Diesel/natural gas double fuel direct injection device

A natural gas and dual-fuel technology, which is applied in the field of dual-fuel engines, can solve problems such as difficult implementation, complex structure, and extremely high requirements for injector machining accuracy, and achieve the effect of convenient replacement and expanding the scope of experimental research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

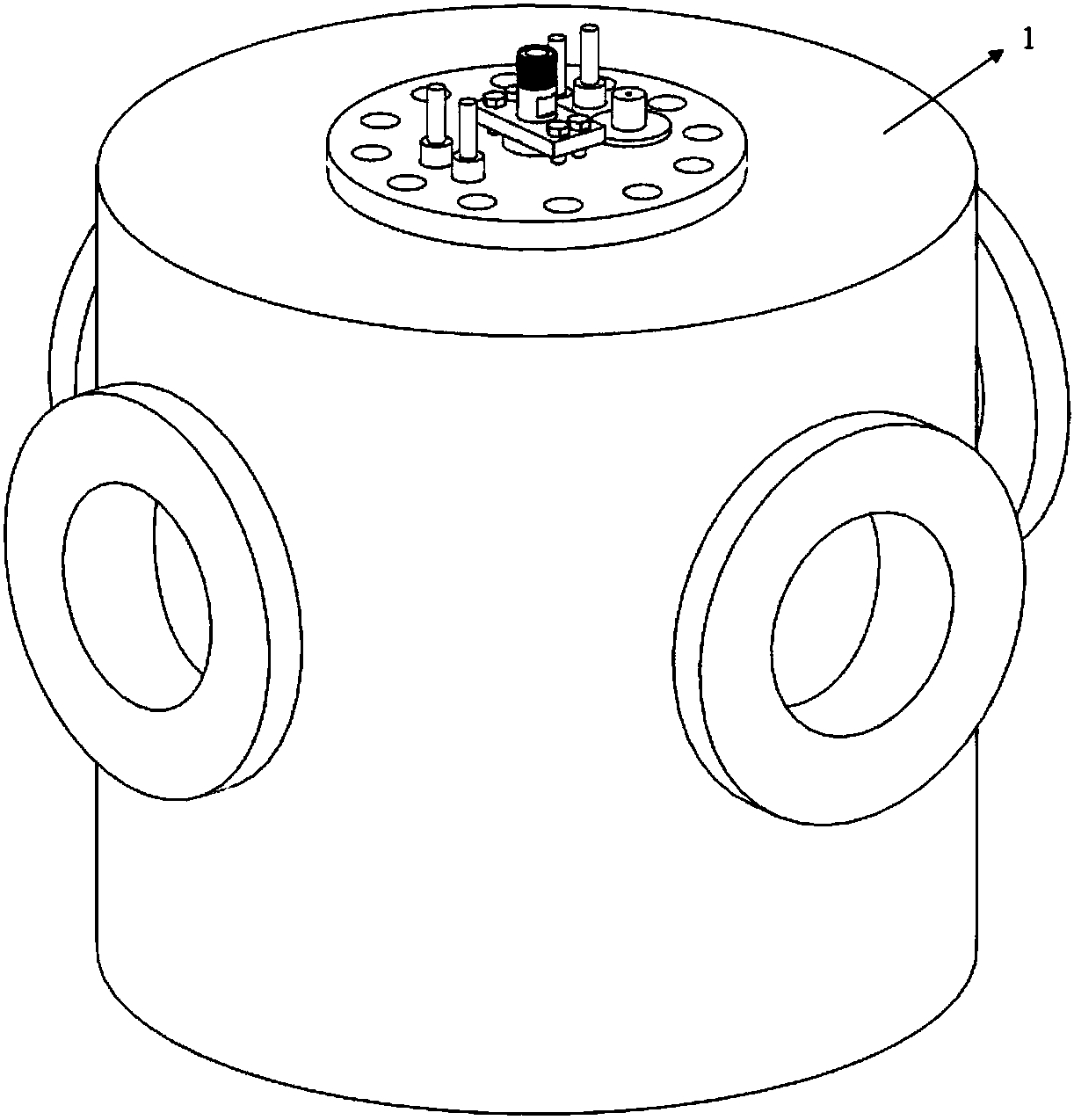

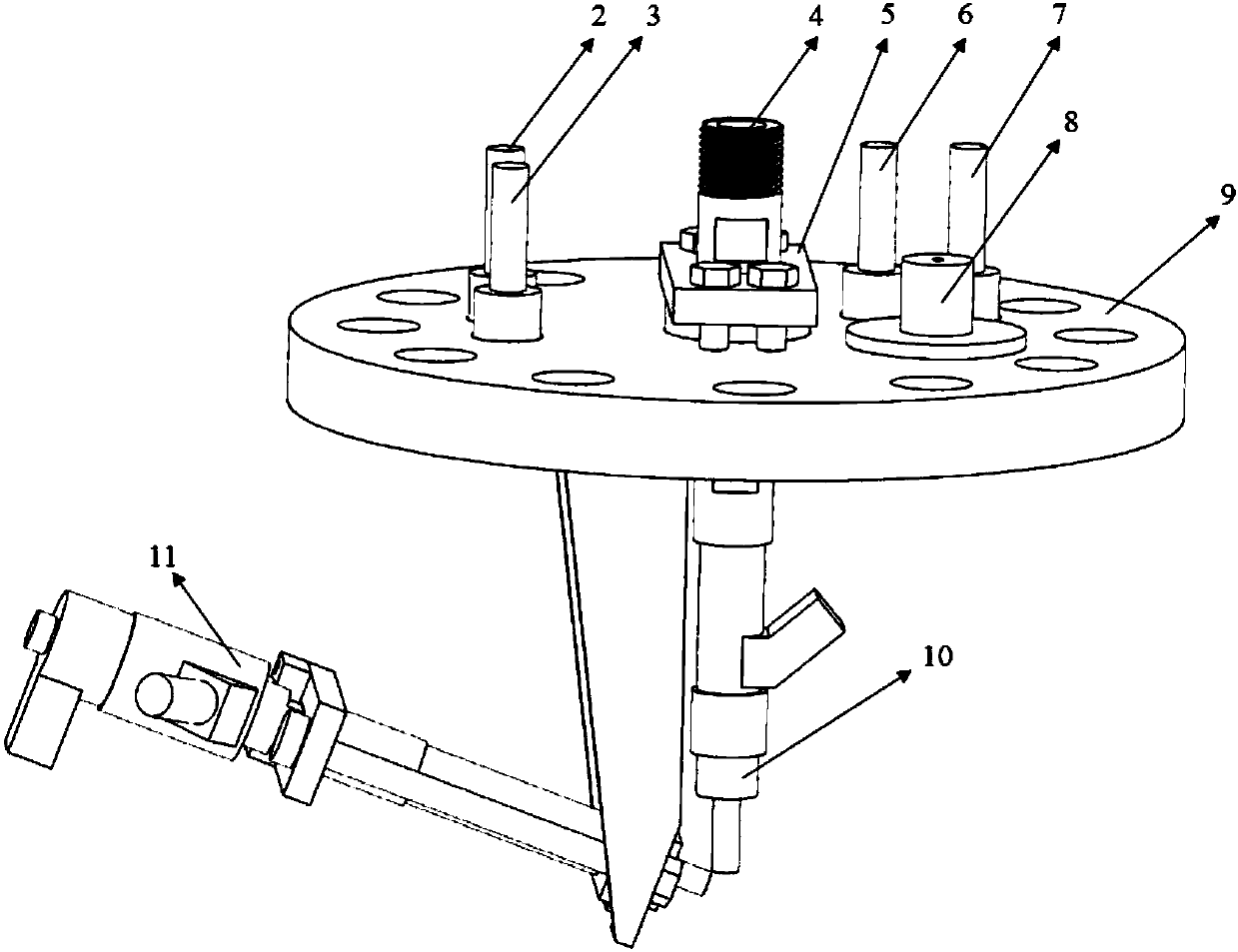

[0034] figure 1 with figure 2 It is an embodiment of a diesel / natural gas dual fuel direct injection device of the present invention, the diesel / natural gas dual fuel direct injection device includes a constant volume bomb 1, a spark plug, a natural gas pipe 4, and a natural gas pipe briquetting block 5 , Oil pipe joint 8, constant volume bomb adapter 9, natural gas injector 10, diesel injector 11, diesel injector bracket.

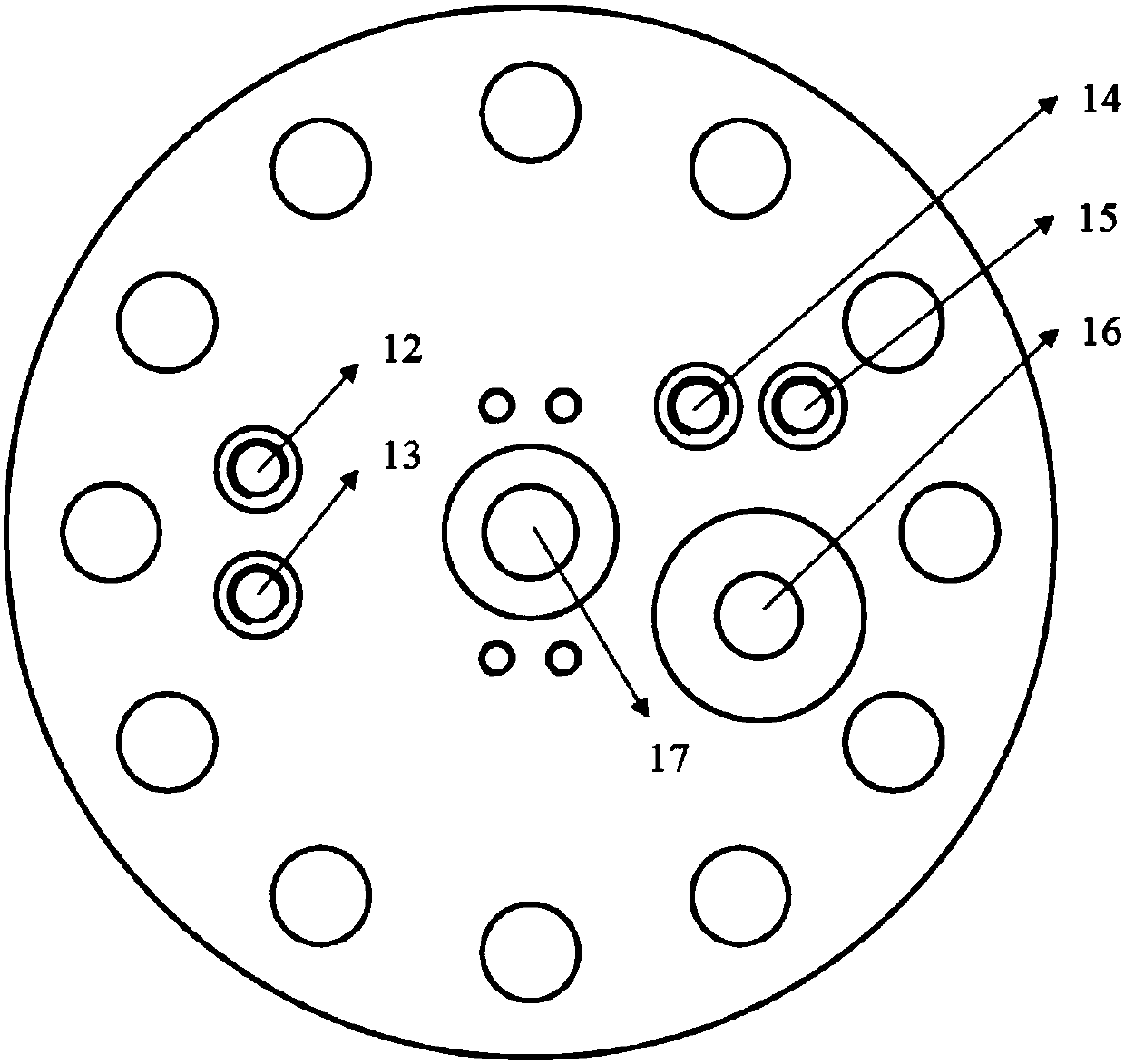

[0035] The constant volume bomb adapter 9 is detachably installed on the top of the constant volume bomb 1 . Preferably, the circumference of the constant volume bomb adapter 9 is provided with a plurality of through holes, and is installed on the top of the constant volume bomb 1 by screws. Such as image 3As shown, hole I12, hole II13, hole III14, hole IV15, hole V16 and hole VI17 are designed on the volumetric bomb adapter 9. The natural gas pipe 4 is installed in the hole VI17, the upper end of the natural gas pipe 4 is connected with the natural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com