Dual fuel engine combustion system and method based on switchable fuel injector

A dual-fuel engine and combustion system technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of dual-fuel engine performance optimization limitations, achieve full-power injection performance optimization, and improve diesel injection atomization quality, optimizing the effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

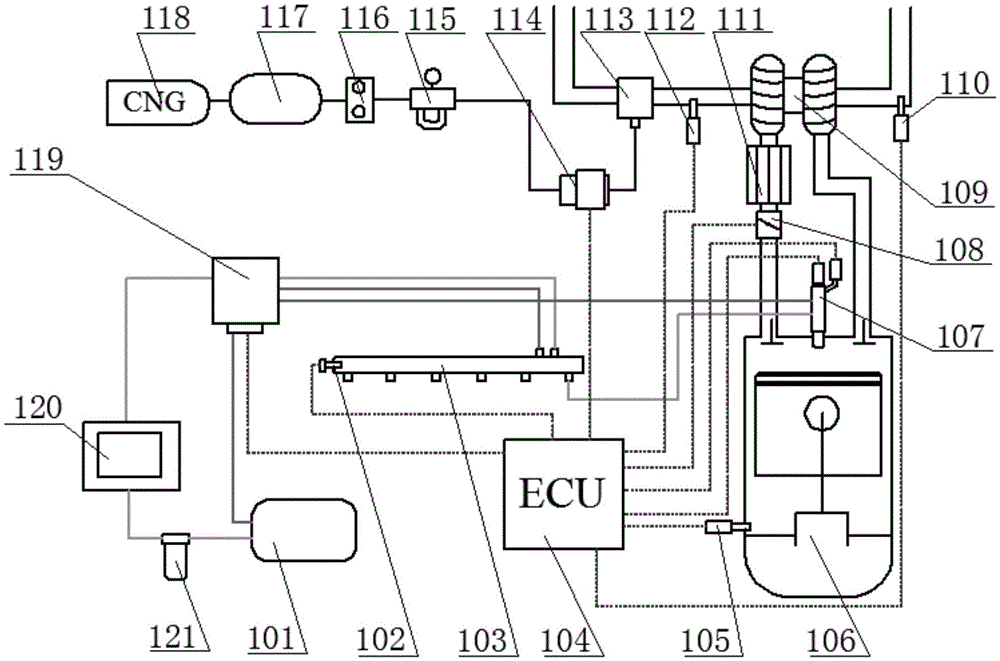

[0032] Such as figure 1 As shown, the dual-fuel engine combustion system includes: an electronically controlled common rail diesel supply device and a premixed natural gas supply device respectively controlled by the electronic control system ECU104. The diesel pump 119 of the device regulates the pilot diesel oil supplied to the dual-fuel engine 106 at a certain pressure, and the electronic control system 104 adjusts the supply of a certain excess pressure to the dual-fuel engine 106 by controlling the natural gas injection module 114 and the electronic throttle 108 according to the working conditions of the dual-fuel engine 106. Air ratio of premixed natural gas.

[0033] Electronically controlled common rail diesel supply device, including: diesel tank 101, diesel filter 121, diesel pump 119 with pressure regulator, diesel rail 103 and switchable in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com