A kind of granular ammonium oil explosives production equipment

A technology for ammonium oil explosives and production equipment, which is applied to explosives processing equipment, explosives, offensive equipment, etc., can solve the problems of high production costs of granular ammonium oil explosives, and achieve the effects of facilitating site transfer, reducing production costs, and compact equipment layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The embodiments are exemplary and are only used to disclose and explain the present invention so as to fully understand the present invention, but the present invention is not therefore limited within the scope of the described embodiments. .

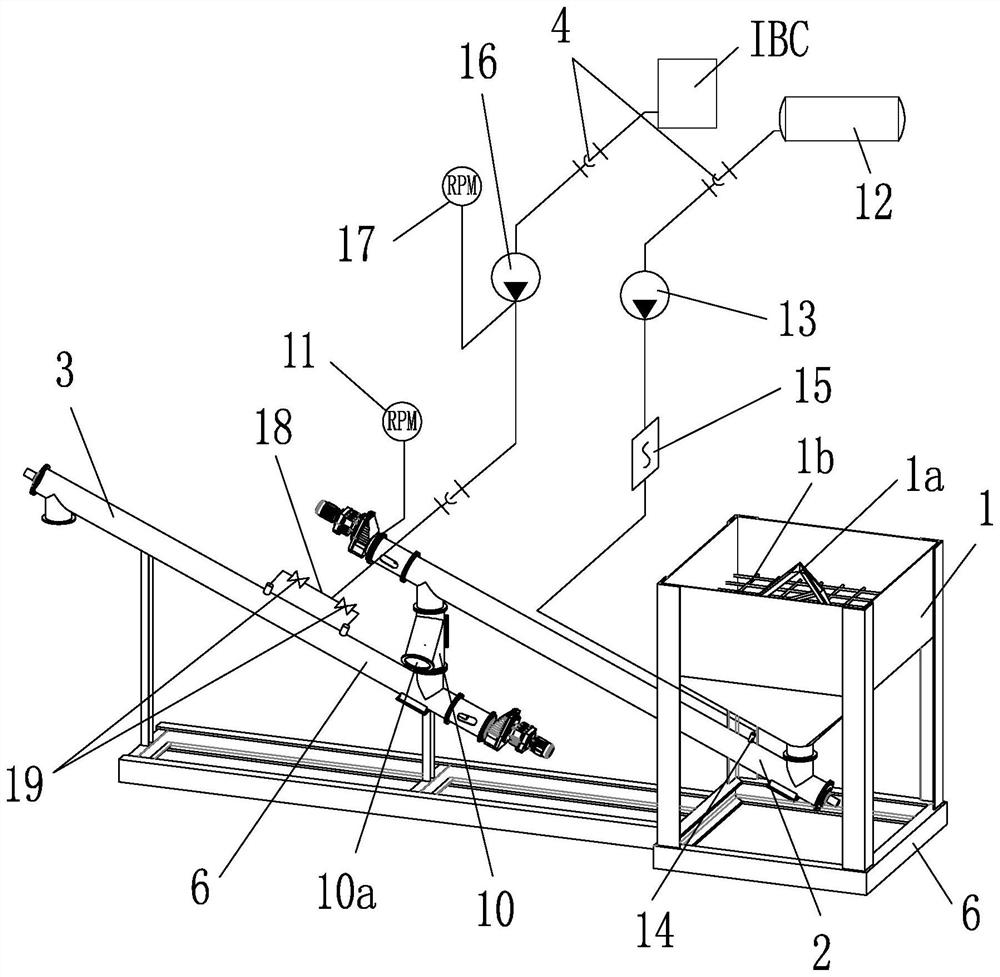

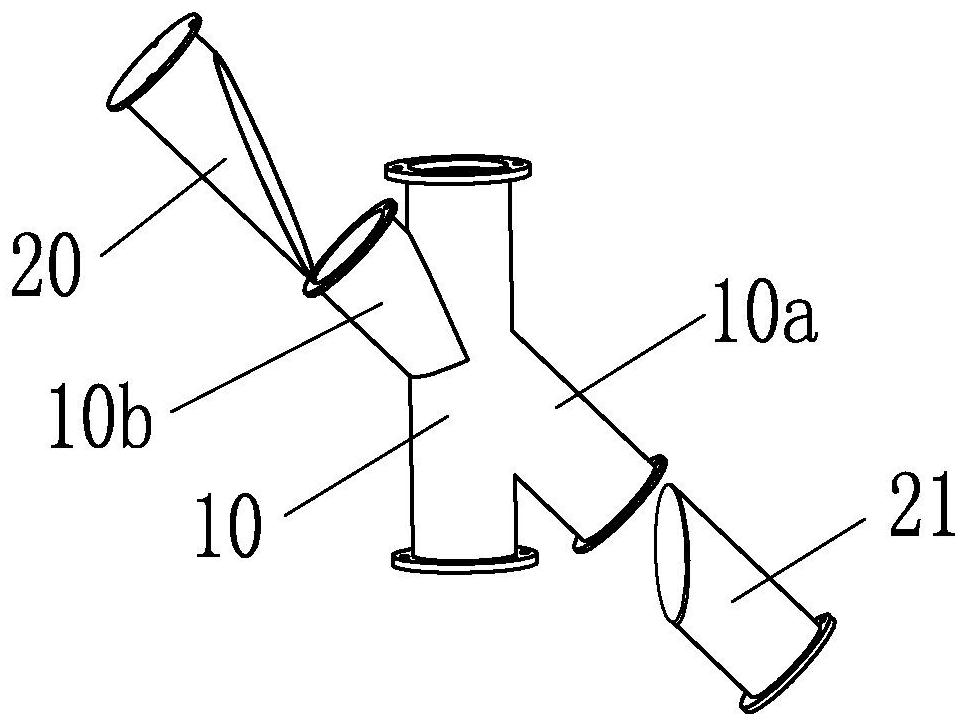

[0020] see figure 1 , a granular ammonium oil explosives production equipment, including a hopper 1, a tubular screw conveyor and a diesel spraying system, the hopper 1 is used to hold porous granular ammonium nitrate; the hopper 1 and the tubular screw conveyor are arranged on a frame 6 ; The tubular screw conveyor is made up of the first tubular screw conveyor 2 and the second tubular screw conveyor 3, the diesel spray system is connected with the first tubular screw conveyor 2, and the first tubular screw conveyor The feed port of machine 2 is connected with the discharge port of hopper 1, and the discharge port of the first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com