Totally-enclosed gas atomizing powder making device for preventing high-melting-point substance from being blocked

A technology of gas atomization and powder making equipment, which is applied in the field of gas atomization melt to produce ultrafine powder, and can solve the problems of metal blockage in the diversion tube and high melting point material blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

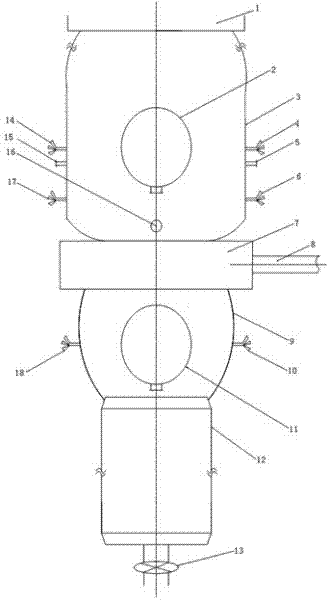

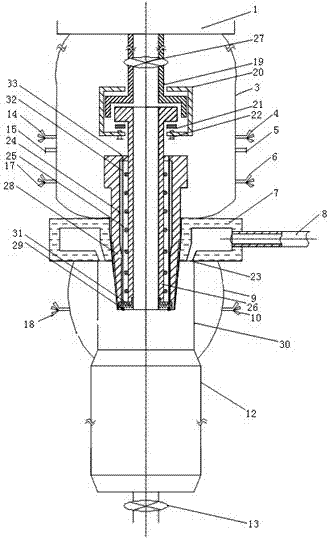

[0064] A fully enclosed gas atomization powder making device to prevent blockage of high melting point substances. Its outline diagram is as follows figure 1 As shown in the figure: 1 is the heat preservation crucible, 2 is the take-out port I, 3 is the retractable plastic tube A, 4 is the glove I, 5 is the heating element of the atomizer, the external power interface I, 6 is the glove II , 7 is the nozzle of the atomizer, 8 is the air inlet pipe of the nozzle, 9 is the retractable plastic tube B, 10 is the glove III, 11 is the take-out port II, 12 is the atomization tower, 13 is the atomization tower valve, 14 Glove III, 15 are the external power supply port II of the heating element of the atomizer, 16 are the vacuum pump ports, 17 are the gloves V, and 18 are the gloves VI.

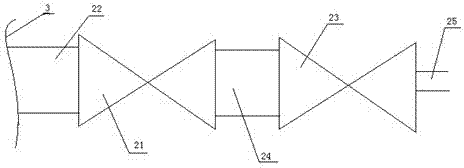

[0065] There is a two-layer vacuum valve on the above-mentioned fetching port A2. figure 2 As shown in the figure, 21 is the inner vacuum valve, 22 is the inner space, 23 is the outer vacuum valve, 24 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com