Temperature control device for periodical working heat source in spaceflight

A temperature control device, periodic technology, applied in auxiliary controllers with auxiliary heating devices, temperature control, indirect heat exchangers, etc., can solve the problem of large temperature difference between cold and hot surfaces, large thermal control power consumption, heat source compensation Problems such as high power consumption, to achieve the effect of reducing the cycle average thermal control power consumption and heat dissipation area, reducing the area of the heat dissipation surface, and compensating for small thermal power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

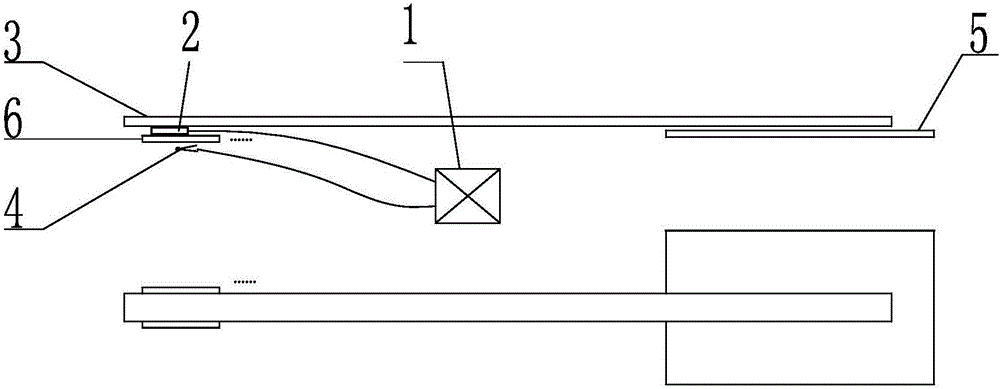

[0061] A temperature control device for an aerospace periodic working heat source, the device includes a control circuit 1, a thermoelectric cooler 2, a phase change heat pipe 3, a temperature sensor 4 and a cooling plate 5;

[0062] The cold surface of the thermoelectric cooler 2 is bonded to the heat source 6, the hot surface of the thermoelectric cooler 2 is bonded to one end of the phase-change heat pipe 3, and the other end of the phase-change heat pipe 3 is bonded to the cooling plate 5; A bonding surface is formed, and the bonding surface is filled with heat-conducting silicone grease to reduce contact thermal resistance; the temperature sensor 4 is connected to the control circuit 1 through a cable, and the thermoelectric cooler 2 is connected to the control circuit 1 through a cable; the temperature The sensor 4 is bonded on the heat source 6 by silicon rubber;

[0063] The thermoelectric material in the thermoelectric cooler 2 is a bismuth telluride material;

[006...

Embodiment 2

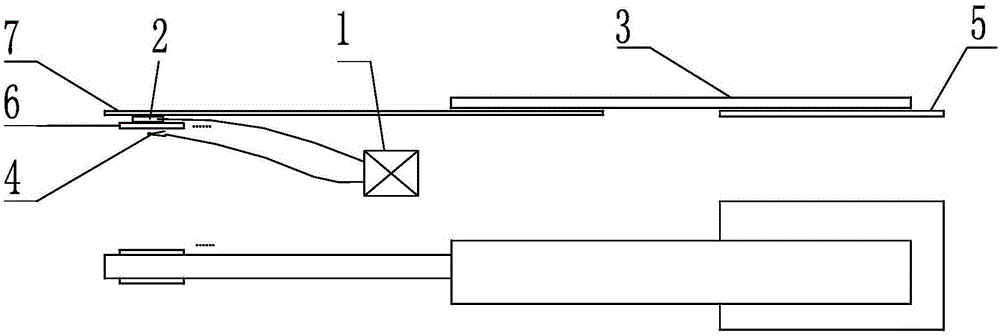

[0069] A temperature control device for an aerospace periodic working heat source, the device includes a control circuit 1, a thermoelectric cooler 2, a phase change heat pipe 3, a temperature sensor 4, a heat dissipation plate 5 and a micro heat pipe 7;

[0070] The cold surface of the thermoelectric cooler 2 is attached to the heat source 6, the hot surface of the thermoelectric cooler 2 is attached to one end of the micro heat pipe 7, the other end of the micro heat pipe 7 is attached to one end of the phase change heat pipe 3, and the phase change heat pipe 3 is attached to the other end of the micro heat pipe 7. The other end is bonded to the heat dissipation plate 5; the above-mentioned bonding parts form a bonding surface, and the bonding surface is filled with thermal silica gel to reduce contact thermal resistance; the temperature sensor 4 and the control circuit 1 are connected by wires, and the thermoelectric The refrigerator 2 and the control circuit 1 are connected...

Embodiment 3

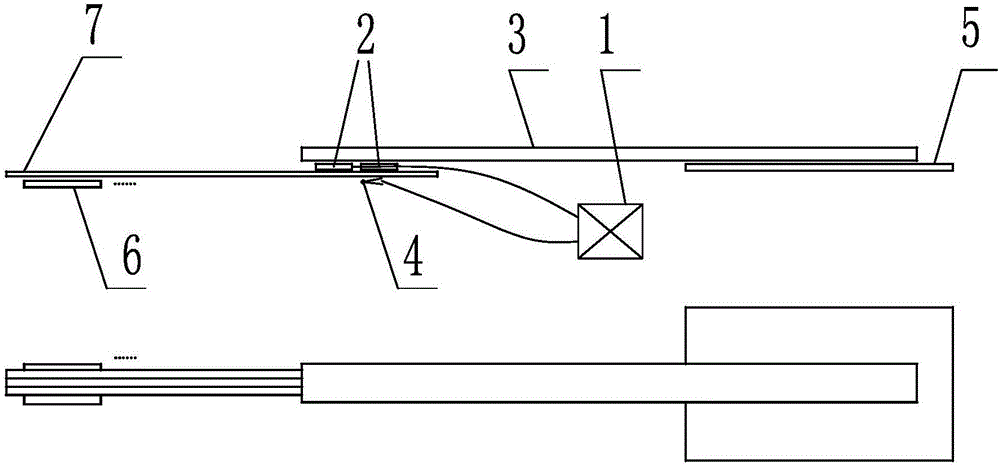

[0078]A temperature control device for an aerospace periodic working heat source, the device includes a control circuit 1, a thermoelectric cooler 2, a phase change heat pipe 3, a temperature sensor 4, a heat dissipation plate 5 and a micro heat pipe 7;

[0079] The cold surface of the thermoelectric cooler 2 is bonded to one end of the micro heat pipe 7, the other end of the micro heat pipe 7 is bonded to the heat source 6, the hot surface of the thermoelectric cooler 2 is bonded to one end of the phase change heat pipe 3, and the phase change heat pipe 3 The other end is bonded to the heat dissipation plate 5; the above-mentioned bonding places form a bonding surface, and the bonding surfaces are filled with heat-conducting insulating pads to reduce contact thermal resistance; the temperature sensor 4 is connected to the control circuit 1 through a cable, The thermoelectric cooler 2 is connected to the control circuit 1 through a cable; the temperature sensor 4 is bonded to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com