A diesel spray penetration prediction method with variable fuel injection rate

A prediction method, diesel technology, used in engine testing, machine/structural component testing, measuring devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below in conjunction with the accompanying drawings:

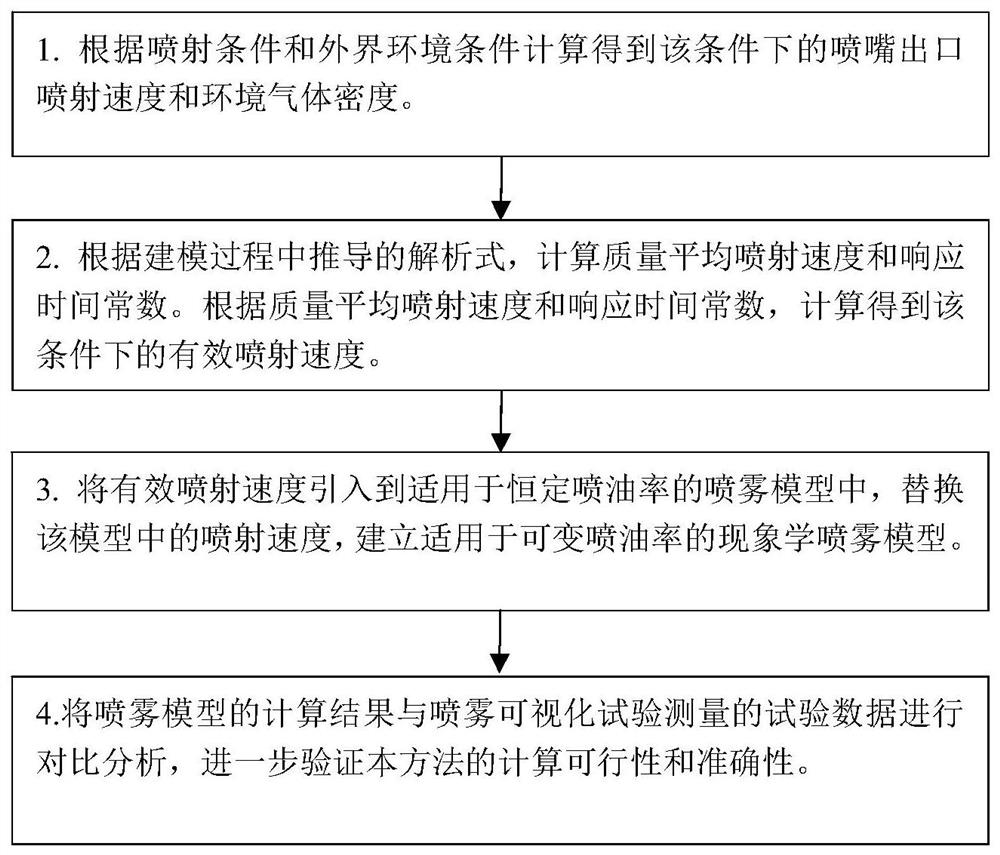

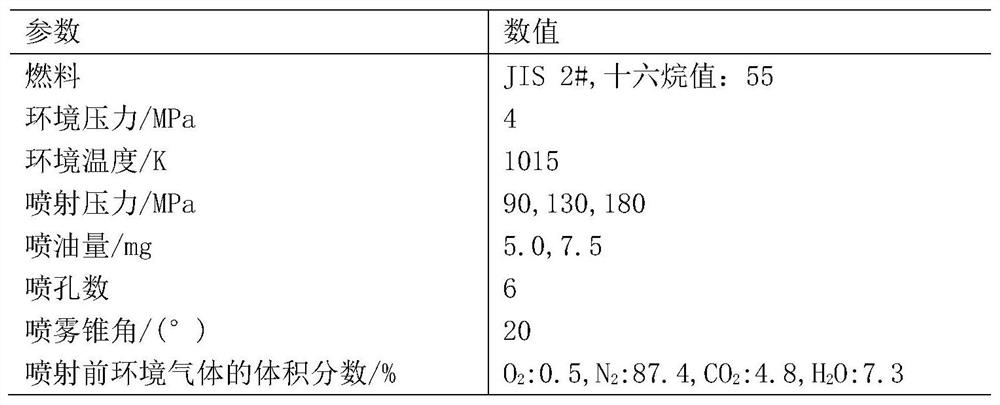

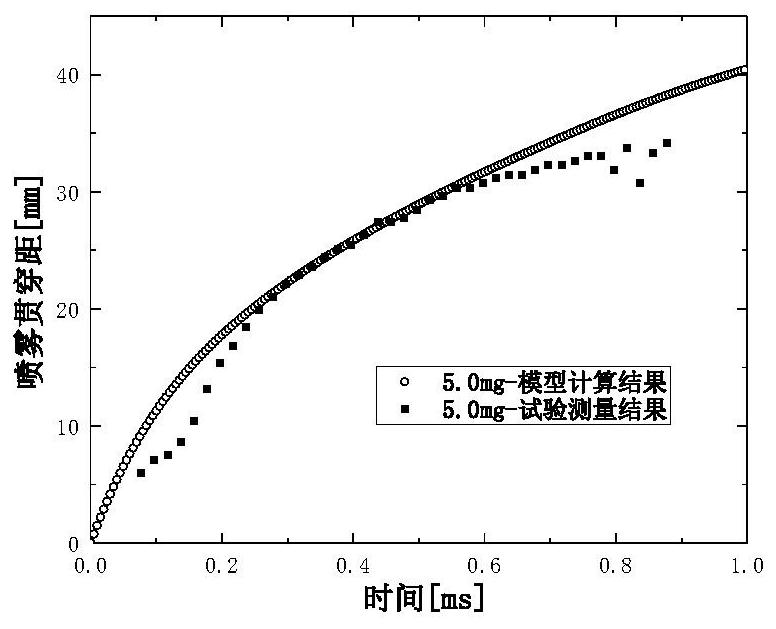

[0025] combine Figure 1-8 , Most of the existing diesel phenomenological spray models are only suitable for the calculation under the condition of constant fuel injection rate. For the prediction of spray characteristic parameters under the condition of variable fuel injection rate, the applicant proposed the concept of effective injection speed, which will effectively The injection velocity is related to the injection speed, and the spray penetration distance is related to the effective injection speed. The analytical formula for quantitatively calculating the effective injection speed and the penetration distance is derived, and a new phenomenology suitable for the prediction of the penetration distance with variable injection rate is proposed. The calculation method is used to establish a new spray model and apply it to the prediction of penetration distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com