A Method for Optimizing the Mixing Quality of Oil and Gas in a Diesel Internal Combustion Engine

A technology of diesel internal combustion engine, oil and gas mixing, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., can solve the problem of unsatisfactory, achieve the effect of improving combustion efficiency and emission potential, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

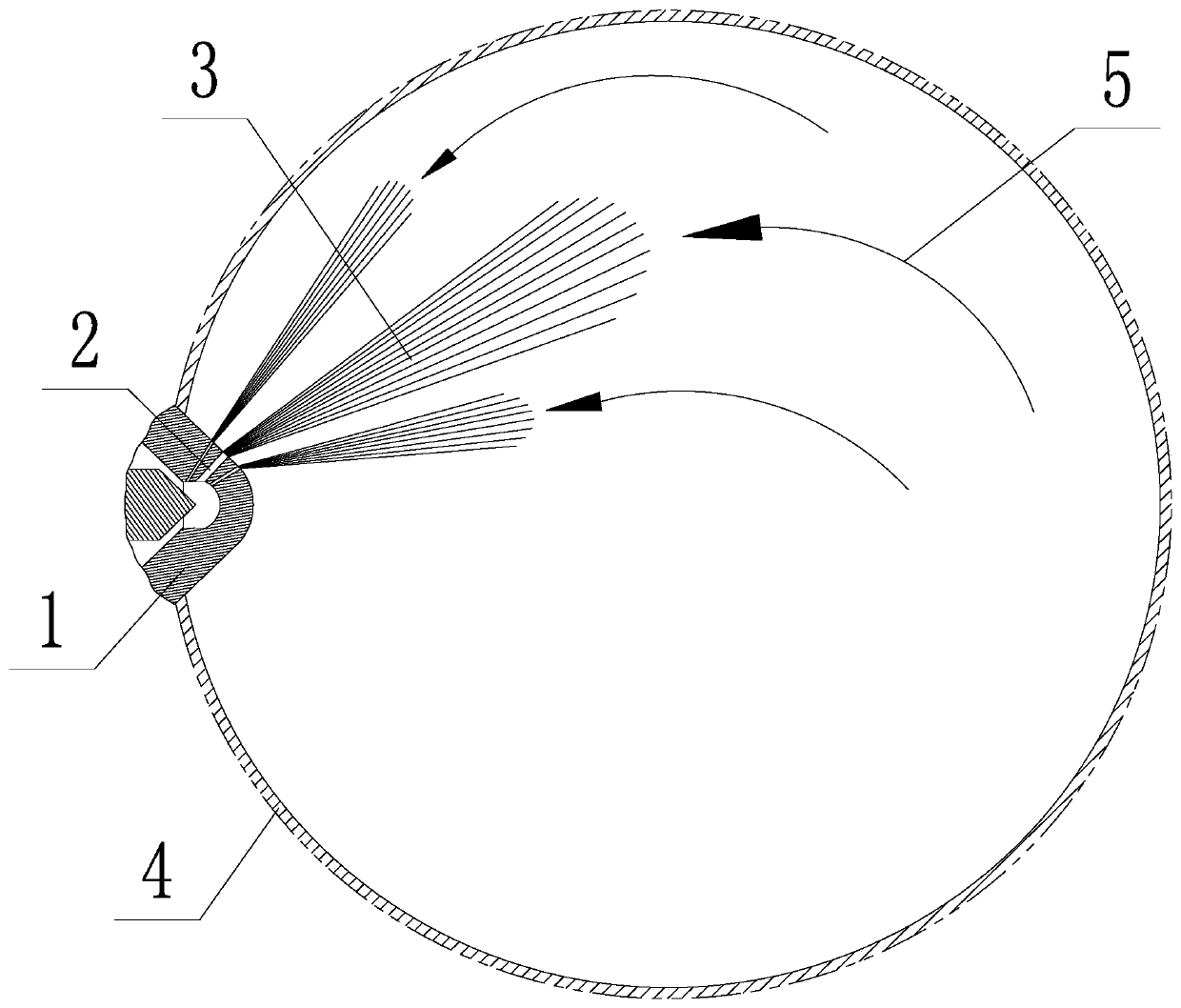

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] A method for optimizing the oil-gas mixing quality of a diesel internal combustion engine, including three optimization aspects, specifically:

[0015] The first optimization aspect: adjust the injection direction of the diesel spray, so that an angle greater than 90° is formed between the injection direction of the diesel spray and the incoming flow direction of the air vortex;

[0016] The second optimization aspect: based on the first optimization aspect, adjust the number of nozzle holes on the diesel nozzle, and the number of nozzle holes should be at least two, and different nozzle holes have different apertures; the larger the diameter of the nozzle holes, the more diesel spray The greater the mass flow rate; the smaller the nozzle hole diameter, the smaller the mass flow rate of diesel spray;

[0017] The third optimiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com