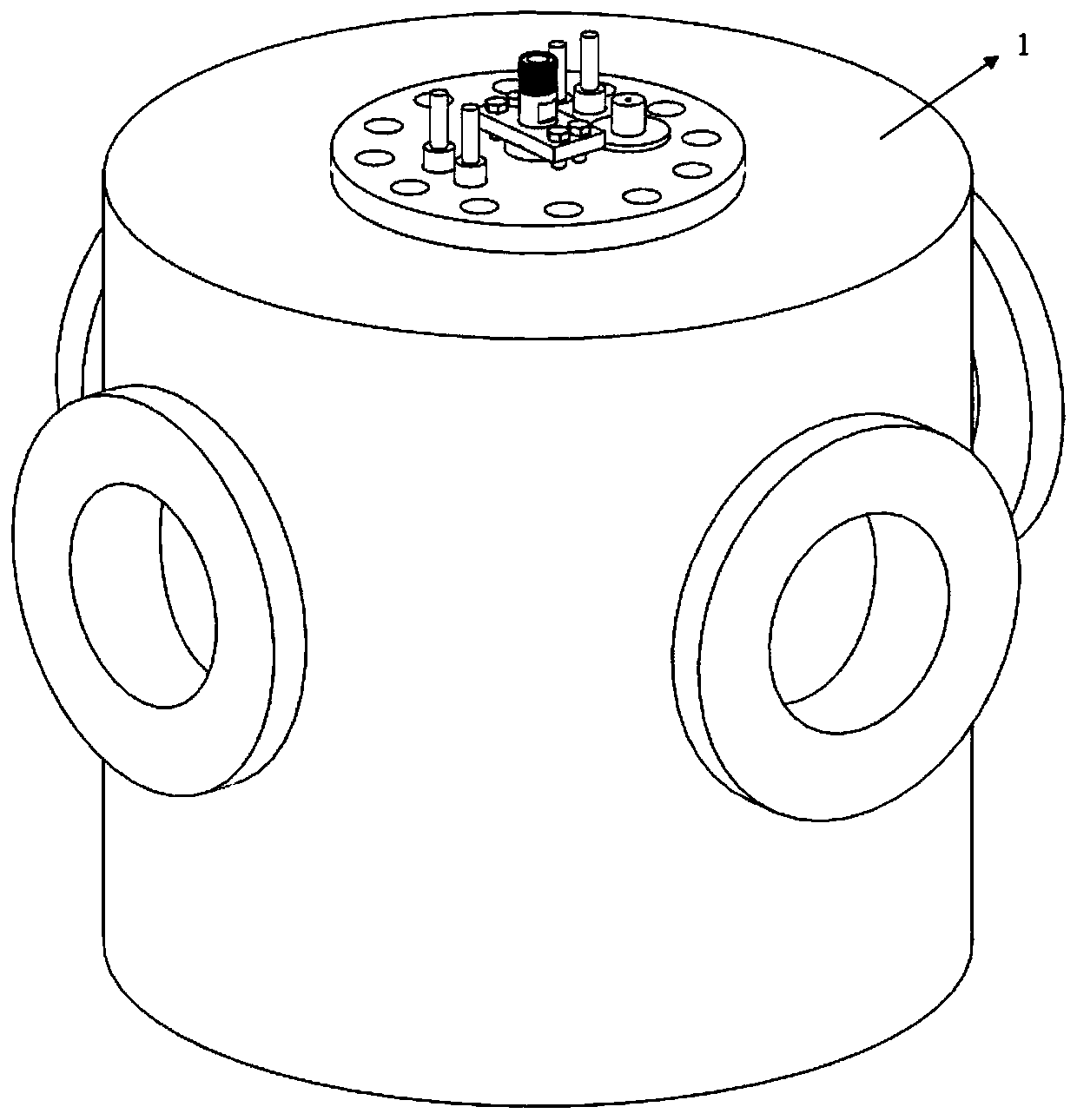

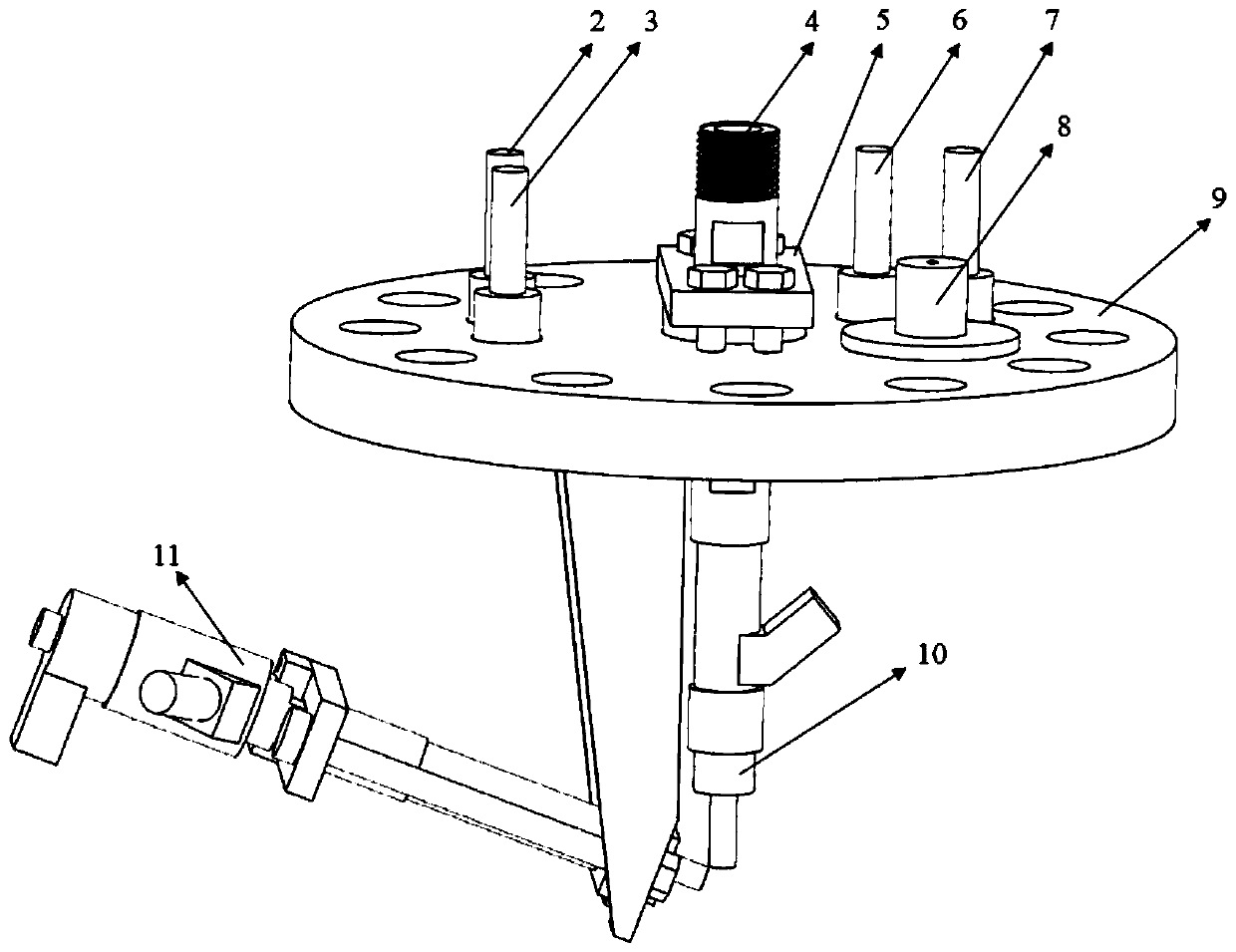

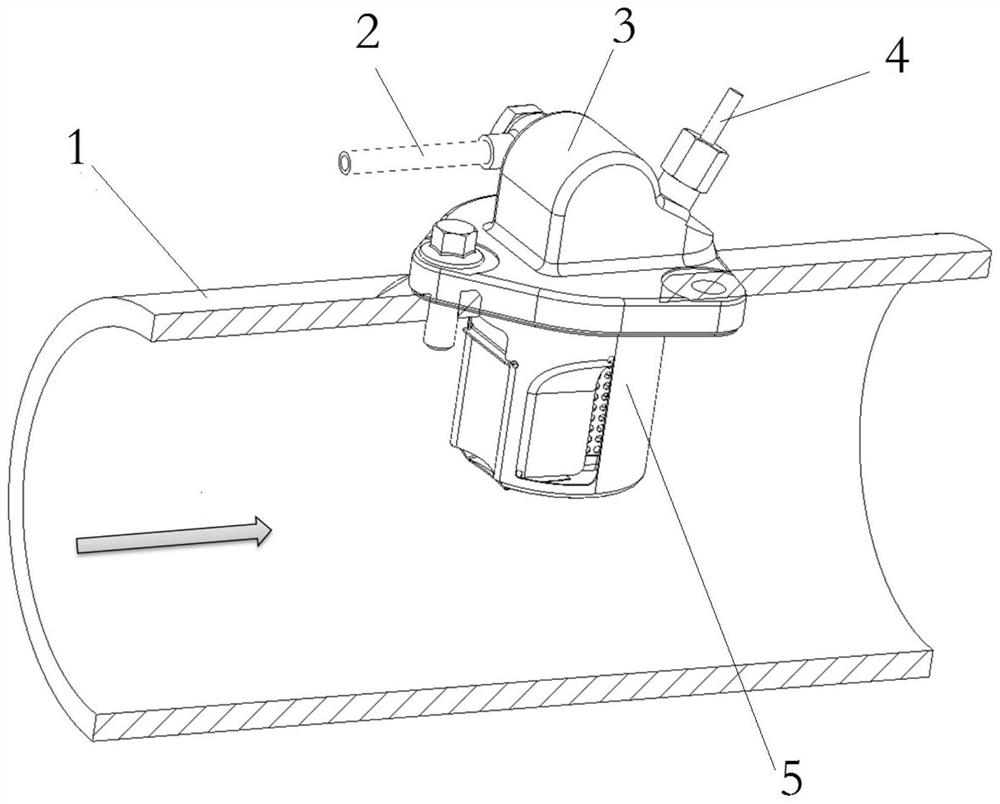

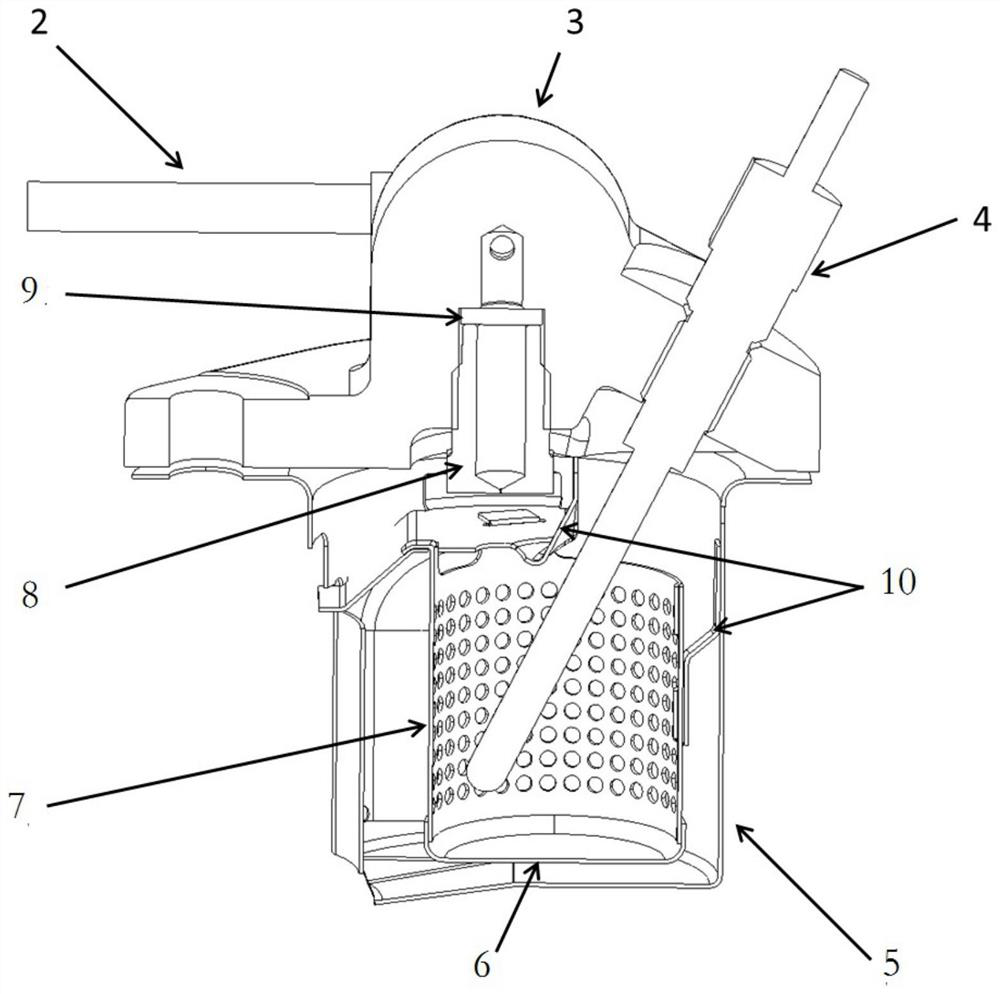

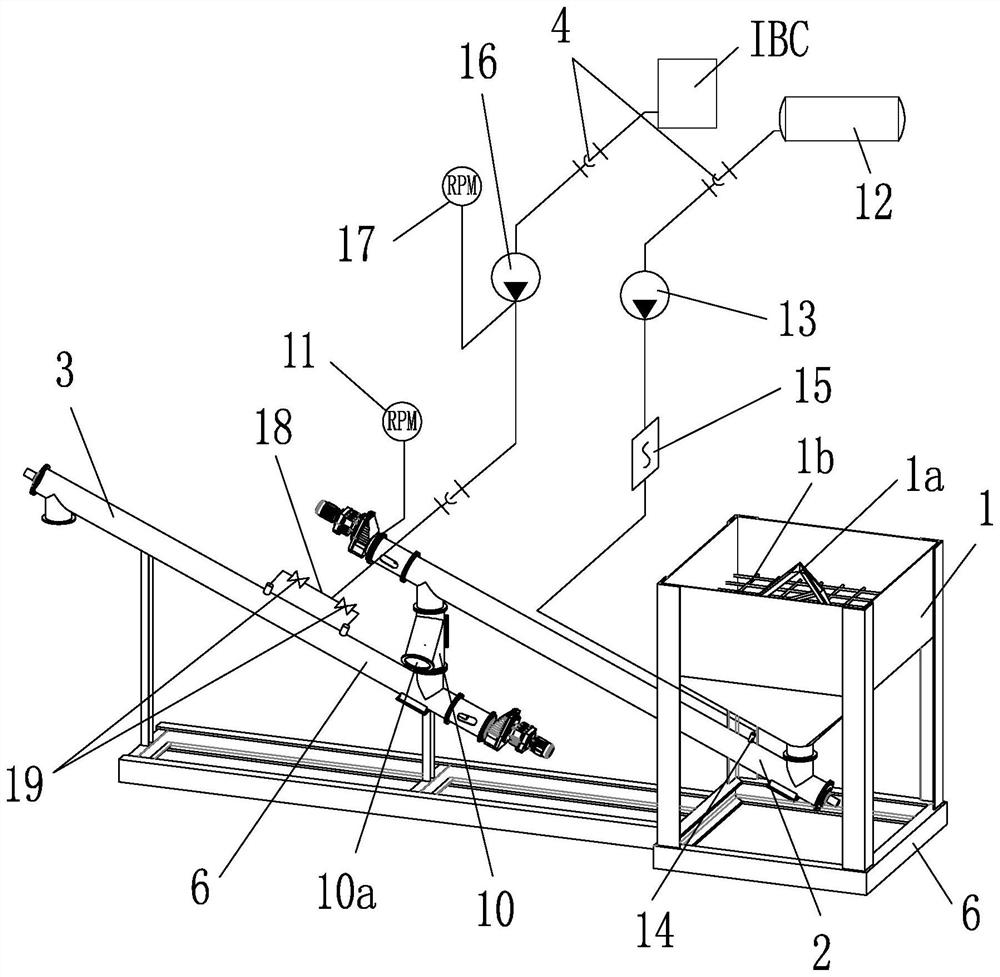

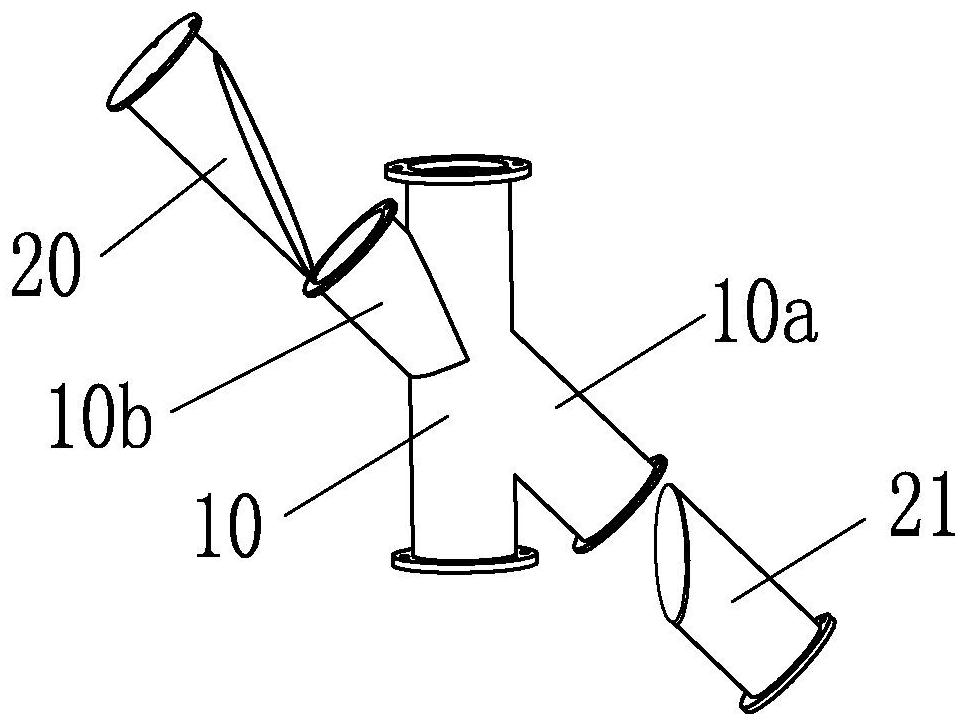

Diesel/natural gas double fuel direct injection device

ActiveCN107605634AEnables direct injection jet mixingGood for studying interactionsInternal combustion piston enginesFuel supply apparatusDiesel sprayEngineering

The invention provides a diesel / natural gas double fuel direct injection device including a constant volume bomb, a sparking plug, a natural gas pipe, a fuel pipe union, a constant volume bomb adapter, a natural gas ejector, a diesel ejector and a diesel ejector supporting frame. The constant volume bomb adapter is installed on the top of the constant volume bomb. The natural gas pipe is installedon the constant volume bomb adapter. The lower end of the natural gas pipe is connected with the top end of the natural gas ejector in a threaded mode. The upper end of the diesel ejector supportingframe is connected with the bottom of the constant volume bomb adapter and the lower end of the diesel ejector supporting frame is connected with the lower end of the diesel ejector in a detachable mode. A top electrode of the sparking plug is connected with an ECU output circuit and a bottom electrode of the sparking plug is connected with power connections of the diesel ejector and the natural gas ejector separately. The position of the diesel ejector can be flexibly adjusted and the distance between a diesel spraying hole and a natural gas spraying hole can be as small as 3mm. The interaction of double fuels is researched more advantageously. The diesel / natural gas double fuel direct injection device realizes the mixing of direct injection of the double fuels and provides research datafor the exploration of a direct injection engine for a diesel ignited natural gas cylinder.

Owner:JIANGSU UNIV

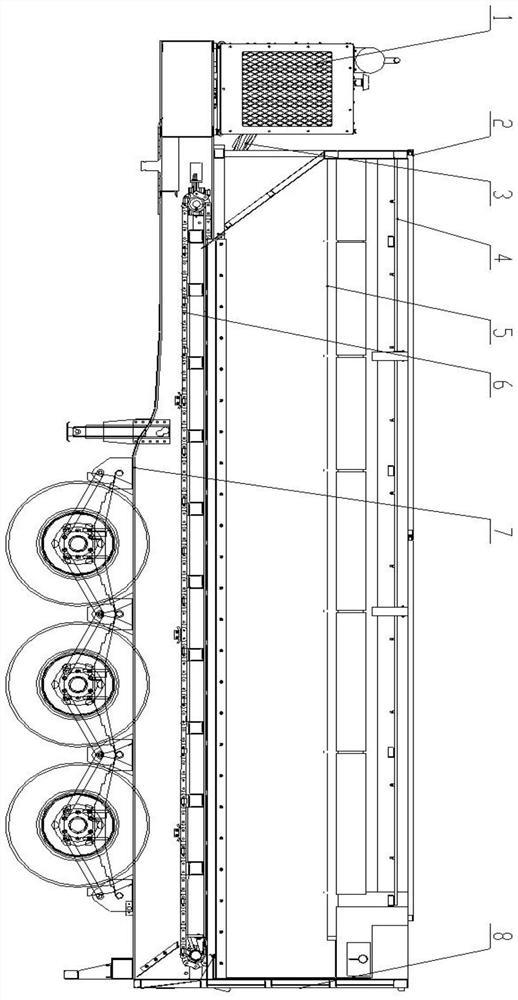

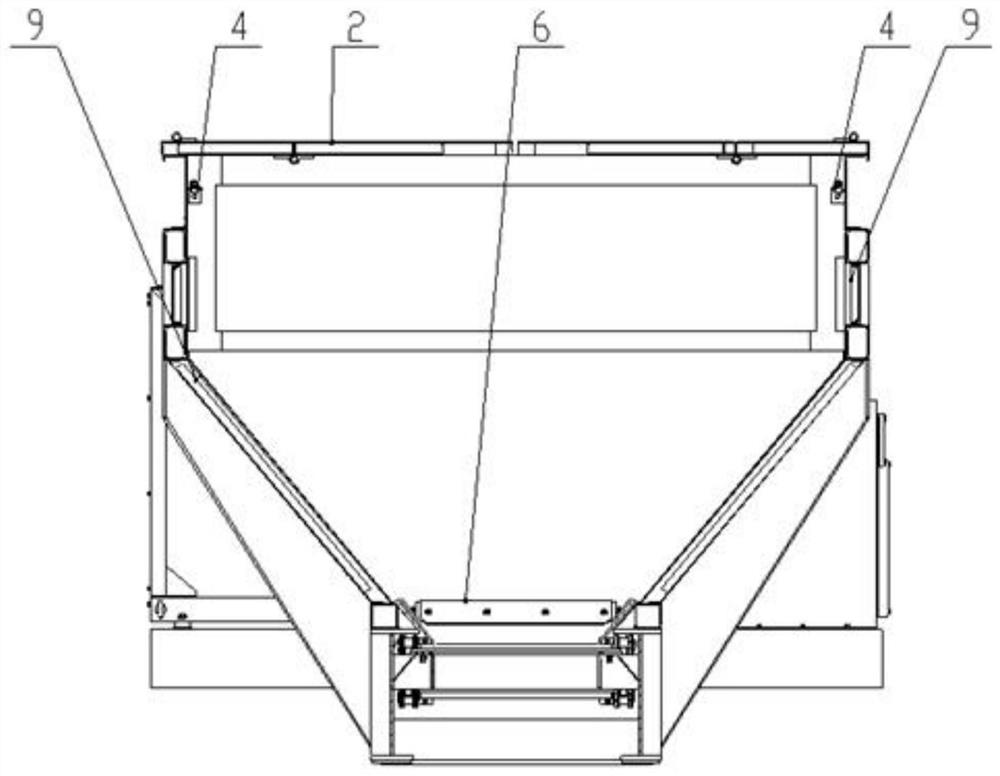

Scraper conveyer belt type heat preservation semi-trailer carrier vehicle

PendingCN111663404AImprove construction safetyIncrease single shipment volumeRoads maintainenceDiesel sprayDrive motor

The invention discloses a scraper conveyer belt type heat preservation semi-trailer carrier vehicle. The carrier vehicle comprises a semi-trailer chassis and a stock bin. An engine and a hydraulic system are installed on a front portion of the semi-trailer chassis, and the engine is connected with the hydraulic system; the stock bin is installed on the semi-trailer chassis and has a heat preservation function; and a stock bin cover is installed on an upper portion of the stock bin, a rear cover door is installed on a rear portion of the stock bin, a diesel spraying device is installed on an inner wall of the stock bin, a scraper conveying chain is arranged at a bottom of the stock bin, the scraper conveying chain is installed in the middle of the semi-trailer chassis, and a driving motor is installed on the scraper conveying chain. The engine drives the hydraulic system to drive the scraper conveying chain to work through the driving motor. According to the scraper conveyer belt type heat preservation semi-trailer carrier vehicle, a design of a scraper conveying structure and a heat preservation stock bin is adopted, when the scraper conveyer belt type heat preservation semi-trailer carrier vehicle is matched with a paver for construction, the stock bin does not need to be lifted, and construction safety is improved. A maximum allowable loading capacity of the semitrailer carrier vehicle is 40000kg, a single-time transport capacity is improved, and transport cost is reduced.

Owner:XUZHOU XCMG MAINTENANCE MACHINERY CO LTD

Auxiliary fuel saving and environmental protection device for diesel internal combustion engine

InactiveCN105020061BBurn fullyReduce usageInternal combustion piston enginesNon-fuel substance addition to fuelElectrolysisExternal combustion engine

The invention discloses an auxiliary oil-saving environmental protection device of a diesel internal combustion engine. The auxiliary oil-saving environmental protection device of the diesel internal combustion engine is communicated with a cylinder of the diesel internal combustion engine through a pipeline. Hydrogen and oxygen mixed gas is led into the cylinder and is mixed with diesel spray for combustion. The auxiliary oil-saving environmental protection device comprises a circulating gas supply device, a separating and filtering device and a circuit control system. The circulating gas supply device comprises a hydrogen an oxygen generator. A gas inlet of the separating and filtering device and a gas outlet of the hydrogen and oxygen generator are communicated through a first pipeline. A gas outlet of the separating and filtering device is communicated with a gas supply pipeline of the diesel internal combustion engine. Electrolytic gas is led in through the gas supply pipeline of the diesel internal combustion engine. The separating and filtering device is communicated with the hydrogen and oxygen generator through a second pipeline so that an electrolyte solution of the hydrogen and oxygen generator can be recycled. The circuit control system is electrically connected with the hydrogen and oxygen generator and the separating and filtering device. The auxiliary oil-saving environmental protection device can promote sufficient combustion of diesel oil in the diesel internal combustion engine, increase the combustion rate and the utilization rate of the diesel and effectively reduce the content of pollutants in exhausted tail gas, and therefore the comprehensive benefits of saving energy, reducing emission and protect the environment are achieved.

Owner:江苏博润通科技有限公司

Method for preparing flexible graphite granules

The invention relates to the technical field of the preparation of flexible graphite and relates to a method for preparing flexible graphite granules. In the method, expandable graphite is adopted. And the method comprises the following four steps of: a, expanding the graphite, namely adding the expandable graphite and diesel spray into an expanding furnace to perform expansion; b, performing vermiform forming, namely forming a vermiform forming opening at an outlet of the expanding furnace, and extruding the expanded graphite at the vermiform forming opening to form a vermiform shape; c, performing exhaust extrusion by a tapered screw type feeder; and d, pelletizing through bundling under high pressure, namely performing extrusion bundling on the expanded vermiform graphite through a funneled bundling device, allowing the bundled graphite to form a stick of which the sectional area perimeter phi is between 1.5 and 3 millimeters through a hydraulic forming pair roller, and cutting the stick and pelletizing to form 5 to 36-mesh granules. By the method, the problem of single purpose caused by the preparation method of the original expandable graphite is solved, and the problem that expandable graphite paper is easy to drop and crack in finished products of brake sheets due to the utilization of the original expandable paper and the problem that the original expandable paper is so thin that other rigid materials penetrate to coupling surface and cause noise in the braking process are solved.

Owner:殷国忠

A device and method for simultaneously measuring diesel fuel spray structure and combustion characteristics

ActiveCN106404410BReduce radiation interferenceAchieve resolutionInternal-combustion engine testingDiesel sprayMeasurement device

The invention belongs to the diesel spray and combustion visualization research field and discloses a measurement apparatus capable of simultaneously measuring a diesel spray structure and a combustion characteristic based on a laser diagnosis technology and a method thereof. In the past, test researches of a diesel spray characteristic and the combustion characteristic can not be performed simultaneously. In the invention, through using a Mie scattering technology of a laser and a laser induced fluorescence technology (OH-PLIF), the spray structure and the combustion characteristic during diesel combustion can be simultaneously measured and researched. The corresponding apparatus comprises a laser system, a constant volume combustion bomb system, a fuel oil supply system, a signal synchronization system and a signal acquisition system. The test apparatus can simultaneously carry out test researches of a liquid phase length of diesel spray and OH-PLIF distribution under a combustion condition, simultaneously can indicate a liquid phase area in a diesel combustion OH-PLIF distribution map and solves an interference problem of a liquid phase signal to a laser-induced fluorescence signal.

Owner:JIANGSU UNIV

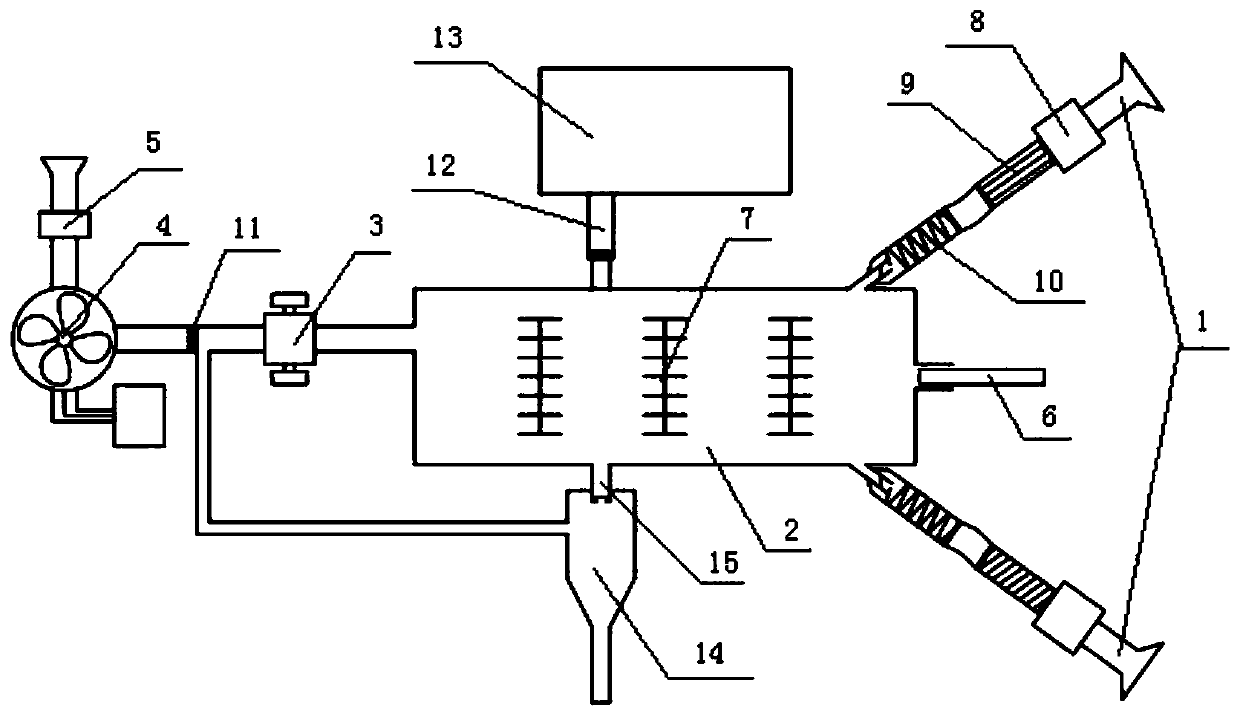

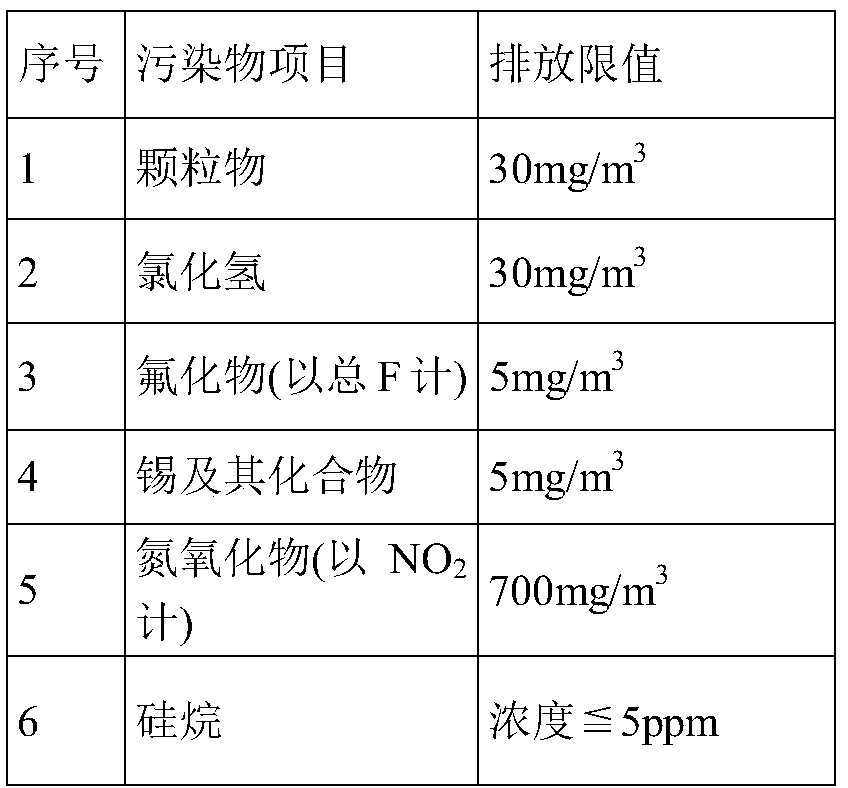

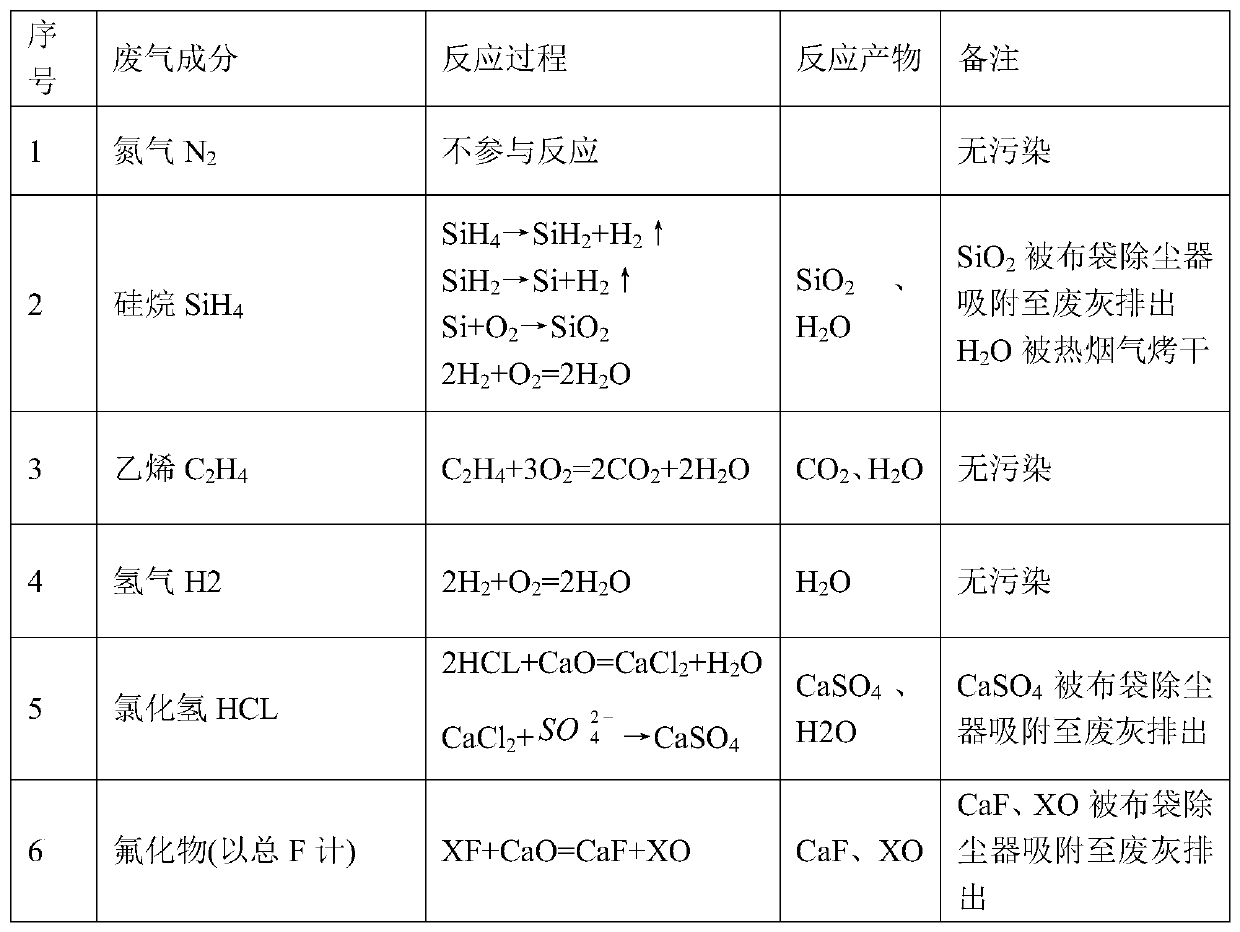

An online sunlight control coating tail gas treatment device and its treatment process

ActiveCN108119904BEasy to handleAvoid secondary pollutionLiquid carbonaceous fuelsFuel additivesParticulatesCombustion chamber

The invention relates to an online sunlight control coating tail gas treatment device and a process thereof. A modified device for operation, tail gas is mixed with nitrogen through a booster, the mixed gas enters a combustion chamber through a spiral air inlet pipe and is mixed with diesel sprayed by a diesel atomizing spray gun and then combustion is performed; exhaust gas generated after the performed passes through an air outlet regulator, a dust removing membrane, a frequency conversion fan and a denitrification desulfurization system and then is directly discharged; and dust generated bythe combustion enters a dedusting device through an ash removal hole. All the components in the coating exhaust gas can be effectively treated in the back end reaction, discharge up to the standard can be performed, and the amount of the coating exhaust gas is small is one ten thousandth of the amount of original chimney smoke, and particles generated by the reaction can be adsorbed by cloth bag,and nitrogen and water vapor and the like do not need to be treated. A desulfurization, denitration and dust removal device of an environmental protection system can effectively treat the tail gas, thereby avoiding secondary pollution; the operating cost is reduced, the service life of the device is prolonged, and purification efficiency is high.

Owner:长兴旗滨玻璃有限公司

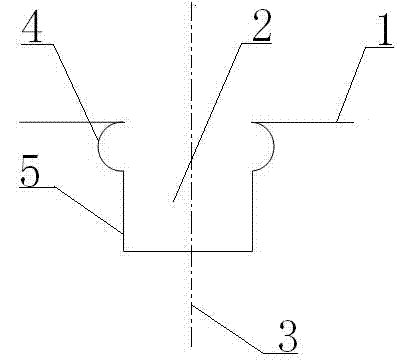

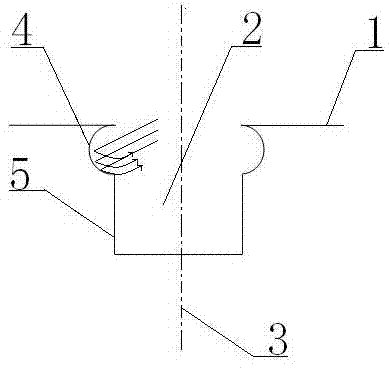

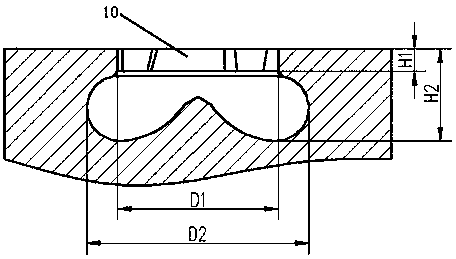

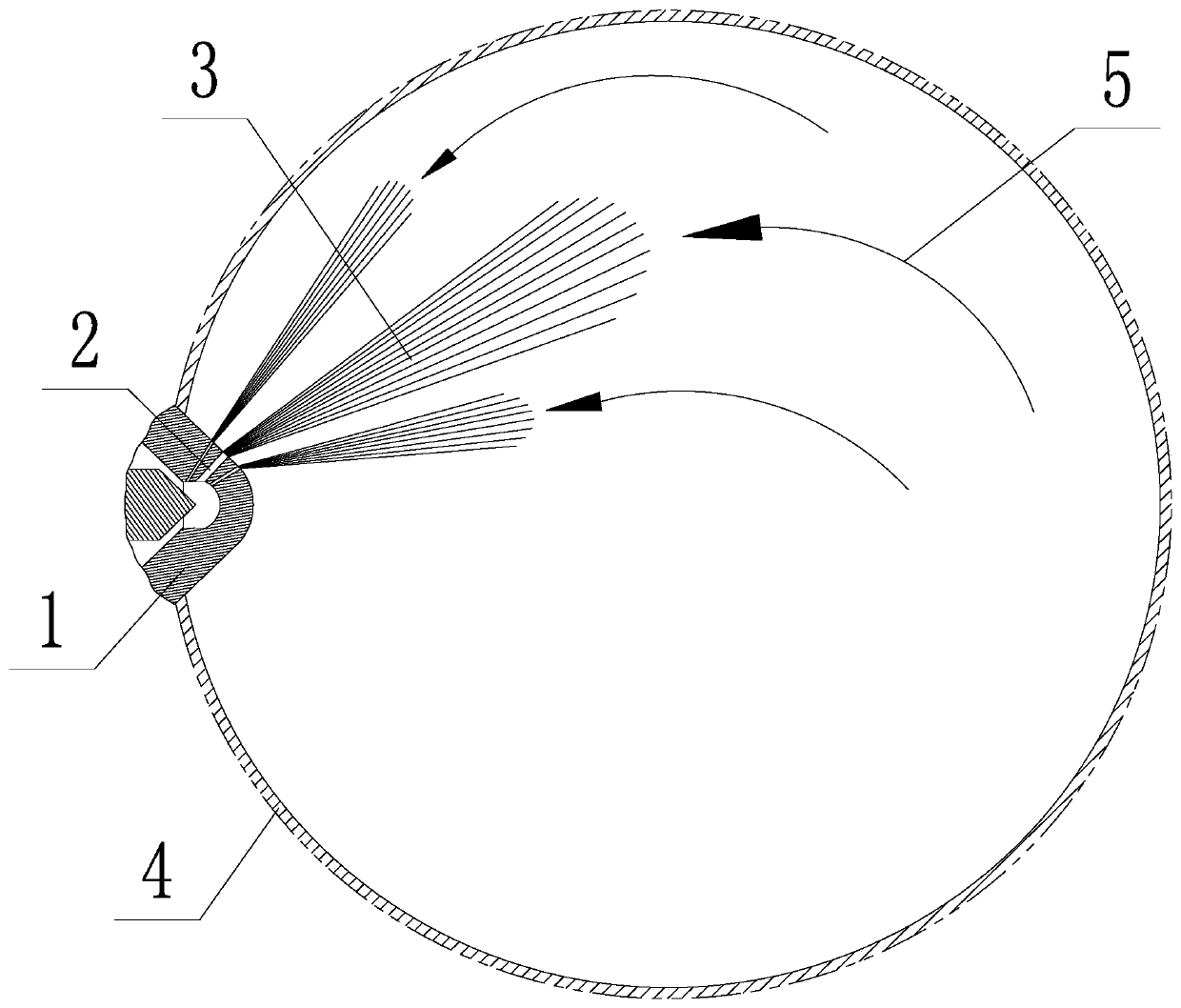

Side wall circulation combustion chamber for diesel engine

InactiveCN104727925ABest volumeReduce cooling areaInternal combustion piston enginesDiesel sprayCombustion chamber

The invention mainly relates to the technical field of diesel engines, in particular to a side wall circulation combustion chamber for a diesel engine. The side wall circulation combustion chamber for the diesel engine is a concave deep pit which is formed in the top of a piston. The concave deep pit is symmetric about the central axis of the piston. The concave deep pit comprises an annular part and a columnar part. The shape of the longitudinal section of the annular part is a semicircle which is symmetric about the central axis of the piston. The circle center of the semicircle is positioned on the side edge of the longitudinal section of the concave deep pit. The upper portion of the semicircle is tangent to a straight line formed by the longitudinal section of the end face on the top of the piston. The columnar part is cylinder-shaped. The side edge of the longitudinal section of the columnar part is connected with the lower portion of the semicircle. The side edge of the longitudinal section of the columnar part and the circle center of the semicircle of the longitudinal section of the annular part are in the same vertical straight line. According to the side wall circulation combustion chamber for the diesel engine, the structure is simple and compact, the layout is reasonable, when diesel is injected into the side wall circulation combustion chamber, diesel sprays are injected to the arc surface of the side wall of the side wall circulation combustion chamber, then the rebound is generated, and circulation is generated in the side wall circulation combustion chamber, so that mixing of the diesel and air is more even, and the efficient combustion of the diesel is facilitated.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

A Diesel/Natural Gas Dual Fuel Direct Injection Device

ActiveCN107605634BEnables direct injection jet mixingGood for studying interactionsInternal combustion piston enginesFuel supply apparatusDiesel sprayEngineering

The invention provides a diesel / natural gas double fuel direct injection device including a constant volume bomb, a sparking plug, a natural gas pipe, a fuel pipe union, a constant volume bomb adapter, a natural gas ejector, a diesel ejector and a diesel ejector supporting frame. The constant volume bomb adapter is installed on the top of the constant volume bomb. The natural gas pipe is installedon the constant volume bomb adapter. The lower end of the natural gas pipe is connected with the top end of the natural gas ejector in a threaded mode. The upper end of the diesel ejector supportingframe is connected with the bottom of the constant volume bomb adapter and the lower end of the diesel ejector supporting frame is connected with the lower end of the diesel ejector in a detachable mode. A top electrode of the sparking plug is connected with an ECU output circuit and a bottom electrode of the sparking plug is connected with power connections of the diesel ejector and the natural gas ejector separately. The position of the diesel ejector can be flexibly adjusted and the distance between a diesel spraying hole and a natural gas spraying hole can be as small as 3mm. The interaction of double fuels is researched more advantageously. The diesel / natural gas double fuel direct injection device realizes the mixing of direct injection of the double fuels and provides research datafor the exploration of a direct injection engine for a diesel ignited natural gas cylinder.

Owner:JIANGSU UNIV

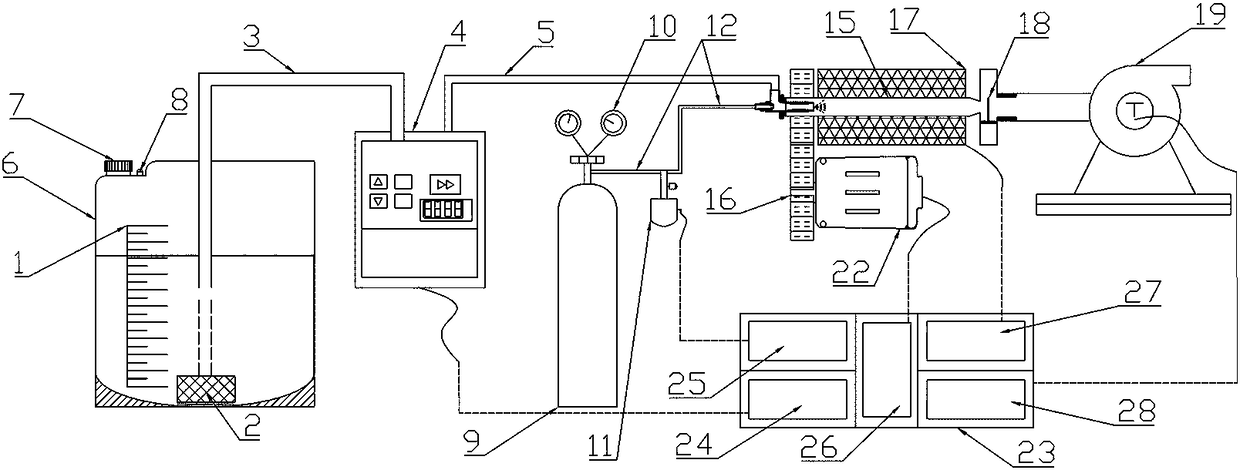

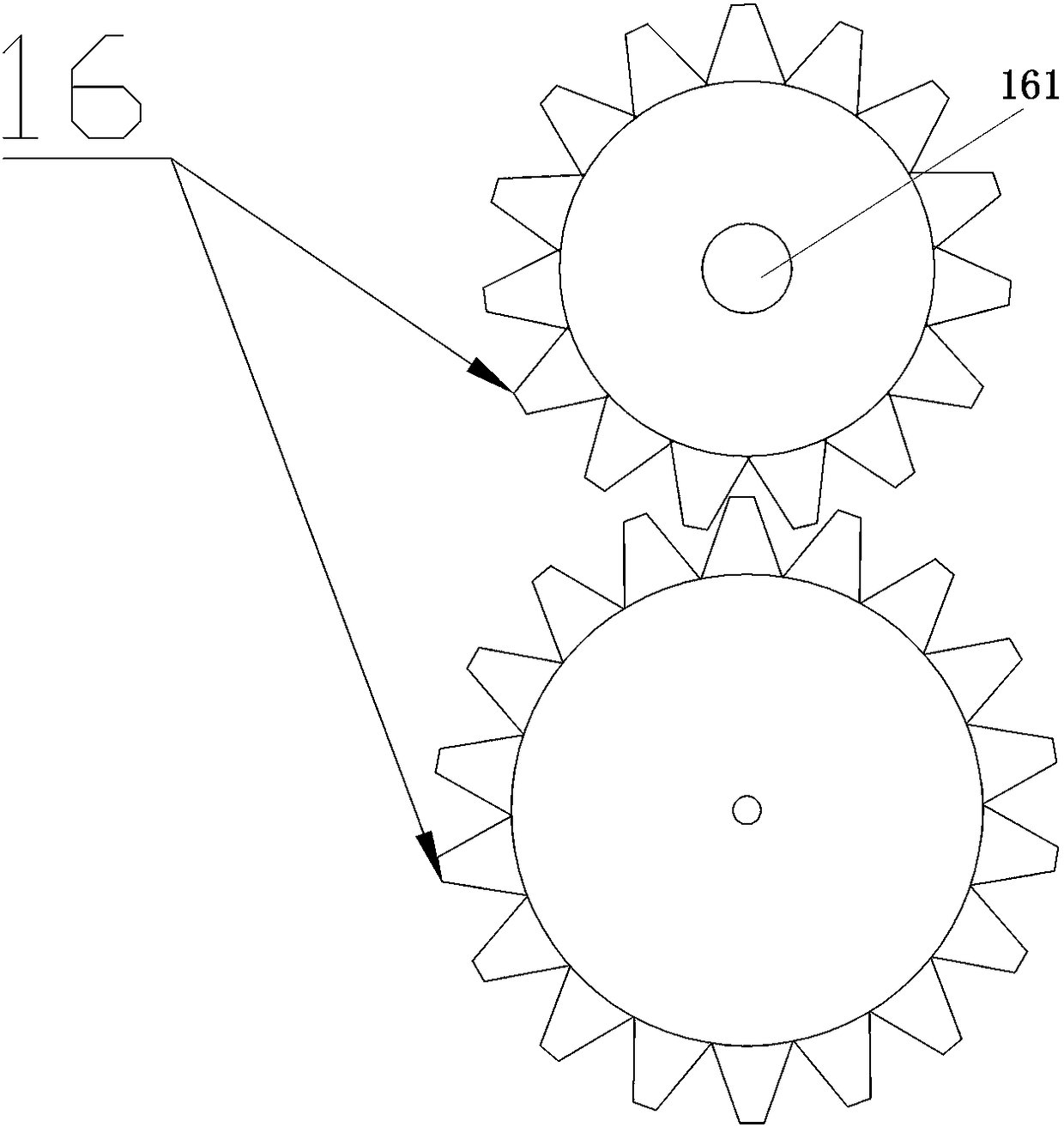

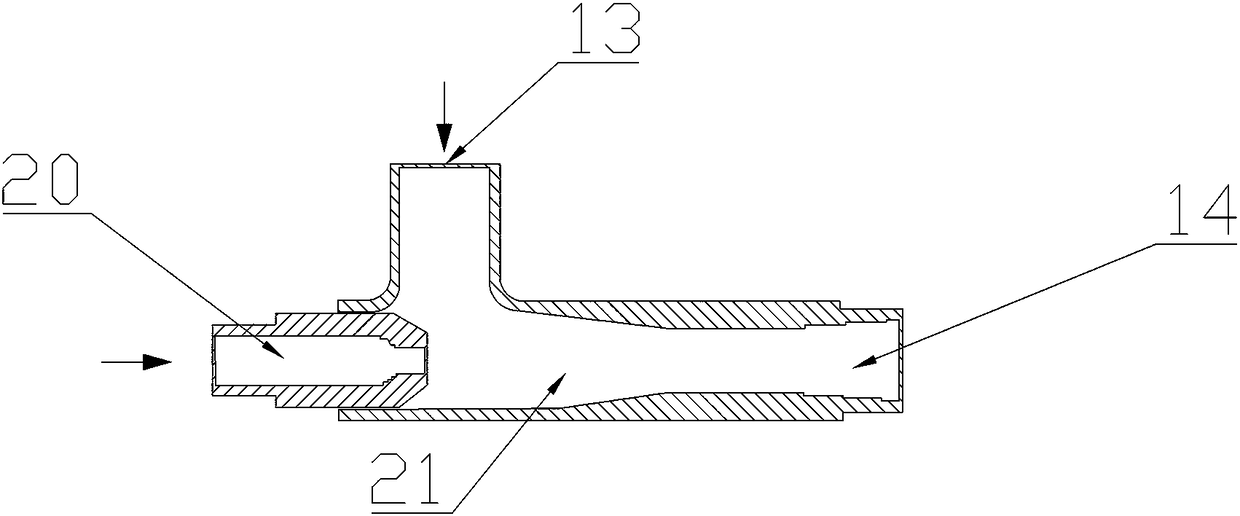

Spray type diesel coking test simulation device and diesel detergency detection method

PendingCN108318667ASolve the problem of long time-consuming decontamination testIncrease the areaJet pumpsMachines/enginesDiesel sprayTested time

The invention relates to a spray type diesel coking test simulation device and a diesel detergency detection method. In a coking simulation test, an oil supply device supplies diesel to a diesel spraynozzle; the diesel is sprayed from the diesel spray nozzle to a diesel channel simulation pipe; a heating structure heats the diesel channel simulation pipe, so that an inner cavity of the diesel channel simulation pipe remains at a relatively high temperature; the diesel cokes in the diesel channel simulation pipe and is attached to an inner wall of the diesel channel simulation pipe under the temperature condition. The diesel channel simulation pipe is used for coking the diesel to increase a diesel coking area, so as to improve coking efficiency, obviously shortening detection test time and solve a problem of long time consumption of detection test of diesel detergency in the prior art.

Owner:河南郑大嘉源环保技术有限公司

A diesel spray penetration prediction method with variable fuel injection rate

The purpose of the present invention is to provide a variable fuel injection rate diesel spray penetration distance prediction method, which is suitable for variable fuel injection rate diesel spray penetration distance prediction, and belongs to a phenomenological modeling method. The method mainly includes: based on the theory of jet mechanics, establishing an analytical formula for the change of the effective injection velocity with the injection velocity, introducing the effective injection velocity instead of the injection velocity into the spray model suitable for the calculation of the constant injection rate, and obtaining a suitable injection rate for variable injection. The rate of spray model is used for the prediction of penetration distance. The spray model established by the present invention has a reliable theoretical basis, and the modeling method used has strong property description ability, the model is simple, the parameterized research is easy, and the spray penetration distance prediction of variable fuel injection rate can be realized.

Owner:HARBIN ENG UNIV

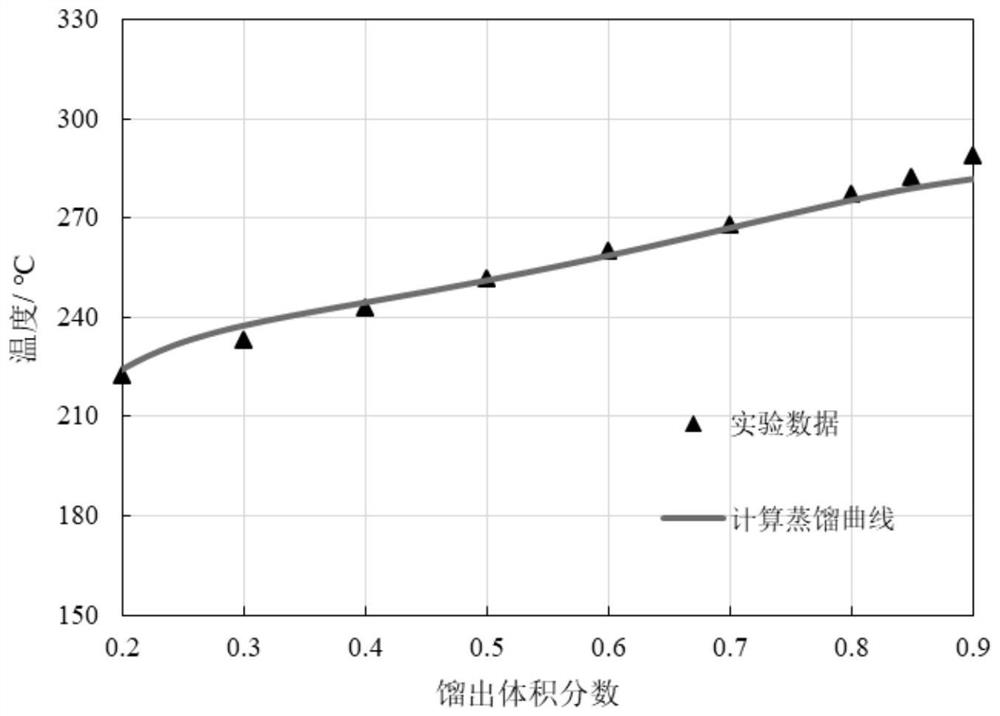

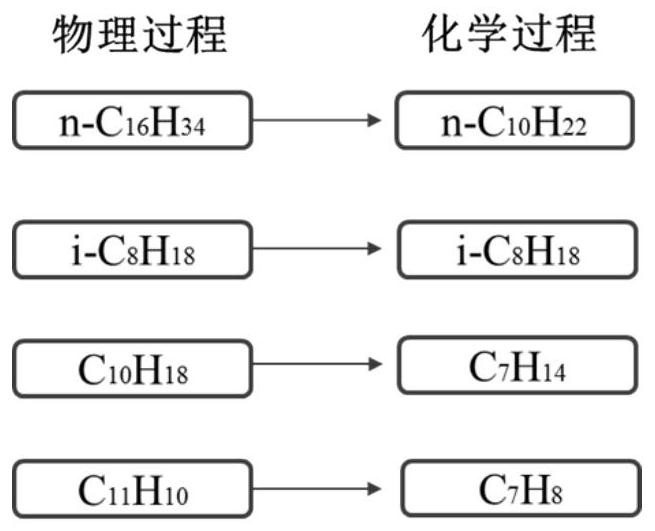

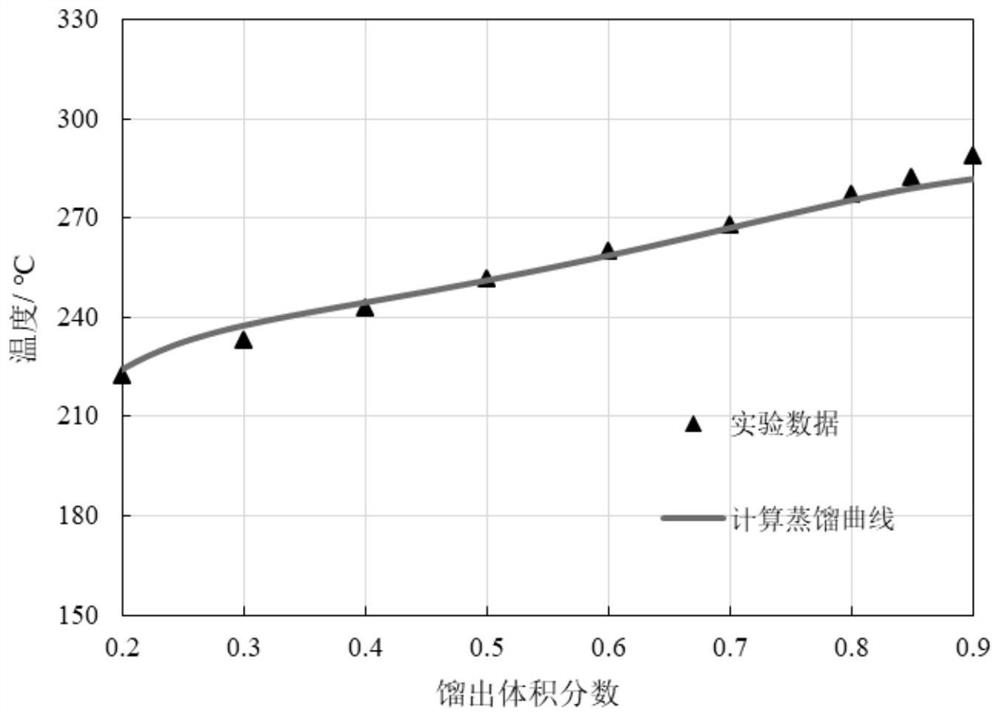

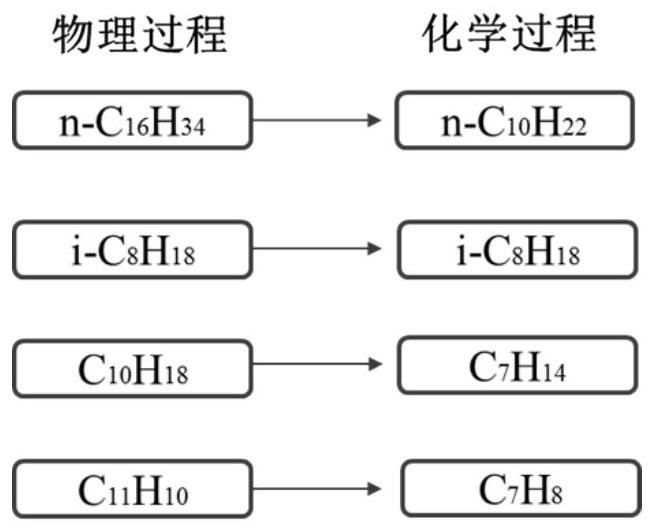

Simulation Method of Diesel Spray Combustion Based on Multi-Component Decoupling Physicochemical Surrogates

The invention discloses a diesel spray combustion simulation method based on multi-component decoupling physical and chemical substitutes, which is used for simulating the spray combustion characteristics of ‑50# diesel in alpine regions; the method includes: selecting physical substitutes for characterization‑ For the physical properties of 50# diesel, select chemical substitutes to characterize the chemical properties of 50# diesel; when carrying out diesel spray combustion simulation, when diesel is in liquid state, use the physical substitutes as diesel substitutes; when diesel evaporates from liquid Switches the diesel replacement from a physical to a chemical replacement when it becomes gaseous. The invention can better reproduce the spraying and combustion characteristics of actual diesel oil at the same time.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

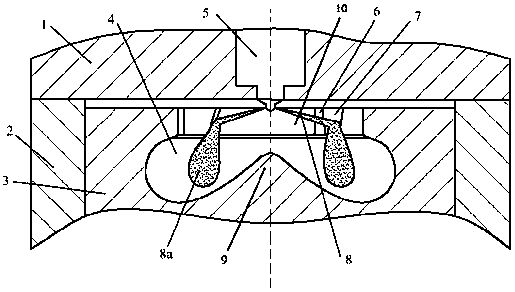

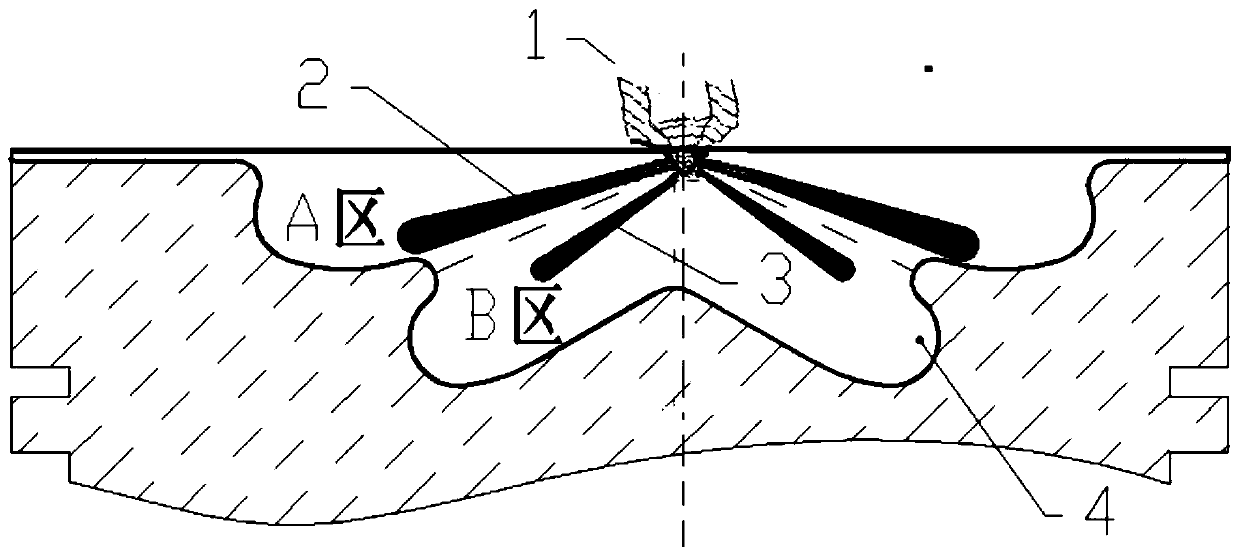

A Direct Injection Diesel Engine Collision Spray Diffusion Combustion System

InactiveCN104632353BReduce bumpsQuality improvementInternal combustion piston enginesCombustion systemDiesel spray

The invention discloses a direct injection diesel engine collision spray diffusion combustion system. A combustion chamber of the combustion system is located in the middle of the head of a piston and needs to be used in cooperation with an oil injector with a multi-hole oil nozzle. According to the structure, a boss is arranged at the bottom of the center of the combustion chamber, collision guide blocks are evenly distributed on a throat of the combustion chamber in the circumferential direction, and each guide block is provided with a collision guide bevel. In the operating process, the oil injector directly sprays oil streams onto the collision guide blocks so that the primary oil streams can be spread along the collision guide bevels without accumulating on drop points, the spray diffusion speed is high, and the space distribution range is large; besides, secondary atomization enables the sprayed particle size to become small, and distribution is more uniform under the squish effect, so that the oil and gas distribution uniformity is improved, and the goals of improving combustion and lowering oil consumption and emission are achieved.

Owner:JIANGSU UNIV

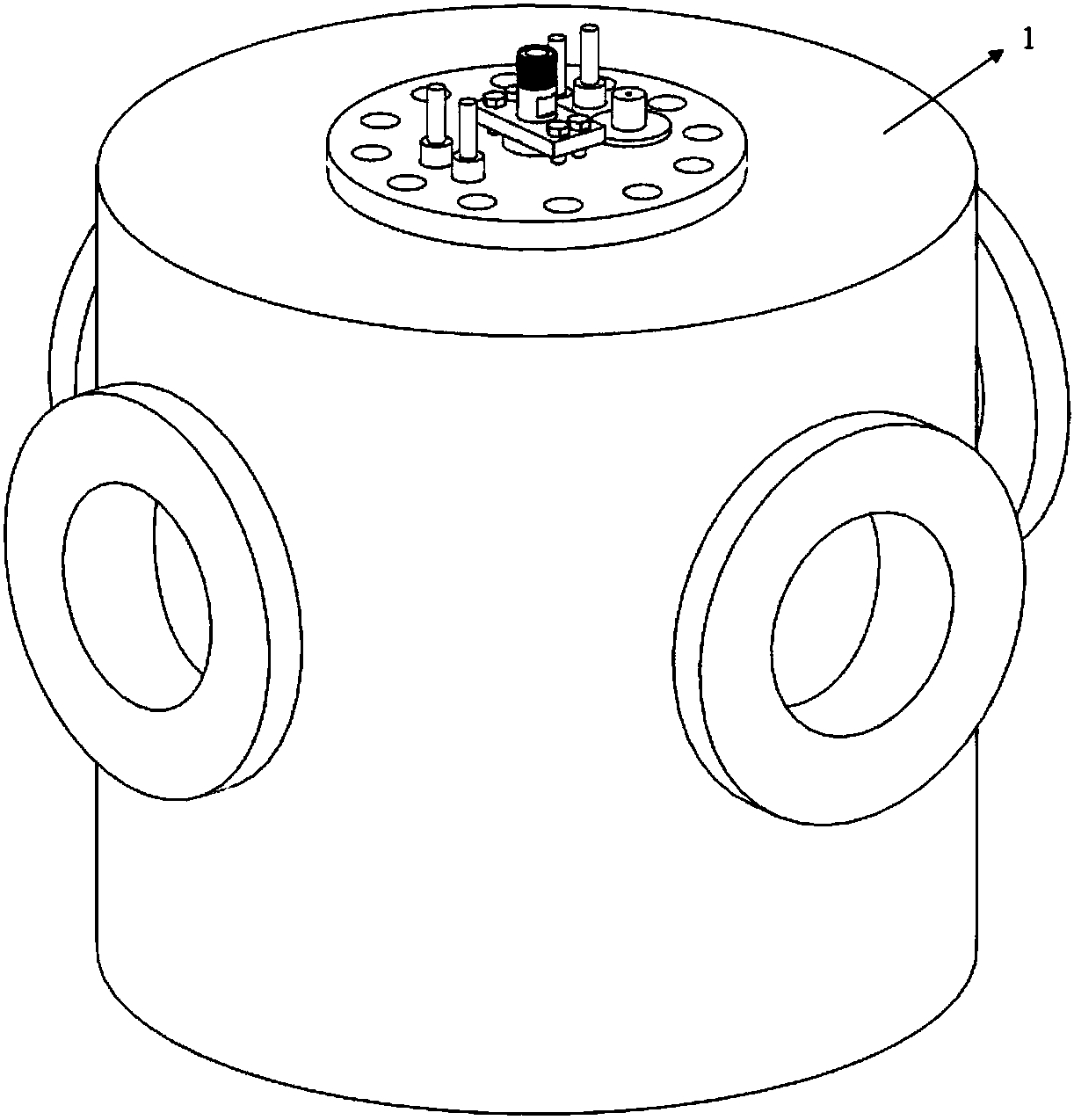

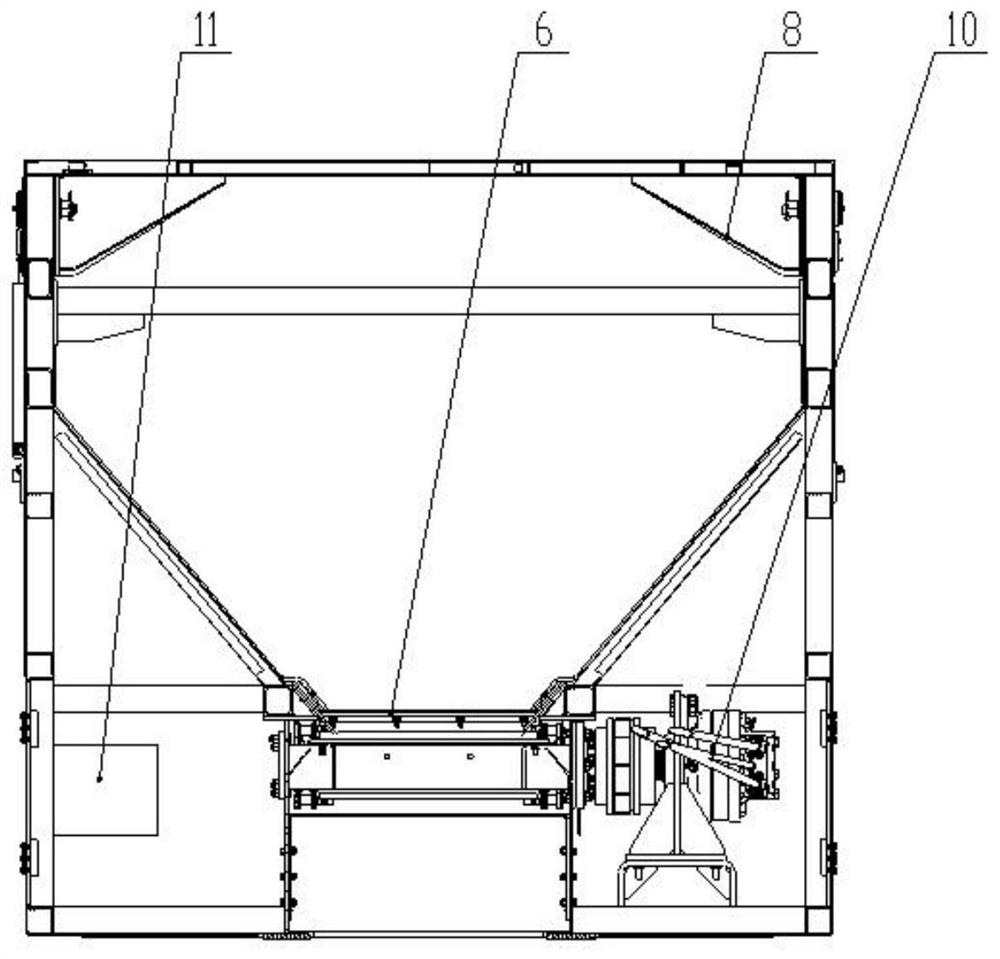

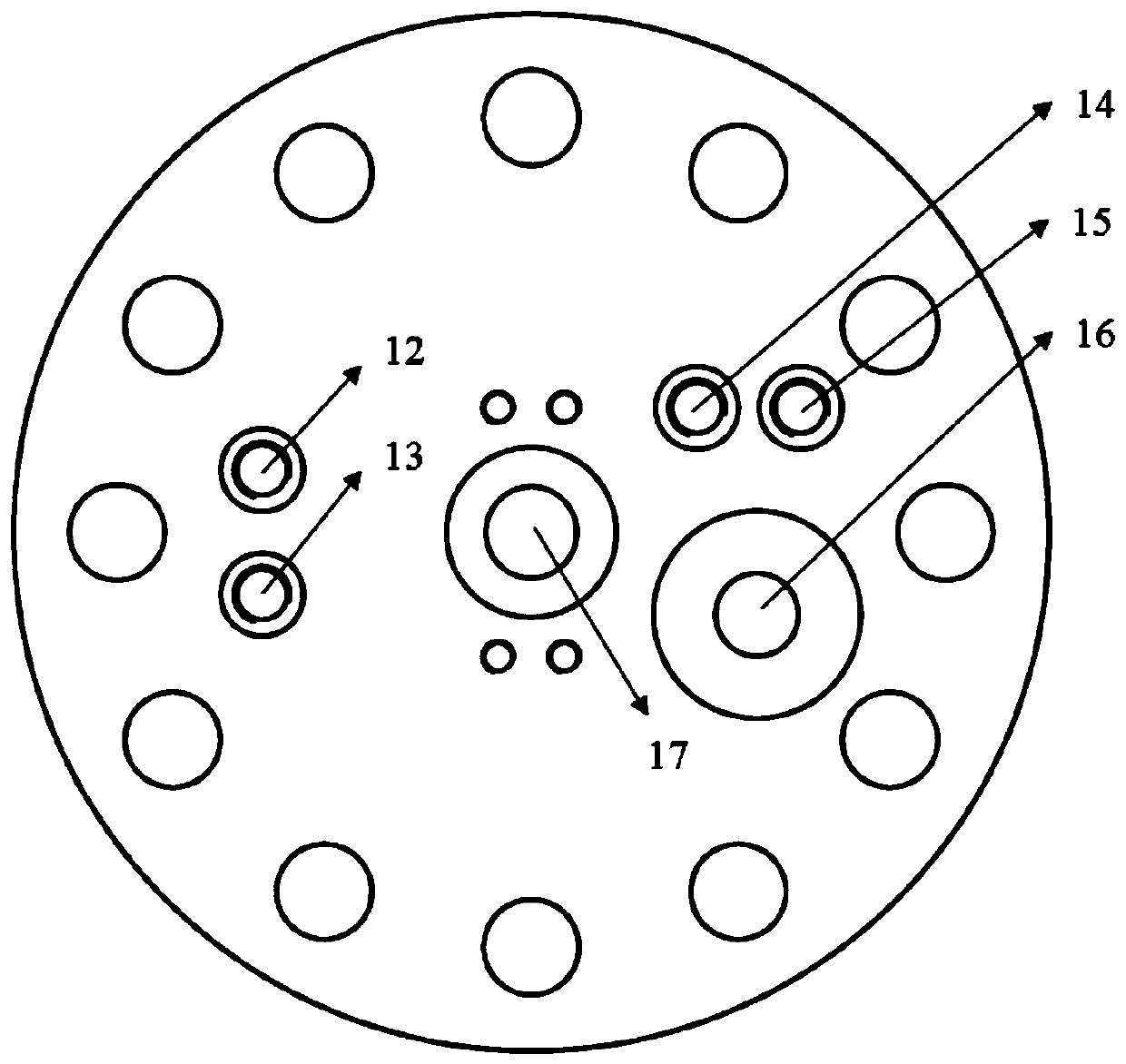

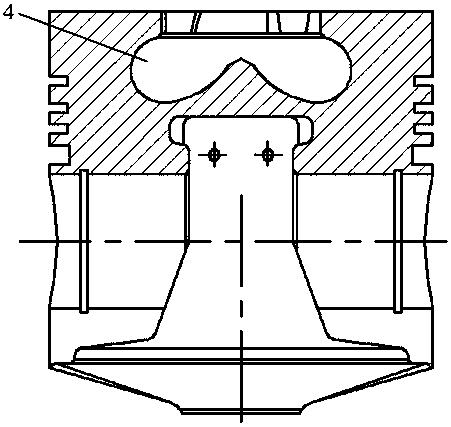

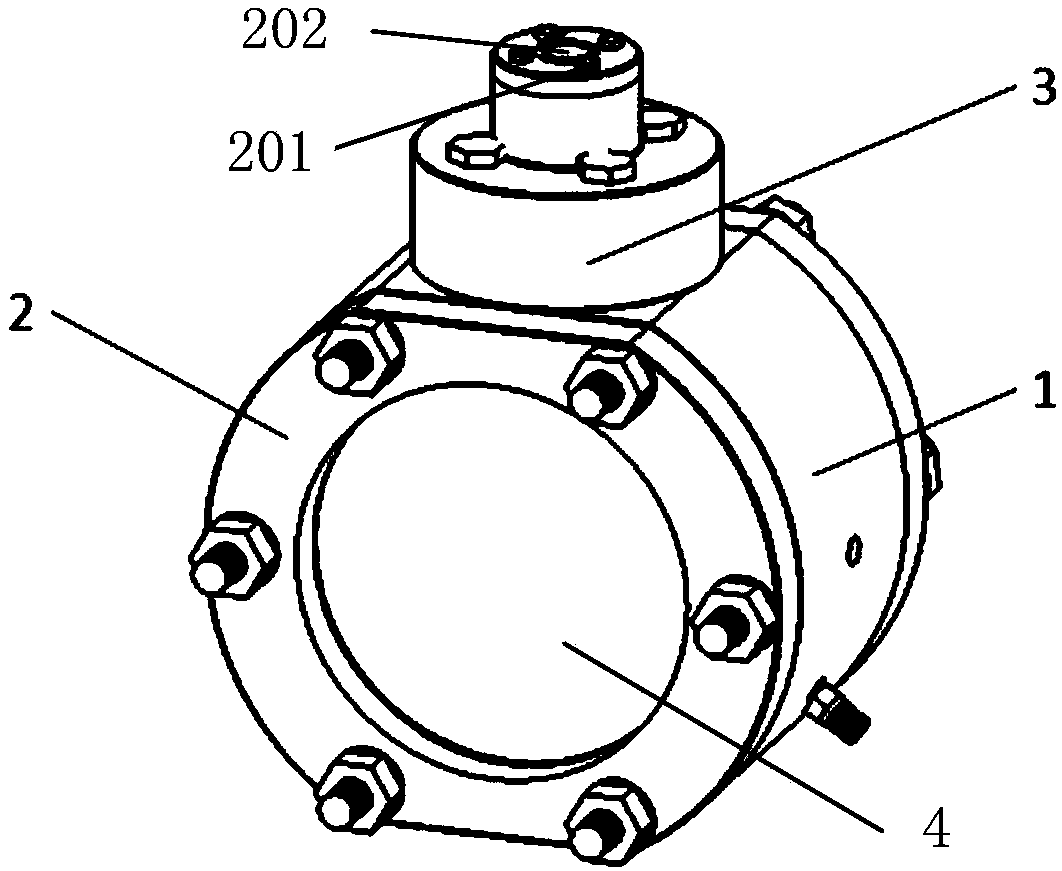

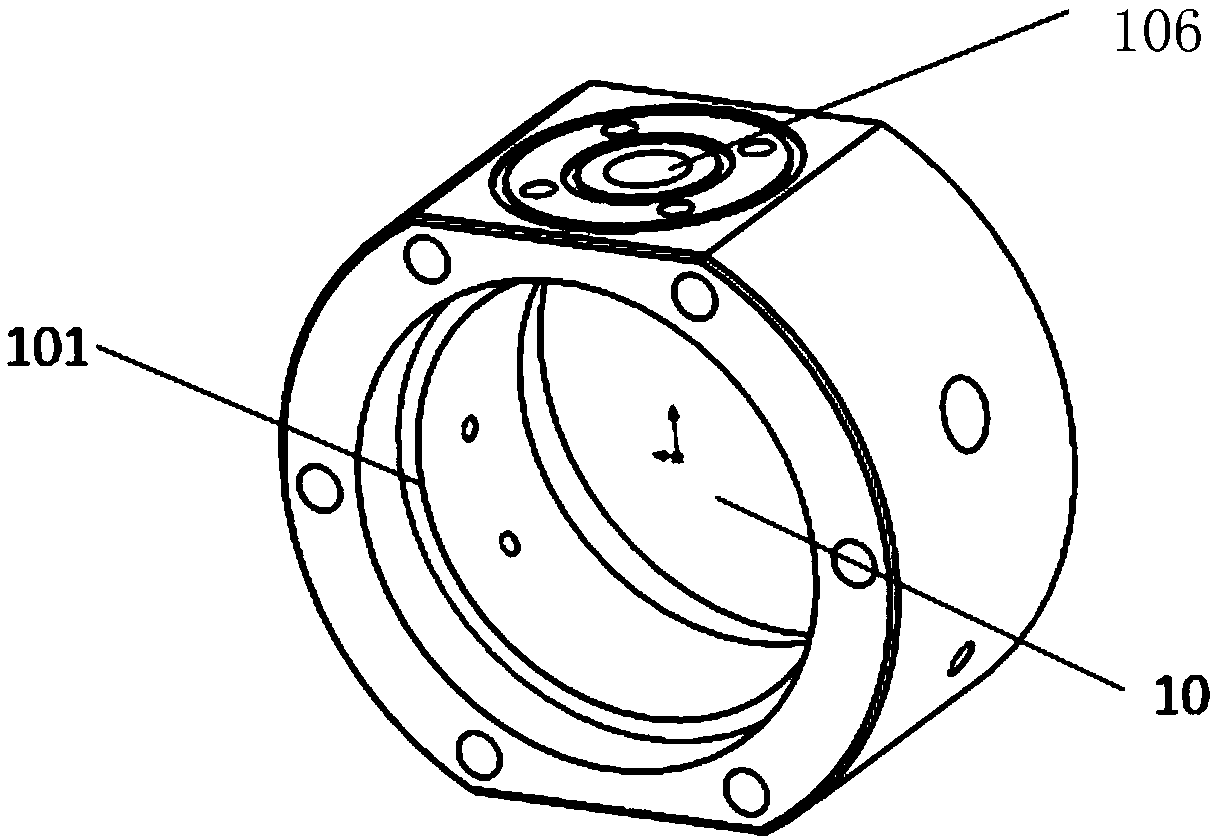

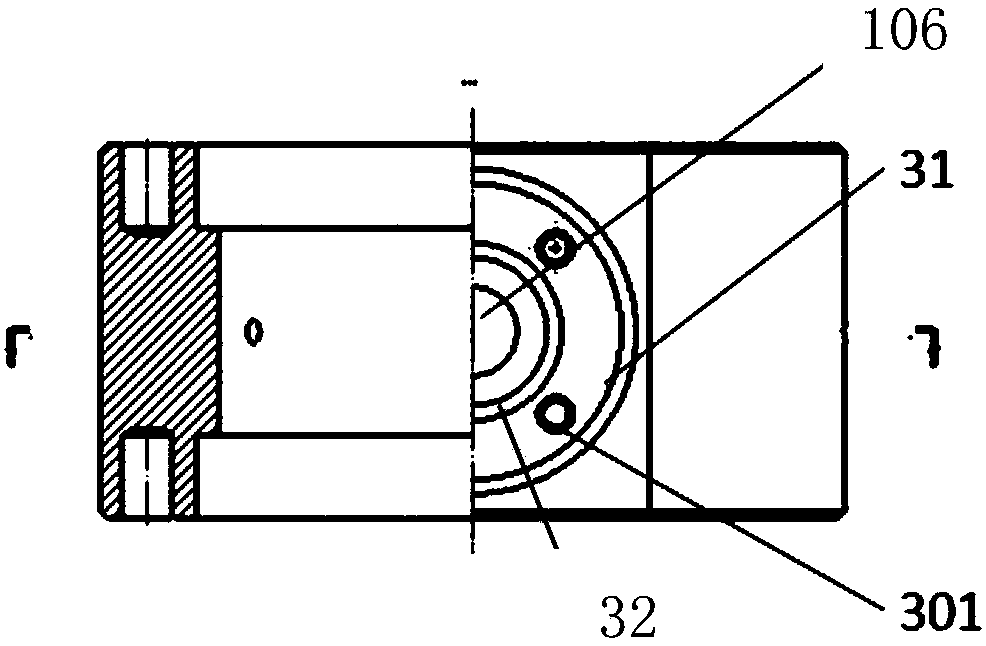

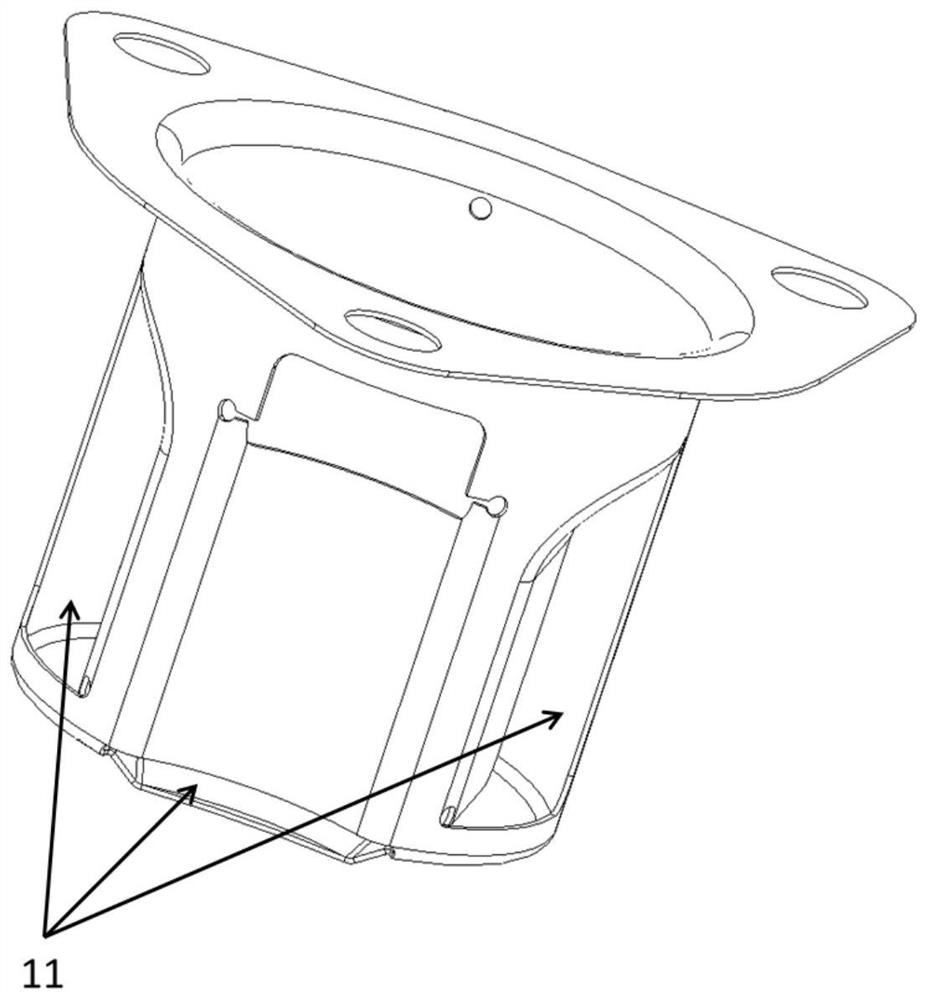

A Constant Volume Projectile Used in Diesel Spray and Combustion Visualization Test

ActiveCN106353098BSimple structureEasy to processInternal-combustion engine testingDiesel sprayVisual test

The invention provides a constant volume bomb for a diesel spraying and burning visualization experiment. The constant volume bomb comprises a constant volume bomb body. The constant volume bomb body uses the circular-cake-shaped structure, the interior is hollow and used for forming the visualization experiment area, two sides of the circular cake are opened with visualization window holes and the end faces of the windows are pressed by sealing cover plates for sealing. The quartz glass is clamped between the body and the sealing cover plates. The upper end face is opened with a positioning hole for an oil sprayer installing base, and the unique design is suitable for use of various oil sprayers. The lower end face is opened with a positioning threaded hole for fixing the position of the constant volume bomb. The constant volume bomb body is radially opened with various installing through holes for installing various data collecting devices. The visualization spraying constant volume napalm bomb has the characteristics of simple structure, wide experiment area and transparent light path, and is capable of observing and measuring the spraying and burning processes through cooperating the schlieren method and the laser-induced fluorescence technology, remarkably improving the experiment efficiency, performing the spraying feature test to different oil sprayers and improving the adaptability of the spraying constant volume test bomb.

Owner:HARBIN ENG UNIV

A Method for Optimizing the Mixing Quality of Oil and Gas in a Diesel Internal Combustion Engine

ActiveCN108167101BImprove combustion efficiencyImprove performanceInternal combustion piston enginesFuel injection apparatusDiesel sprayEngineering

Owner:SHENYANG AEROSPACE UNIVERSITY

Self-rectification type diesel engine air inlet flame warmer

InactiveCN112682227AStable combustionImprove ignition reliabilityFuel injection apparatusMachines/enginesDiesel sprayCombustor

The invention provides a self-rectification type diesel engine air inlet flame warmer. The self-rectification type diesel engine air inlet flame warmer comprises a warmer base, a warmer outer barrel, a warmer inner barrel, an electric heating plug, a fuel nozzle and related components; the warmer outer barrel is used for guiding air flow in the air inlet pipe into the warmer; the warmer inner barrel and the warmer outer barrel are eccentrically arranged; the warmer inner barrel and the warmer outer barrel jointly organize the air flow to form an internal stable wind field; after the glow plug is powered on, the glow head of the glow plug is used for igniting diesel oil spray sprayed by the fuel oil nozzle; and high-temperature fuel gas generated by combustion is mixed with inlet gas, and then the inlet gas of the diesel engine is heated. The self-rectification type diesel engine air inlet flame warmer has the beneficial effects that in the starting process of a diesel engine, reliable ignition is achieved by spraying fuel oil to the glow plug incandescent head; a stable wind field is formed by organizing gas flow in the gas inlet pipe through the structure body; stable combustion in the combustor is guaranteed; and the working reliability and stability of the gas inlet flame heater can be improved.

Owner:CHINA NORTH ENGINE INST TIANJIN

A Diesel Engine Electronically Controlled Speed Regulation and Testing Method Based on Fuzzy Variable Structure

ActiveCN108757192BGood control effectEasy to controlElectrical controlSpeed sensing governorsDiesel sprayDieseling

The invention provides a diesel engine electronic-control speed adjusting and testing method based on a fuzzy variable structure. An electronic-control speed adjusting system algorithm of a diesel engine is optimally designed. A nonlinear object dynamic model and an executer of the diesel engine are subjected to modeling, and a diesel spraying system of the diesel engine is controlled through thefuzzy variable structure; then discontinuous control conditions are deduced through the Lyapunov function, and it is proved that a system has the capacity of stability adaptive adjusting under uncertain interference; and finally, the diesel engine speed-adjusting system is subjected to a Matlab / Simulink simulation experiment. Control over accuracy of the rotating speed of the diesel engine by thediesel engine electronic-control speed adjusting system can be improved to a great extent under the uncertain interference, and the good effect under various uncertain interference backgrounds such asstarting, idling, working condition sudden increasing and reducing is achieved so that the method can meet the situation that the good control effect is achieved on the diesel engine in the practicalworking process.

Owner:HANGZHOU DIANZI UNIV

Diesel spray combustion simulation method based on multi-component decoupling physical and chemical substitutes

ActiveCN112908140AReproduction sprayReproduce combustion characteristicsInternal combustion piston enginesEducational modelsDiesel sprayThermodynamics

The invention discloses a diesel oil spray combustion simulation method based on multi-component decoupling physical and chemical substitutes. The method is used for simulating spray combustion characteristics of -50 # diesel oil in alpine regions. The method comprises the following steps: selecting a physical substitute to characterize the physical characteristics of the -50 # diesel oil, and selecting a chemical substitute to characterize the chemical characteristics of the -50 # diesel oil; when diesel oil is in a liquid state during diesel oil spray combustion simulation, selecting the physical substitute as a diesel oil substitute; and when the diesel oil is evaporated from a liquid state to a gaseous state, selecting the chemical substitute as a diesel oil substitute to replace the physical substitute. According to the invention, spraying and combustion characteristics of actual diesel oil can be well reproduced at the same time.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

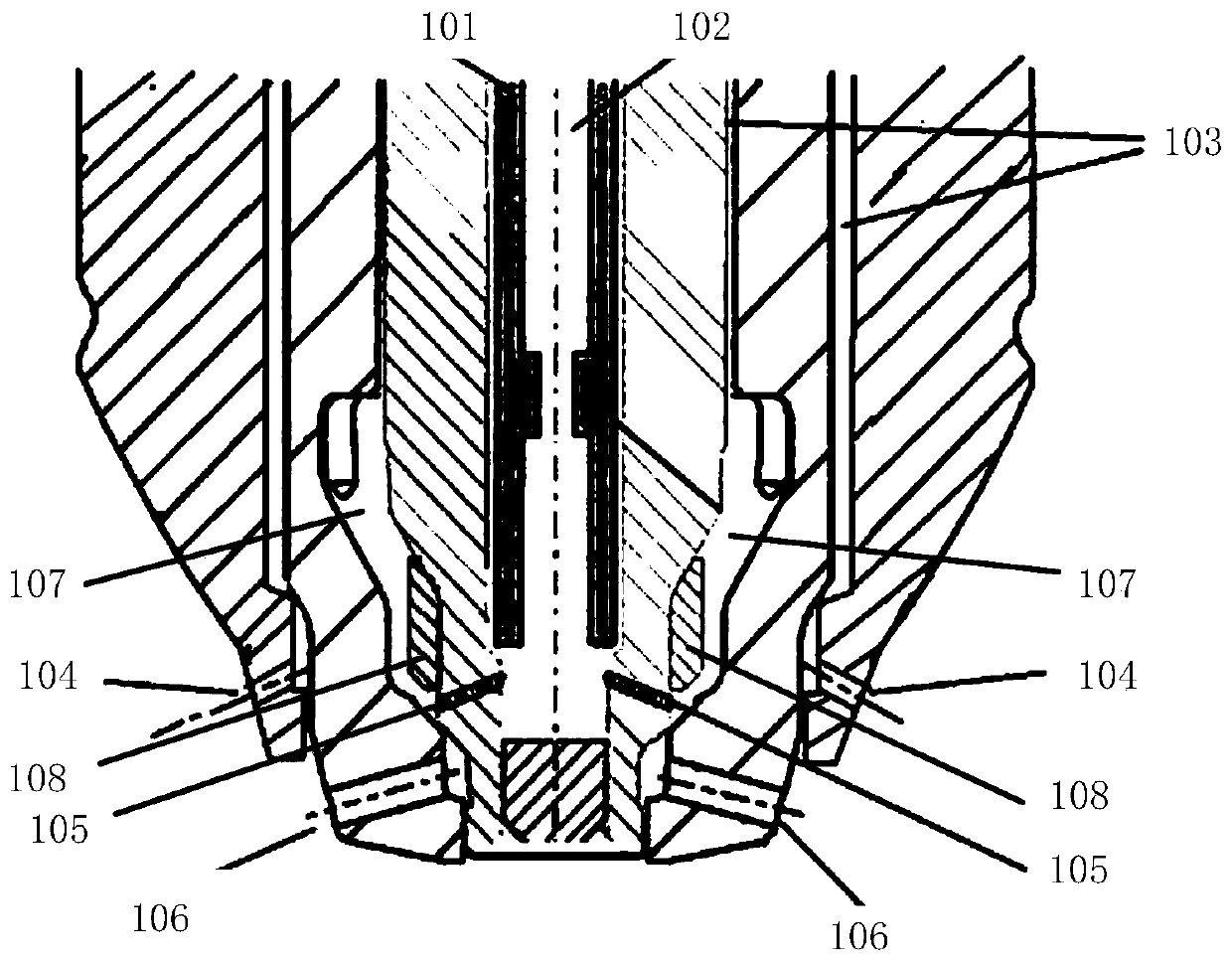

Combustion-supporting injection device and method for internal combustion engine and internal combustion engine

ActiveCN110848059AImprove atomization effectEfficient combustionElectrical controlFuel injection apparatusDiesel sprayInternal combustion engine

The invention discloses a combustion-supporting injection device and method for an internal combustion engine and the internal combustion engine. The device comprises a main body, a controller, a drainage device, a diesel channel, an internal storage cavity, a limiting sleeve, natural gas channels, natural gas spray holes, natural gas assisted diesel spray holes and diesel internal circulation holes, wherein a center line of the diesel channel coincides with a center line of the main body; the internal storage cavity surrounds the diesel channel; the drainage device is mounted in the middle ofthe diesel channel; the natural gas channels comprise a first natural gas channel and a second natural gas channel; the lower end of the first natural gas channel communicates with the internal storage cavity; the diesel internal circulation holes communicate with the diesel channel and the internal storage cavity; the natural gas assisted diesel spray holes are located on one side of the lower end of the main body and communicate with the internal storage cavity; and the natural gas spray holes are located at the tail end of the second natural gas channel and communicate with the second natural gas channel, and the downward inclined angle of the natural gas spray holes is not equal to that of the natural gas assisted diesel spray holes.

Owner:BEIJING JIAOTONG UNIV

A method for automatic identification of diesel spray breaking process and automatic realization of spray continuous calculation

The invention discloses a method for automatically identifying the diesel spray breaking process and automatically realizing spray continuous calculation, thereby automatically judging the process of liquid film breaking to liquid droplets in the diesel spray process, and realizing the SD-ELSA algorithm for spray continuous calculation. The SD-ELSA algorithm is based on the calculation of the sphericity and average particle diameter of the liquid phase in the grid, uses the Lagrangian method to calculate the particles in the flow field, and uses the Euler model to calculate the grid node information in the full flow field. For the grid of continuous liquid phase, the Euler clumps that meet the two criteria are converted into particles and recalculated by Lagrangian method. This method realizes the dynamic conversion coupling of the Euler-Lagrangian model, can automatically obtain the complete information of the discrete phase and the continuous phase of the flow field and perform iterative calculations, and obtain the liquid column, primary crushing and secondary crushing of the diesel jet flow. stage, fully expressing the process of diesel spraying.

Owner:BEIJING UNIV OF TECH

A kind of granular ammonium oil explosives production equipment

ActiveCN110041152BEasy to assemble and disassembleEasy transferExplosive working-up apparatusDiesel sprayExplosive Agents

The invention discloses a granular ammonium nitrate fuel oil explosive production device. The granular ammonium nitrate fuel oil explosive production equipment comprises a hopper pipe type screw conveyor arranged on a rack. The tubular screw conveyor consists of a first tubular screw conveyor and a second tubular screw conveyor; the first tubular screw conveyor is connected with a diesel sprayingsystem; wherein a feed port of the first tubular screw conveyor is connected with a discharge port of the hopper, a discharge port of the first tubular screw conveyor is connected with a distributor,the distributor is provided with a first outlet and a second outlet, the first outlet is connected with a feed port of the second tubular screw conveyor, and the first outlet and the second outlet isopened alternatively. When the second outlet is opened, the porous granular ammonium nitrate fuel oil explosive is output to the outside. The second tubular screw conveyor is connected with an emulsion matrix pipeline, and a discharge port of the second tubular screw conveyor outputs emulsified granular ammonium nitrate fuel oil explosives. The production equipment has the production capacity of two kinds of granular explosives, is compact in layout, facilitates overall carrying and site transferring and can achieve continuous production.

Owner:CHINA GEZHOUBA GRP YIPULI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com