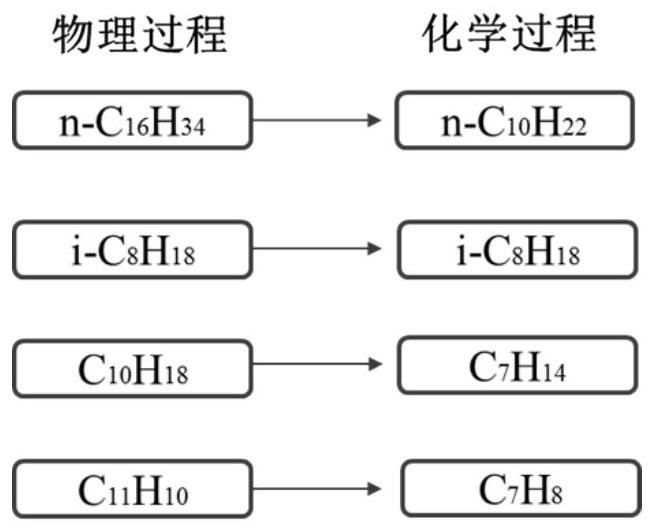

Diesel spray combustion simulation method based on multi-component decoupling physical and chemical substitutes

A technology of spray combustion and physical chemistry, which is applied to combustion engines, teaching models, internal combustion piston engines, etc., can solve the problems that the actual diesel spray and combustion characteristics cannot be well reproduced at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

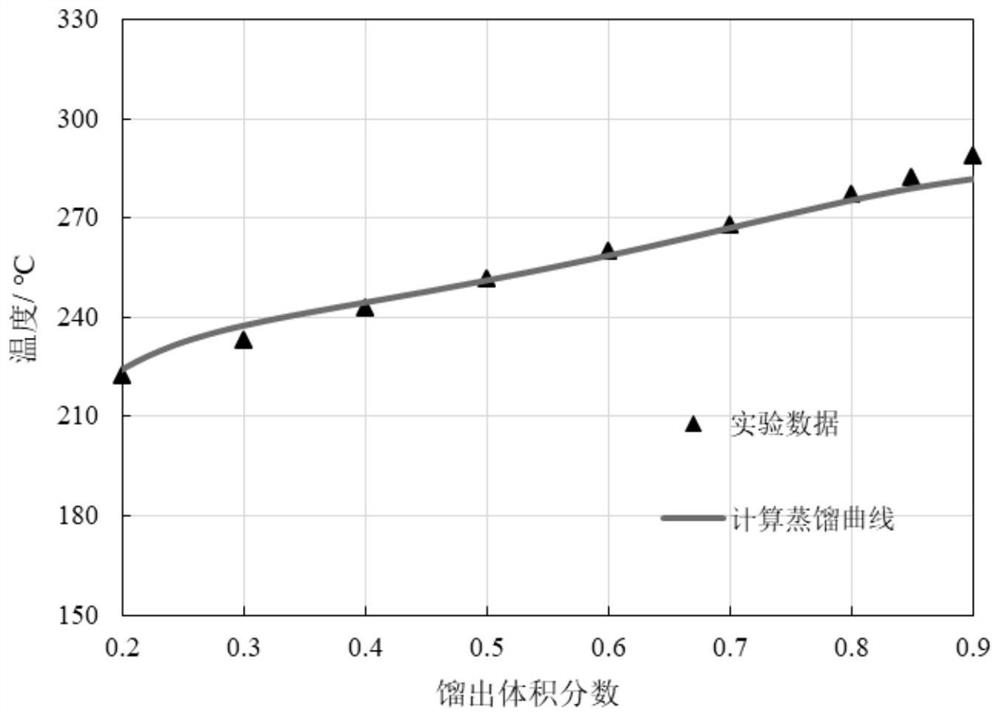

[0046] The mass fractions of n-hexadecane, isooctane, decahydronaphthalene, and 1-methylnaphthalene were selected to be 42%, 8%, 23%, and 27%, respectively.

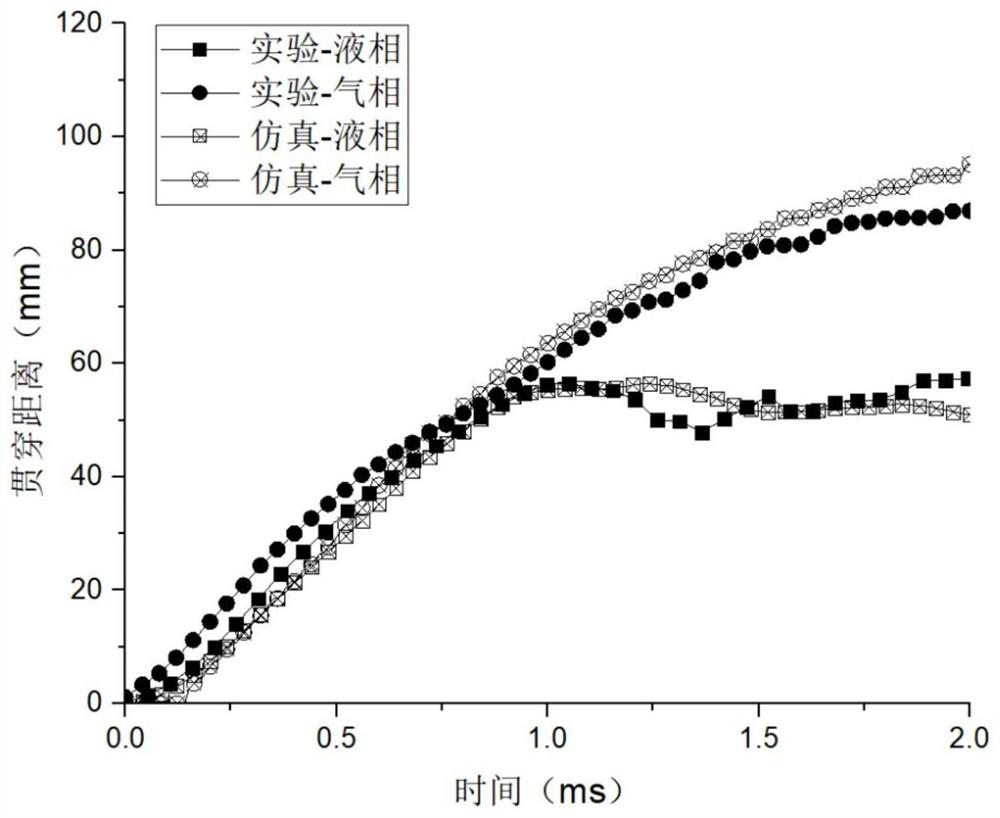

[0047] The simulation and experiment were carried out under the same environmental conditions and injection conditions. The ambient temperature was 850K / 900K, the ambient pressure was 4MPa, the injection pressure was 40Mpa, and the diameter of the nozzle hole was 0.32mm. The experiment was carried out in a visual constant volume incendiary bomb.

[0048] In the simulation, the KH-RT model is selected as the spray breakage model, the Frossling model is selected as the evaporation model, the NTC model is selected as the collision model, and the RNG k-ε model is selected as the turbulence model.

[0049]In the simulation, the basic grid is selected as 2mm, and 3-level local encryption is set near the nozzle, and 3-level adaptive encryption is performed on the speed and temperature, and the minimum grid size is 0.25mm.

[00...

Embodiment 2

[0052] The mass fractions of n-hexadecane, isooctane, decahydronaphthalene, and 1-methylnaphthalene were selected to be 40%, 12%, 21%, and 27%, respectively.

[0053] The rest of the simulation parameters are the same as those in Embodiment 1.

[0054] Comparing the gas-liquid phase penetration distance of the free jet spray at an ambient temperature of 850K between the simulation and the experiment, the two are in good agreement. Under the condition of ambient temperature of 900K, the experimental flame delay period is 1.50ms, and the axial ignition position is 50mm; the simulation result shows a flame delay period of 1.62ms, which has an error of 8% from the experimental result, and the simulated axial ignition position is 58mm , which is larger than the experimental results.

Embodiment 3

[0056] The mass fractions of n-hexadecane, isooctane, decahydronaphthalene, and 1-methylnaphthalene were selected as 44%, 12%, 17%, and 27%, respectively.

[0057] The rest of the simulation parameters are the same as those in Embodiment 1.

[0058] Comparing the gas-liquid phase penetration distance of the free jet spray at an ambient temperature of 850K between the simulation and the experiment, the two are in good agreement. Under the condition of ambient temperature of 900K, the experimental ignition delay period is 1.50ms, and the axial ignition position is 50mm; the ignition delay period obtained from the simulation results is 1.50ms, which is completely consistent with the experimental results, and the simulation axial ignition position is 53mm, which is higher than the experimental results. The result is too large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com