A method for automatic identification of diesel spray breaking process and automatic realization of spray continuous calculation

A crushing process and automatic identification technology, which is applied in the direction of engine testing, engine components, machines/engines, etc., can solve the problems that it is not suitable for changing the working state, cannot dynamically change the position of the interval, and has a great influence on the calculation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

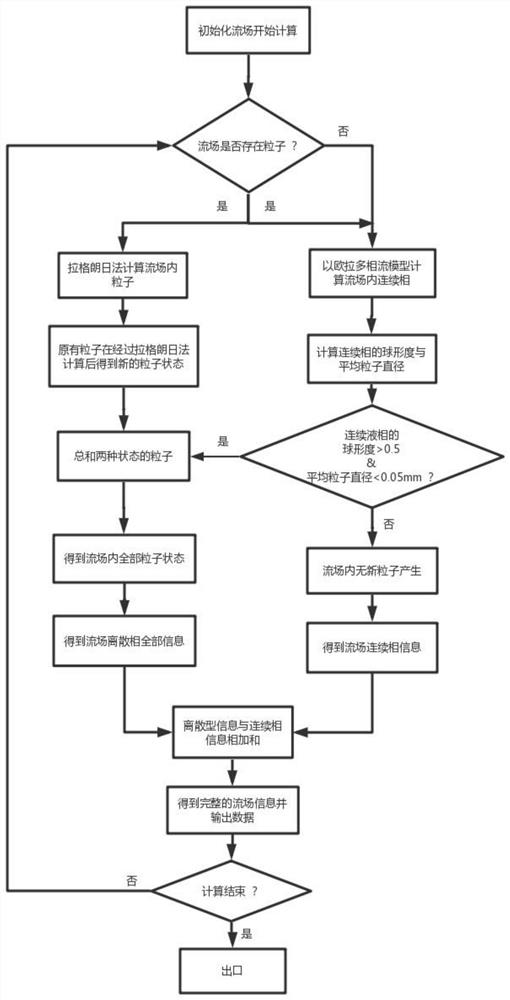

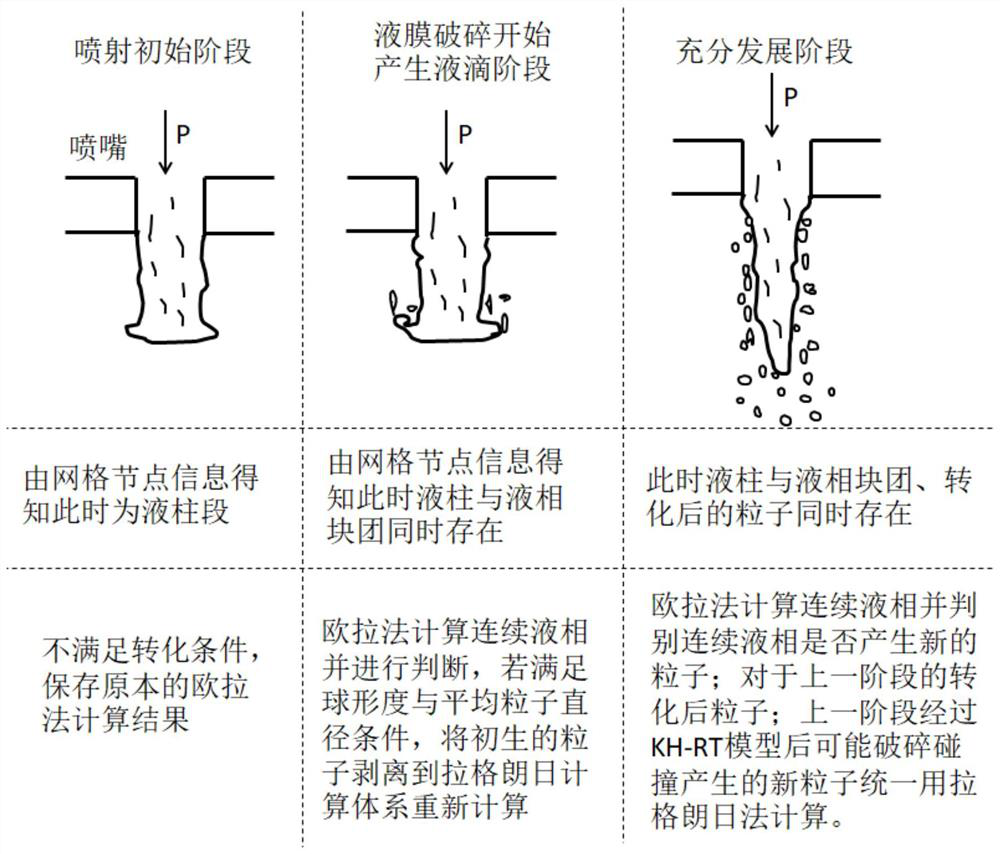

[0030] Enter the entire flow field calculation domain from the outlet of the nozzle, calculate the flow field grid at the first step, and use the large eddy simulation method for the atomization flow field, and in order to simplify the calculation amount, use the RANS equation for near-wall processing, free shear The layer is simulated by LES. In order to reduce the calculation amount under the premise of ensuring the calculation accuracy, the sub-model of the large eddy equation is calculated using WNLES S-Omega, the near-field VOF model is calculated using the Explicit method, and the far-field DDM model is calculated using the KH-RT fragmentation model calculate.

[0031] The simulation boundary conditions and calculation model parameters are as follows: inlet pressure 100Mpa, back pressure 1Mpa, nozzle diameter 0.3mm, aspect ratio 5, fluid diesel, wall temperature 298.15K, fluid density 850kg / m3, surface tension coefficient 0.031N / m, the air is a compressible gas, the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com