Patents

Literature

42results about How to "Improve interface bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

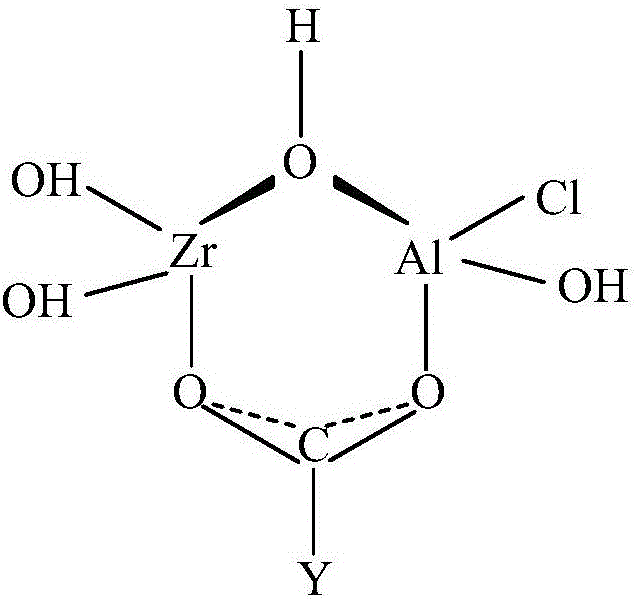

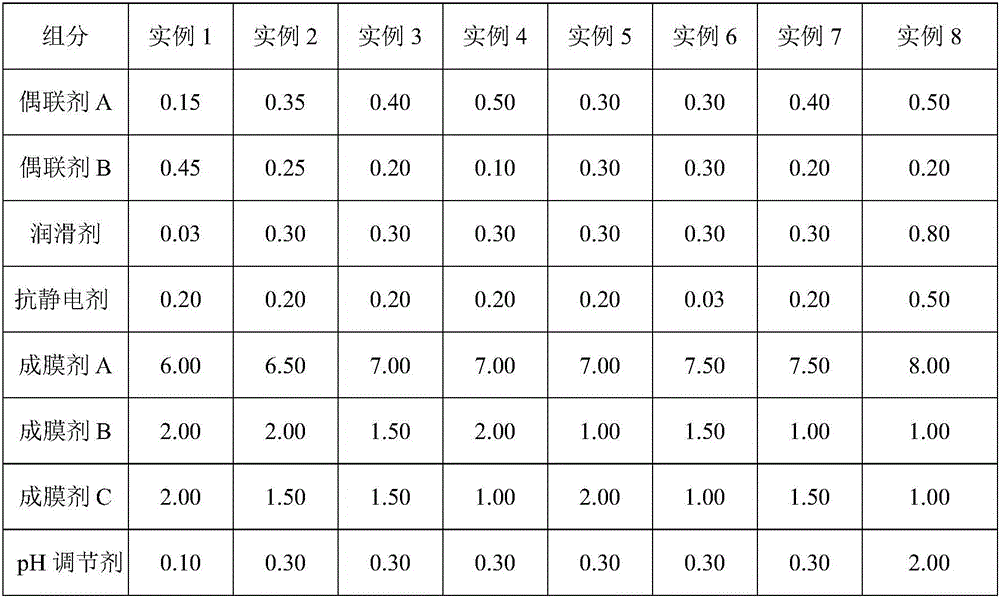

Glass fiber impregnating agent for transparent plate

The invention discloses a glass fiber impregnating agent for a transparent plate, which basically comprises the following components in percentage by weight: 0.15-1.0 percent of silane coupling agent, 3.0-20.0 percent of binding agent, 0.02-1.0 percent of lubricating agent, 0.05-0.8 percent of antistatic agent, 0.1-2 percent of pH value adjusting agent and the balance of deionized water, wherein the binding agent is epoxy-ester emulsion or a mixture of PVAc emulsion and the epoxy-ester emulsion, and the contents of the PVAc emulsion and the epoxy-ester emulsion are calculated by respective solid content. The invention adopting the epoxy-ester emulsion or the mixture of the PVAc emulsion and the epoxy-ester emulsion as the binding agent can improve the glass fiber impregnating speed and the production efficiency; in addition, the light refractive rates of the impregnating agent and matrix resin are close, and the transmittance of the produced plate is high.

Owner:JUSHI GRP CO

Chopped glass fiber sizing agent for bulk molding compounds (BMC) for reinforcing thermosetting resin

The invention discloses a chopped glass fiber sizing agent for reinforcing thermosetting resin, which is prepared by the components by weight percent: (1) 0.2-1.5% of coupling agent; (2) 3.0-20.0% of binding agent that is cross-linked polyurethane emulsion or the mixture of the cross-linked polyurethane emulsion and medium and high molecular weight epoxy emulsion, wherein the contents of the cross-linked polyurethane emulsion and the medium and high molecular weight elastic epoxy ester emulsion are based on the respective solid content; (3) 0.0-1.2% of lubricating agent; (4) 0.05-0.8% of antistatic agent; (5) 0.1-2% of pH value conditioning agent; and (6) the balance of deionized water, wherein the total weight of all the components is 100%. The chopped glass fiber sizing agent improves the bundling property of chopped glass fiber, reduces the broken filament, improves the mixing uniformity and the fluidity of the glass fiber and the BMC resin paste, and improves the mechanical strength and the appearance performance of BMC products.

Owner:JUSHI GRP CO

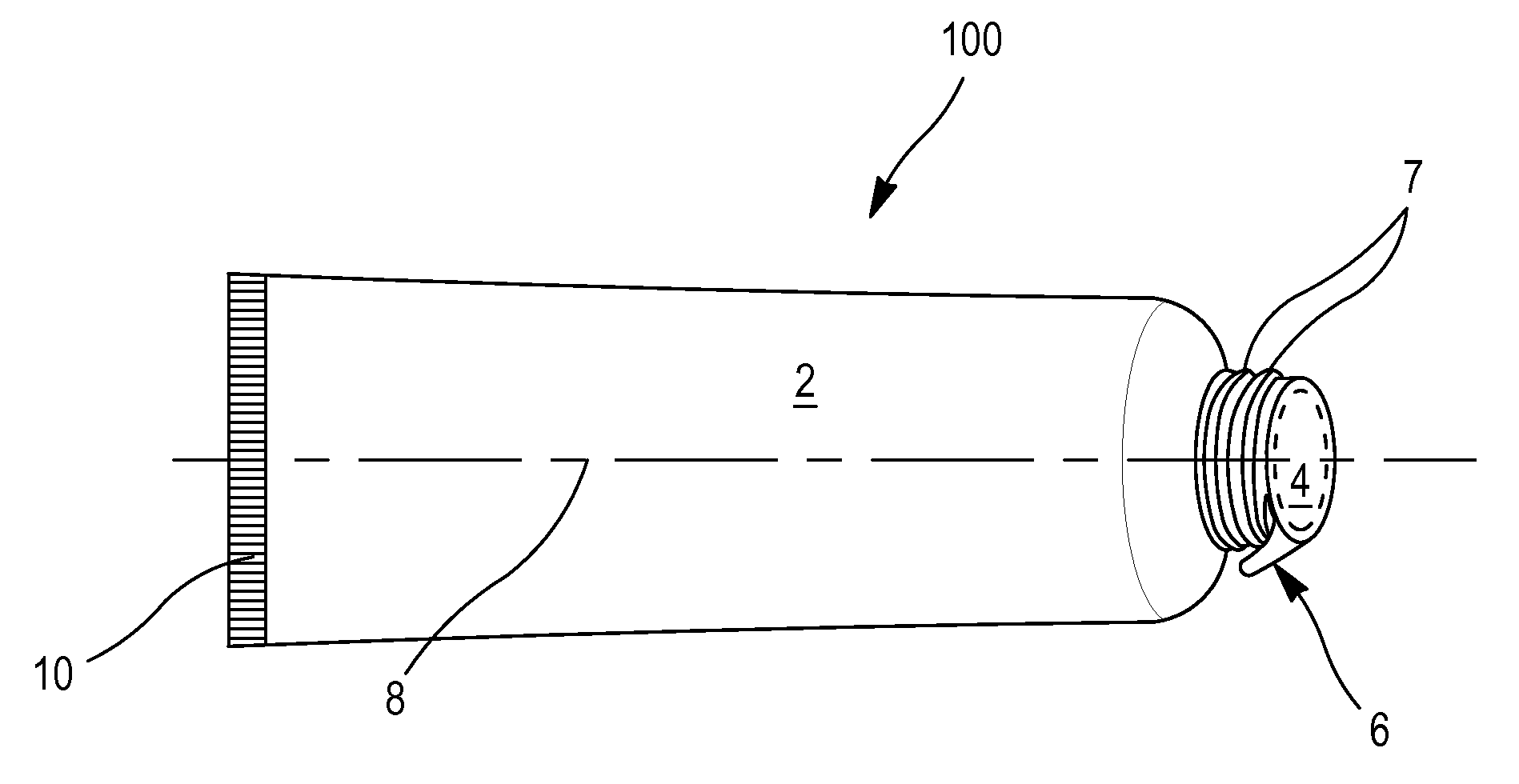

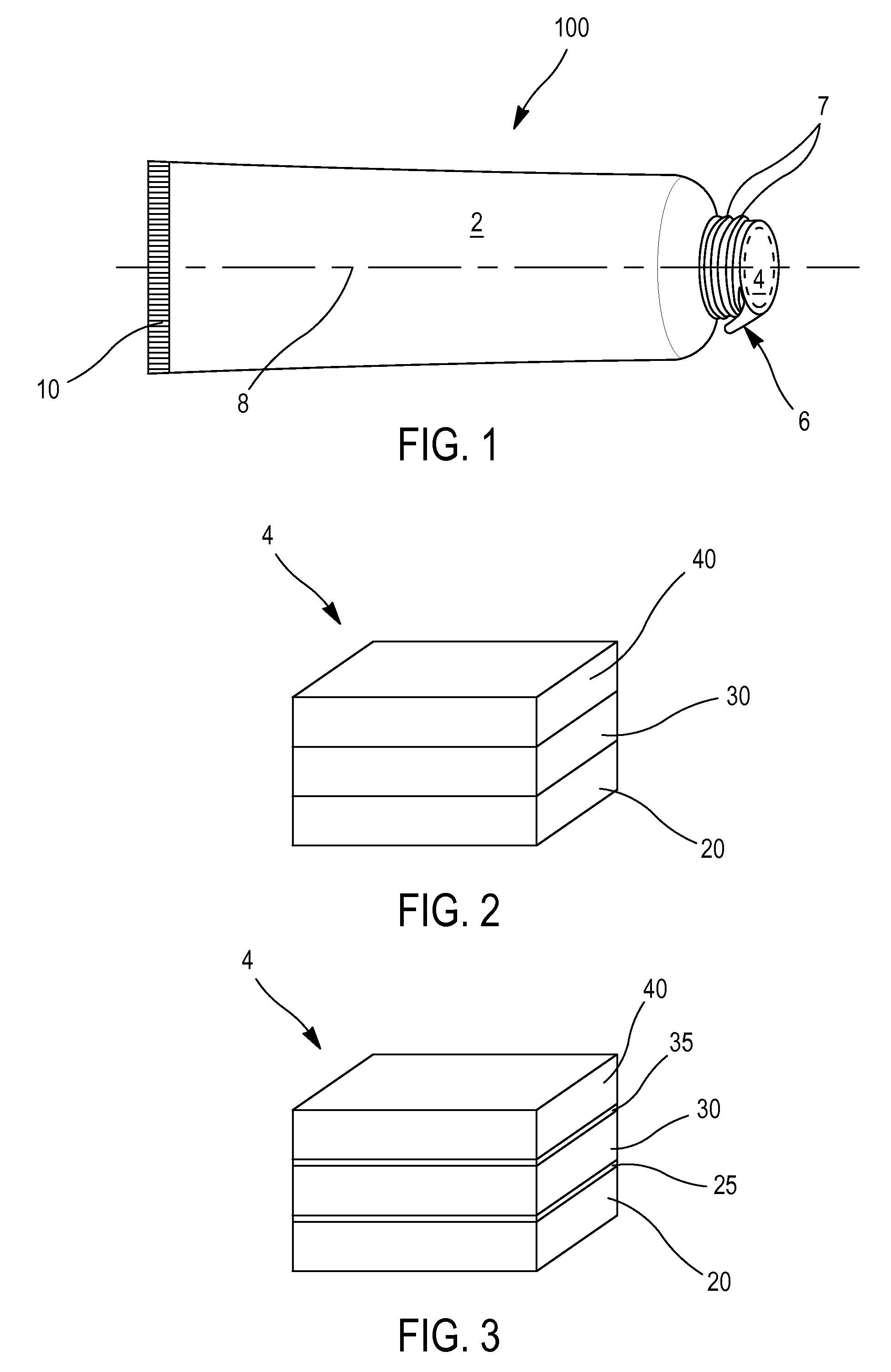

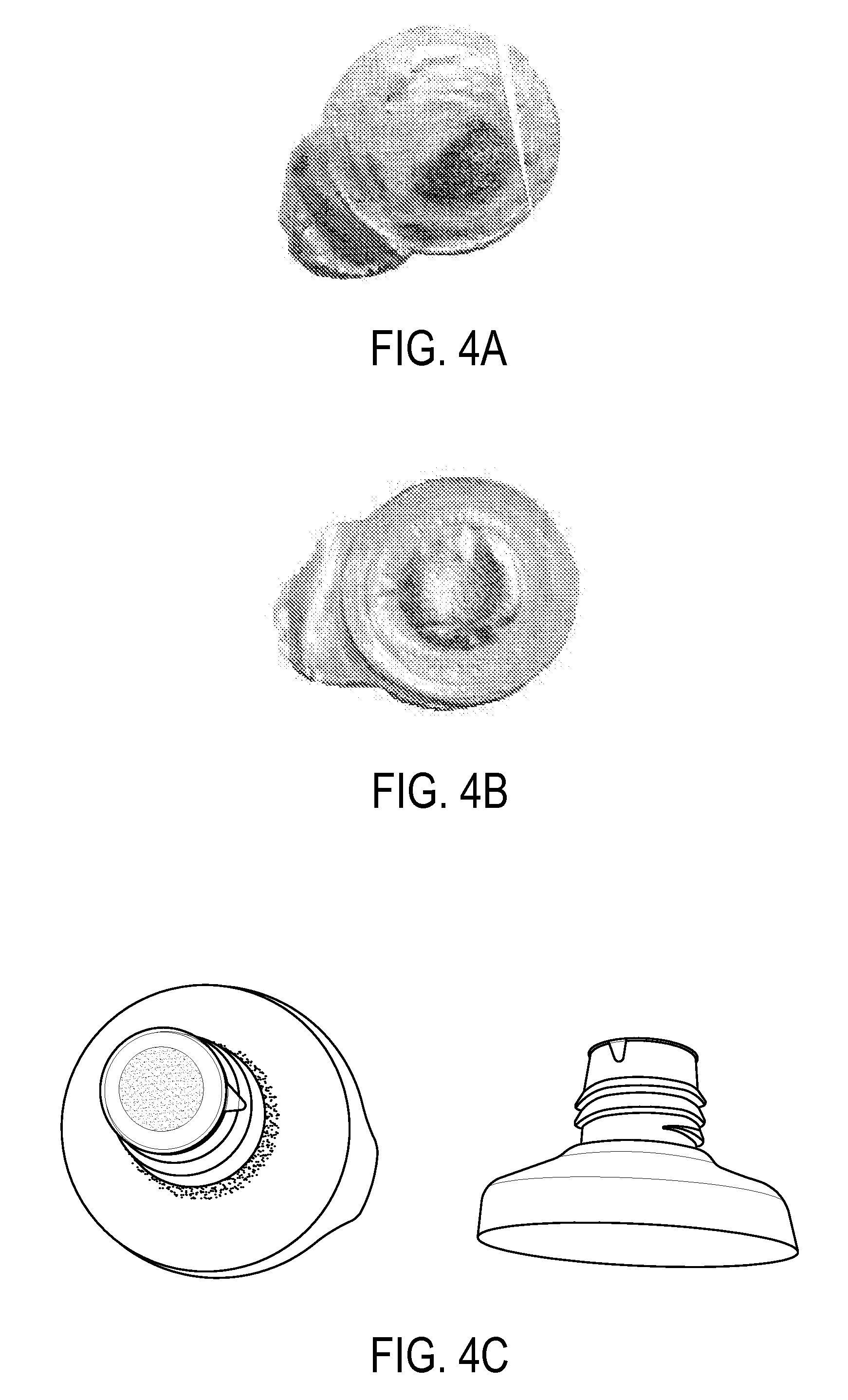

Container and Sealing Membrane for Packaging of Reactive Products

InactiveUS20110017772A1Improved performance characteristicsImprove sealingCapsDecorative coversHigh resistanceChemical reaction

Sealing (peel seal) membranes for packaging aggressive or chemically reactive products such as hair colorants over long periods without seal failure are described. Advantageously, the membranes and other packaging components have a high resistance to chemical attack and exhibit other advantageous characteristics, such as good barrier properties that minimize or eliminate interaction with the external environment, chemical inertness with respect to the product, and desirable heat sealing properties for prolonged adhesion without cracking and / or product leakage. The membranes comprise an inner bonding layer comprising a blend of polyethylene (PE) with an anti-cohesion additive, and a barrier layer.

Owner:ALCAN PACKAGING BEAUTY SERVICES

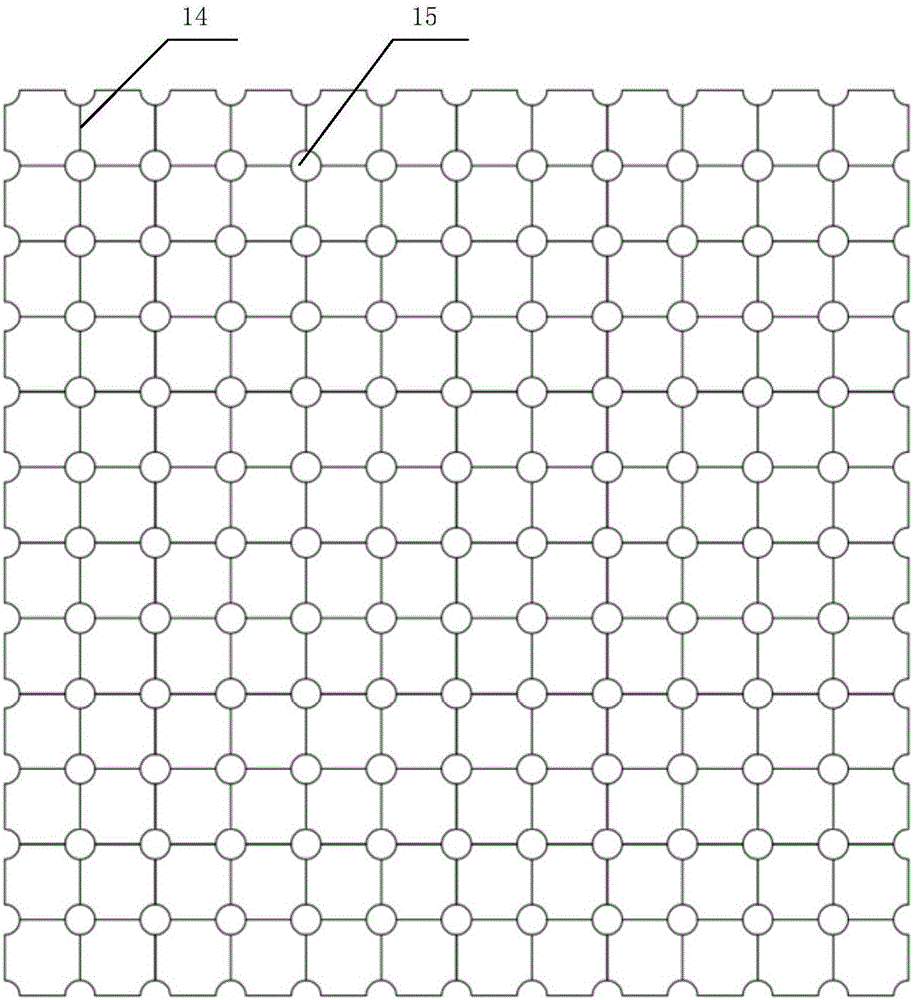

Metal-matrix composite ceramic liner plate and preparation method thereof

ActiveCN102618772AImprove interfacial bond strength and overall performanceImprove interface bondingGearingCylindersCeramic particleChromium

The invention discloses a metal-matrix composite ceramic liner plate. Zirconia aluminum oxide, high chromium iron powder and iron powder are electrically smelted and injected into a metal-matrix ceramic reinforcement with a plurality of communicated plug holes to form the metal-matrix composite ceramic liner plate; the upper and lower end faces of the metal-matrix ceramic reinforcement are provided with communicated plug holes, and four side faces of the metal-matrix ceramic reinforcement are provided with communicated grooves; after different reinforcements are spliced, grooves on edges of two adjacent reinforcements form complete plug holes, a metal liquid is poured into the plug holes and can infiltrate among ceramic particles of the reinforcements through the plug holes and uniformly coat the ceramic particles, so that a ceramic phase and a metal phase are uniformly distributed. Therefore, the toughness and wear resistance of the finished ceramic products are enhanced, and the thermal shock resistance of the finished ceramic products is improved.

Owner:洛阳鹏飞耐磨材料股份有限公司

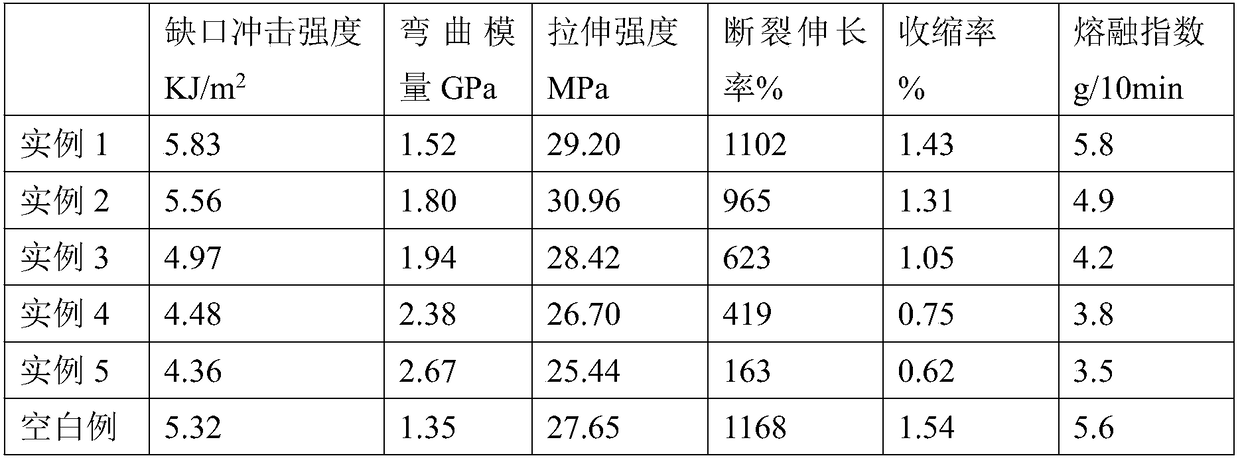

Recycled composite material for enhancing modified waste polypropylene by using waste printed circuit board powder/glass fiber and preparation method of recycled composite material

The invention discloses a recycled composite material for enhancing modified waste polypropylene by using a waste printed circuit board powder / glass fiber and a preparation method of the recycled composite material. The recycled composite material comprises the following raw materials in part by weight: 100 parts of waste polypropylene, 100-300 parts of waste printed circuit board powder, 5-15 parts of compatibilizer, 1-2 parts of antioxidant and 5-15 parts of alkali-free glass fiber. The preparation method comprises the following steps: mixing the waste polypropylene, the waste printed circuit board powder, the compatibilizer and the antioxidant according to a proportion; adding a blending material from a main feeding device of a double-screw extruder for smelting, wherein the rotating speed of a screw is 60 r / min; and adding the alkali-free glass fiber from a fourth processing area of the extruder according to a proportion and blending the alkali-free glass fiber with the smelt mixture; and carrying out extrusion, traction, cooling and particle dicing to obtain the recycled composite material of the modified waste polypropylene. According to the recycled material disclosed by the invention, the waste polypropylene can be effectively enhanced and toughened and the recycled composite material with excellent integrated performance is obtained; and in addition, the waste is fully utilized and energy economization and emission reduction are realized.

Owner:CHINA NAT ELECTRIC APP RES INST +1

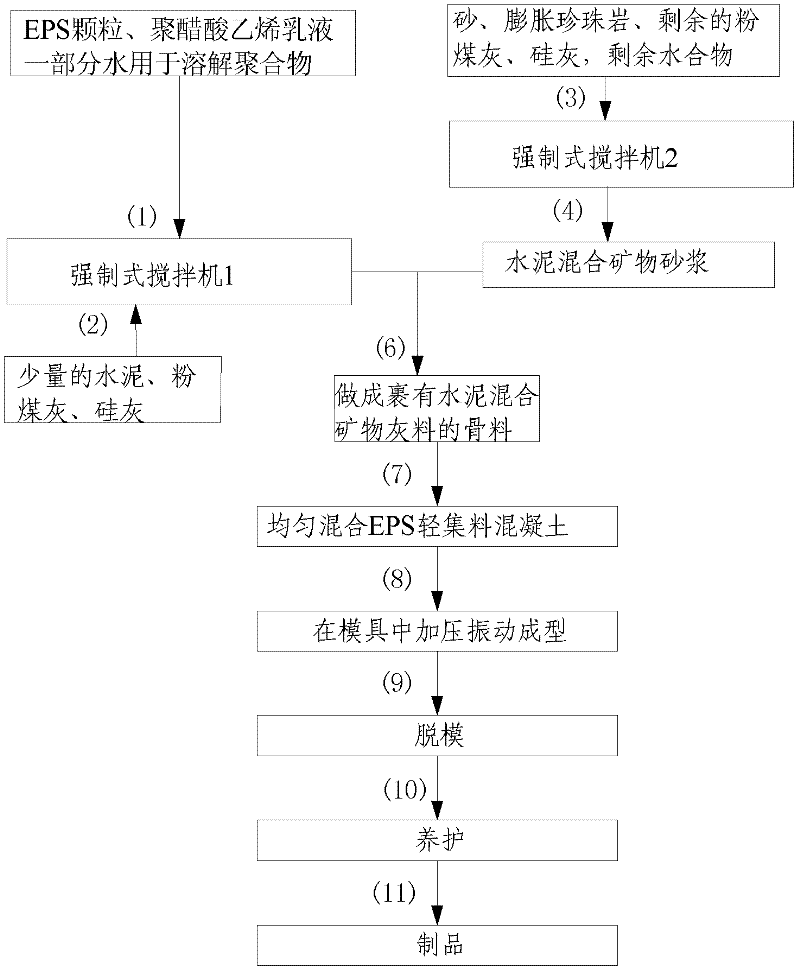

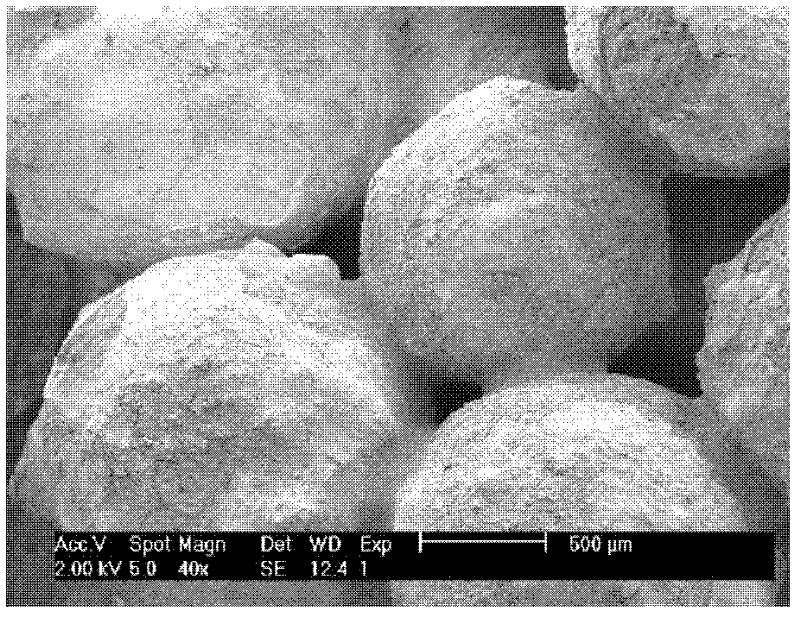

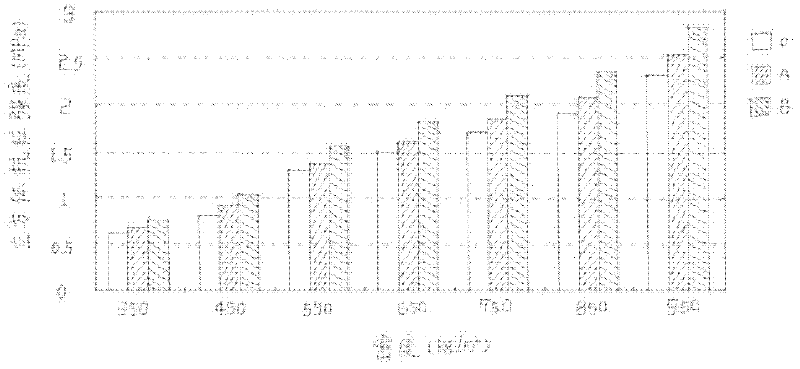

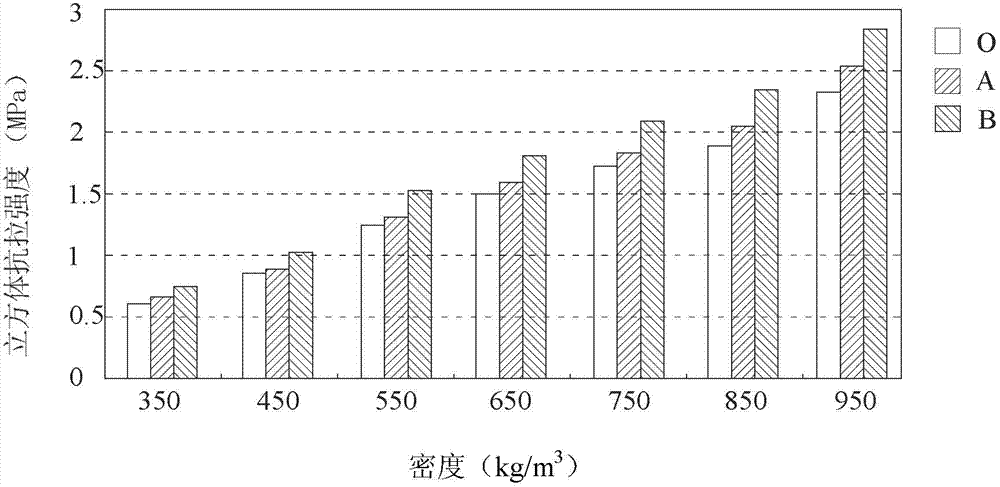

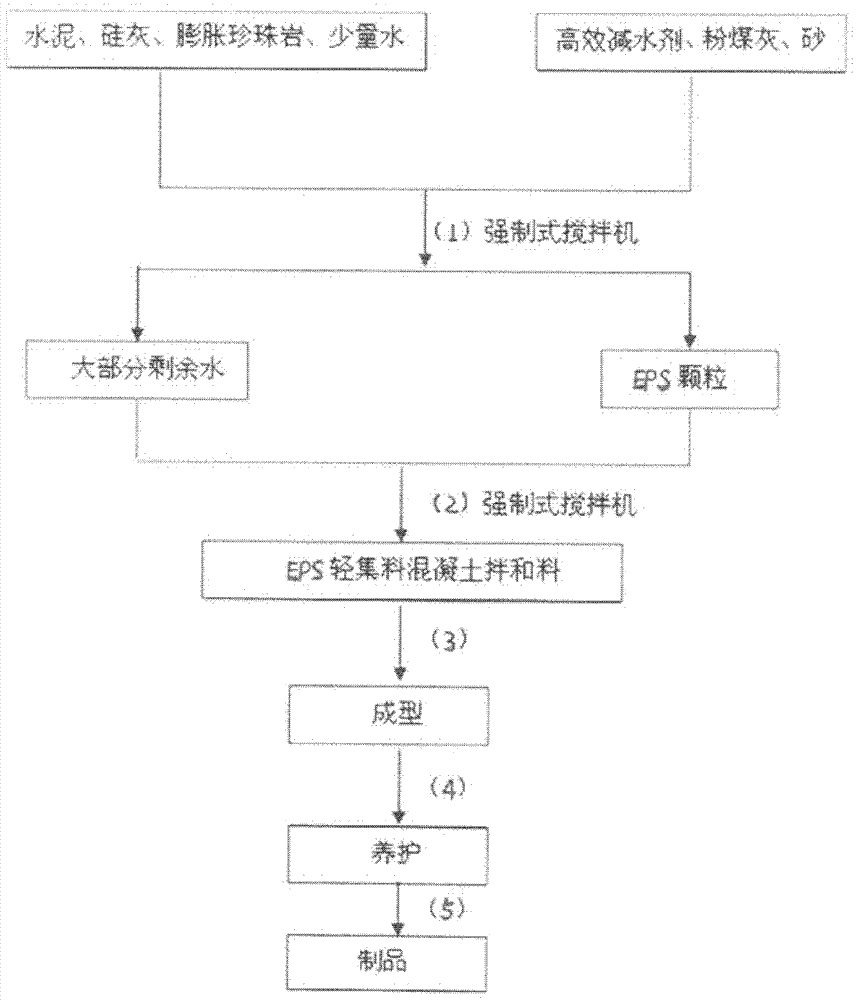

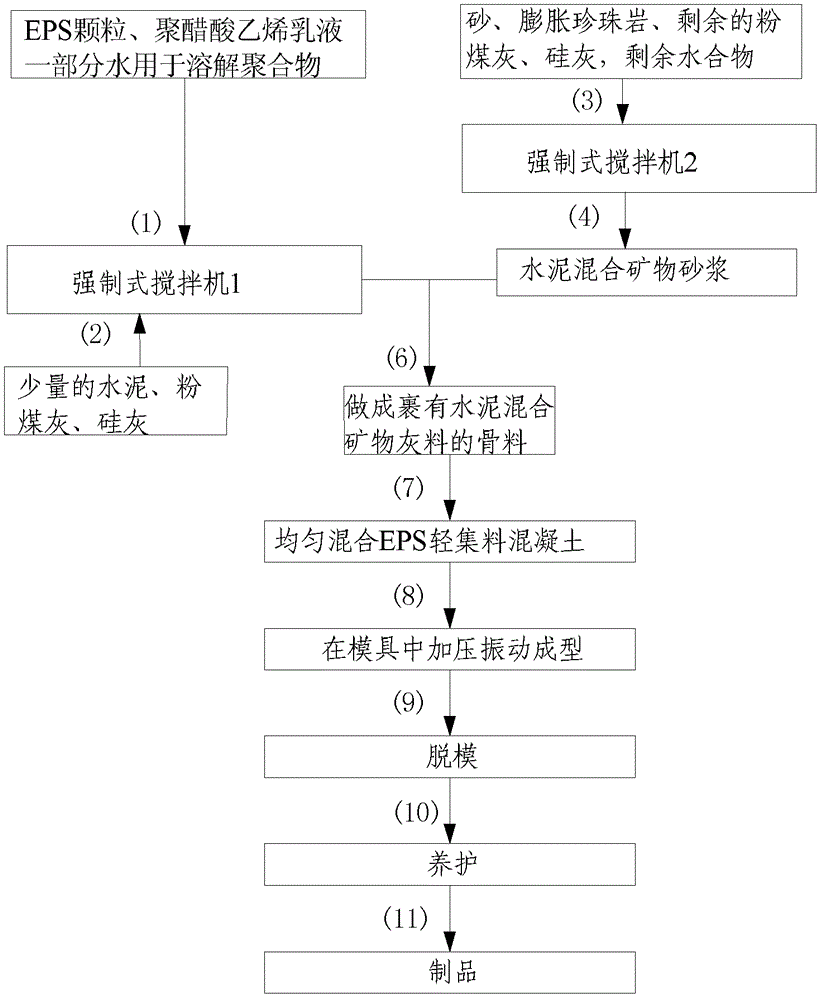

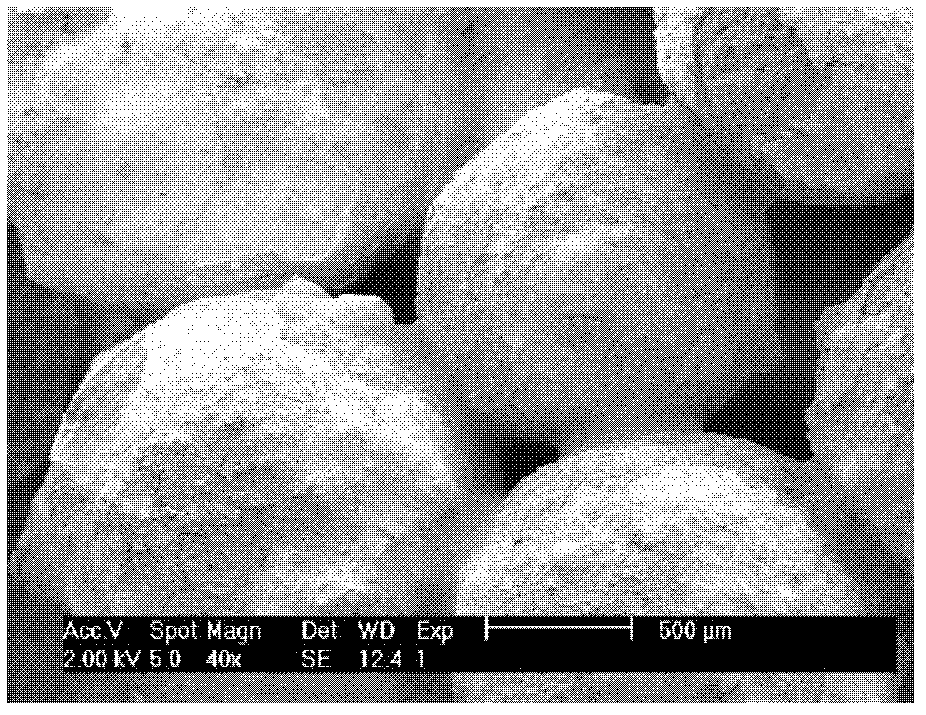

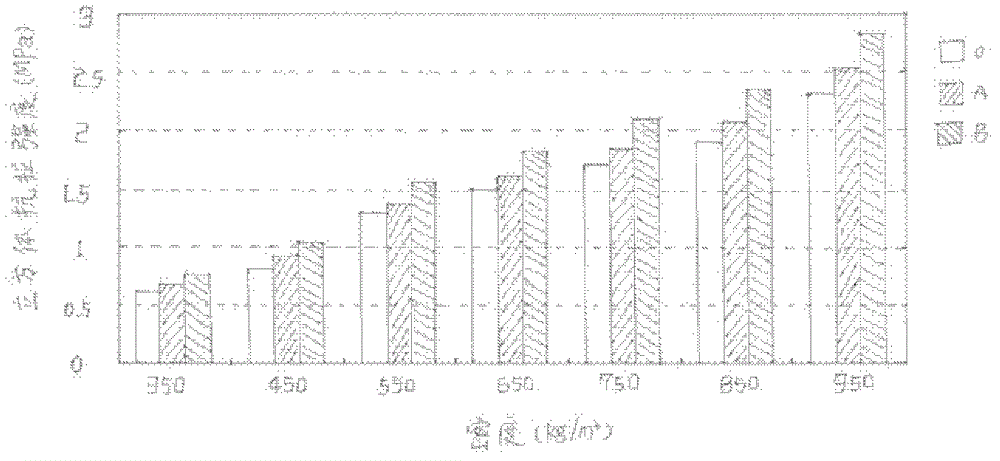

EPS (Expandable Polystyrene) lightweight aggregate concrete and preparation method thereof

The invention provides EPS (Expandable Polystyrene) lightweight aggregate concrete and a preparation method thereof. The EPS lightweight aggregate concrete effectively meets the requirements of concrete on light weight, uniformity and density in the aspect of structure, and simultaneously has excellent comprehensive properties; the volume weight of the EPS lightweight aggregate concrete is higher than 650 kg / m<3>, the cube compressive strength can reach 1.6MPa, the strength meets the service requirements, and the lightweight aggregate concrete has excellent thermal properties and durability; and shown in a compression test, the concrete has larger deformation before the concrete is damaged due to deformation, so that the toughness of the concrete is improved. The lightweight aggregate concrete comprises the following raw materials in parts by weight: 350 parts of cement, 90-120 parts of fly coal ash, 30-70 parts of silica fume, 120-140 parts of river sand, 190-210 parts of water, 15-21 parts of EPS grains, 40-60 parts of perlite and 12-18 parts of polymer emulsion. The preparation method comprises the steps of crusting, slurry wrapping, mixing, forming and curing. The lightweight aggregate concrete obtained according to the mixture ratio and the preparation method is uniform and dense in structure, and various properties meet the design requirements, so that the EPS lightweight aggregate concrete has better application prospects.

Owner:CHINA ELECTRIC POWER RES INST +1

Functional polyolefin/montmorillonite nano-composite material and its preparation method

The present invention discloses a functional polyolefine / montmorillonite nano composite material and its preparation method. Said method includes the following steps: intercalating olefin hydrocarbon polymerization catalyst into interlamination of montmorillonite, introducing olefin hydrocarbon monomer and reactive comonomer and making them implement copolymerization in interlamination of montrorillonite, then utilizing functionalization reaction to convert the reactive group into polar group so as to make the polar group be grafted on the polyolefine macromolecular chain. The polyolefine molecular chain in said functional polyolefine / montrorillonite nano composite material contains polar group, so that the mutual action of said polyolefine and montrorillonite can be greatly raised, the montrorillonite flake layers are uniformly dispersed in the polyolefine base body so as to form the polyolefine / montrorillonite nano composite material with stable structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Infiltration agent of chopped glass fiber for reinforcing cement

The invention discloses an infiltration agent of chopped glass fiber for reinforcing cement. The infiltration agent comprises the following components by weight percent: (1) 0.2-1.5% of coupling agent which is combination of 3-amino propionic triethoxy silane and 3-methacryloyloxyethyl propyl trimethoxysilane; (2) 3.0-30.0% of a film-forming agent, which is crosslinked polyacrylic dispersion or combination of crosslinked polyacrylic acid dispersion and a bisphenol A epoxy emulsion with medium-high molecular weight, wherein the molecular weight of the epoxy resin in the bisphenol A epoxy emulsion with medium-high molecular weight is 1200-6000; (3) 0.01-2.0% of a nonionic lubricant; (4) 0.05-1.0% of organic antistatic agent; (5) 0.1-2% of pH value modifier; (6) 63.5-96.64% of deionized water. A glass fiber yarn produced by using the infiltration agent has the advantages of being good in bundling property, easy to chop, and resistant to alkaline corrosion of cement, the produced cement product is high in mechanical strength, and the product is bright and clean in appearance.

Owner:JUSHI GRP CO

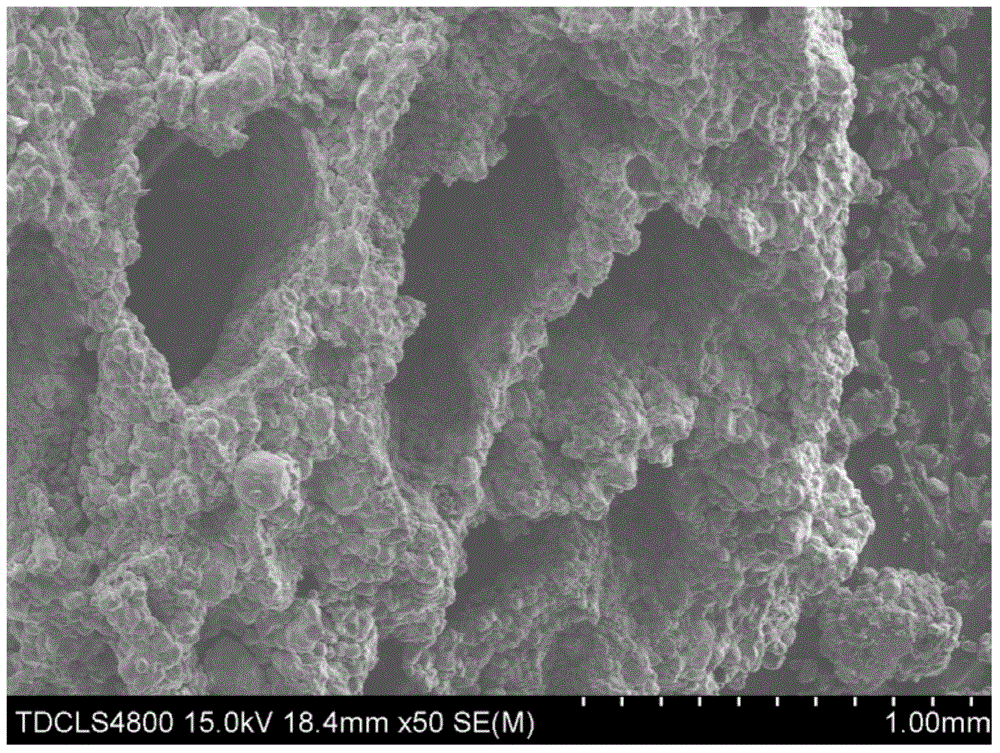

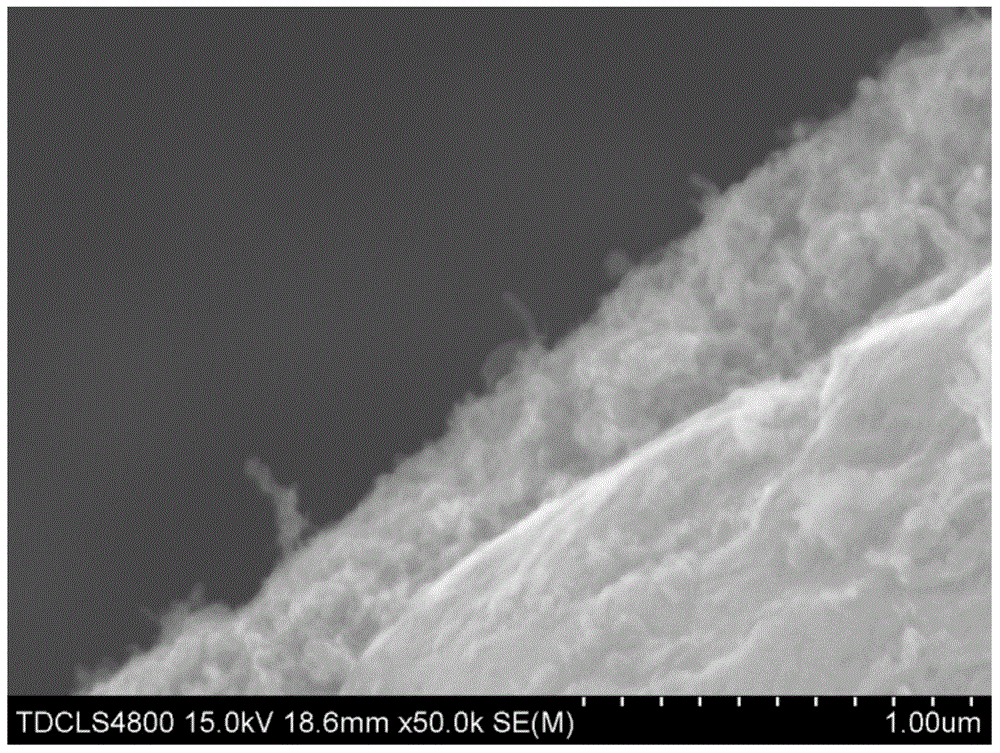

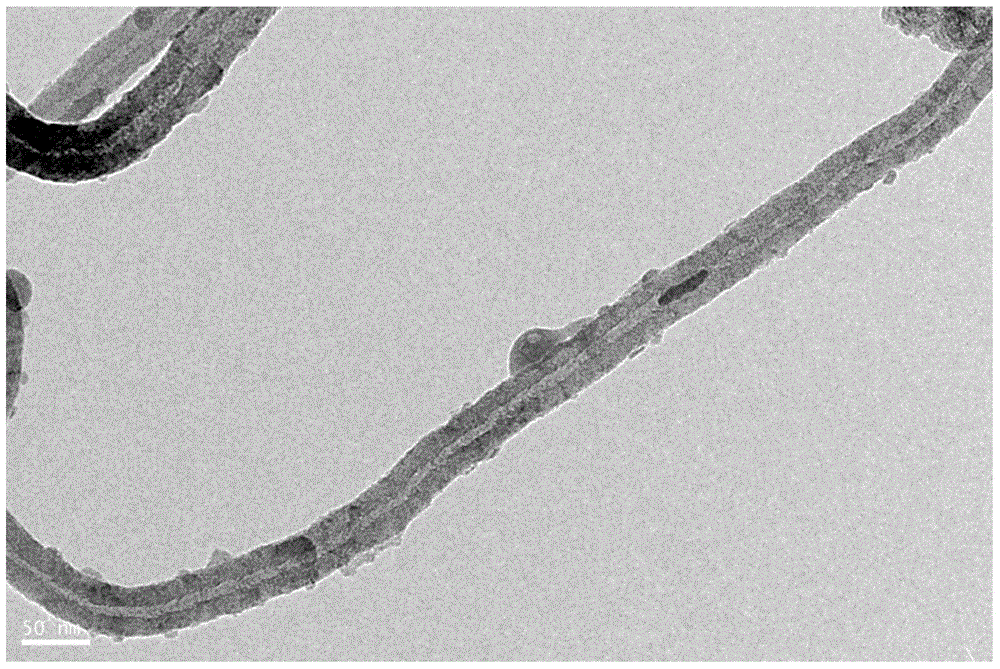

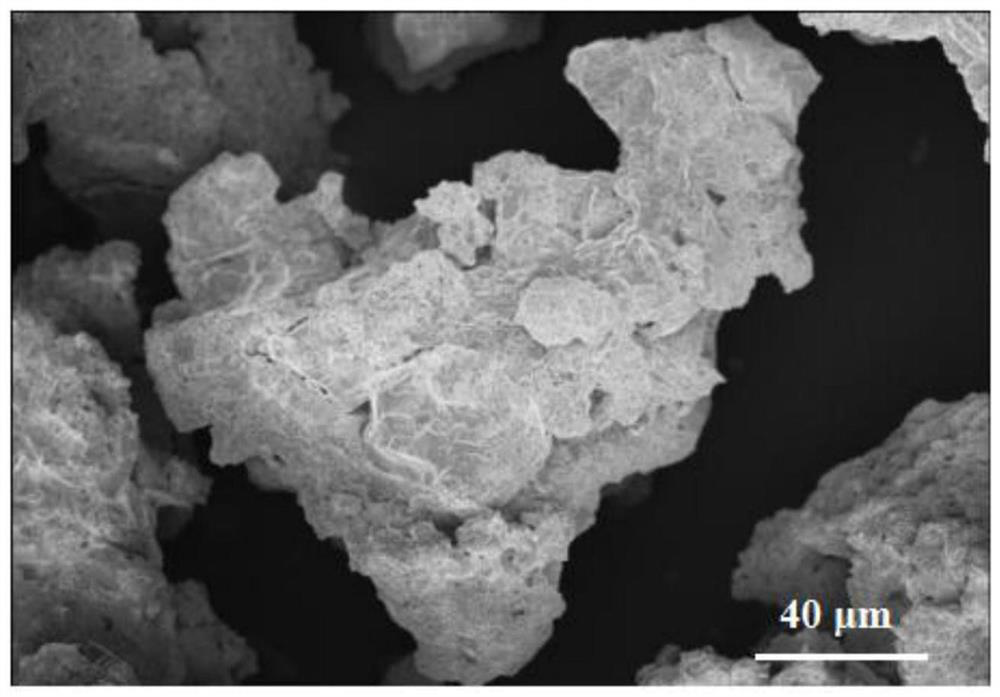

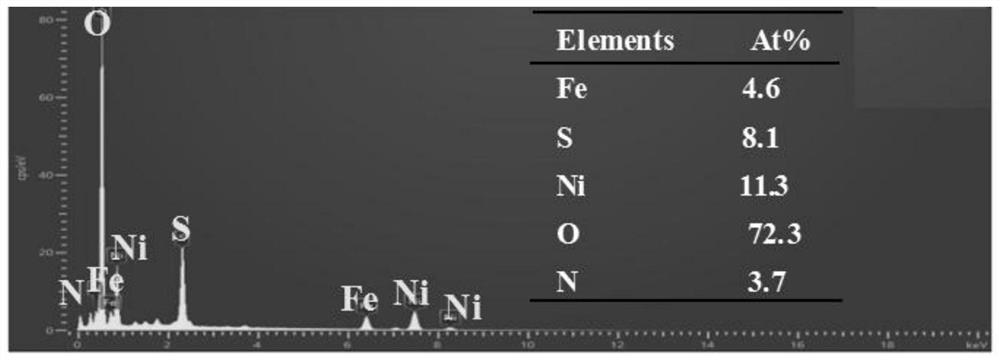

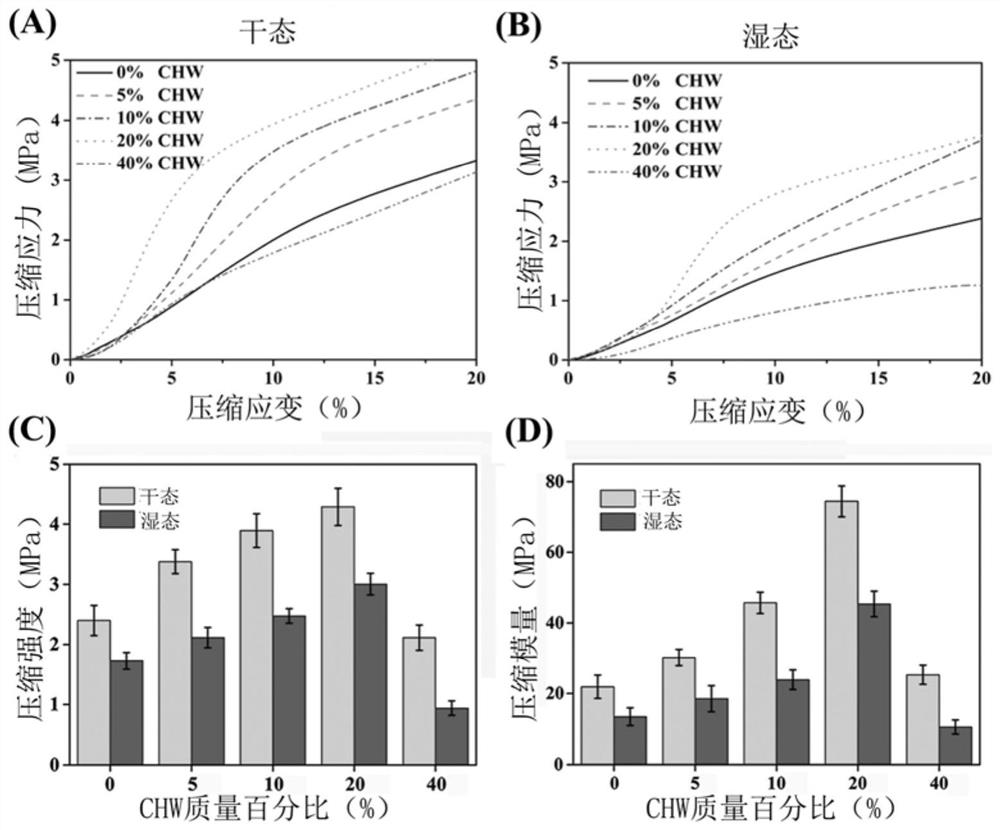

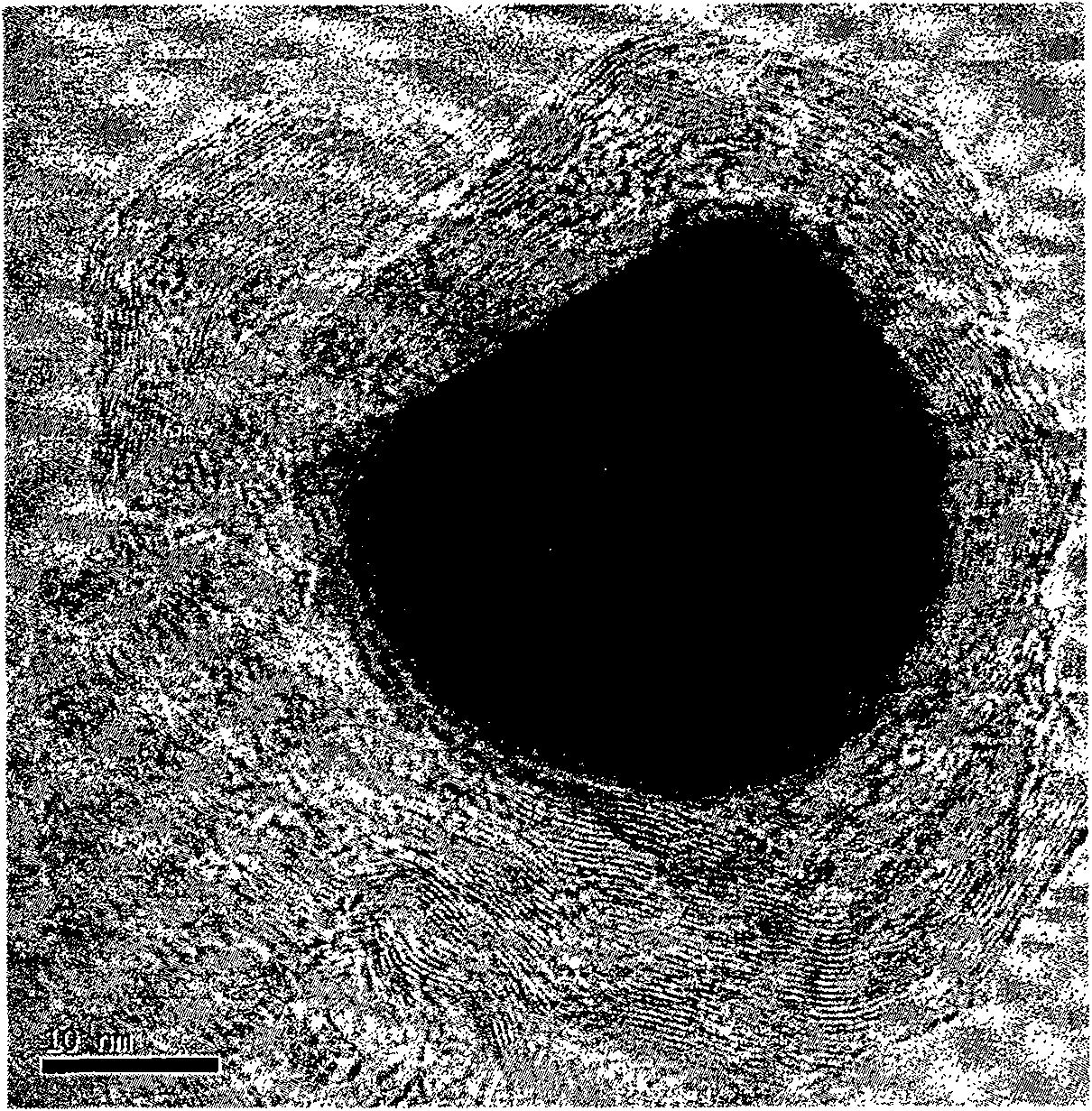

Preparation method of carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption

ActiveCN104911388AHighlight substantiveGood deformabilityChemical vapor deposition coatingVibration attenuationNitrate

The invention provides a preparation method of a carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption, relates to the manufacturing of an alloy with open or closed pores, and specifically relates to the preparation method of the carbon nanotube reinforced foamed aluminum composite material for vibration attenuation and energy absorption with urea as a pore-forming agent and nickel as a carbon nanotube synthesis catalyst; the preparation method comprises the following steps: preparing the mixed powder of nickel nitrate, urea and aluminum powder; preparing a foamed aluminum blank; and preparing the carbon nanotube reinforced foamed aluminum composite material. The method is used for overcoming the defects of structural defect, low mechanical properties and low buffer energy-absorption property, large density and no lightweight property of the foamed aluminum materials prepared in the prior art, complex preparation process, relatively high cost and difficult realization of functional structure integration of the foamed aluminum serving as an energy-absorption material.

Owner:HEBEI UNIV OF TECH

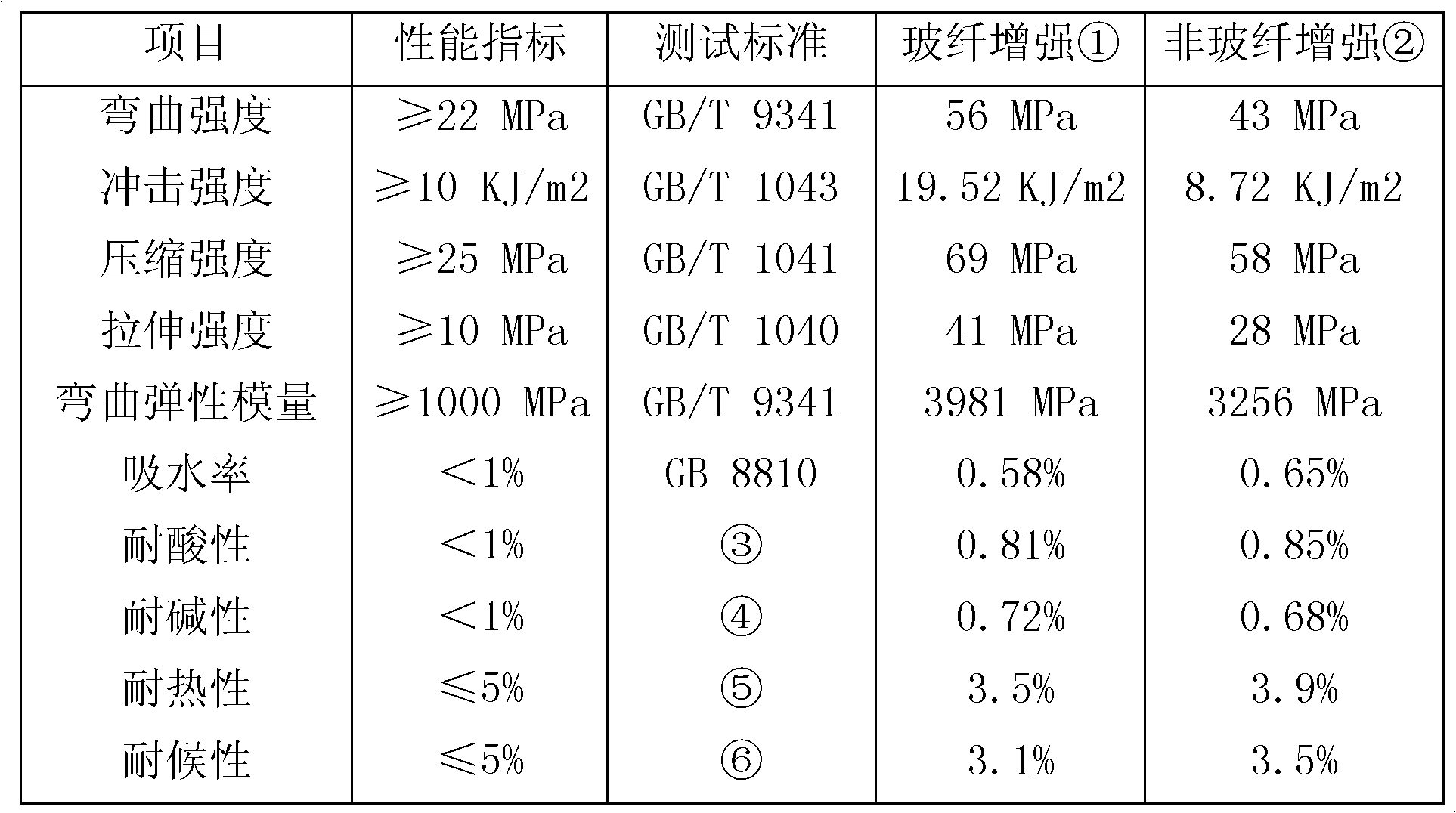

High-strength and high-toughness polyphenylene sulfide composite material and preparation method thereof

The invention relates to a high-strength and high-toughness polyphenylene sulfide composite material and a preparation method thereof. The composite material is prepared from the following raw materials in percentages by weight: 5 to 50% of polyphenylene sulfide resin, 5 to 50% of super-toughened nylon, 5 to 20% of a compatibilizing agent, 30 to 45% of glass fiber, 0 to 1% of an antioxidant, 0 to 1% of a light stabilizer and 0 to 1% of a lubricant. The preparation method for the polyphenylene sulfide composite material comprises the following steps: adding all components except the glass fiber into a high-speed mixer, carrying out dispersion mixing, then adding the obtained mixture into a double screw extruder, introducing the glass fiber into an extruder from a fiber inlet of the extruder, and carrying out mixing granulation so as to obtain the polyphenylene sulfide composite material. The polyphenylene sulfide composite material prepared by using the method provided by the invention has high strength, high toughness and extensive application range, and is especially applicable to preparation of bottom poles and sheaths of frame tent supports.

Owner:常州市法沃森塑胶科技有限公司 +1

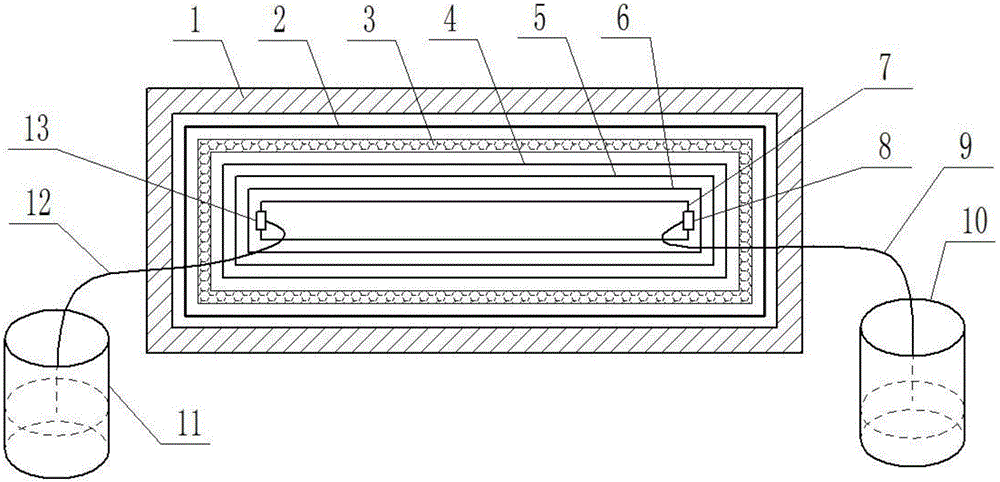

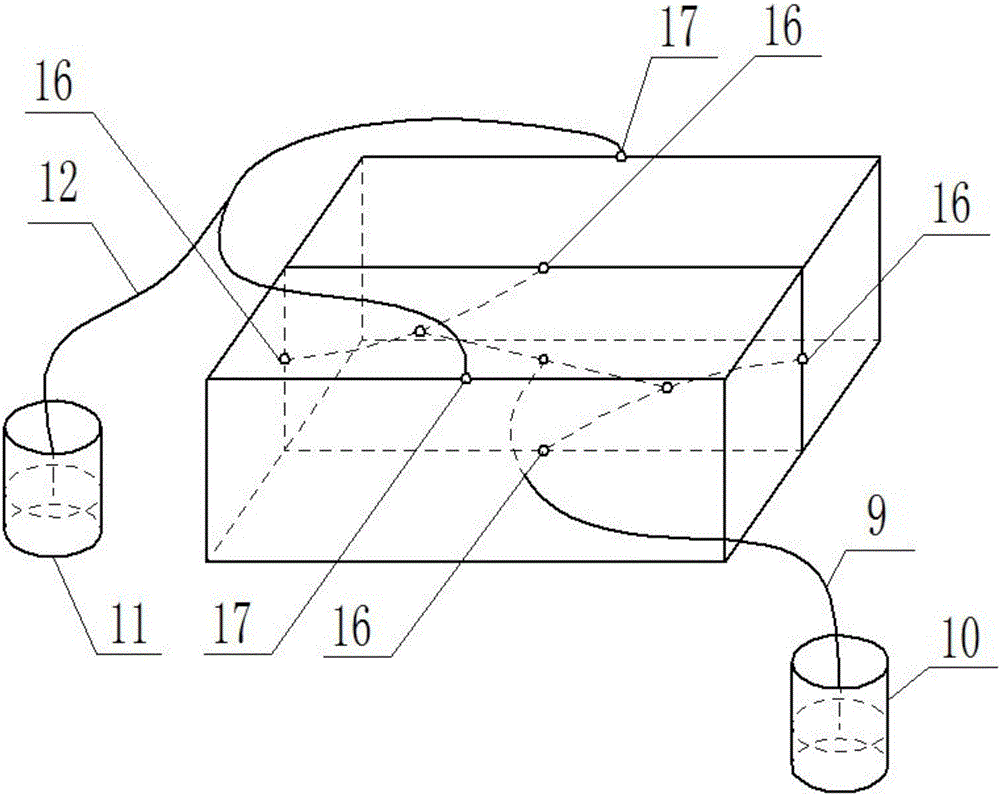

Foam sandwich composite material for aviation dining car and preparation method of foam sandwich composite material

The invention discloses a foam sandwich composite material for an aviation dining car and a preparation method of the foam sandwich composite material. The preparation method of the foam sandwich composite material mainly comprises the steps of preparation before laminating, reinforcing material laminating, glue injection system arranging, vacuum system arranging, air tightness inspecting, resin pouring and solidification demolding. According to the preparation method, holes and grooves are formed in foam cores of reinforcing material laminating layers, and the holes and the grooves communicate with one another; and after vacuumizing is conducted, resin is poured, and complete wetting of the reinforcing material laminating layers is ensured. The prepared composite material is stable in quality, high in production efficiency, low in cost, small in pollution, good in strength and interference bonding performance, and long in service life.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

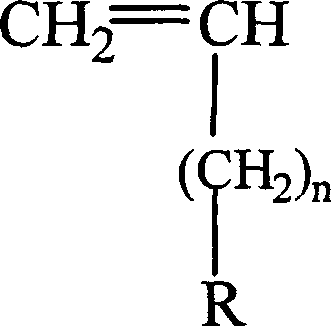

Glass fiber impregnating compound high in permeating speed and application thereof in producing twistless roving

The invention discloses a glass fiber impregnating compound which is prepared from, by weight, 0.02-3.00% of a coupling agent, 3.00-30.00% of a film forming agent, 0.02-2.00% of a lubricating agent, 0.02-0.80% of an antistatic agent, 0.01-2.00% of a pH adjusting agent and deionized water. The film forming agent is prepared by mixing nanosilicon dioxide modified polyester emulsion, PVAc emulsion and polyurethane modified epoxy emulsion, and the content of the nanosilicon dioxide modified polyester emulsion is not smaller than that of the polyurethane modified epoxy emulsion. The invention further provides application of the glass fiber impregnating compound in producing twistless roving. The twistless roving produced through the impregnating compound is high in permeating speed, good in choppability, good in production smoothness and good in compatibility with enhanced resin, production efficiency and the mechanical strength of a produced composite product are greatly improved, and the glass fiber impregnating compound is applicable to an injection process or a centrifugal casting molding process.

Owner:JUSHI GRP CO

Expanded Polystyrene (EPS) light aggregate concrete and preparation method thereof

InactiveCN102875181AEvenly distributed pore structureImprove interface bondingSolid waste managementCeramic shaping apparatusExpanded polystyreneLarge deformation

The invention provides EPS light aggregate concrete and a preparation method thereof. The EPS light aggregate concrete effectively meets the requirements on a light-weight, uniform and dense structure of the concrete, and has an outstanding integrated performance; the EPS light aggregate concrete has a unit weight of up to 550 kg / m<3> and a cube crushing strength of up to 1.3 MPa which meets the using requirement; in addition, the light aggregate concrete has good thermal performance and durability. In a compression test for the concrete, a large deformation occurs before deformed breakage, and the toughness is improved. The light aggregate concrete comprises 350 parts of cement, 90 to 120 parts of coal ash, 30 to 70 parts of silica fume, 120 to 140 parts of river sand, 190 to 210 parts of water, 15 to 21 parts of EPS particles, 40 to 60 parts of perlite and 2 to 6 parts of water reducer. The light aggregate concrete prepared by the preparation method according to the proportion is uniform and dense in structure, and meets the design requirements on each performance and preparation, so as to have a good application prospect.

Owner:CHINA ELECTRIC POWER RES INST +1

Structure-enhanced SMC (Sheet Moulding Compound) glass fibre impregnating agent and application thereof in production of twistless roving

Owner:JUSHI GRP CO

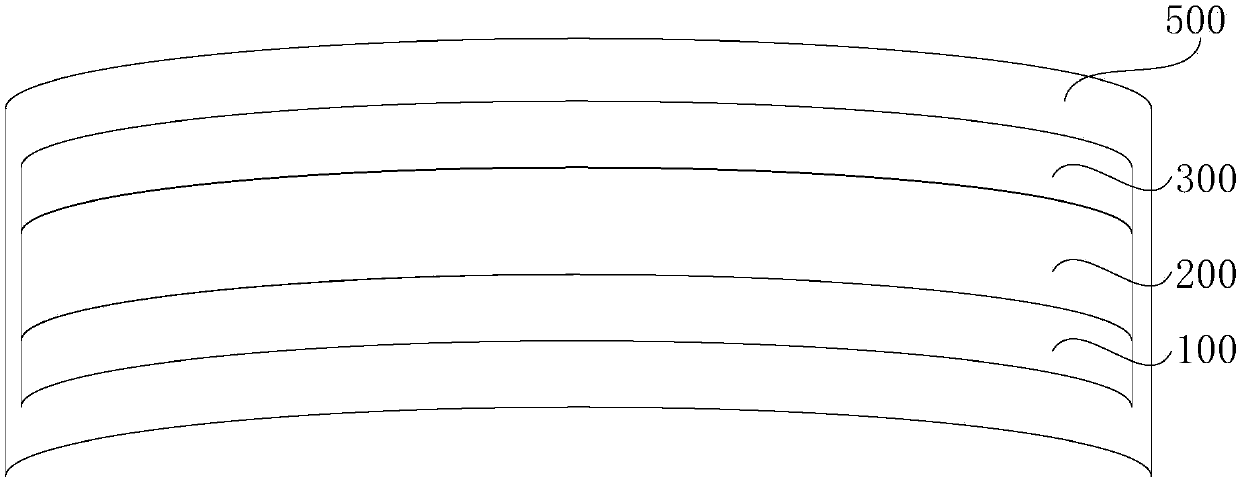

Flexible display panel, manufacturing method thereof and flexible display device

ActiveCN107819004AImprove bendabilityGood compatibilitySolid-state devicesSemiconductor/solid-state device manufacturingNano siliconOrganic light emitting device

The invention provides a flexible display panel, a manufacturing method thereof and a flexible display device. The flexible display panel comprises a first flexible substrate, an organic light emitting device and a second flexible substrate, wherein the organic light emitting device is arranged between the first flexible substrate and the second flexible substrate. The flexible display panel is characterized in that the first flexible substrate and / or the second flexible substrate is prepared from an acrylic material or an epoxy material and a plasticizing copolymerization monomer via copolymerization reaction, and the plasticizing copolymerization monomer is a nano-scale inorganic material. The plasticizing copolymerization monomer such as nano silicon nitride forms certain copolymerization modification with the acrylic material or the epoxy material, so that the abrasion resisting effect is enabled to be more obvious. Meanwhile, the inorganic nano silicon nitride can enhance the hardness of a hard coating film, the thickness of the hard coating film is reduced, and the bending performance of the flexible display panel is improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

EPS (Expandable Polystyrene) lightweight aggregate concrete and preparation method thereof

The invention provides EPS (Expandable Polystyrene) lightweight aggregate concrete and a preparation method thereof. The EPS lightweight aggregate concrete effectively meets the requirements of concrete on light weight, uniformity and density in the aspect of structure, and simultaneously has excellent comprehensive properties; the volume weight of the EPS lightweight aggregate concrete is higher than 650 kg / m<3>, the cube compressive strength can reach 1.6MPa, the strength meets the service requirements, and the lightweight aggregate concrete has excellent thermal properties and durability; and shown in a compression test, the concrete has larger deformation before the concrete is damaged due to deformation, so that the toughness of the concrete is improved. The lightweight aggregate concrete comprises the following raw materials in parts by weight: 350 parts of cement, 90-120 parts of fly coal ash, 30-70 parts of silica fume, 120-140 parts of river sand, 190-210 parts of water, 15-21 parts of EPS grains, 40-60 parts of perlite and 12-18 parts of polymer emulsion. The preparation method comprises the steps of crusting, slurry wrapping, mixing, forming and curing. The lightweight aggregate concrete obtained according to the mixture ratio and the preparation method is uniform and dense in structure, and various properties meet the design requirements, so that the EPS lightweight aggregate concrete has better application prospects.

Owner:CHINA ELECTRIC POWER RES INST +1

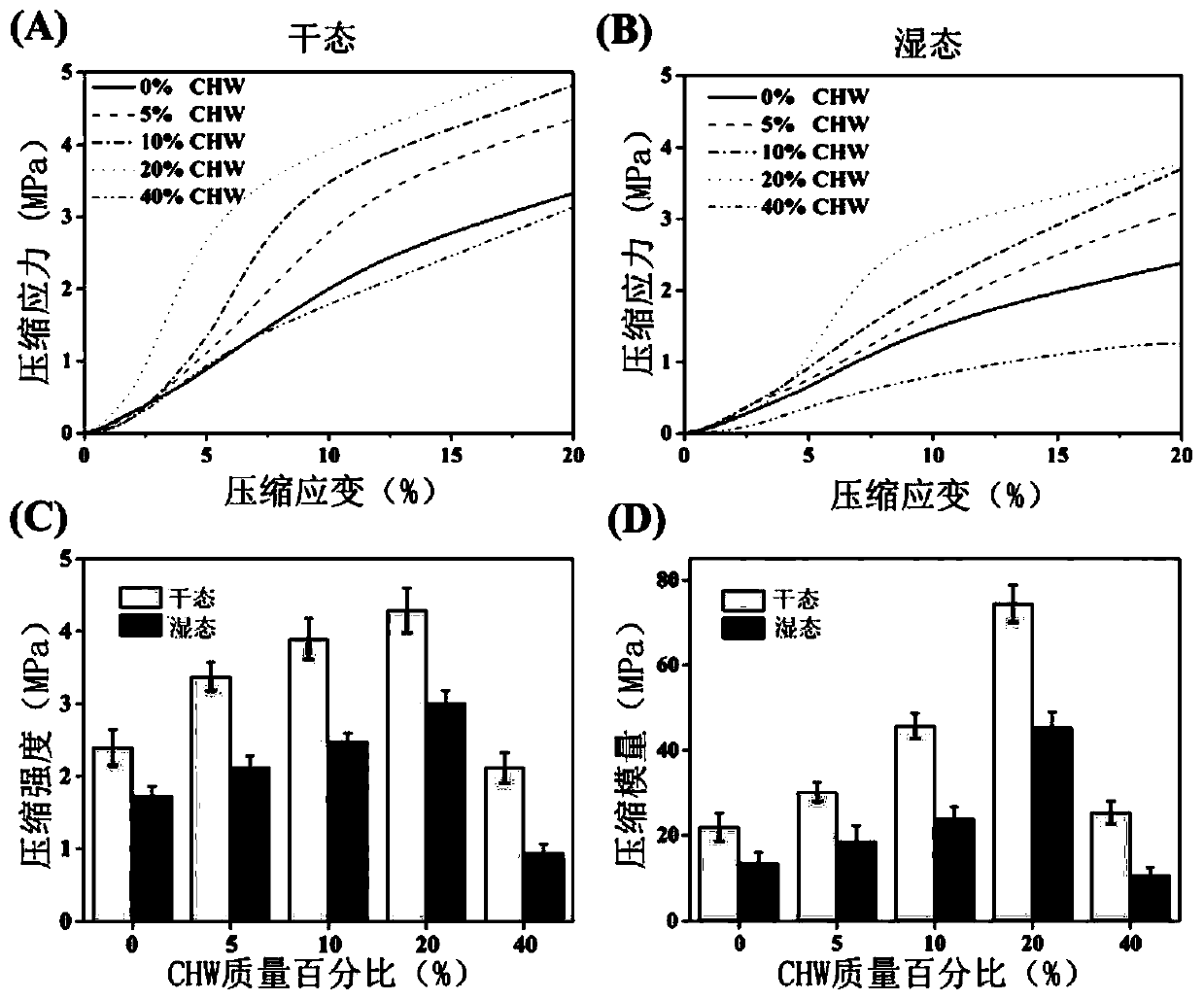

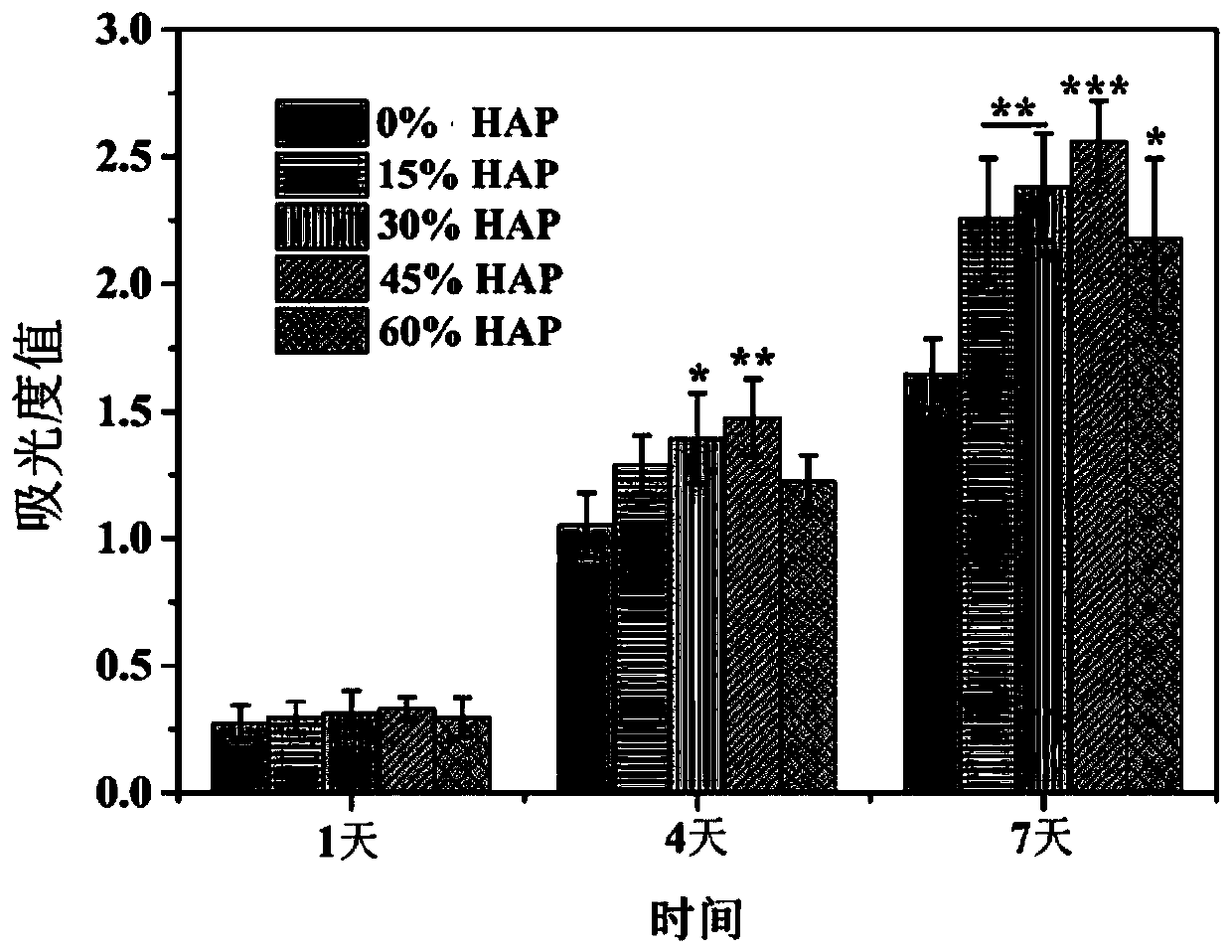

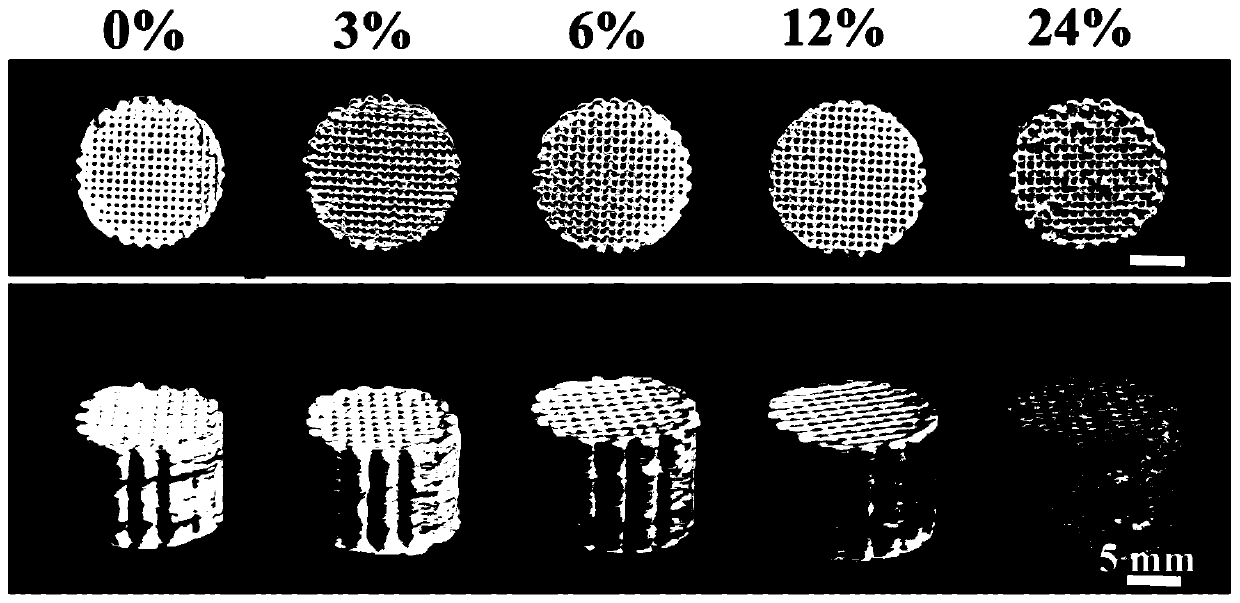

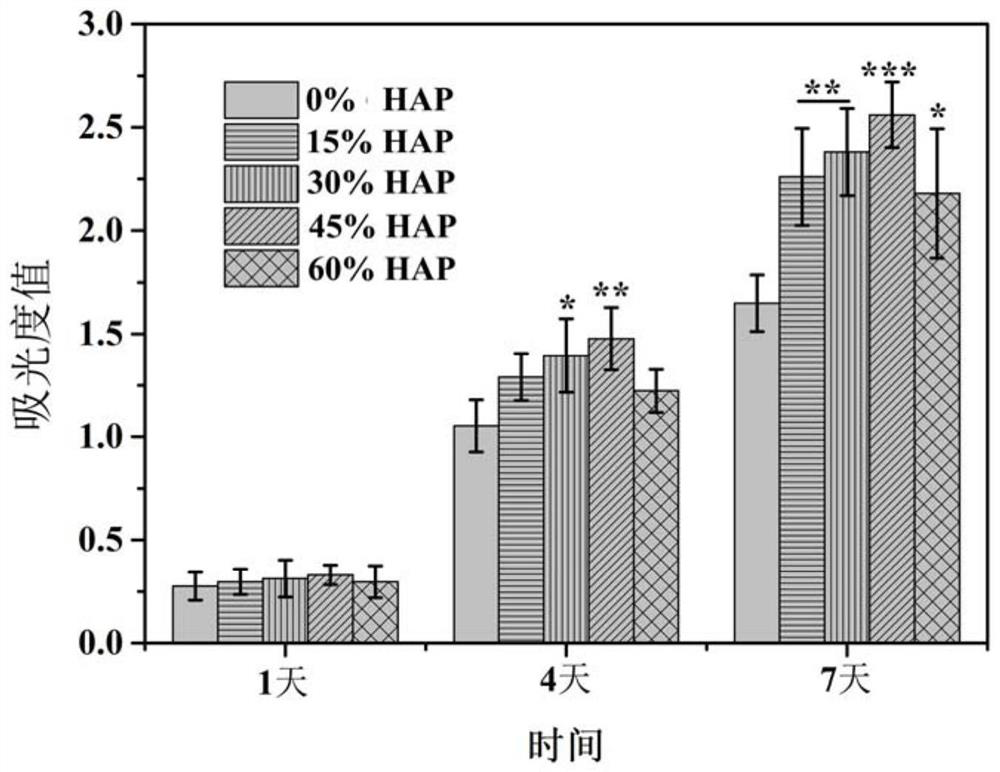

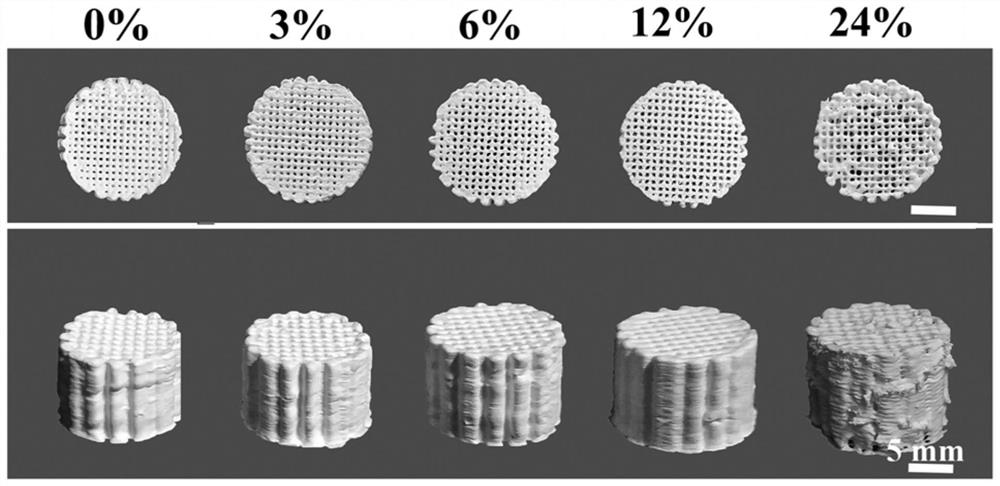

3D printing composite bio-ink material and preparation method and application thereof

ActiveCN110302419AGood printabilityEnhanced interface bindingAdditive manufacturing apparatusCoatingsBiodegradable polyesterMechanical property

The invention discloses a 3D printing composite bio-ink material and a preparation method and an application thereof. The components of the composite bio-ink material include biodegradable polyester,a reinforced toughener, and a ternary solvent system. The ternary solvent system contains 40 to 90% of an organic solvent, 5 to 45% of a surfactant, and 5 to 45% of a plasticizer. Compared with a single low-boiling organic solvent system, the ternary solvent system not only improves the printability of the composite bio-ink, but also improves the interface combination between a biodegradable polyester matrix and a reinforcing toughener. Moreover, the interface bonding between fiber layer and the layer during printing is enhanced, and the good three-dimensional structure and mechanical properties of the 3D printing composite porous support can be imparted. In addition, the used reinforcing toughener can further improve the mechanical properties and osteogenic activity of the biodegradable polyester, and imparts excellent bone-promoting ability to repair the composite porous scaffold.

Owner:JINAN UNIVERSITY

Clothes hanger with mosquito repelling effect and preparation method thereof

ActiveCN113150488AGood compatibilityImprove interface bondingConjugated cellulose/protein artificial filamentsVegetal fibresFiberPolystyrene

The invention relates to the field of plastic products, and particularly discloses a clothes hanger with a mosquito repelling effect and a preparation method thereof. The clothes hanger with the mosquito repelling effect is prepared from the following components in parts by weight: 80 to 100 parts of ABS resin, 40 to 60 parts of PS (Polystyrene) resin, 15 to 20 parts of filler, 2 to 5 parts of light stabilizer, 8 to 20 parts of antioxidant, 30 to 50 parts of mosquito repelling fiber powder, 4 to 8 parts of plasticizer and 1 to 3 parts of styrene-maleic anhydride copolymer. The mosquito repelling fiber powder is prepared from the following components: mosquito-repelling plant powder, carboxymethyl chitosan, an antibacterial aromatic microcapsule finishing agent, polytetrafluoroethylene emulsion, soybean protein isolate, calcium gluconate and a polyurethane elastomer; the preparation method comprises the following steps: weighing raw materials; mixing, extruding and granulating the raw materials; melting and injection molding; the clothes hanger with the mosquito repelling effect has the advantages of being good in mosquito repelling effect, lasting in effect, good in antibacterial property and high in mechanical strength.

Owner:白坤玉

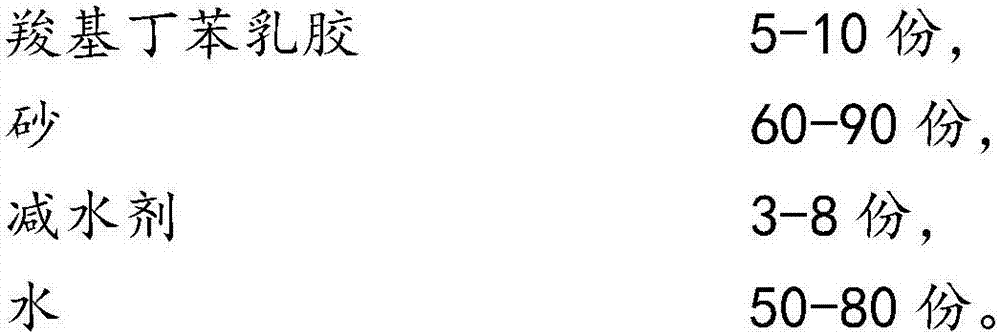

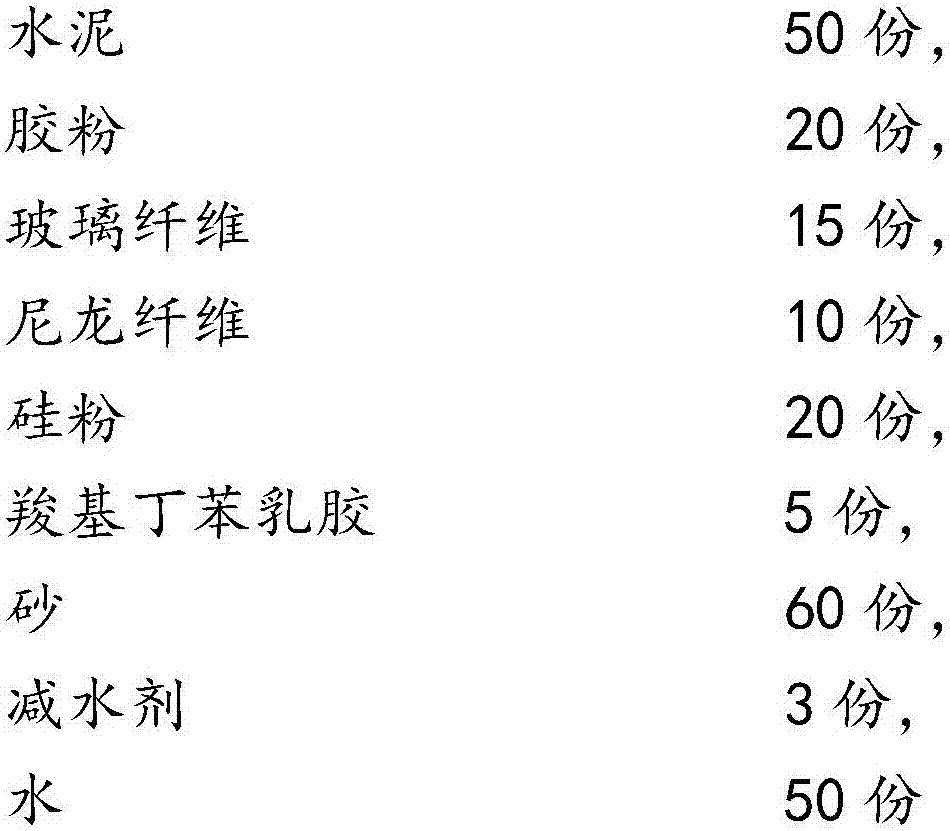

Novel bendable concrete

The invention discloses novel bendable concrete. The novel bendable concrete is prepared from the following raw materials in parts by mass: 50 to 100 parts of cement, 20 to 40 parts of gelatin powder, 15 to 30 parts of glass fibers, 10 to 20 parts of nylon fibers, 20 to 40 parts of silicon powder, 5 to 10 parts of carboxylated styrene-butadiene latex, 60 to 90 parts of sand, 3 to 8 parts of a water reducing agent and 50 to 80 parts of water. The novel bendable concrete disclosed by the invention has the characteristics of good strength, low elastic modulus, good flexibility and ductility, good heat-preservation and heat-insulation effect, good crack resistance and anti-impact strength and the like.

Owner:SUZHOU TANGSHI JIANHUA CONCRETE PILE

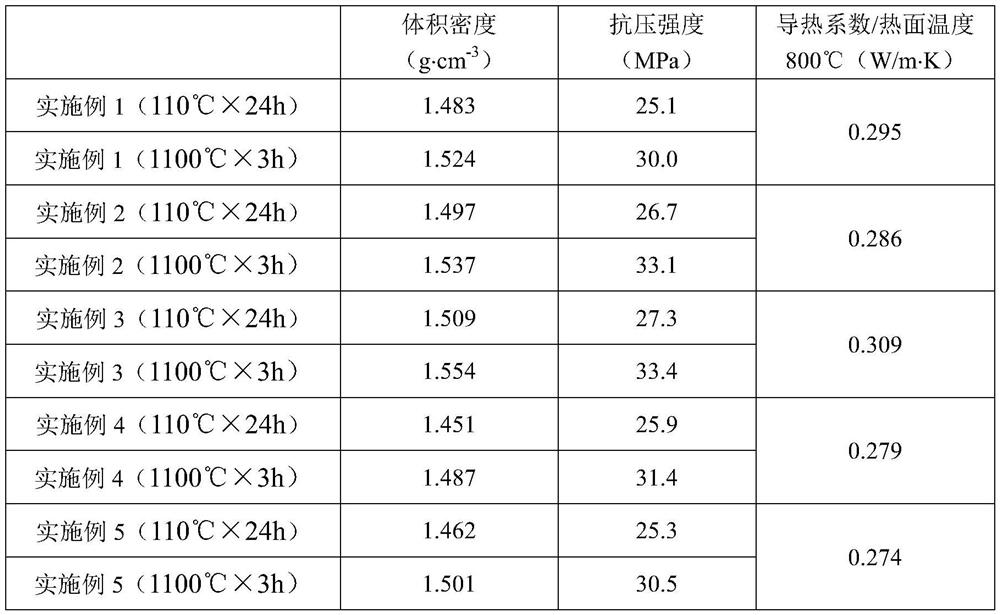

Lightweight high-strength refractory castable

ActiveCN113800894AImprove high temperature performanceImprove insulation performanceCeramicwareFiberInsulation layer

The invention discloses a lightweight high-strength refractory castable which comprises the following raw materials in percentage by weight: 25-35% of lightweight high-strength microporous alumina aggregate, 25-35% of alumina hollow spheres, 3-5% of floating beads, 5-8% of kyanite powder, 5-8% of calcined bauxite fine powder, 5-8% of silica powder, 6-9% of alpha-Al2O3 micro powder, 5-10% of alumina cement, 3-5% of refractory fibers, 0.1-0.3% of a composite water reducing agent and 0.02-0.05% of a water-based silicon polyether defoaming agent. The refractory castable can effectively reduce the water-cooling heat loss of a high-temperature water-cooling furnace roller of a thin slab continuous casting and rolling tunnel type heating furnace, improve the heat efficiency of the heating furnace and prolong the service life of a heat insulation layer of the furnace roller, and has the characteristics of stable performance, light volume weight, good mechanical property and excellent heat insulation performance and thermal shock resistance stability.

Owner:武汉钢铁有限公司

Polymer-based carbon conductivity macromolecule composite material

InactiveCN100514502CImprove interface bondingEvenly distributedNon-conductive material with dispersed conductive materialConductive polymer compositeConductive materials

The invention provides a polymer-based carbon-based conductive polymer composite material. The raw material composition mainly includes a polymer as a matrix of the composite material and a carbon-based conductive filler dispersed in the polymer. The matrix polymer and the carbon-based conductive filler are both Composed of no less than two different types of materials, and at least one phase of the polar polymer and the non-polar polymer in the polymer, the weight content of the carbon-based conductive material in the composite material is controlled within the range of 0.1 to 50%. . The present invention reduces the amount of filler and improves the conductivity of the material through the non-uniform distribution of the conductive filler in the two-phase polymer, and uses two carbon materials with different spatial geometry as the conductive filler to form a more complete and stable conductive network structure to further improve the electrical conductivity of the material. The invention has the advantages of low conductive filler content, high electrical conductivity, good processing performance and mechanical performance, high electrical conductivity, and flexible adjustment of processing performance and mechanical performance according to needs.

Owner:SICHUAN UNIV

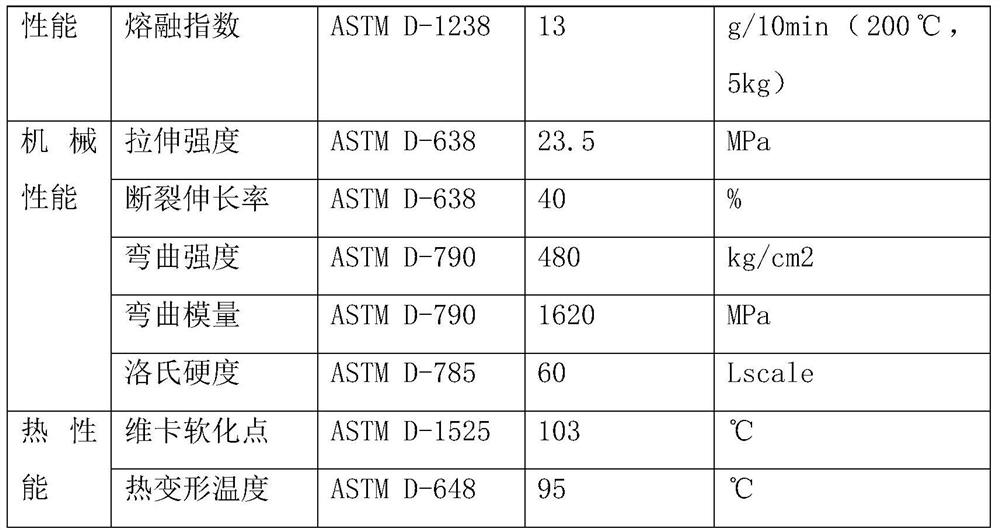

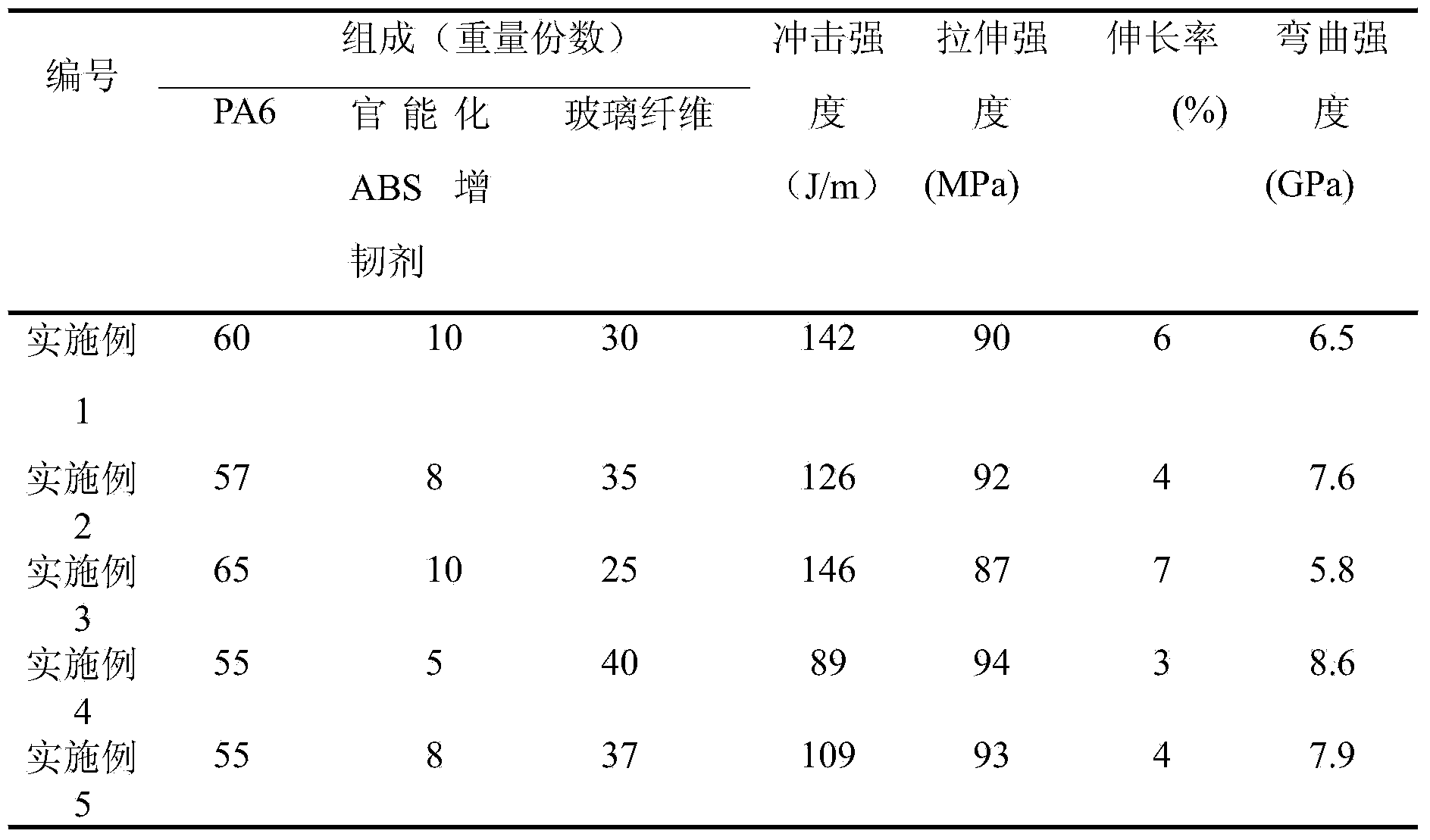

Polyamide (PA) composition

The invention provides a polyamide (PA) composition, belonging to the field of PA. The PA composition is used for solving the problems of the existing PA / ABS (Acrylonitrile-Butadiene-Styrene copolymer) alloy products that strength and toughness can not be improved simultaneously. The PA composition contains the following ingredients in percentage by weight: 55-65% of PA, 5-10% of functionalized ABS toughening agent and 25-40% of glass fibers. According to the PA composition, in the functionalized ABS toughening agent, a rubber phase and the glass fibers are dispersed into PA matrix resin, and GMA (Glycidyl Methacrylate) in functionalized ABS can react with terminal groups in PA, so that the interfacial adhesion force is increased, the interfacial adhesion for the glass fibers and a PA matrix is promoted, and the interfacial adhesion force of the glass fibers is increased, thus the prepared PA composition has relatively high strength and toughness. The PA composition provided by the invention has the advantages that the impact strength is not lower than 120J / m, the elongation at break is not lower than 3%, the tensile strength is not lower than 85MPa, and the bending strength is not lower than 5.5GPa.

Owner:CHANGCHUN UNIV OF TECH

Glass fiber impregnating agent for transparent plate

The invention discloses a glass fiber impregnating agent for a transparent plate, which basically comprises the following components in percentage by weight: 0.15-1.0 percent of silane coupling agent, 3.0-20.0 percent of binding agent, 0.02-1.0 percent of lubricating agent, 0.05-0.8 percent of antistatic agent, 0.1-2 percent of pH value adjusting agent and the balance of deionized water, wherein the binding agent is epoxy-ester emulsion or a mixture of PVAc emulsion and the epoxy-ester emulsion, and the contents of the PVAc emulsion and the epoxy-ester emulsion are calculated by respective solid content. The invention adopting the epoxy-ester emulsion or the mixture of the PVAc emulsion and the epoxy-ester emulsion as the binding agent can improve the glass fiber impregnating speed and the production efficiency; in addition, the light refractive rates of the impregnating agent and matrix resin are close, and the transmittance of the produced plate is high.

Owner:JUSHI GRP CO

Modified high performance concrete and preparation method thereof

Relating to the technical field of concrete materials, the invention provides a modified high performance concrete and a preparation method thereof. The modified high performance concrete is preparedform the following raw materials: cement, modified broken stone, fly ash, modified zeolite, ultrafine quartz tailing powder, asbestos wool, epoxy resin, citric acid, a toughening agent, a water reducing agent, dimethylformamide, hydroxypropyl-beta-cyclodextrin, and water. The modified high performance concrete provided by the invention has good durability, strength, crack resistance, corrosion resistance, acid and alkali resistance, good internal structure compactness and good impermeability, is high performance concrete, and has long service life.

Owner:ANHUI YUTE CONCRETE STRUCTURE TECH

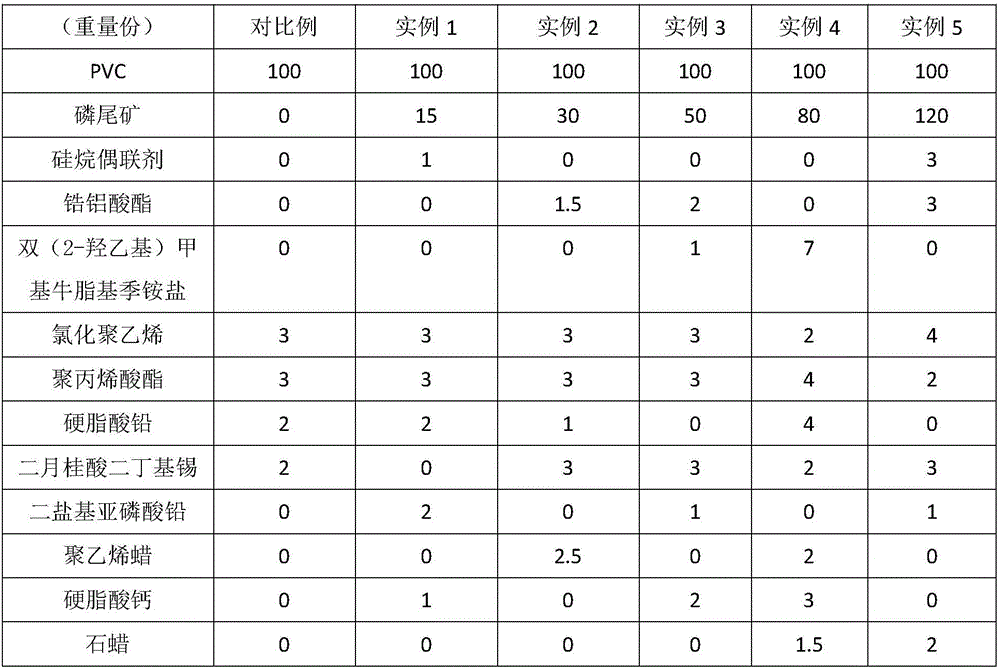

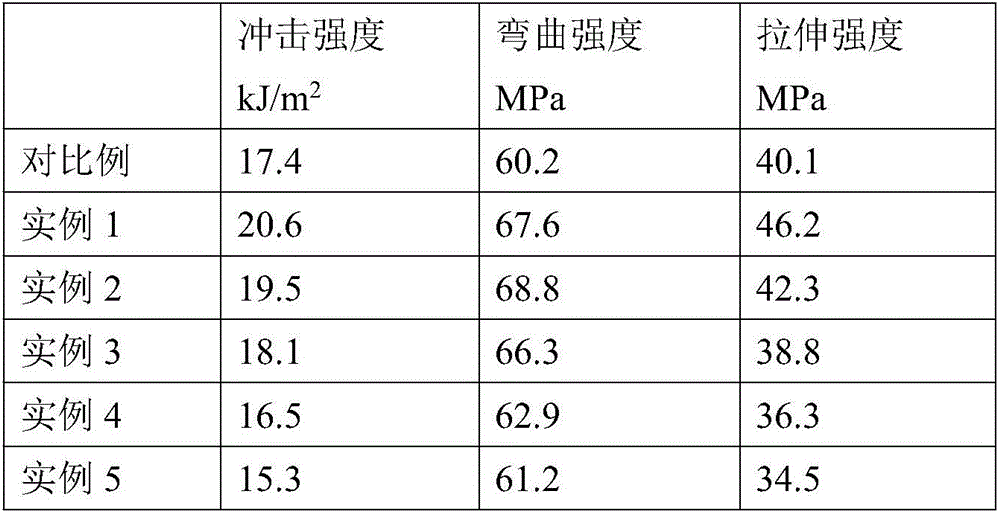

Phosphorus tailing/polyvinyl chloride composite material and preparation method thereof

The invention discloses a phosphate tailing / polyvinyl chloride composite material and a preparation method of the phosphate tailing / polyvinyl chloride composite material. The phosphate tailing / polyvinyl chloride composite material comprises the following components in parts by weight: 100 parts of polyvinyl chloride, 15 to 120 parts of phosphate tailings, 1 to 4 parts of surface modifiers, 3 to 8 parts of polymer modifiers, 3 to 7 parts of heat stabilizers, and 1 to 5 parts of lubricants, wherein the particle sizes of the phosphate tailings are below 200 meshes. The preparation method comprises the following steps: uniformly mixing the dried phosphorus tailings, polyvinyl chloride aggregates, the surface modifiers, the polymer modifiers, the heat stabilizers and the lubricants to obtain a premix, and adding the obtained premix to a twin-screw extruder to be extruded in a melting manner so as to obtain the phosphorus tailing / polyvinyl chloride composite material. According to the invention, phosphate flotation tailings are taken as fillers to lower the cost of the polyvinyl chloride, furthermore, organic flotation agents are attached on the surfaces of the phosphate tailings, so that interfacial adhesion between inorganic particles of the phosphate tailings and polyvinyl chloride matrix resin can be improved, furthermore, the mechanical properties of the composite material are enhanced, and the processing rheological properties thereof are improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Copper-based wide-temperature-range liquid-solid synergistic self-lubricating composite material with controllable porosity and preparation method of copper-based wide-temperature-range liquid-solid synergistic self-lubricating composite material

ActiveCN115418522AImprove tribological performanceImprove mechanical propertiesTransportation and packagingMetal-working apparatusFriction reductionLubrication

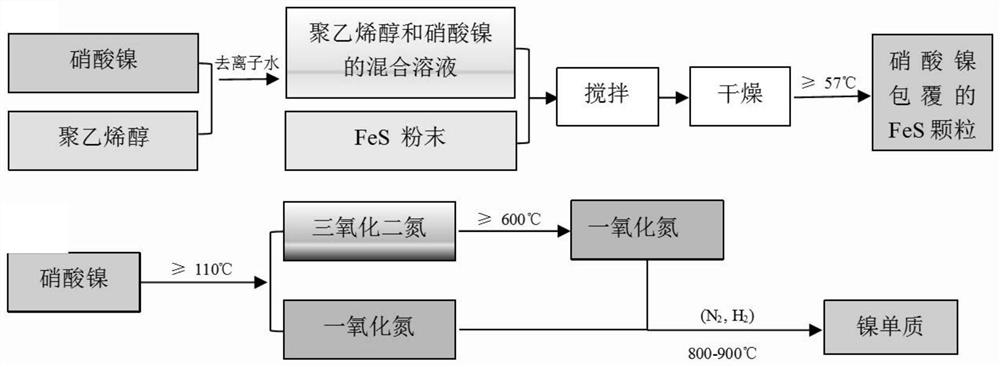

The invention discloses a porosity-controllable copper-based wide-temperature-range liquid-solid synergistic self-lubricating composite material and a preparation method thereof. The copper-based wide-temperature-range liquid-solid synergistic self-lubricating composite material is obtained by processing components including a copper alloy matrix, a solid lubricant, a liquid lubricant and the like. According to the method, nickel nitrate has a high decomposition temperature, firstly, FeS is subjected to nickel nitrate coating treatment and in-situ reaction in green body sintering to generate nickel-coated FeS, bonding of FeS and a copper alloy matrix is improved, high-temperature continuous reaction in the material sintering process can be met, gas is generated, uniform through holes are formed in the material, and the through holes are uniformly formed in the material; the porosity of the material can be regulated and controlled, the oil storage capacity can be improved, and the through holes are more beneficial to conveying lubricating oil to a friction interface so as to achieve better lubricating and antifriction effects. According to the method, the service conditions of the copper-based composite material are greatly widened, and a new scheme and thought are provided for research and development of a novel controllable-porosity copper-based wide-temperature-range liquid-solid synergistic self-lubricating composite material.

Owner:HEFEI UNIV OF TECH

A 3D printing composite bio-ink material and its preparation method and application

ActiveCN110302419BGood printabilityEnhanced interface bindingAdditive manufacturing apparatusCoatingsFiberActive agent

The invention discloses a 3D printing composite bio-ink material as well as a preparation method and application thereof. The composition of the composite biological ink material includes biodegradable polyester, reinforcing and toughening agent and ternary solvent system. Wherein, the ternary solvent system contains 40-90% of organic solvent, 5-45% of surfactant and 5-45% of plasticizer by mass percentage. Compared with a single low-boiling-point organic solvent system, the ternary solvent system not only improves the printability of the composite bioink, but also improves the interfacial bonding between the biodegradable polyester matrix and the reinforcing toughener, and enhances the printing process. The interfacial bonding between the middle fiber layer and the layer can endow the 3D printed composite porous scaffold with good three-dimensional structure and mechanical properties. In addition, the reinforced and toughening agent used can further improve the mechanical properties and osteogenic activity of the biodegradable polyester, endowing the composite porous scaffold with excellent ability to promote bone tissue repair.

Owner:JINAN UNIVERSITY

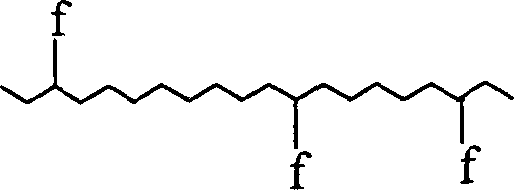

A kind of phosphorus tailings/polypropylene composite material and preparation method thereof

InactiveCN105906943BReduce manufacturing costImprove surface hydrophobicityPolypropylene compositesPolymer science

The invention discloses a phosphorus tailing / polypropylene composite material and a preparation method thereof. The phosphorus tailing / polypropylene composite material is prepared from the following raw materials in percentage by mass: 60-95 wt% of polypropylene and 5-40 wt% of phosphorus tailing. The particle size of the phosphorus tailing is 200 mesh or below. The melt index of the polypropylene is 4g / 10 minutes. The preparation method comprises the following steps: uniformly mixing the dried phosphorus tailing and polypropylene granules to obtain a premix; and adding the premix into the double screw extruder, and carrying out melt extrusion, wherein the double screw extruder is in an identical-direction parallel double-screw mode with the length-diameter ratio of 32:1-48:1. The method reduces the polypropylene resin consumption, and lowers the cost of the polypropylene composite material. The organic floatation aid attached to the phosphorus tailing surface can enhance the interface bonding property between the tailing inorganic granules and polypropylene matrix resin, thereby enhancing the mechanical properties of the composite material and changing the processing rheological properties.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A kind of chopped glass fiber sizing agent for bmc that strengthens thermosetting resin

The invention discloses a chopped glass fiber sizing agent for reinforcing thermosetting resin, which is prepared by the components by weight percent: (1) 0.2-1.5% of coupling agent; (2) 3.0-20.0% of binding agent that is cross-linked polyurethane emulsion or the mixture of the cross-linked polyurethane emulsion and medium and high molecular weight epoxy emulsion, wherein the contents of the cross-linked polyurethane emulsion and the medium and high molecular weight elastic epoxy ester emulsion are based on the respective solid content; (3) 0.0-1.2% of lubricating agent; (4) 0.05-0.8% of antistatic agent; (5) 0.1-2% of pH value conditioning agent; and (6) the balance of deionized water, wherein the total weight of all the components is 100%. The chopped glass fiber sizing agent improves the bundling property of chopped glass fiber, reduces the broken filament, improves the mixing uniformity and the fluidity of the glass fiber and the BMC resin paste, and improves the mechanical strength and the appearance performance of BMC products.

Owner:JUSHI GRP CO

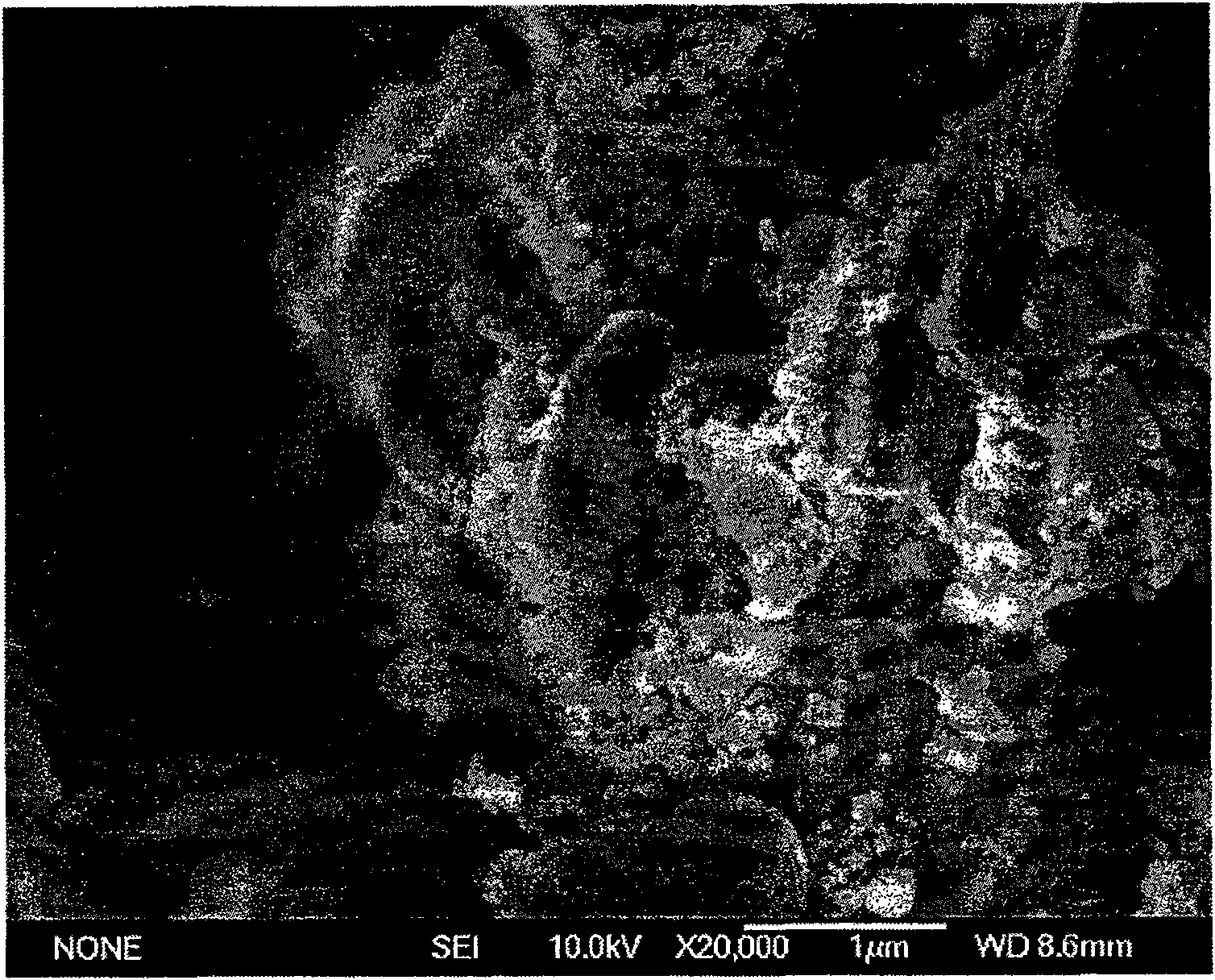

Method for preparing carbon covered nickel nano grain enhanced silver based composite material

InactiveCN100594258COvercoming the disadvantages of introducing foreign pollutantsSimple manufacturing processChemical vapor deposition coatingDeposition precipitationAlloy

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com