Urea ejector capable of forming vortex

A technology of injector and injector body, which is applied in the directions of machines/engines, chemical instruments and methods, mechanical equipment, etc., can solve the problems of complex structure, reduced atomization quality, poor spray atomization quality, etc., and achieves improved spray atomization. Quality, improved quality and efficiency, effect of improved atomization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

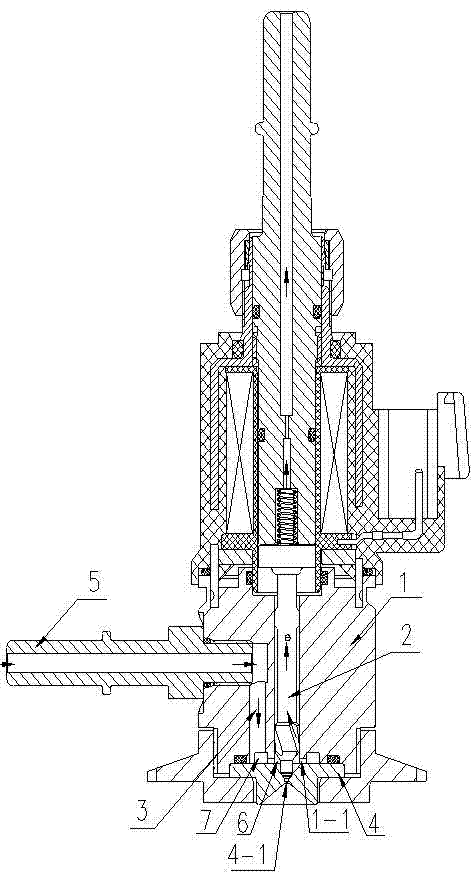

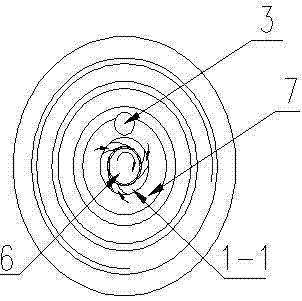

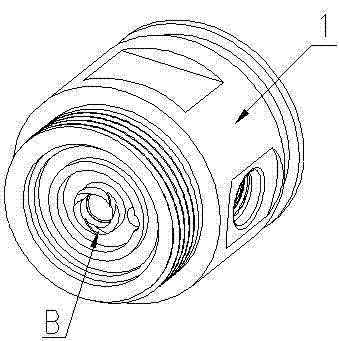

[0021] The structure of the present invention is: including: injector body 1, needle valve body 2, urea liquid inlet channel 3, injection hole body 4 and urea liquid inlet pipe joint 5, and the improvement is that the injection hole body 4 is arranged on the injector body 1 In the lower part, the lower end of the injector body 1 is provided with an annular protrusion 1-1; the lower end surface of the annular protrusion 1-1 is in contact with the upper end surface of the injection hole body 4, and the annular protrusion 1-1 connects the injection hole body 4 and the injector body 1. The connection is divided into two chambers, the chamber inside the annular protrusion 1-1 forms the injection chamber 6, the chamber outside the annular protrusion 1-1 forms the liquid inlet chamber 7, and the annular protrusion 1-1 is provided with multiple arc-shaped holes, the arc-shaped holes run through the annular protrusion 1-1, and the bending directions of the plurality of arc-shaped holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com