Hard polyurethane foam material and insulator

A technology of rigid polyurethane and foam materials, which is applied in the field of rigid polyurethane foam materials and heat insulators, and can solve problems such as variation, increased gas ratio, and poor dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

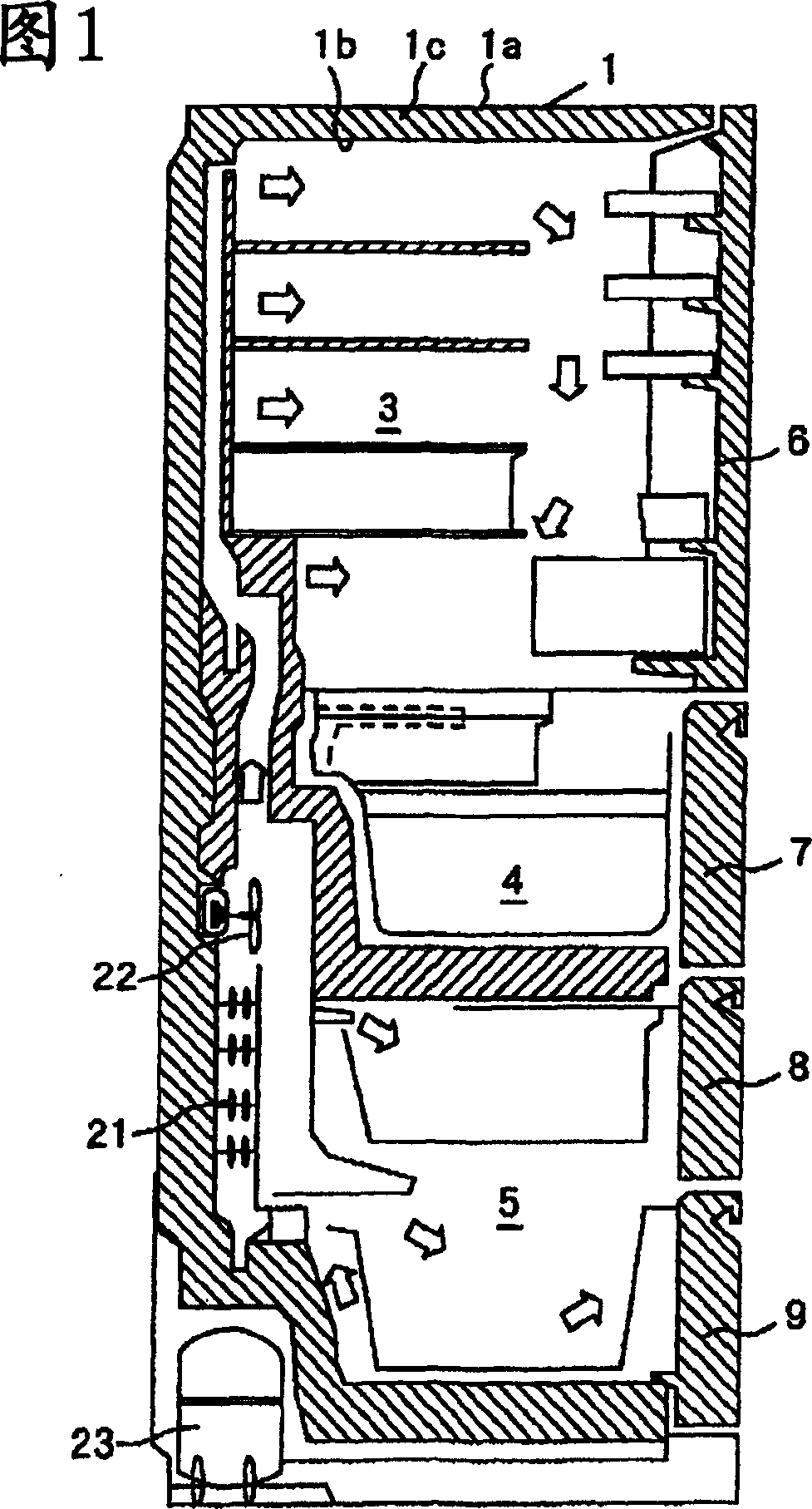

[0081] Embodiment 1 of the present invention, as the polyol component, as shown in the embodiment 1 of table 1, by polyol A40 parts, polyol B35 parts, polyol C10 parts, polyol D5 part, polyol E10 parts mixed polyhydric Alcohol composition.

[0082] Furthermore, 15 parts of cyclopentane blowing agent, 1.2 parts of water, and N,N',N"-tris(3-dimethylaminopropyl)hexahydro - 1 part of s-triazine (manufactured by Kao Corporation), 2 parts of N, N'-dimethylcyclohexylamine (manufactured by Kao Corporation), N, N, N', N', N"-pentamethyldiethylene 1 part of ethyltriamine (manufactured by Kao Corporation), and 2 parts of an organosiloxane compound (trade name: B-8462 (manufactured by Goldshyumit Co., Ltd.)) as a foam stabilizer.

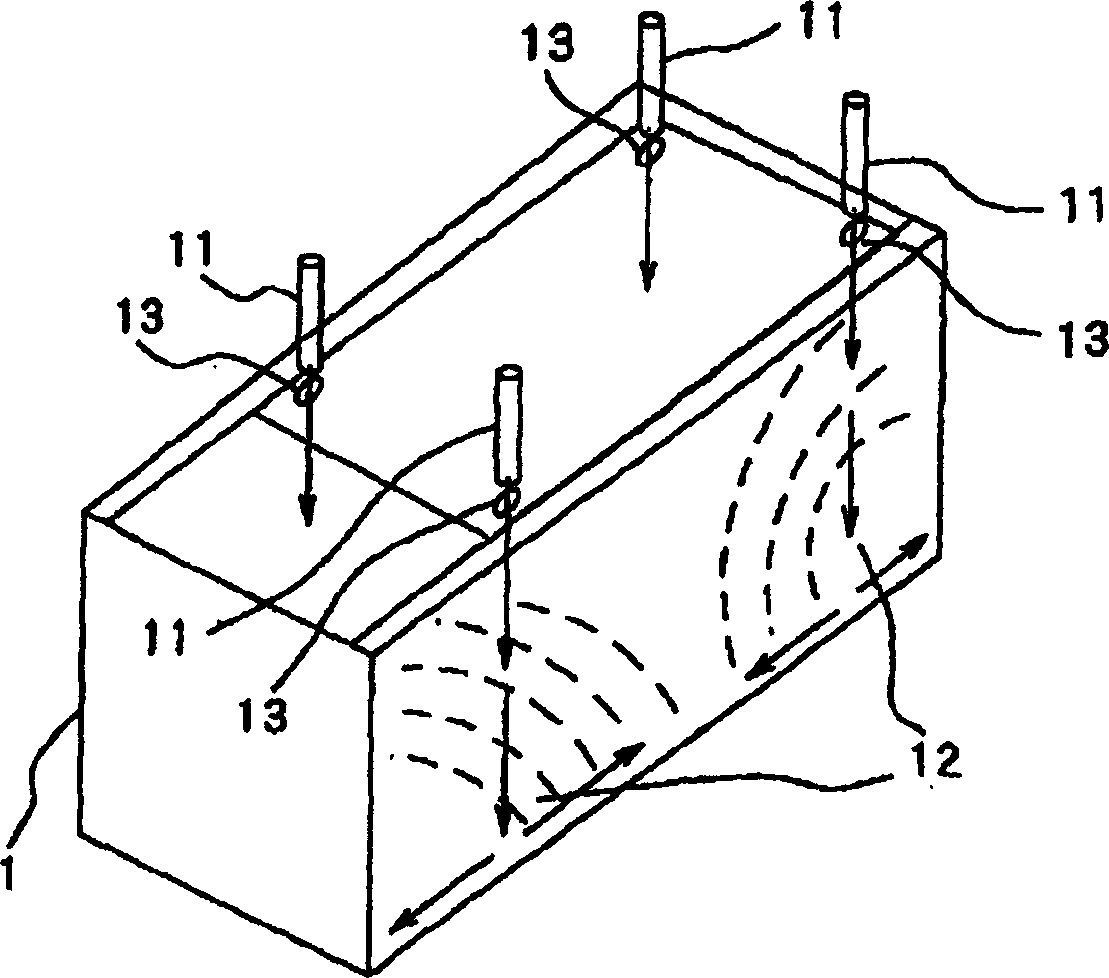

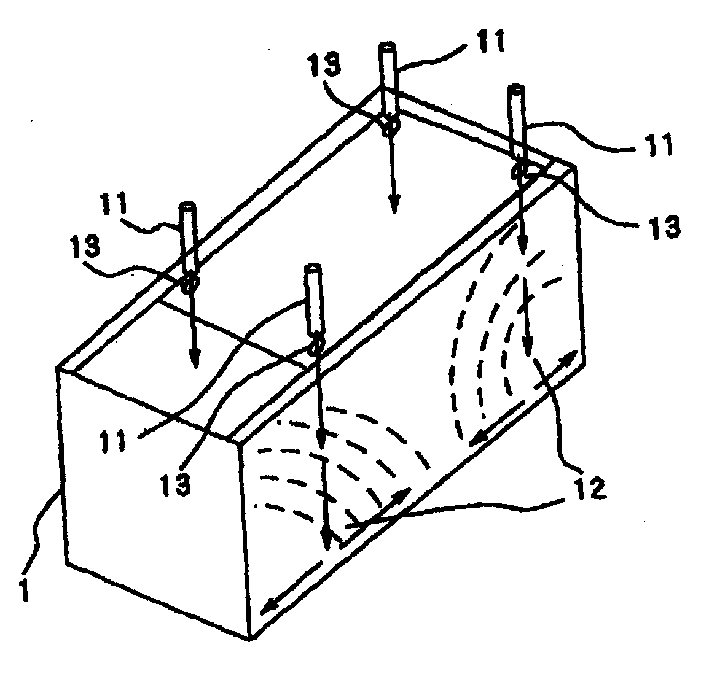

[0083] In addition, as the isocyanate component, foaming was performed using 135 parts of a mixture of diphenylmethane diisocyanate polynuclear body and prepolymer-modified toluene diisocyanate. First, polyol and isocyanate were stirred, poured into an alumin...

Embodiment 2

[0087] Embodiment 2 of the present invention, as the polyol component, as shown in Example 2 of Table 1, consists of 50 parts of polyol A, 25 parts of polyol B, 7.5 parts of polyol C, 7.5 parts of polyol D and polyol E 10 parts mixed mixed polyol ingredients make up.

[0088] Furthermore, in 100 parts of the mixed polyol component, 18 parts of cyclopentane blowing agent, 0.8 part of water and N,N',N"-tris(3-dimethylaminopropyl)hexahydro -0.5 parts of s-triazine (manufactured by Kao Corporation), 2.2 parts of N,N'-dimethylcyclohexylamine (manufactured by Kao Corporation), N,N,N',N',N"-pentamethyldiethylene 1.5 parts of ethyltriamine (manufactured by Kao Corporation), and 2 parts of organosiloxane (trade name: F-392, manufactured by Shin-Etsu Chemical Co., Ltd.) as a foam stabilizer.

[0089] In addition, as isocyanate, 133 parts of diphenylmethane diisocyanate polynuclear bodies were used for foaming. The liquid temperature of the polyol and isocyanate at this time was adjust...

Embodiment 3

[0093] Example 3 of the present invention, as the polyol component, as shown in Example 3 of Table 1, is a mixture of 50 parts of polyol A, 30 parts of polyol B, 5 parts of polyol C, 5 parts of polyol D and 10 parts of polyol E Polyol composition.

[0094] Furthermore, 14 parts of cyclopentane blowing agent, 1.2 parts of water, and N,N',N"-tris(3-dimethylaminopropyl)hexahydro - 1 part of s-triazine (manufactured by Kao Corporation), 1.8 parts of N, N'-dimethylcyclohexylamine (manufactured by Kao Corporation), N, N, N', N', N"-pentamethyldiethylene 1.4 parts of ethyltriamine (manufactured by Kao Corporation), and 2 parts of organosiloxane B-8462 (manufactured by Goldshyumit Corporation) as a foam stabilizer.

[0095] In addition, as isocyanate, 133 parts of diphenylmethane diisocyanate polynuclear bodies were used for foaming. The liquid temperature of the polyol and isocyanate at this time was adjusted to 20 degreeC. First, polyol and isocyanate were stirred, poured into an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com