An online sunlight control coating tail gas treatment device and its treatment process

A technology for exhaust gas treatment and sunlight control, applied in the petroleum industry, combustion type, lighting and heating equipment, etc., to achieve the effect of improving service life, high purification efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

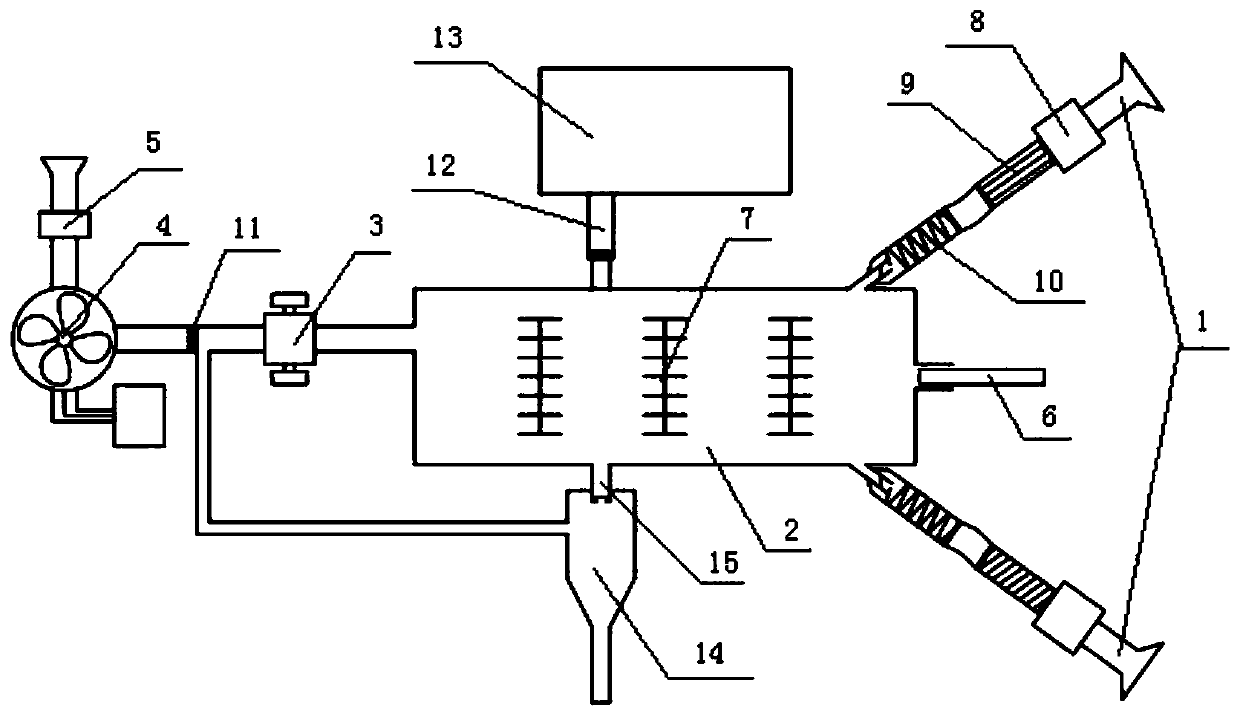

[0047] An online sunlight control coating tail gas treatment device, comprising two tail gas inlet pipes 1, a combustion chamber 2, an air outlet regulator 3, a frequency conversion fan 4, and a denitrification and desulfurization system 5, which are sequentially connected through connecting pipes. The tail gas inlet pipe 1 They are respectively arranged on both sides of the front end of the combustion chamber 2, and a diesel atomizing spray gun 6 is also provided in the middle of the same end of the combustion chamber 2 and the exhaust gas intake pipe 1. The interior of the combustion chamber 2 is provided with 3 combustion-supporting rods 7, and the combustion chamber 2 is long. One side of the edge is provided with an automatic pressure relief explosion-proof device 12 and a pressure relief pool 13, and the other side is provided with a dust removal hole 15 communicating with the dust removal equipment 14.

[0048] The pipeline between the exhaust gas intake pipeline 1 and t...

Embodiment 2

[0056] The device is the same as that of Example 1, except that a combustion-supporting improver is added to the diesel sprayed from the diesel atomizing spray gun 6, and the amount of the combustion-supporting improver is 1.2 g / L.

[0057] The combustion-supporting improver includes the following raw materials in parts by weight: 45 parts of rare earth oxygen storage materials, 42 parts of potassium permanganate, 51 parts of activated carbon, 10 parts of potassium perborate, 8 parts of dicyclopentadienyl iron and 12 parts of formazan ethyl ethyl ketone.

[0058] The rare earth oxygen storage material is Ce modified with Bi and Y elements 0.9 Zr 0.1 O oxygen storage material.

[0059] The combustion rod 7 is made of the following raw materials in parts by weight: 135 parts of manganese ore, 78 parts of waste incineration slag, 36 parts of lime mud, 4 parts of tin-doped indium oxide ITO and 7 parts of rosin pentaerythritol ester.

Embodiment 3

[0061] The device is the same as that in Example 1, except that a combustion-supporting improver is added to the diesel sprayed from the diesel atomizing spray gun 6, and the amount of the combustion-supporting improver is 1.5 g / L.

[0062] The combustion-supporting improver includes the following raw materials in parts by weight: 60 parts of rare earth oxygen storage materials, 45 parts of potassium permanganate, 55 parts of activated carbon, 12 parts of potassium perborate, 10 parts of dicyclopentadienyl iron and 15 parts of formazan ethyl ethyl ketone.

[0063] The rare earth oxygen storage material is Ce modified by Sr, Bi and Y elements 0.9 Zr 0.1 O oxygen storage material.

[0064] The combustion rod 7 is made of the following raw materials in parts by weight: 150 parts of manganese ore, 80 parts of waste incineration slag, 50 parts of lime mud, 5 parts of tin-doped indium oxide ITO and 8 parts of rosin pentaerythritol ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com