Side wall circulation combustion chamber for diesel engine

A diesel engine, combustion chamber technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems affecting the rationality of airflow movement organization, the uniformity of mixture distribution, the further improvement of thermal efficiency, and the insufficiency of the combustion process. To achieve the effect of promoting atomization and spatial mixing and distribution, reducing carbon deposition, and reducing local combustion high temperature areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

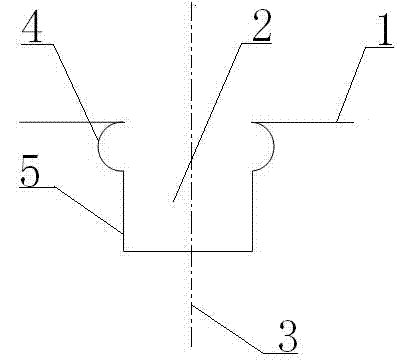

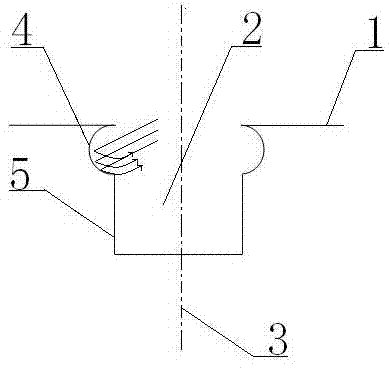

[0020] Such as figure 1 , figure 2 As shown in the side wall circulation combustion chamber of the diesel engine, the depth of the upper end surface of the side wall circulation combustion chamber of the diesel engine from the upper bottom surface of the piston chamber is 24mm ~ 26mm; the side wall circulation combustion chamber of the diesel engine is opened in The concave deep pit 2 on the top of the piston 1, the concave deep pit 2 is symmetrical about the central axis 3 of the piston; the concave deep pit 2 includes an annular part 4 and a columnar part 5; Symmetrical semi-circular arc, the diameter of the semi-circular arc-shaped annular part 4 is 7 mm to 8 mm, the center of the semi-circular arc is located on the side of the longitudinal section of the concave deep pit 2, and the upper part of the semi-circular arc is formed with the longitudinal sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com