Short-flame and large-diameter diesel burner

A burner and large-diameter technology, applied in the direction of burners, lighting and heating equipment, etc., can solve the problems of small combustion flame diameter, complex overall structure, loss of atomized diesel oil, etc., to reduce loss, reduce boiler volume, and fully mix Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

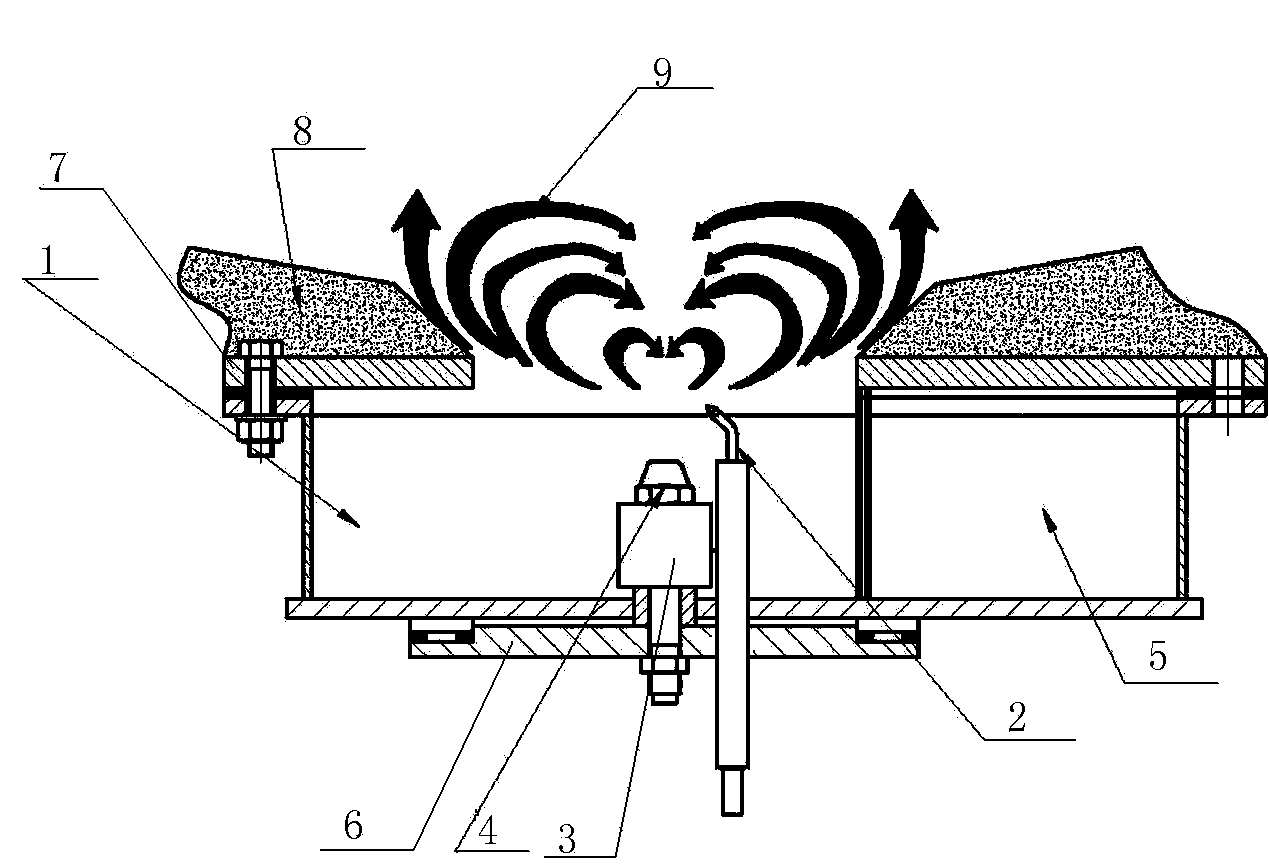

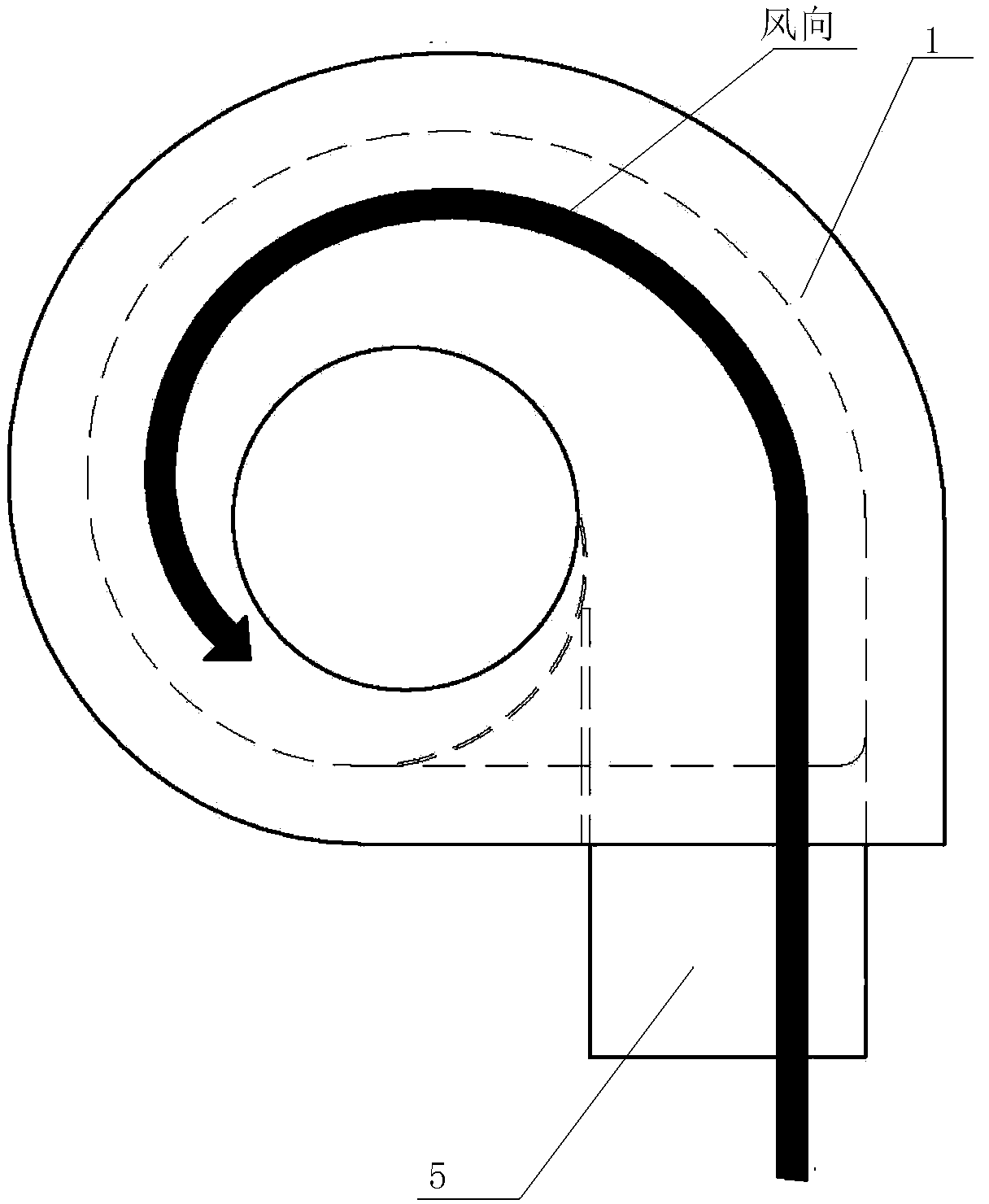

[0015] like figure 1 and 2 As shown, a short-flame large-diameter diesel burner includes a burner housing, an ignition rod 2 and a fuel injector 3 arranged in the burner housing, and the burner housing is a spiral volute 1, and the volute 1 There is an air inlet 5 on one side of the outer ring, and an air outlet is provided on the inner ring of the volute 1. The direction of the air inlet 5 is consistent with the tangential direction of the volute 1, and the position of the nozzle 4 of the injector 3 is in line with the outlet of the volute 1. The position of the tuyere is corresponding, and the ignition position of the ignition rod 2 is located above the fuel injector 4 and the air outlet. The fuel injector 3 is connected to the volute 1 through a connecting plate 6 , the fuel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com