Functional polyolefin/montmorillonite nano-composite material and its preparation method

A technology for nanocomposite materials and montmorillonite nanosheets, which is applied in the preparation field of the above materials, can solve the problems of poor structural stability and difficult peeling of montmorillonite sheets, and achieves enhanced interface bonding, clear and controllable composition and structure. , to avoid the effect of inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

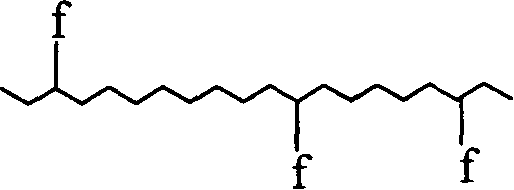

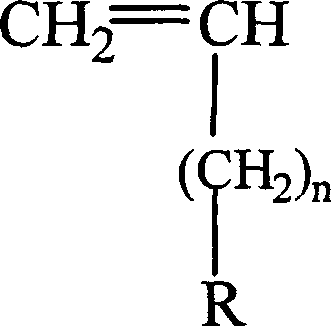

[0047] Preparation of the intercalation catalyst: 10 g of Na-montmorillonite was formulated into a 5%-20% suspension, settled still, and the upper suspension was taken for later use. Make a certain amount of cetyltrimethylammonium bromide (long carbon chain alkyl quaternary ammonium salt) into an aqueous solution, add it to the clay suspension, heat to 90°C, stir vigorously, and react for 4 hours. The solution was suction filtered to obtain a white precipitate, which was washed with deionized water until there was no Cl- (checked with 0.1% silver nitrate solution). The obtained product was vacuum-dried at 80° C. for 24 hours to obtain organic montmorillonite, which was ground into powder.

[0048] Under the protection of argon or nitrogen, disperse 5 g of the above organic montmorillonite in 300 ml of toluene at 60 ° C, add 20 ml of methylaluminoxane (MAO), stir for 6 hours, add 100 ml of toluene solvent and metallocene such as Et after filtration [Ind] 2 ZrCl 2 The toluene...

Embodiment 2-6

[0054] The preparation method of the intercalation catalyst of Examples 2-6 is the same as that of Example 1.

[0055] Example 2-6

[0056] Preparation of reactive polyethylene / montmorillonite nanocomposite intermediate: Others are the same as in Example 2, and the operating conditions and properties of the composite are listed in Table 1.

[0057] Preparation of functionalized polyethylene / montmorillonite nanocomposite material: Others are the same as in Example 2, and the operating conditions and properties of the composite material are listed in Table 2.

[0058] Reality

[0059] Example

[0060] The data in Table 1 shows that after the reactive polyethylene / montmorillonite nanocomposite intermediate is processed, the montmorillonite nanosheets are aggregated, and in-situ copolymerization is not easy to prepare structurally stable polyolefin nanocomposites. The data in Table 2 show that the obtained functionalized polyethylene / montmorillonite nanocompo...

Embodiment 7-9

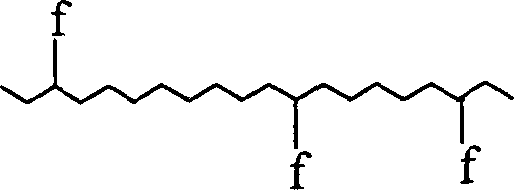

[0062] The preparation of intercalation catalyst: modifying agent is dioctadecyl dimethyl quaternary ammonium salt (long carbon chain alkyl quaternary ammonium salt), and other operating conditions are with embodiment 1.

[0063] Preparation of reactive polyethylene / montmorillonite nanocomposite intermediate: same as Example 2, 3 and 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com