VOCs thermal oxidation treatment-based comprehensive waste heat recycling system and recycling method

A technology of thermal oxidation and waste heat, which is applied in the direction of combustion methods, machines using waste heat, and machine operation methods. It can solve problems such as difficulty in using VOCs waste heat, expensive catalysts, and high energy consumption, so as to improve energy utilization efficiency and fully Utilize waste heat, low concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

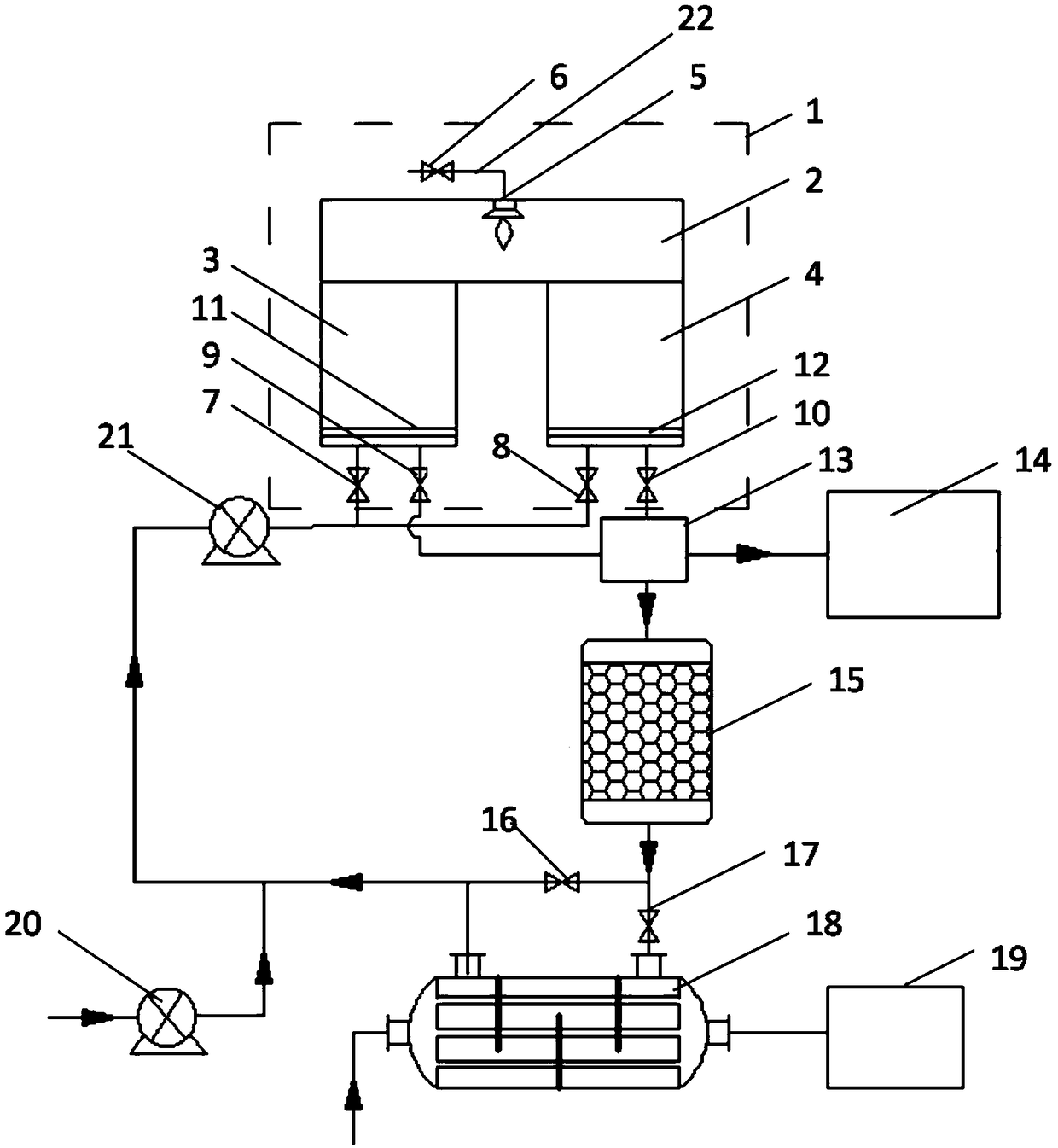

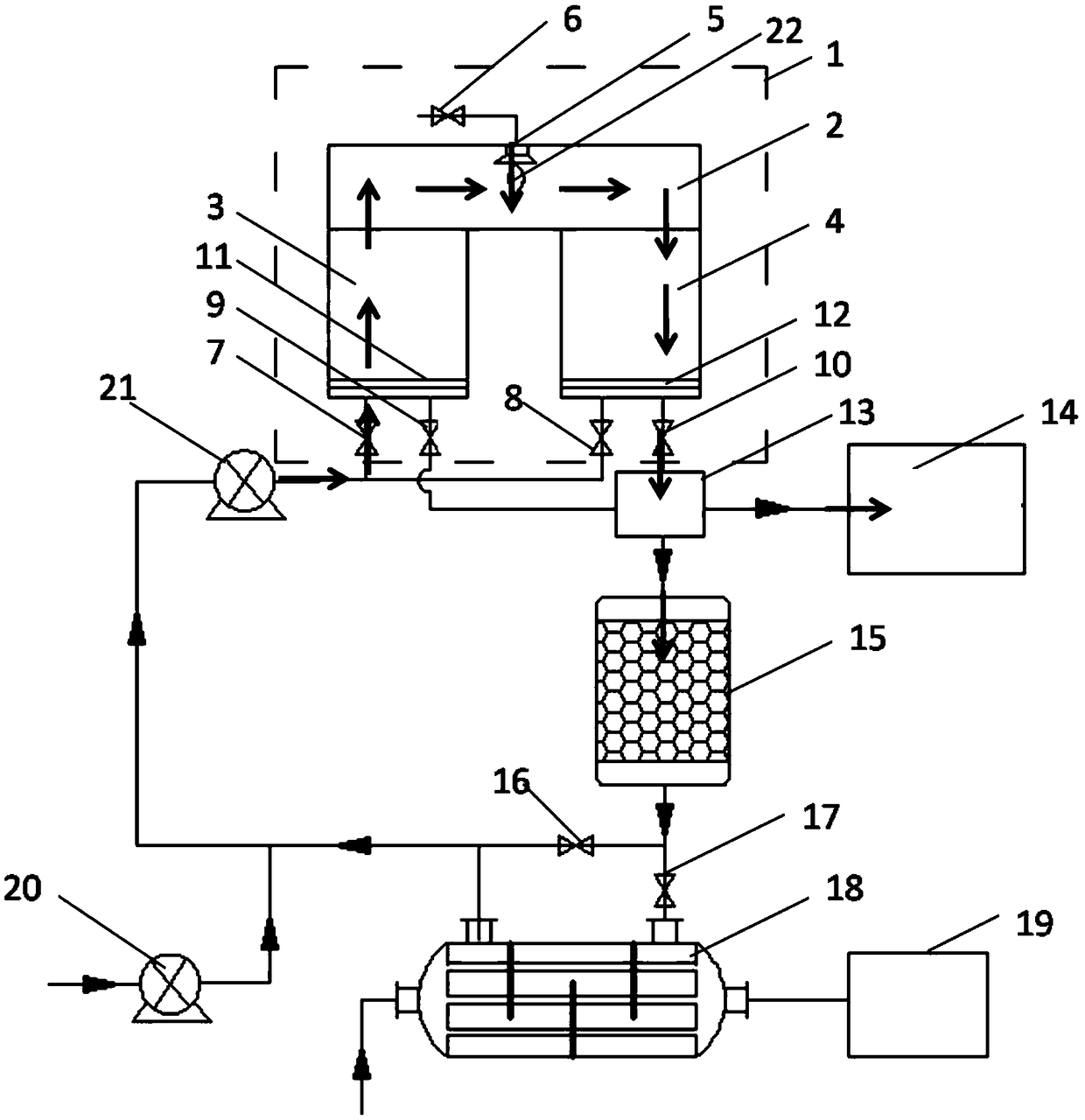

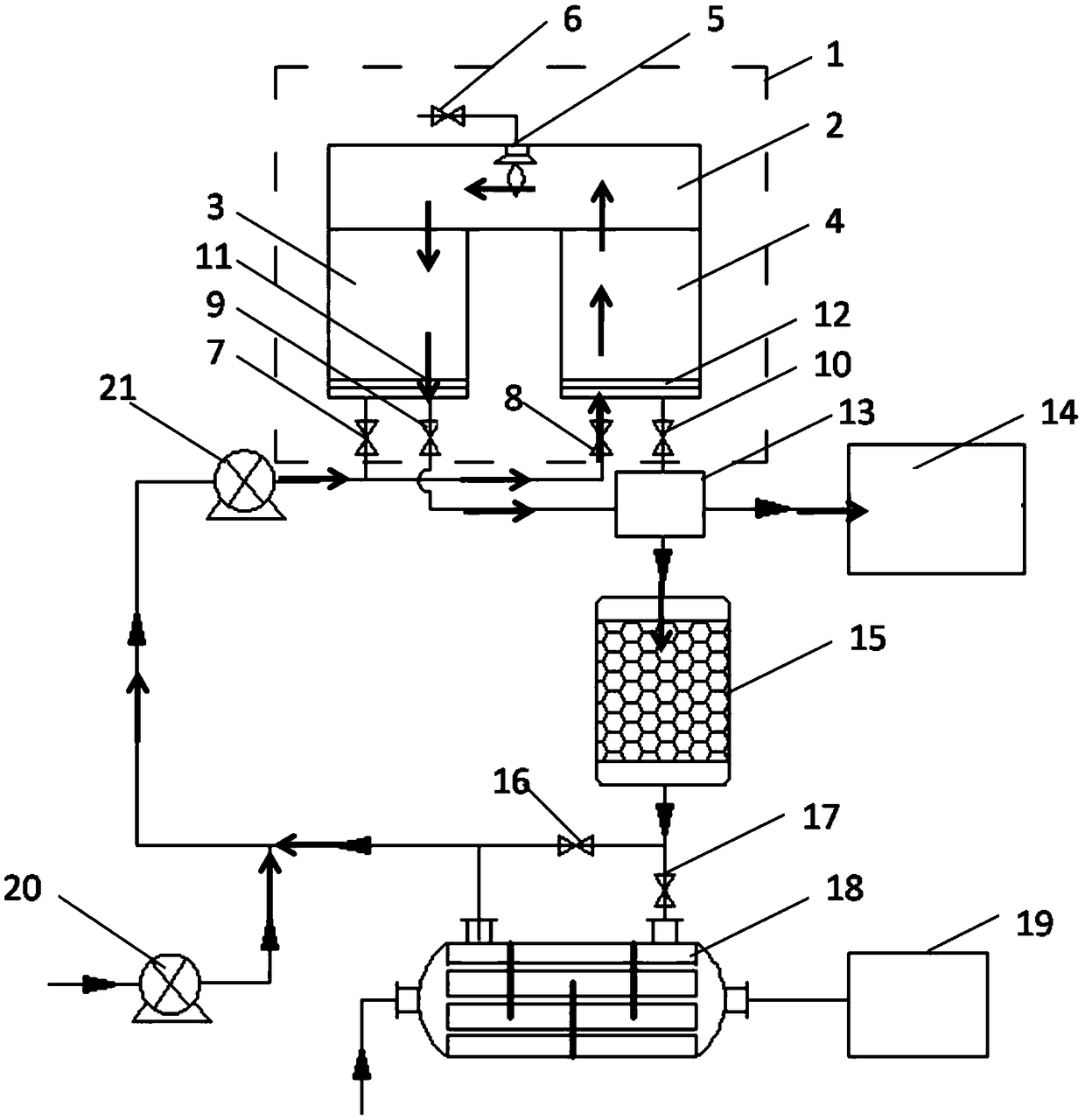

[0043] The invention provides a comprehensive waste heat recycling system and recycling method based on VOCs thermal oxidation treatment. In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the present invention will be further described in detail with reference to the accompanying drawings and embodiments. It should be pointed out that for those of ordinary skill in the art, the principles of the present invention are not deviated from Under the premise of, several modifications and improvements can be made, which are also deemed to belong to the protection scope of the present invention.

[0044]

[0045] Such as figure 1 As shown, the integrated waste heat reuse system of the present invention includes a regenerative incinerator 1, a splitter 13, an absorption chiller 14, an adsorption bed 15, a circulating fan 21, a supplemental fan 20, and a concentration monitor (not shown in the figure) , Heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com