Patents

Literature

36results about How to "Evenly distributed pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

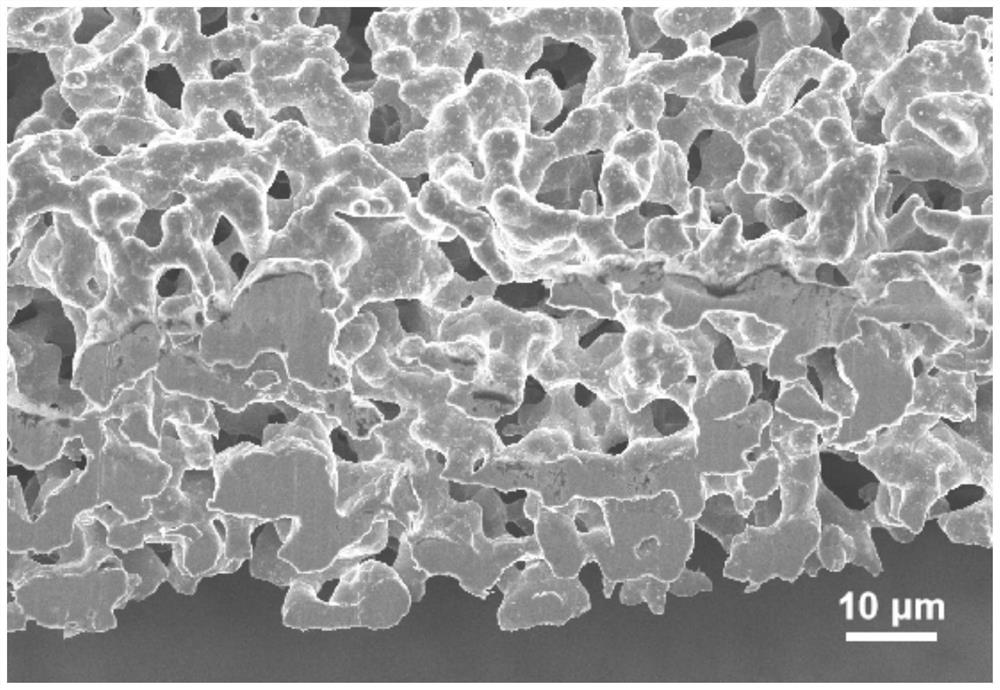

Lithium ion battery diaphragm, preparation method of lithium ion battery diaphragm and lithium ion battery

ActiveCN104157812ARequirements to ensure the strength of the diaphragmMeet the requirements of diaphragm strengthCell seperators/membranes/diaphragms/spacersSecondary cellsPorosityElectrical battery

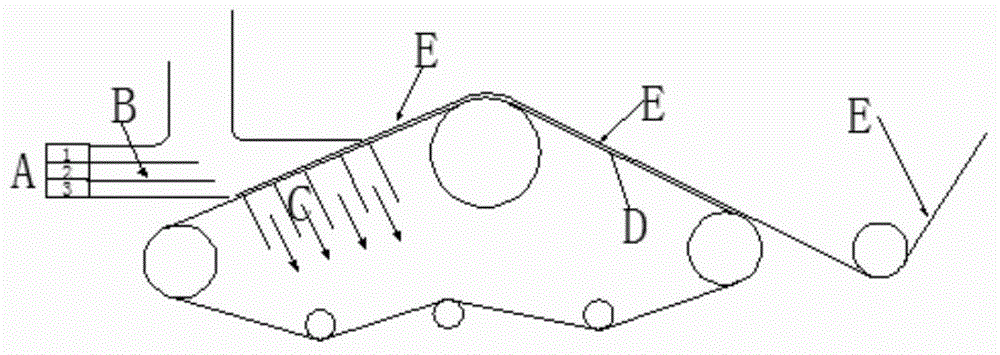

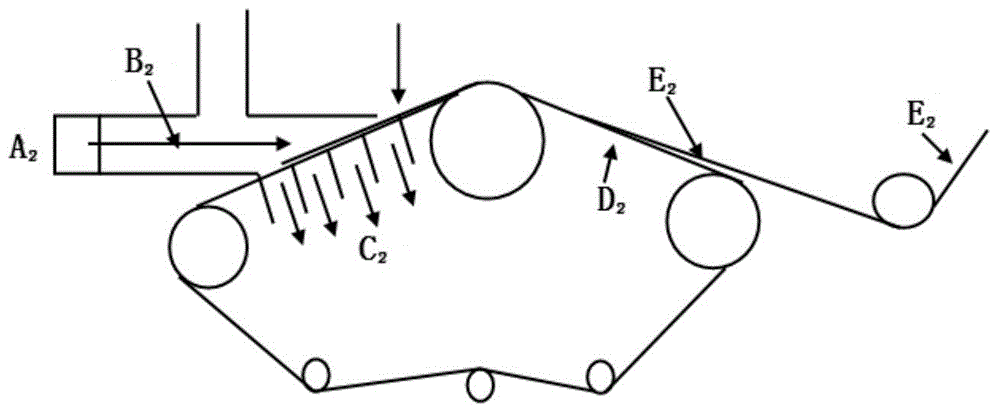

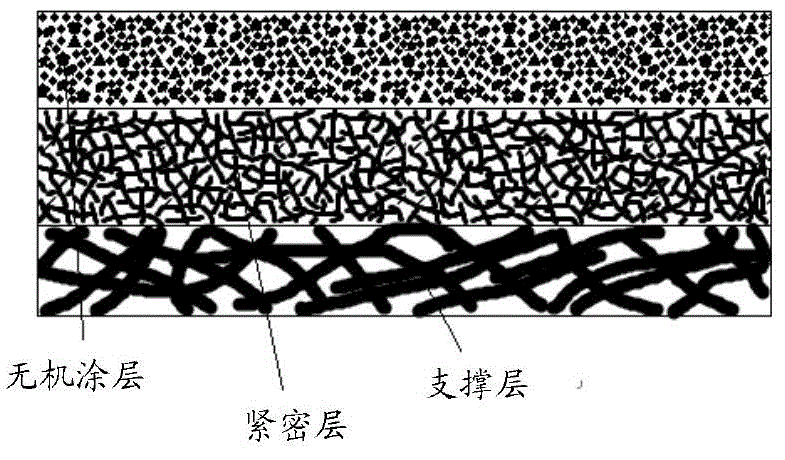

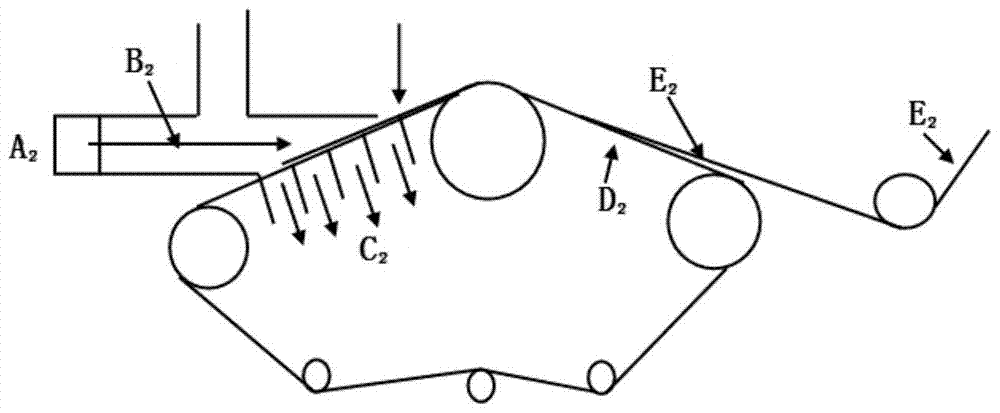

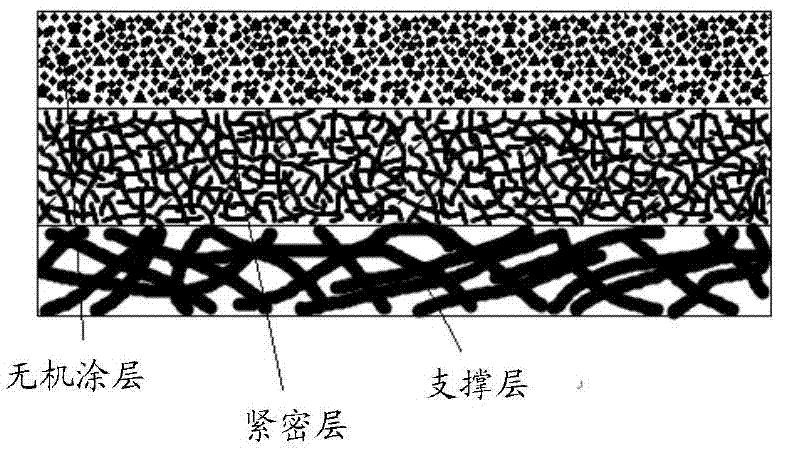

The invention provides a lithium ion battery diaphragm, a preparation method of the lithium ion battery diaphragm and a lithium ion battery. The lithium ion battery diaphragm comprises a support layer, wherein either or both of a dense layer or an inorganic coating are compounded on the support layer; the average quantity of the lithium ion battery diaphragm is 8-25g / m<2>, the thickness is 15-60 mu m, the average aperture is 50-500nm, and the porosity is 78-82%. The lithium ion battery diaphragm provided by the invention is good in isolating property and excellent in electrolyte absorbing property, is further relatively high in tension strength, is capable of realizing high power capacity of a battery, and can meet the requirement of rapid large-current charge and discharge of the lithium ion battery.

Owner:SOUTH CHINA UNIV OF TECH

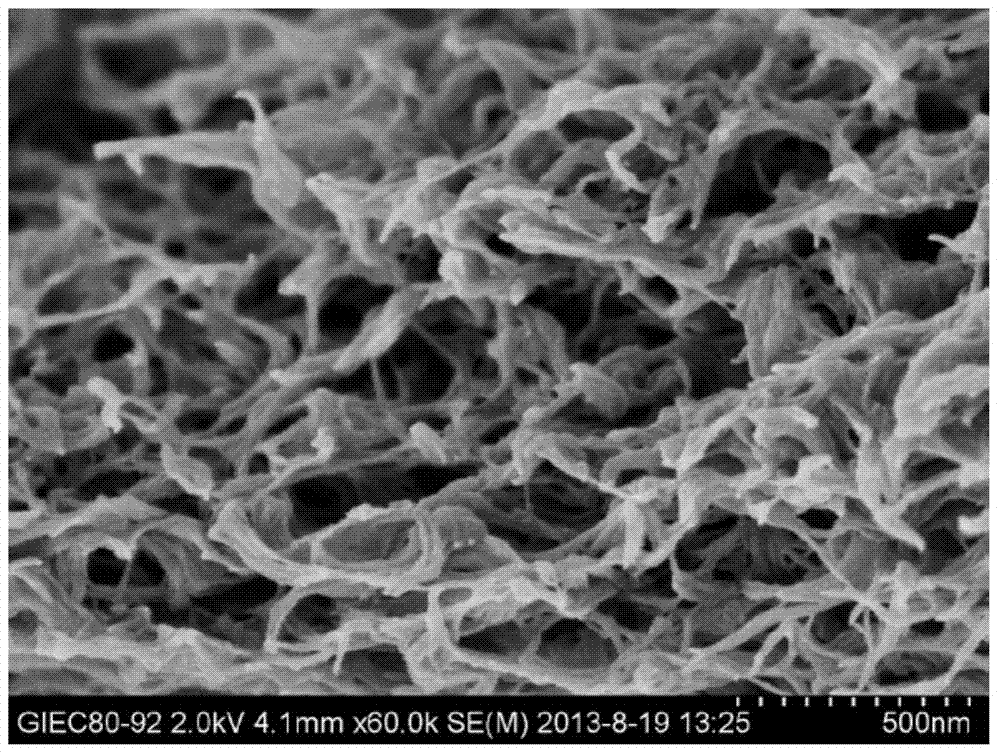

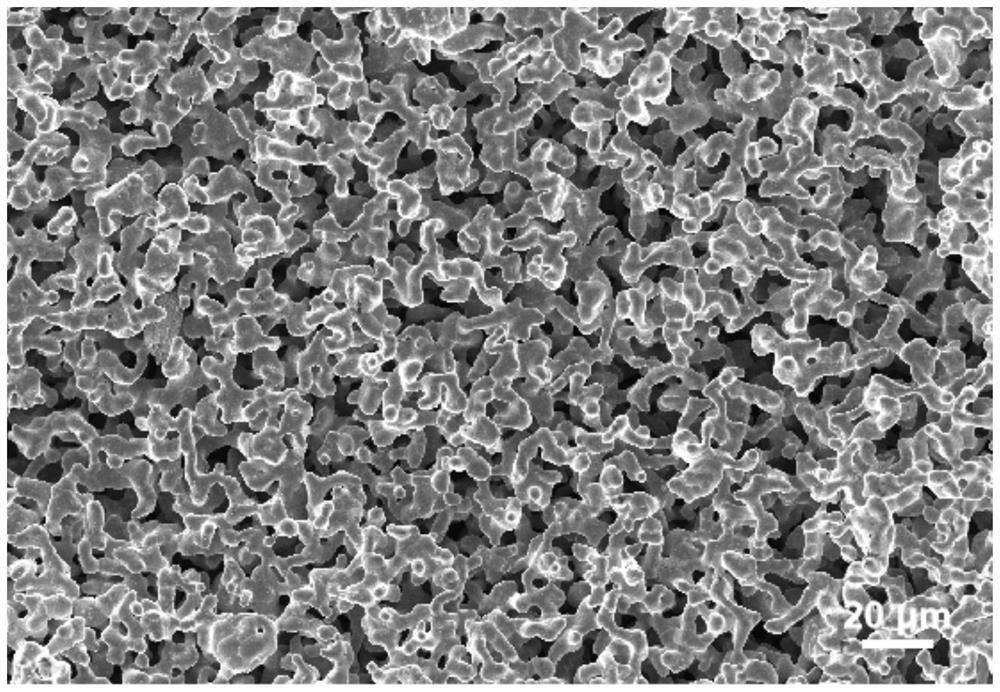

Kevlar nano fiber porous membrane, and preparation method and application thereof

ActiveCN103537198AEvenly distributed pore structureHigh porositySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSolventPorous membrane

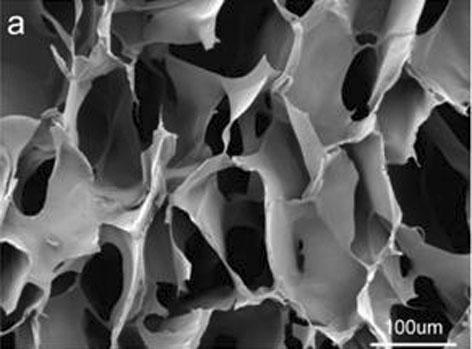

The invention belongs to the technical field of fiber membranes, and discloses a Kevlar nano fiber porous membrane which has high strength, high temperature resistance and solvent resistance, and a preparation method and application thereof. The preparation method comprises the following specific steps: dissolving Kevlar fibers in organic solvent, adding assistants and strong alkali, heating, and stirring to disperse, thus obtaining a Kevlar nano fiber dispersion; adding a pore forming agent into the dispersion, uniformly stirring to from a membrane casting solution, and performing vacuum degassing for later use; forming the membrane casting solution into a membrane on a glass plate through blade coating, evaporating the solvent, putting into a gel bath to obtain a gel membrane, and soaking in water; and performing heat treatment on the soaked gel membrane to obtain the Kevlar nano fiber porous membrane having high strength, high temperature resistance and solvent resistance. According to the invention, the Kevlar fibers are dispersed into nano fibers and then formed into the membrane through a mild method, so that the excellent properties of high strength, high modulus and solvent resistance are reserved; and a three-dimensional porous structure is endued. Thus, the Kevlar nano fiber porous membrane is applicable to water treatment in a harsh environment.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

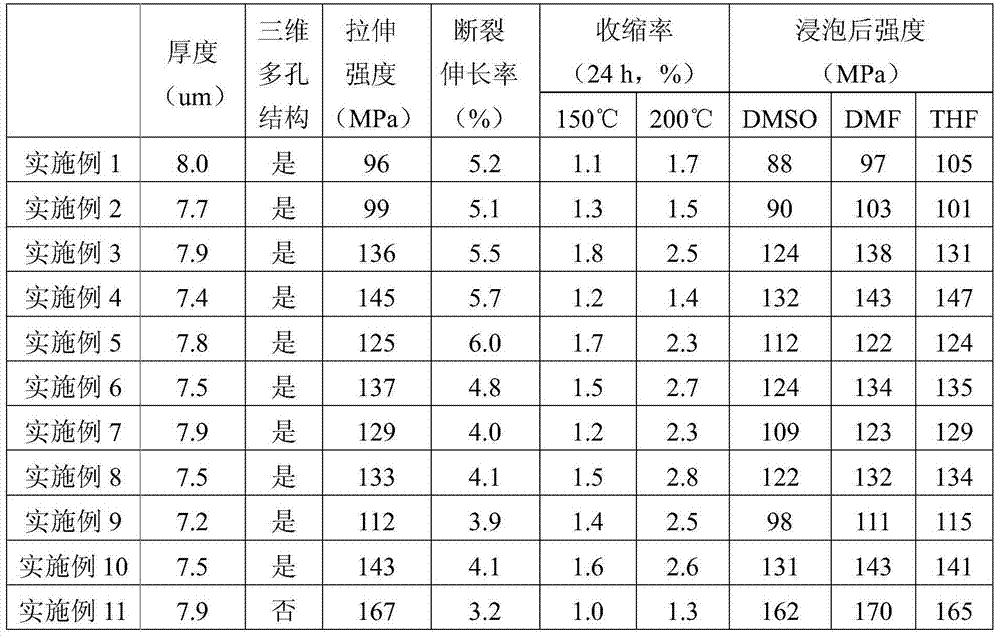

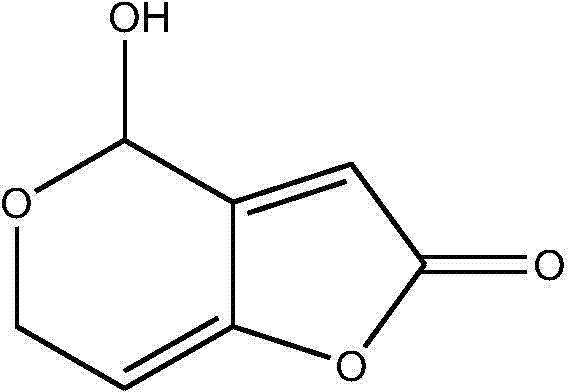

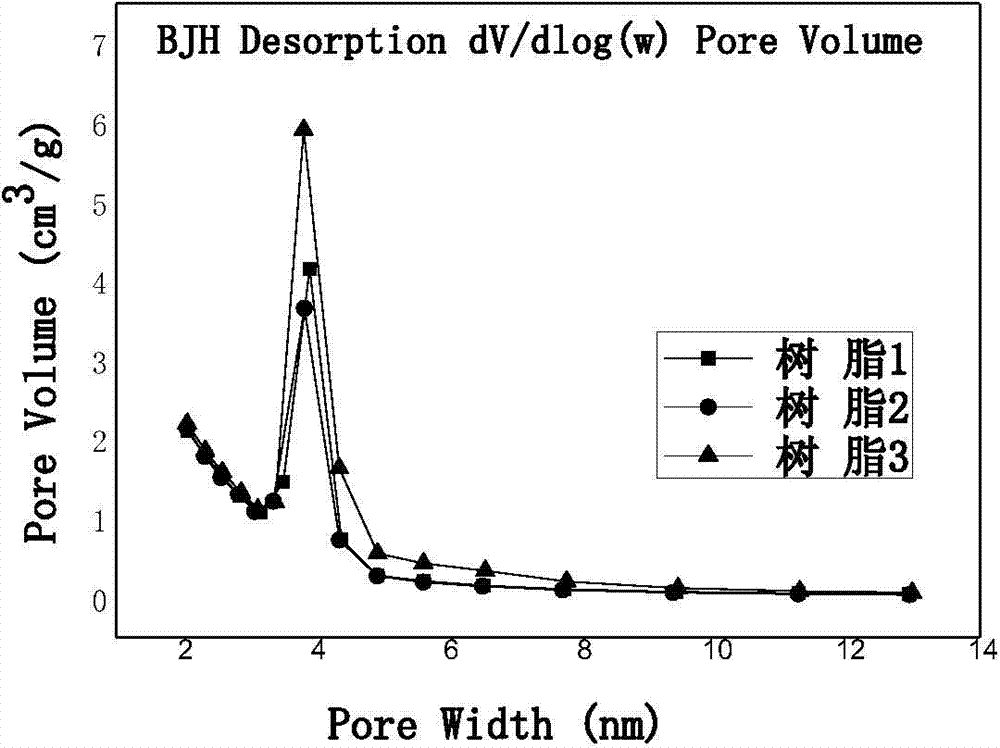

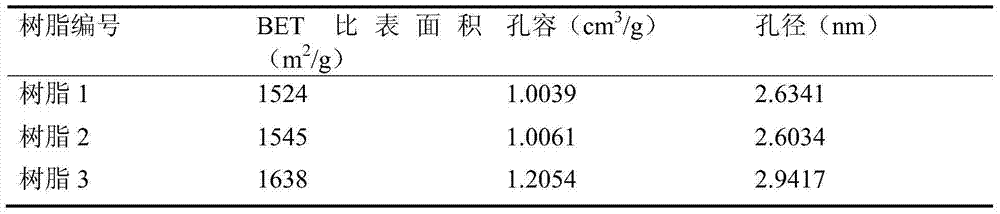

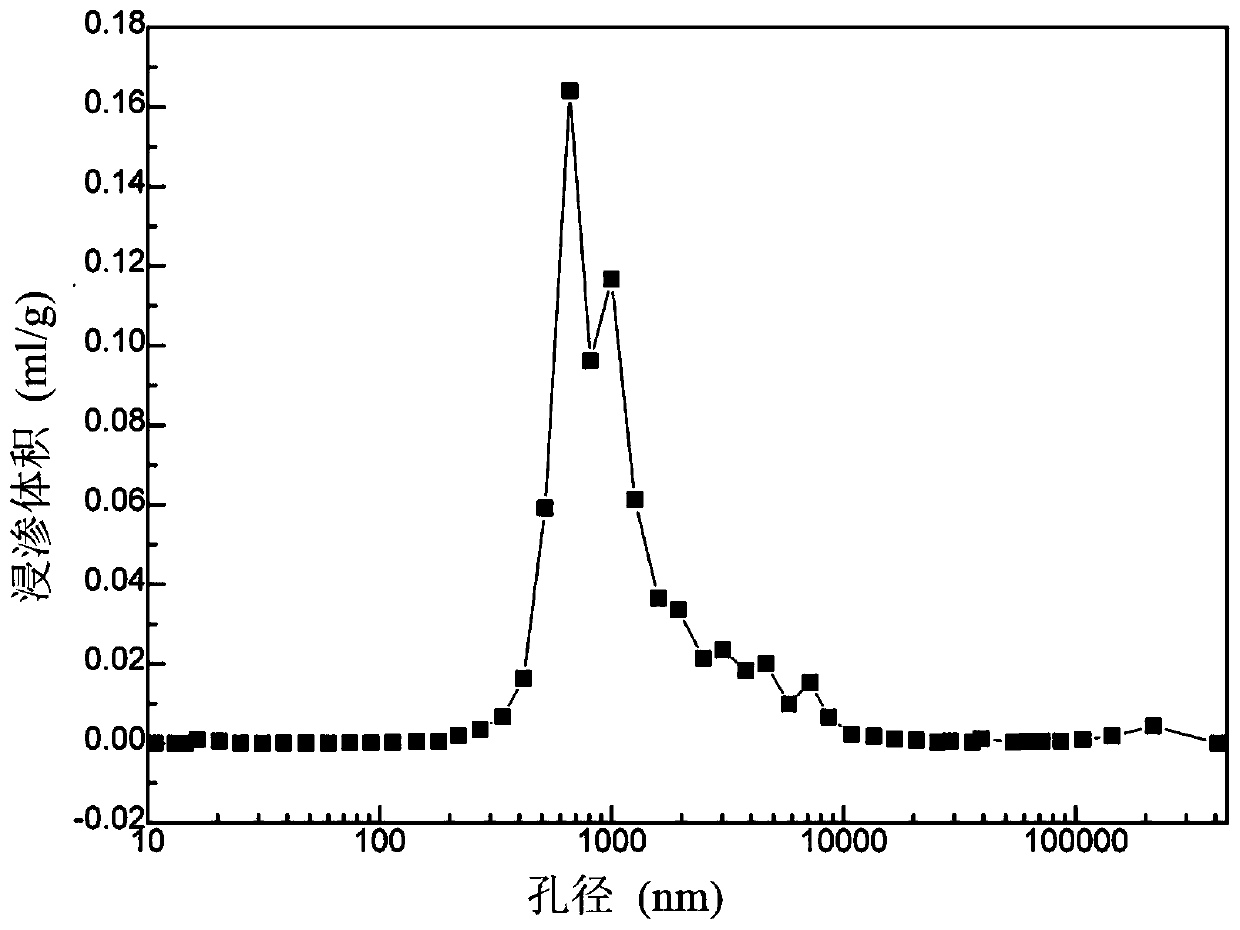

Ultrahigh cross-linked macro-porous adsorption resin applicable to removal of patulin

ActiveCN103772573ADense channelsUnique Pore Size DistributionIon-exchange process apparatusOther chemical processesCross-linkFunctional monomer

The invention provides ultrahigh cross-linked macro-porous adsorption resin which is obtained by taking a styrene monomer as a functional monomer, taking a multi-vinyl monomer as a cross-linking agent, suspending and polymerizing in the presence of a pore forming agent to obtain low-cross-linked macro-porous polystyrene white ball, reacting the obtained white ball with chloromethyl ether under the catalysis of lewis acid to obtain chloromethylation macro-porous polystyrene resin, and carrying out a Friedel-Crafts alkylation reaction on the obtained chloromethylation macro-porous polystyrene resin in the presence of a swelling agent by taking the lewis acid as a catalyst. Through adopting a novel cross-linking agent and pore forming agent system, the obtained resin has the advantages of high specific surface area and uniform pore diameter; the specific surface area is up to 1500-1800m<2> / g, the pore diameter distribution is uniform, a pore channel is dense and the average pore diameter is small; the pore diameter of the obtained macro-porous resin is rightly applicable to removal of patulin in juice and the removing efficiency is high; the resin can be used for pointedly removing the patulin which stably exists in the juice and the potential hazards on the human health, caused by the patulin in the juice, are solved; the ultrahigh cross-linked macro-porous adsorption resin has great social and economic benefits.

Owner:AMICOGEN CHINA BIOPHARM CO LTD

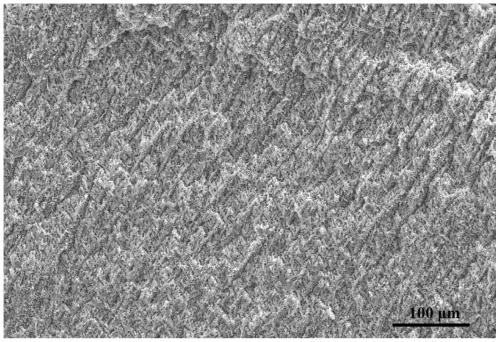

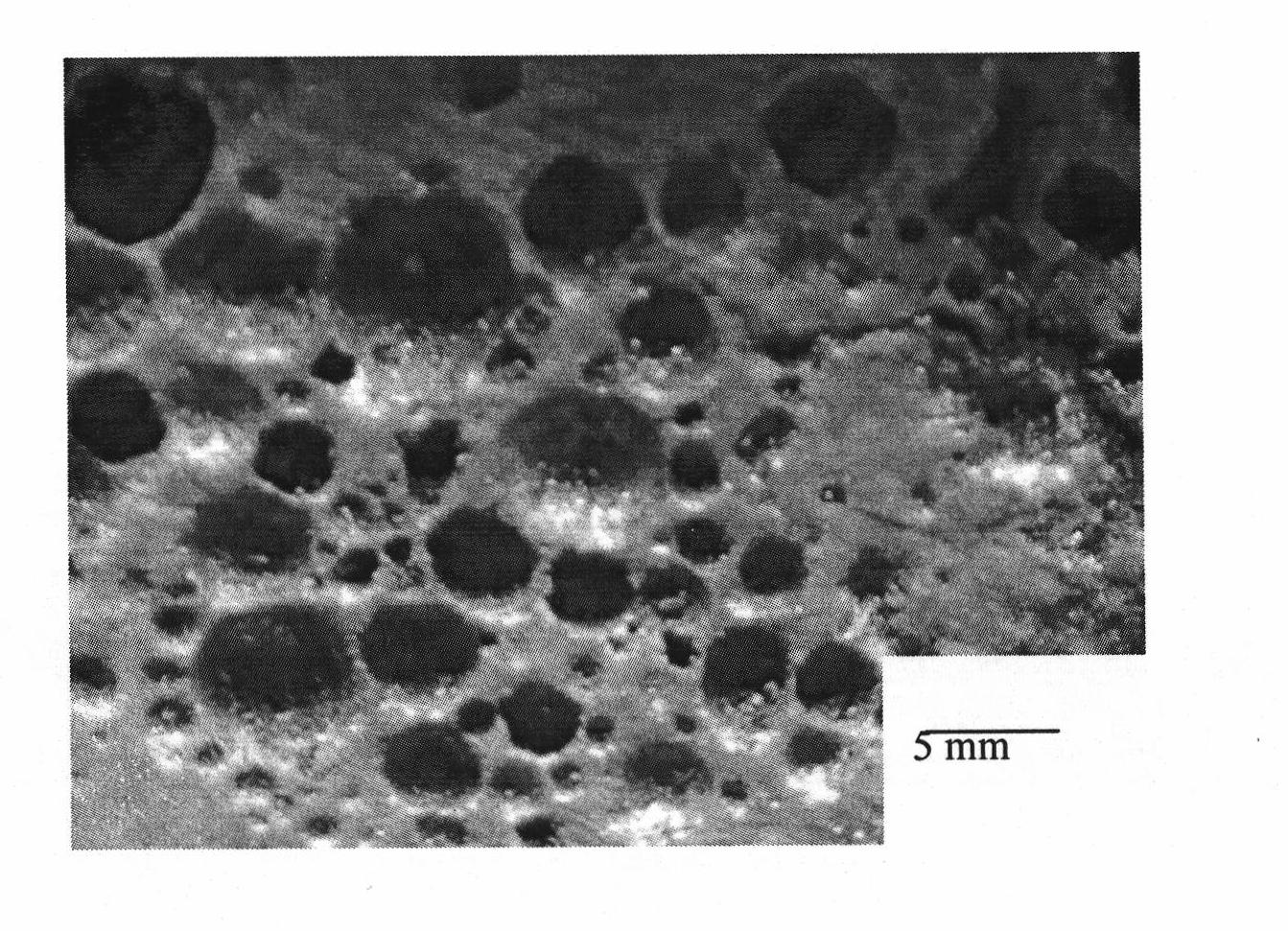

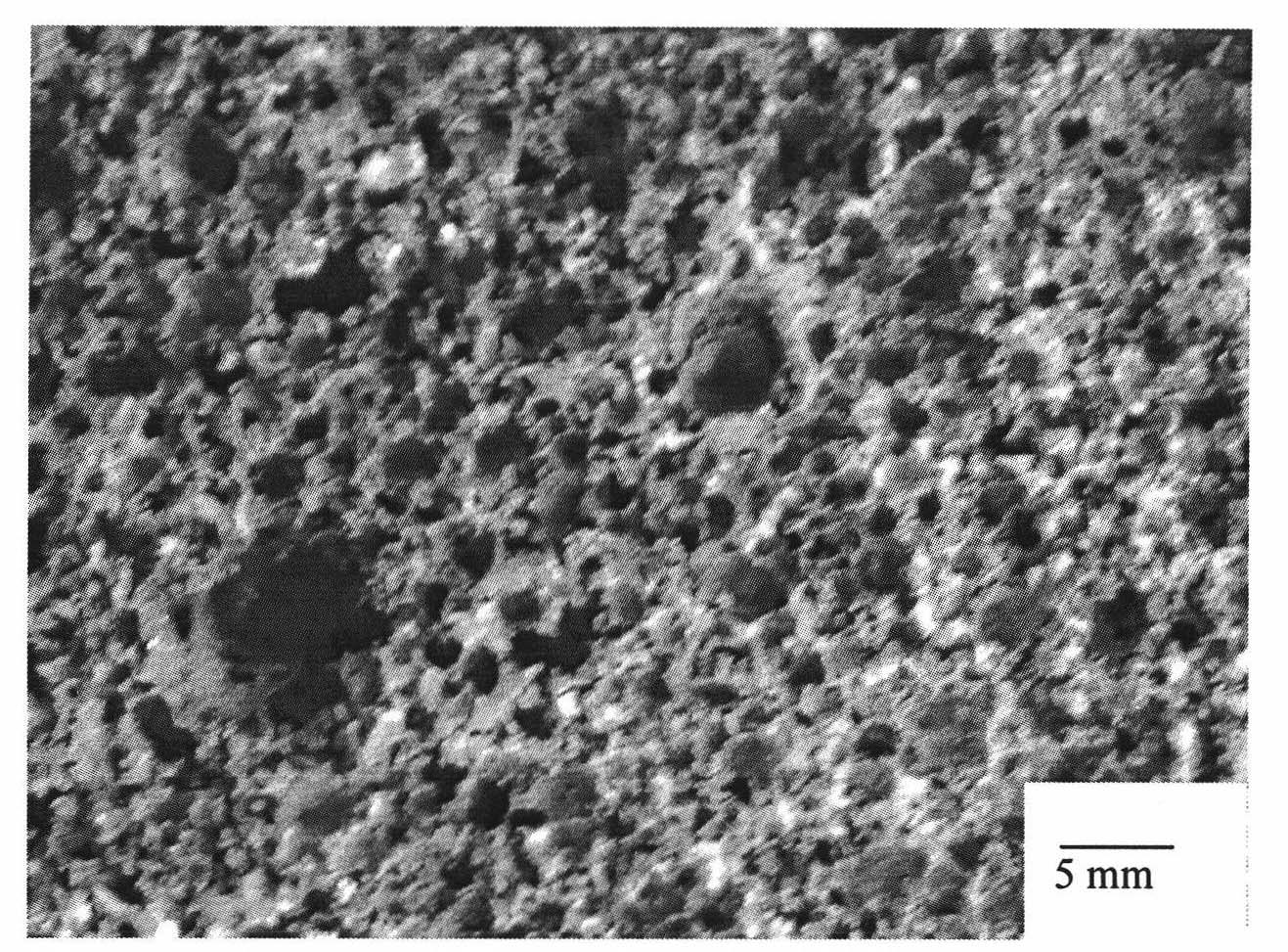

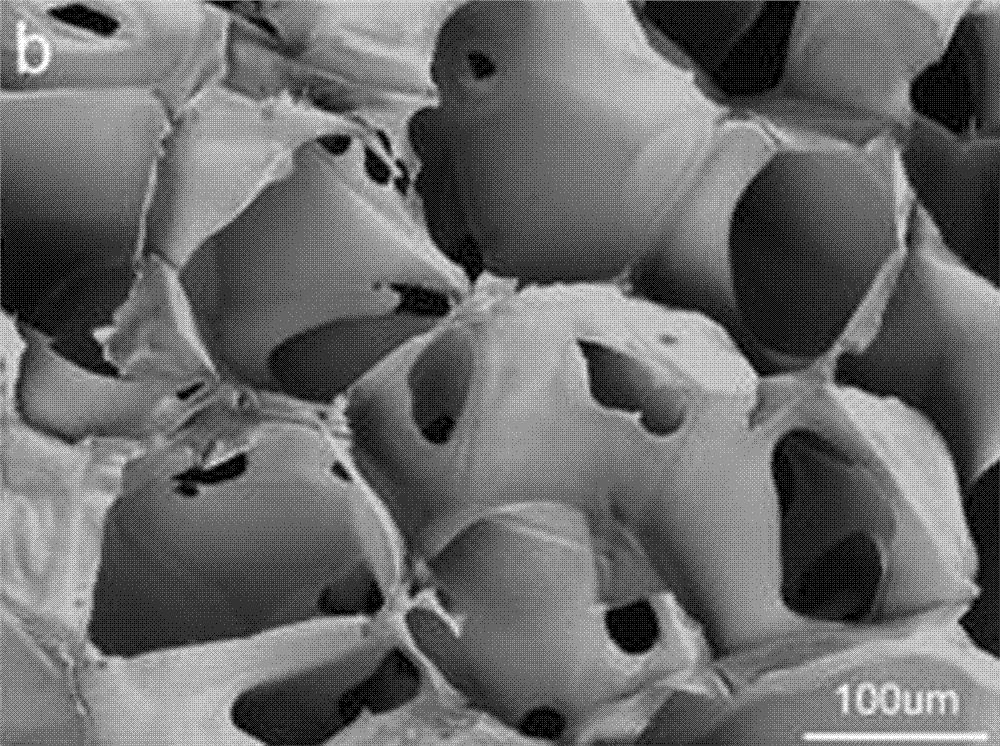

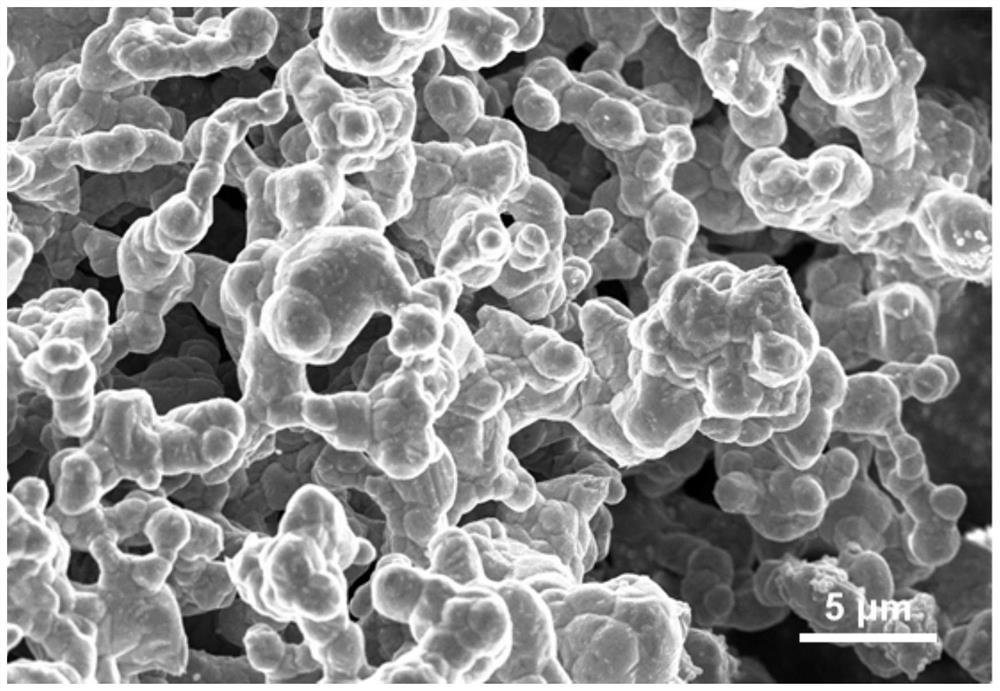

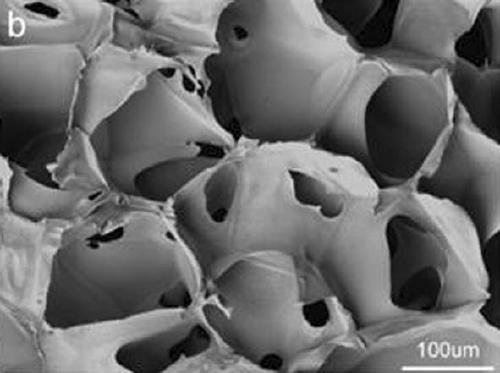

Preparation method of foamed copper

InactiveCN104087975AHigh porosityEvenly distributed pore structureLiquid/solution decomposition chemical coatingPorosityCopper plating

The invention discloses a preparation method of foamed copper to solve the problems of nonuniform pore structure distribution and small specific surface area of foamed copper obtained by existing foamed copper preparation processes. The method mainly comprises the steps of: (1) oil removal; (2) first coarsening; (3) second coarsening; (4) sensitization; (5) activation; (6) dispergation; (7) electroless copper plating; (8) step-by-step electroplating; and (9) heat treatment. The preparation method provided by the invention has the characteristics of simple technological steps, easily controllable process and low cost. By wholly optimizing the foamed copper preparation process, the obtained foamed copper has the advantages of high porosity, uniform pore structure distribution, large specific surface area, and good strength and toughness.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

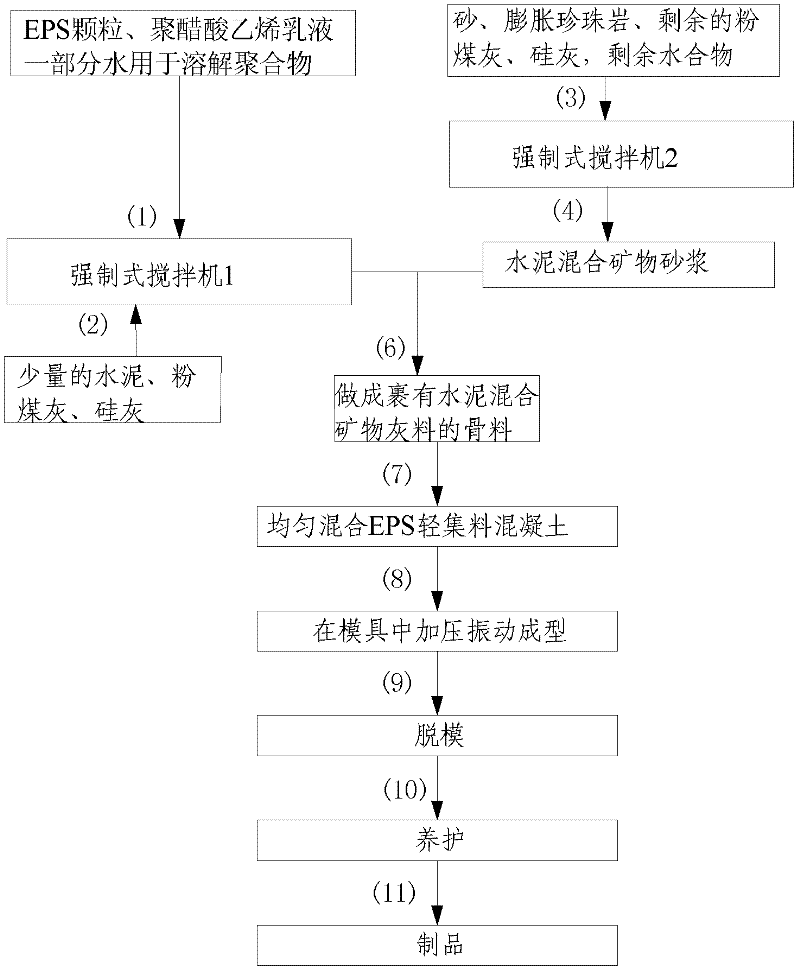

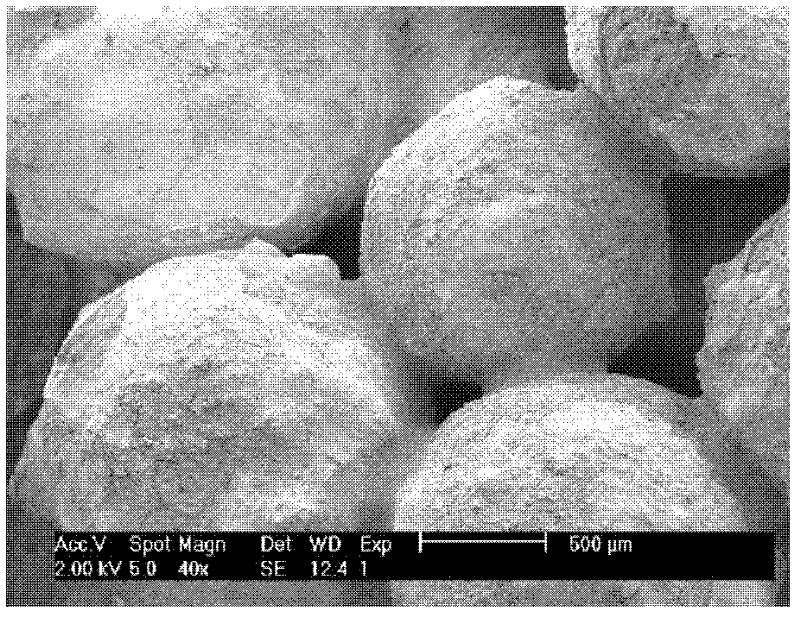

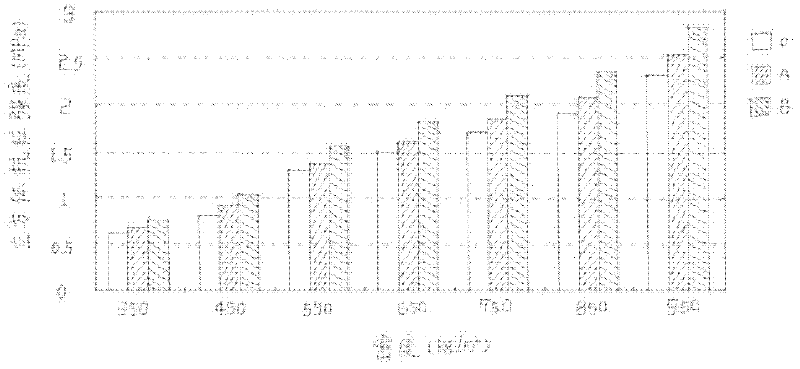

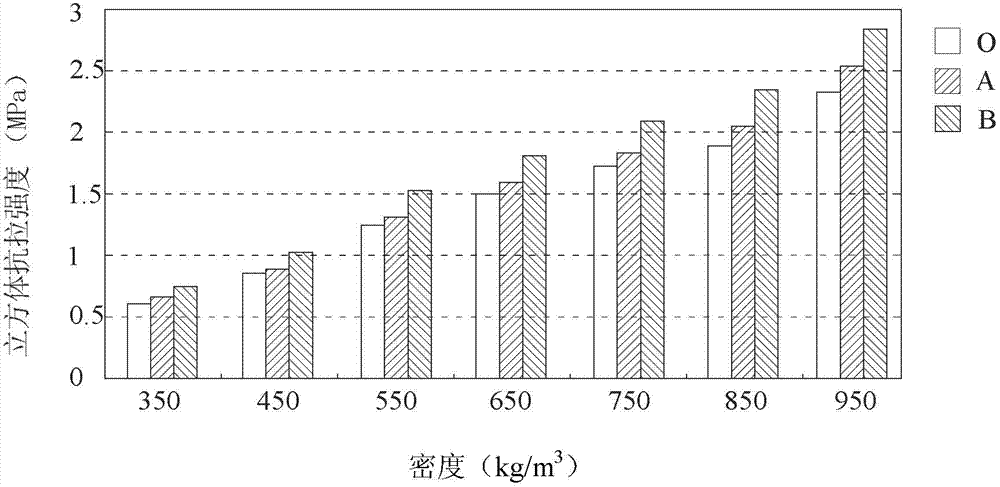

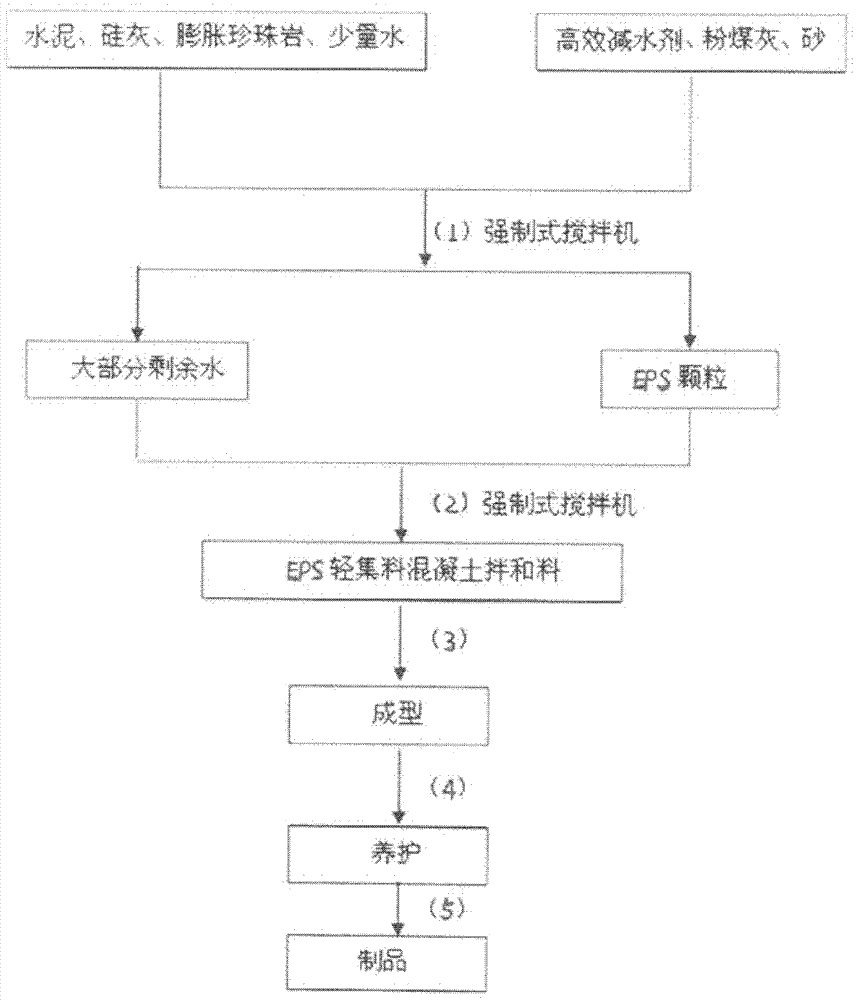

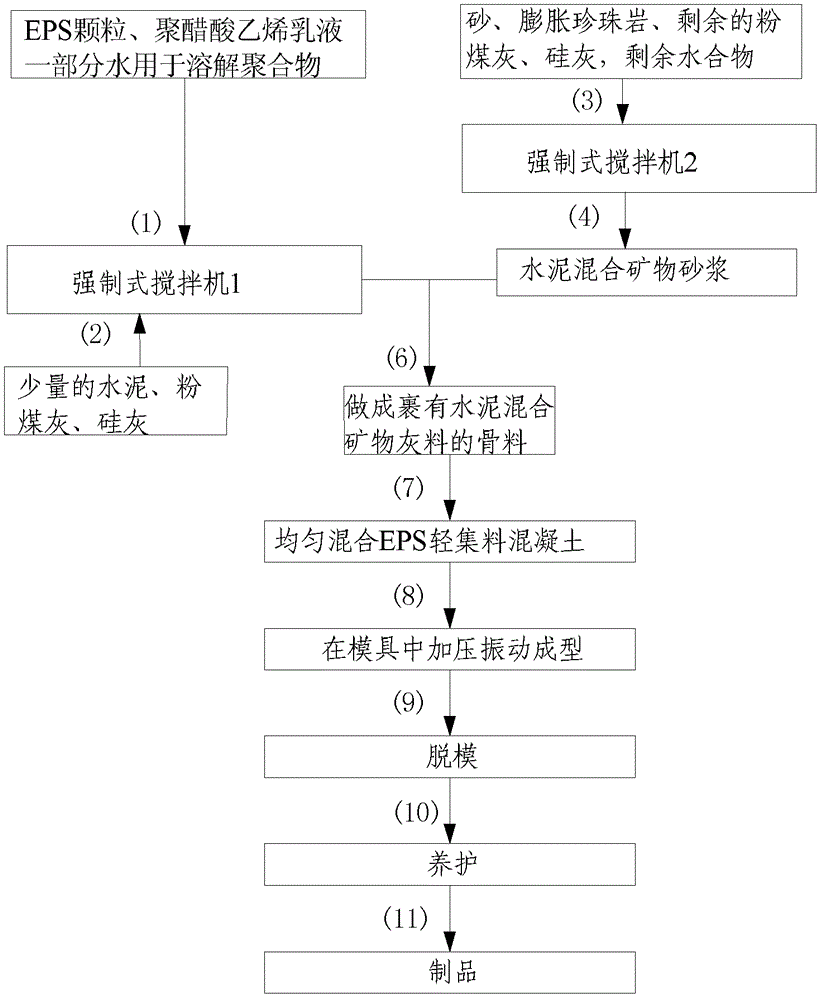

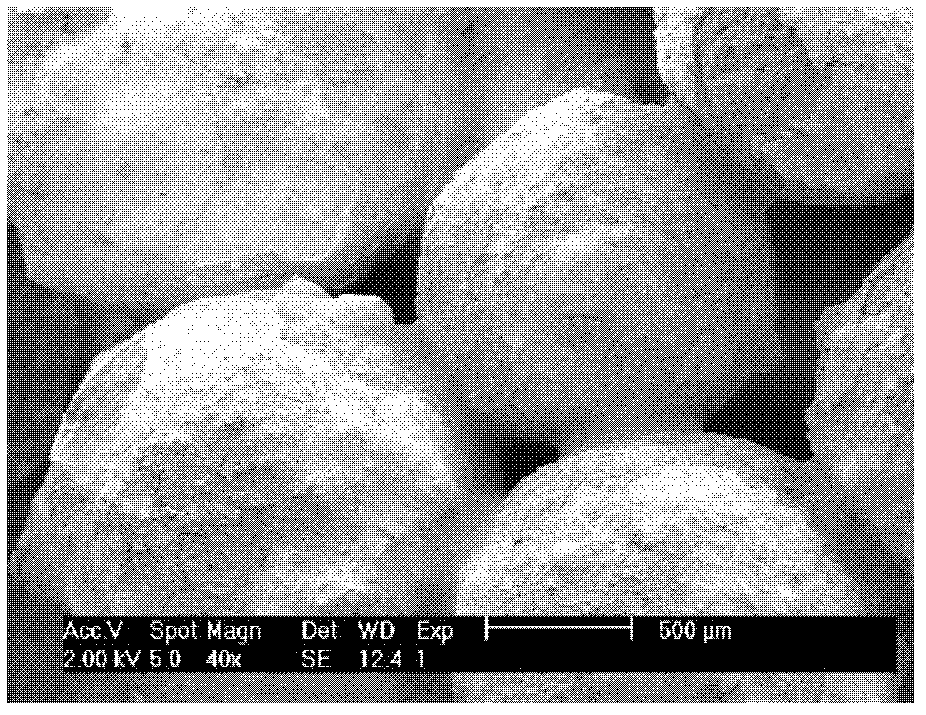

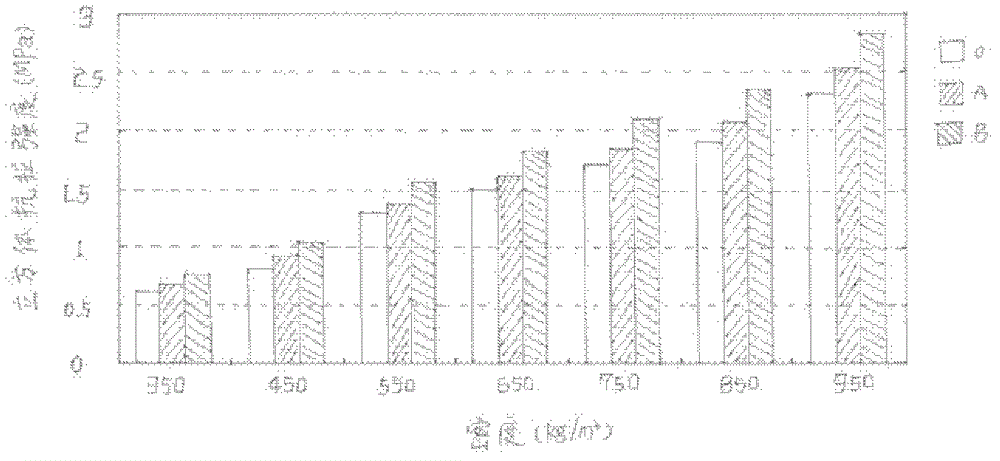

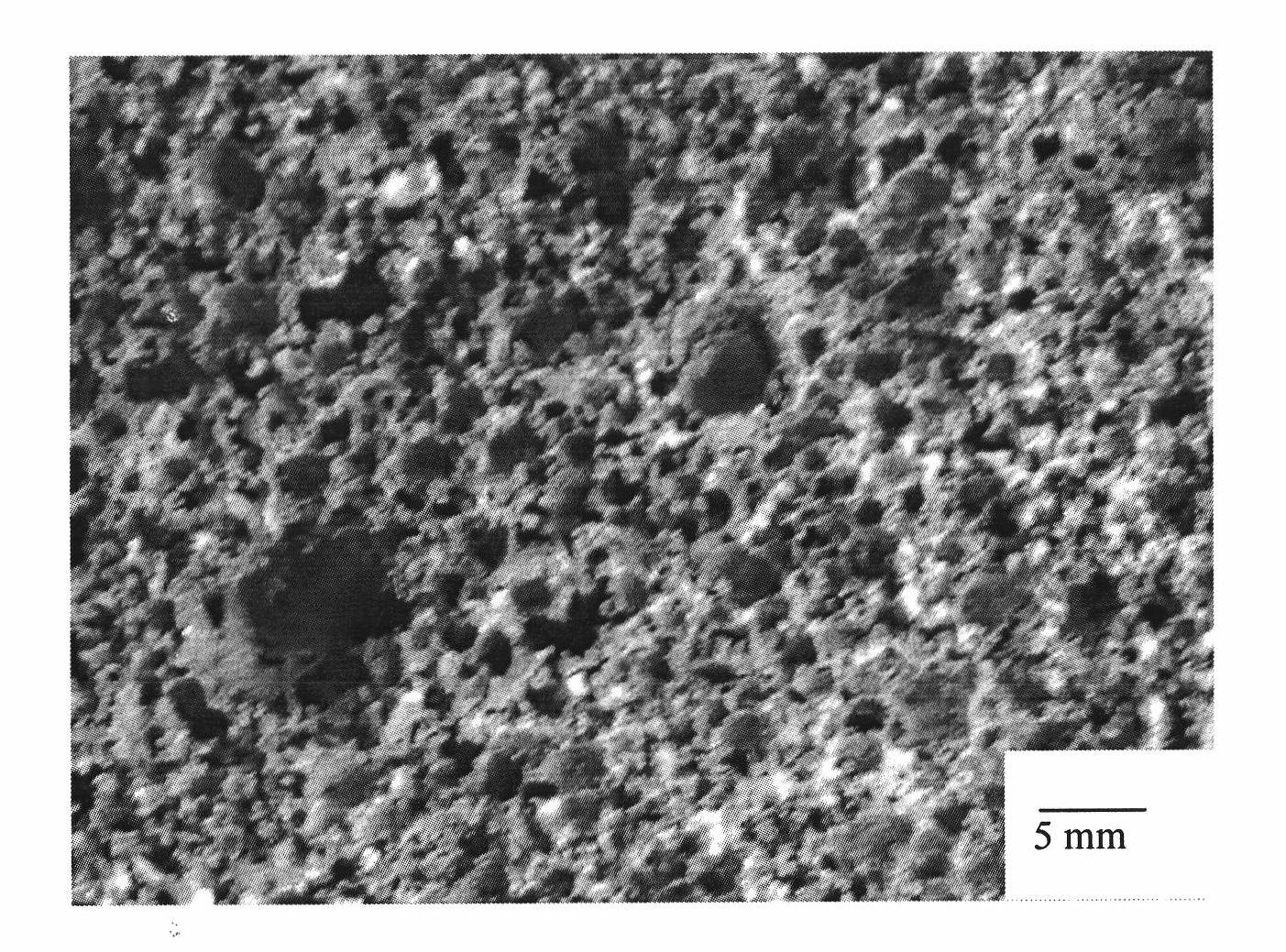

EPS (Expandable Polystyrene) lightweight aggregate concrete and preparation method thereof

The invention provides EPS (Expandable Polystyrene) lightweight aggregate concrete and a preparation method thereof. The EPS lightweight aggregate concrete effectively meets the requirements of concrete on light weight, uniformity and density in the aspect of structure, and simultaneously has excellent comprehensive properties; the volume weight of the EPS lightweight aggregate concrete is higher than 650 kg / m<3>, the cube compressive strength can reach 1.6MPa, the strength meets the service requirements, and the lightweight aggregate concrete has excellent thermal properties and durability; and shown in a compression test, the concrete has larger deformation before the concrete is damaged due to deformation, so that the toughness of the concrete is improved. The lightweight aggregate concrete comprises the following raw materials in parts by weight: 350 parts of cement, 90-120 parts of fly coal ash, 30-70 parts of silica fume, 120-140 parts of river sand, 190-210 parts of water, 15-21 parts of EPS grains, 40-60 parts of perlite and 12-18 parts of polymer emulsion. The preparation method comprises the steps of crusting, slurry wrapping, mixing, forming and curing. The lightweight aggregate concrete obtained according to the mixture ratio and the preparation method is uniform and dense in structure, and various properties meet the design requirements, so that the EPS lightweight aggregate concrete has better application prospects.

Owner:CHINA ELECTRIC POWER RES INST +1

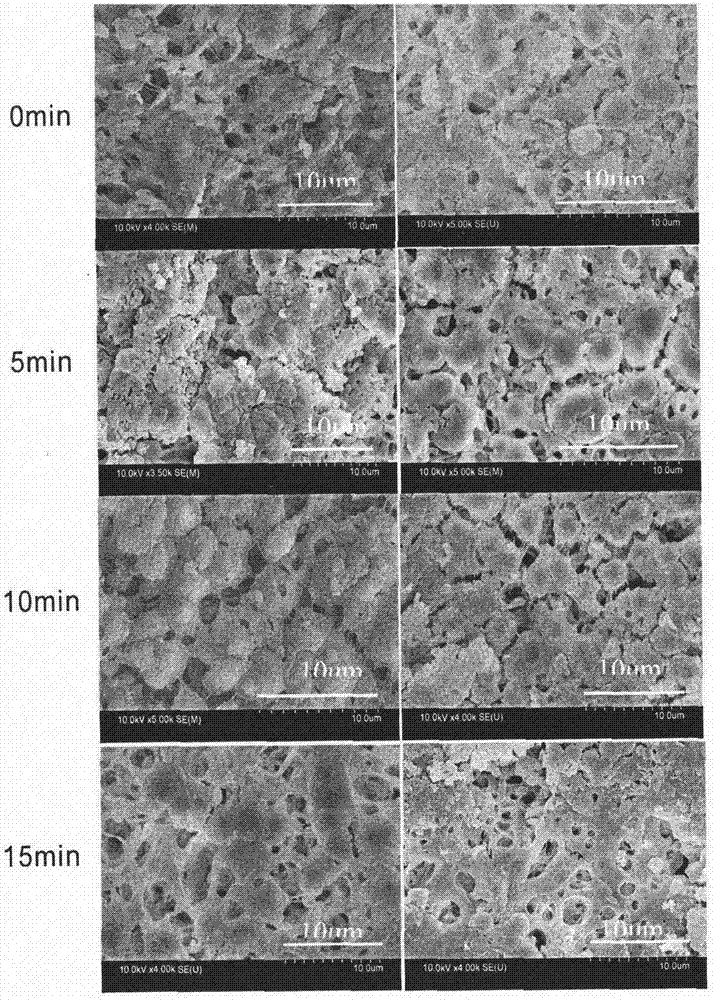

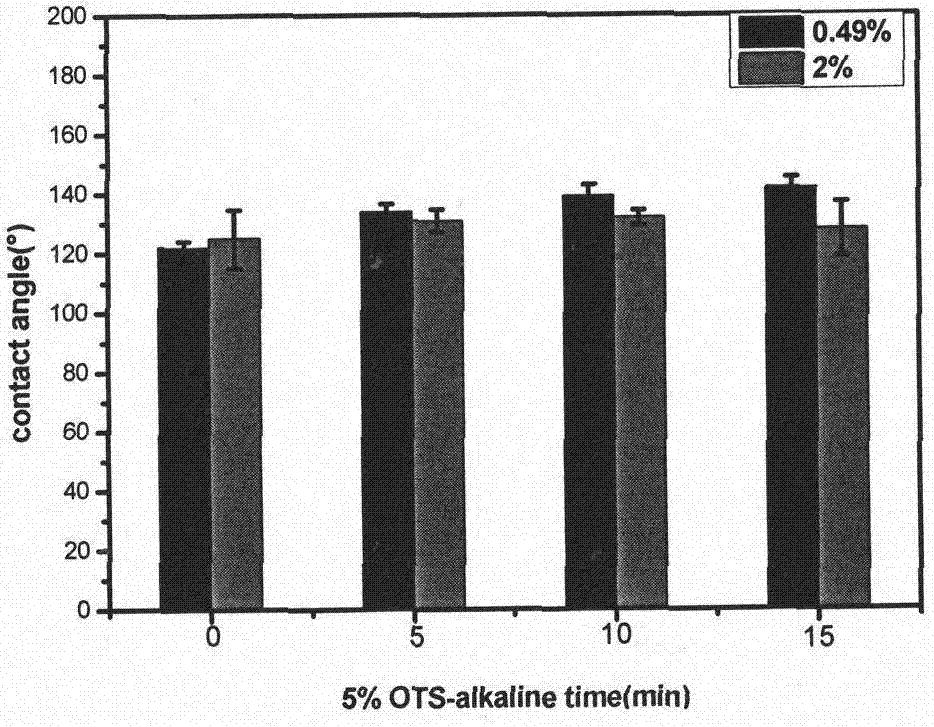

Novel hydrophobic modification system p-carboxyl MWCNT/PVDF blend membrane surface modification method

InactiveCN106914148ASimple processEasy to operateSemi-permeable membranesMembranesWater bathsMembrane surface

The invention relates to a novel hydrophobic modification system p-carboxyl MWCNT / PVDF blend membrane surface plasma modification method. The method comprises the following steps: 1) MWCNT / PVDF blend membrane preparation: 0.05 g of MWCNTs-COOH (0.49%,2%) and 30 ml of DMF are subjected to ultrasonic wave for 40 min to fully disperse the MWCNTs-COOH, 5g of PVDF powder is added in a constant temperature water-bath at the temperature of 70 DEG C for violent stirring for 4 h, a casting solution is prepared; 2) alkaline pretreatment: the MWCNT / PVDF blend membranes with different carboxylation contents are wet by ethanol, and then are immersed in a NaOH solution (pH=10) for alkaline treatment for 0, 5, 10, 15 min; 3) silanization modification: 98% of OTS and 90% (w / w) of ethanol / water are prepared to the silane coupling agent solutions with concentration of 2%, 5% and 7%, the blend membrane processed by alkaline treatment is immersed, the material is placed in an oscillation shaking table for a reaction for 4 h; and 4) post-treatment phase: the reacted blend membrane is taken out, and placed into a vacuum baking oven, heat treatment is carried out for 2 hours at the temperature of 50-80 DEG C, and washing by 30% of ethanol / water is carried out for three times. The method has the advantages of simple operation, short experiment period and low cost.

Owner:TIANJIN POLYTECHNIC UNIV

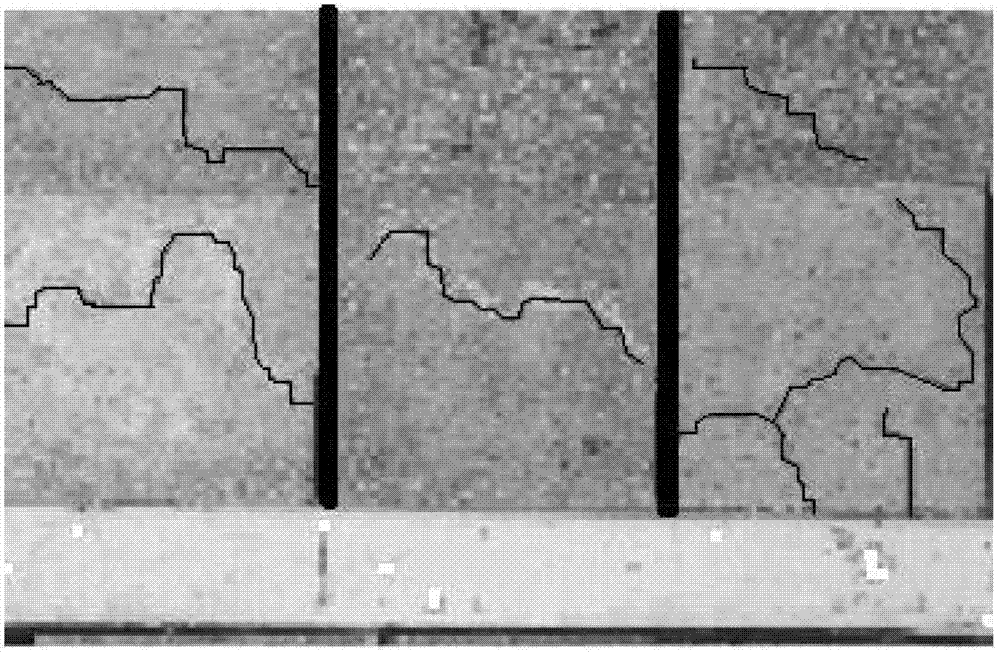

Expanded Polystyrene (EPS) light aggregate concrete and preparation method thereof

InactiveCN102875181AEvenly distributed pore structureImprove interface bondingSolid waste managementCeramic shaping apparatusExpanded polystyreneLarge deformation

The invention provides EPS light aggregate concrete and a preparation method thereof. The EPS light aggregate concrete effectively meets the requirements on a light-weight, uniform and dense structure of the concrete, and has an outstanding integrated performance; the EPS light aggregate concrete has a unit weight of up to 550 kg / m<3> and a cube crushing strength of up to 1.3 MPa which meets the using requirement; in addition, the light aggregate concrete has good thermal performance and durability. In a compression test for the concrete, a large deformation occurs before deformed breakage, and the toughness is improved. The light aggregate concrete comprises 350 parts of cement, 90 to 120 parts of coal ash, 30 to 70 parts of silica fume, 120 to 140 parts of river sand, 190 to 210 parts of water, 15 to 21 parts of EPS particles, 40 to 60 parts of perlite and 2 to 6 parts of water reducer. The light aggregate concrete prepared by the preparation method according to the proportion is uniform and dense in structure, and meets the design requirements on each performance and preparation, so as to have a good application prospect.

Owner:CHINA ELECTRIC POWER RES INST +1

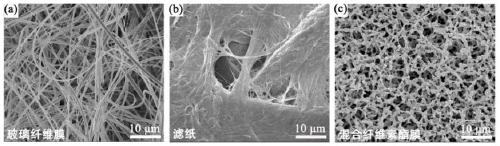

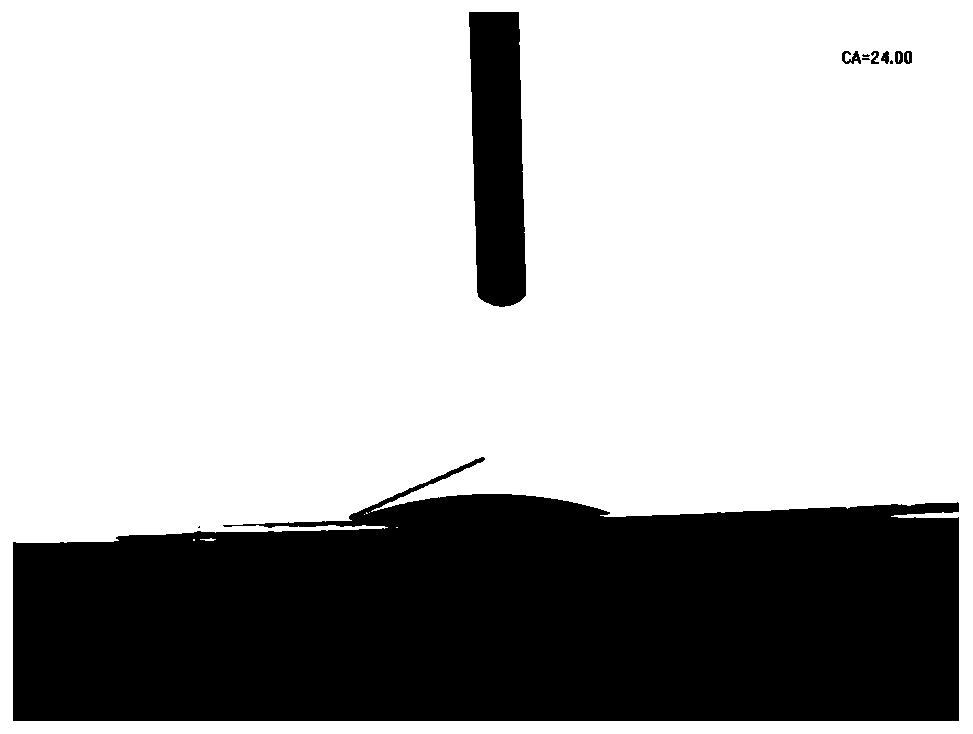

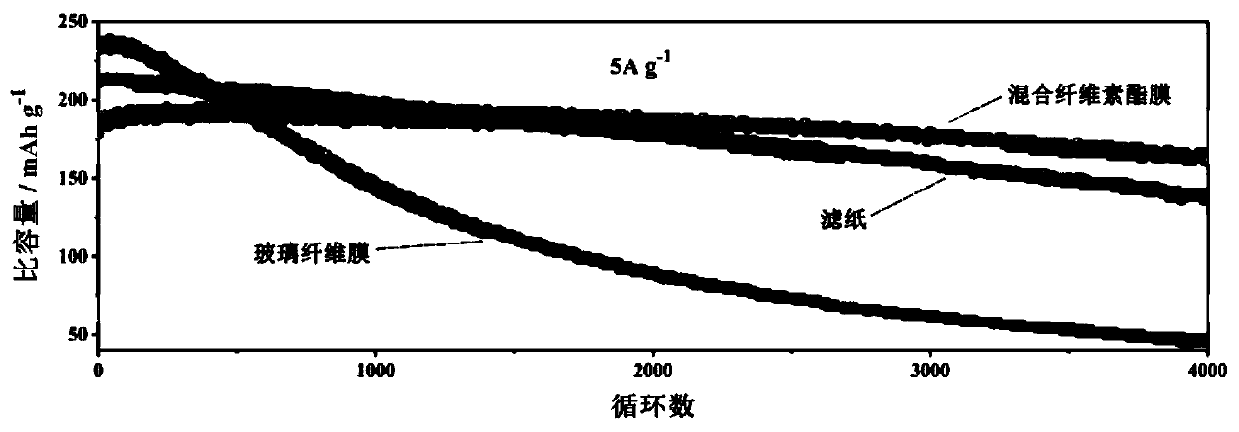

Application of mixed cellulose ester film, prepared battery and preparation method

ActiveCN111584810ALow film resistanceImprove cycle lifeFinal product manufactureCylindrical casing cells/batteryElectrical batteryCyclic stability

The invention discloses the application of a mixed cellulose ester film, a prepared battery and a preparation method. The film shows very excellent electrochemical performance as a diaphragm of an aqueous zinc-ion battery. And under the large current density of 5A g<-1>, the capacity retention ratio is still as high as 91.8% after circulation for 4000 circles, and the coulombic efficiency is closeto 100%. The novel diaphragm provided by the invention can greatly prolong the cycle life of the aqueous zinc-ion battery and improve the cycle stability of the aqueous zinc-ion battery, and is beneficial to promoting the development and application of the aqueous zinc-ion battery.

Owner:CENT SOUTH UNIV

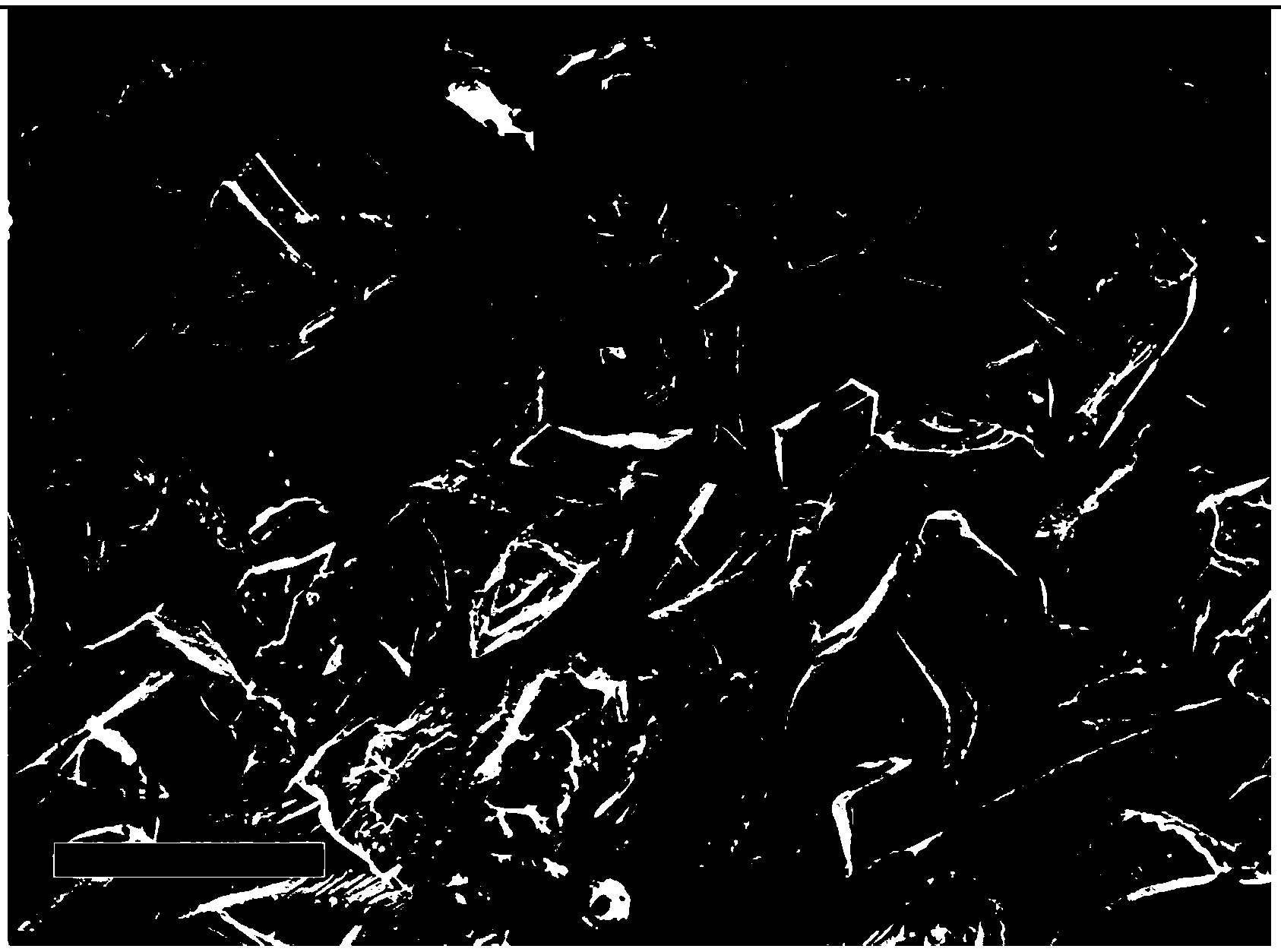

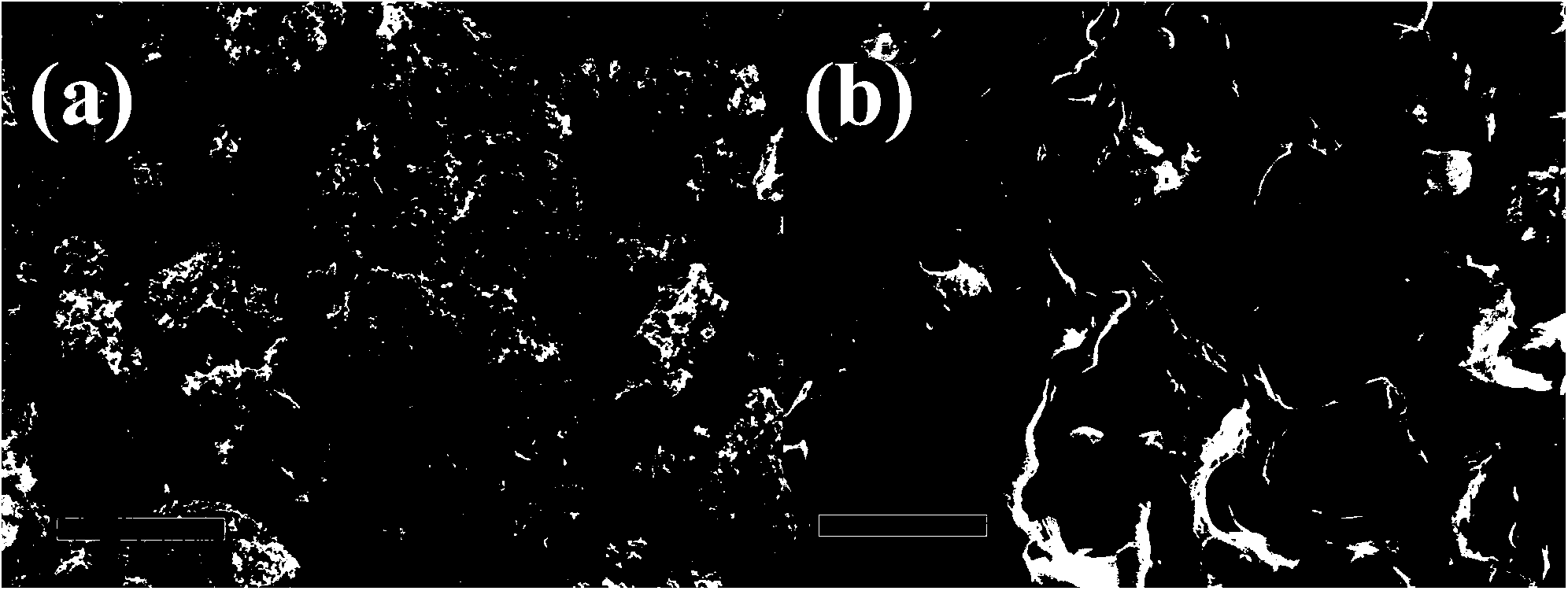

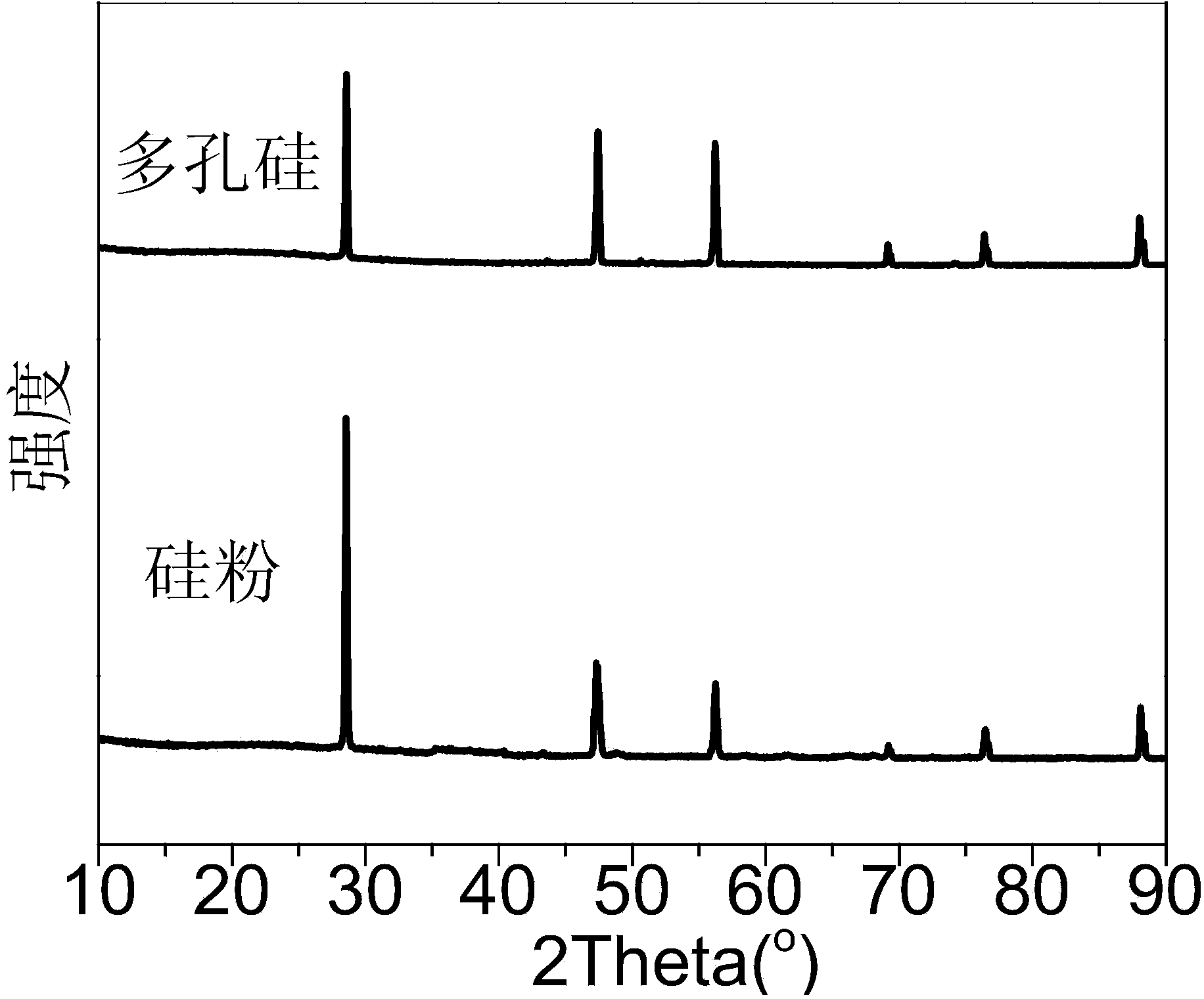

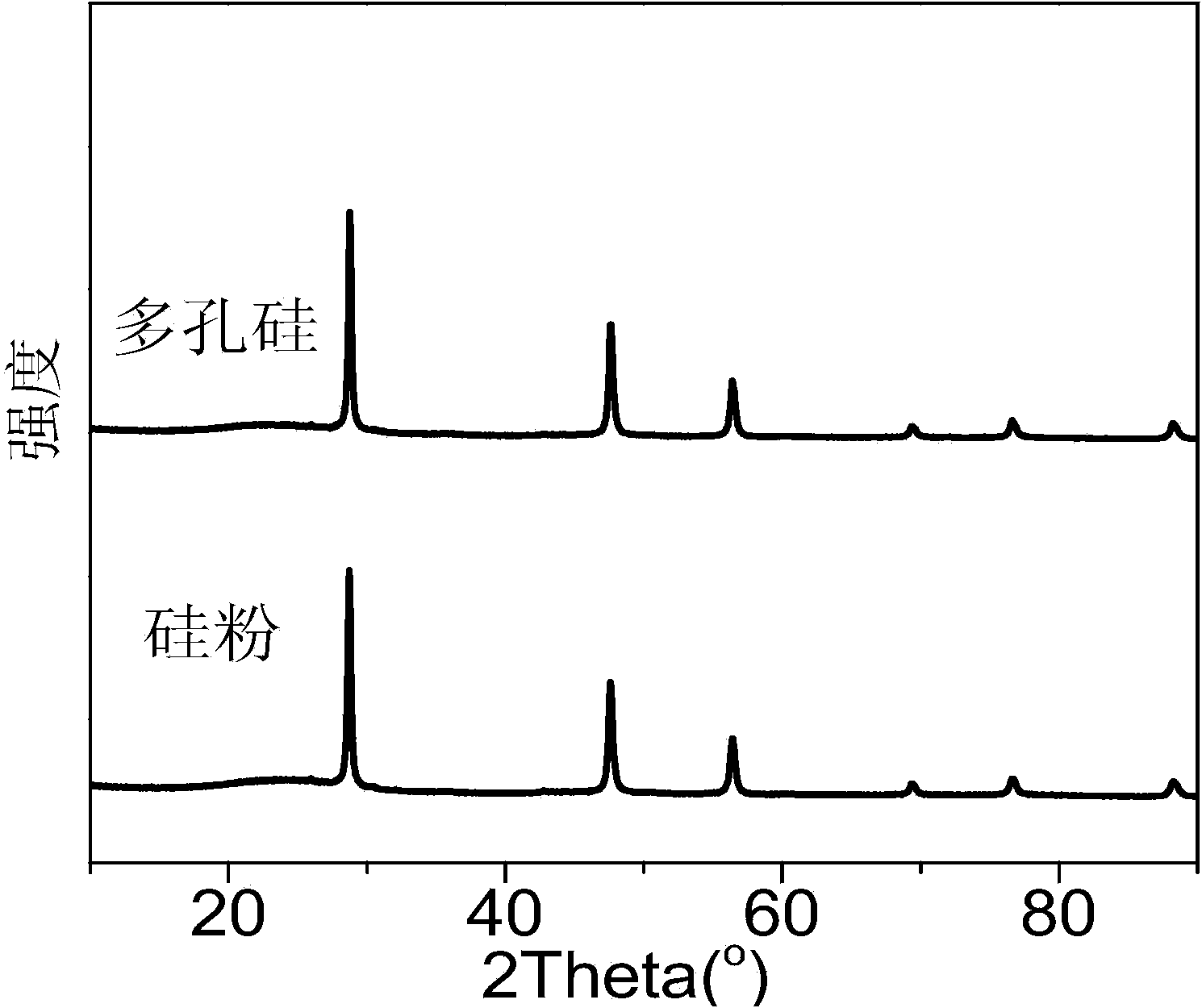

Porous silicon material and preparation method thereof

The invention relates to a porous silicon material and a preparation method thereof. The method for preparing the porous silicon material comprises the following steps: carrying out an in-situ catalytic reaction between a silicon material and chloromethane at the temperature of 401 to 800 DEG C in the presence of a solid copper-based catalyst, and preparing the porous silicon material through calcining, acid pickling, alkaline washing and other after-treatment impurity removal technologies, wherein the solid copper-based catalyst comprises one or a mixture of more than two in primary catalysts such as CuOx, CuCl and CuCl2, x is more than or equal to 0 and less than or equal to 1, as well as a small amount of secondary catalysts. Reaction condition parameters are regulated, so that the pore size, pore size distribution and porosity of the silicon material can be regulated. According to the method, a porous silicon material which is difficultly obtained in the patented technology at present is obtained, and important organic silicon monomer chemicals can be obtained. The porous silicon material prepared by the method is uniform in pore size, low in production cost, simple in process and suitable for industrial production and has wide application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Porous silicon material and preparation method of porous silicon material

InactiveCN104229804AUniform hole sizeSize fine-tuningSilicon compoundsMetal/metal-oxides/metal-hydroxide catalystsAlcoholCopper

The invention provides a porous silicon material and a preparation method of the porous silicon material. The preparation method of the porous silicon material comprises the following steps: carrying out in-situ catalytic reaction on silicon and alcohol at 60-400 DEG C under the action of a solid copper-based catalyst, and preparing the porous silicon material by post-treatment and purification technologies such as burning, and pickling and alkali washing. The porous silicon material prepared by the method is uniform in aperture, and the pore structure, size and porosity of silicon can be regulated and controlled by adjusting reaction parameters. The method is low in production cost, simple in process, easy to operate, clean in preparation process, and suitable for industrial production, and has a wide application prospect. In addition, the process can be combined with an alkoxy silane production process, and the process is expected to achieve double-win of porous silicon material and alkoxy silane production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

EPS (Expandable Polystyrene) lightweight aggregate concrete and preparation method thereof

The invention provides EPS (Expandable Polystyrene) lightweight aggregate concrete and a preparation method thereof. The EPS lightweight aggregate concrete effectively meets the requirements of concrete on light weight, uniformity and density in the aspect of structure, and simultaneously has excellent comprehensive properties; the volume weight of the EPS lightweight aggregate concrete is higher than 650 kg / m<3>, the cube compressive strength can reach 1.6MPa, the strength meets the service requirements, and the lightweight aggregate concrete has excellent thermal properties and durability; and shown in a compression test, the concrete has larger deformation before the concrete is damaged due to deformation, so that the toughness of the concrete is improved. The lightweight aggregate concrete comprises the following raw materials in parts by weight: 350 parts of cement, 90-120 parts of fly coal ash, 30-70 parts of silica fume, 120-140 parts of river sand, 190-210 parts of water, 15-21 parts of EPS grains, 40-60 parts of perlite and 12-18 parts of polymer emulsion. The preparation method comprises the steps of crusting, slurry wrapping, mixing, forming and curing. The lightweight aggregate concrete obtained according to the mixture ratio and the preparation method is uniform and dense in structure, and various properties meet the design requirements, so that the EPS lightweight aggregate concrete has better application prospects.

Owner:CHINA ELECTRIC POWER RES INST +1

Preparation method of loop heat pipe and porous silicon nitride ceramic

ActiveCN109956751AHigh porosityImprove flexural strengthIndirect heat exchangersCeramicwareSlurryMuffle furnace

The invention discloses a loop heat pipe and a preparation method of porous silicon nitride ceramic. The loop heat pipe is prepared from porous silicon nitride ceramic, of which the porosity is 50-70%, the strength is 10-30 MPa, and the average pore diameter is 0.5-1 [mu]m. The method comprises the following steps: with Si3N4 powder as a raw material, adding a sintering aid, and carrying out uniform mechanical wet ball milling mixing to form slurry; defoaming and degassing the slurry, freezing and curing the slurry at low temperature in a mold, and drying the material; putting the material into a muffle furnace for heat preservation to remove organic matter impurities; and finally, sintering the material in a sintering furnace at a high temperature to obtain the Si3N4 porous ceramic tube.The ceramic tube has the characteristics of high porosity, high strength, uniform pore structure distribution and the like, and can replace a metal loop heat tube to meet the use in the fields of loopheat tubes under a high-temperature condition and the like.

Owner:CENT SOUTH UNIV

Preparation of foam magnesium alloy

The invention discloses a foam magnesium alloy preparing method, belonging to the field of the production of an alloy with open or closed pores. The method is particularly a method for preparing a magnesium alloy by means of foaming a powder entity and comprises the following steps: firstly, mixing 150-270-mesh pure magnesium powder and 250-400-mesh pure aluminum powder according to a mass ratio (pure magnesium powder : pure aluminum powder) ranging from 4:1 to 9:1 so as to obtain a metal powder mixture, uniformly mixing the metal powder mixture with 200-325-mesh TiH2 powder vesicant which accounts for 1.0-2.5 percent of the mass of the metal powder mixture, carrying out cold pressing and hot pressing on the mixture obtained from the previous step, and then obtaining a magnesium alloy foaming precast block; and then, under the protection of argon, preparing the foam magnesium alloy with an average aperture ranging from 1 mm to 5 mm by means of heating the foaming precast block in a mould. The method has the advantages of simple and flexible process, short period, high productive rate and no impurity; and the foam magnesium alloy prepared according to the method has a closed-pore structure and the advantages of high porosity, uniform pore structure distribution, regular pore shapes, wide application scope and good comprehensive performance.

Owner:HEBEI UNIV OF TECH

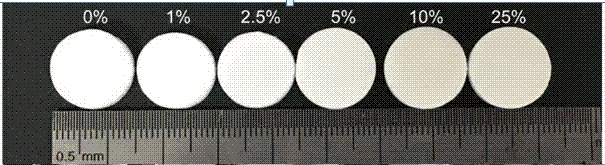

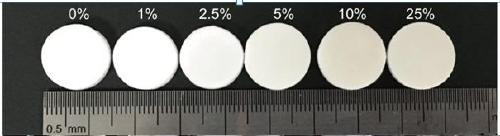

Preparation method of nano-pearl powder/C-HA composite scaffold

ActiveCN107185048AImprove wettabilityHigh compressive strengthTissue regenerationProsthesisFreeze-dryingBiocompatibility Testing

The invention discloses a preparation method of nano-pearl powder / C-HA composite scaffold. The preparation method comprises the following steps: firstly, dissolving chitosan and hyaluronic acid into an acetic acid solution with concentration of 1% respectively, stirring at 2000rpm for 5min, placing at room temperature for 24 hours, and obtaining a chitosan acetic acid solution and a hyaluronic acid acetic acid solution; secondly, 24 hours later, mixing the chitosan acetic acid solution and the hyaluronic acid acetic acid solution, and stirring at 2000rpm for 5 min; thirdly, adding the nano-pearl powder with the weight percentage of 1 to 25%, stirring at 2000 rpm for 5min; fourthly, putting into a -20 DEG C refrigerator for 24h, then freeze drying for 24h, and obtaining the composite scaffold. The technical problem to be solved by the invention is to provide a preparation method of nano-pearl powder / C-HA composite scaffold which has a suitable pore structure, is advantageous for cell proliferation, blood vessel growth and transport of nutrients, has good biological activity, biocompatibility and biodegradability, and can adapt to the specific shape of bone defects.

Owner:海口市人民医院

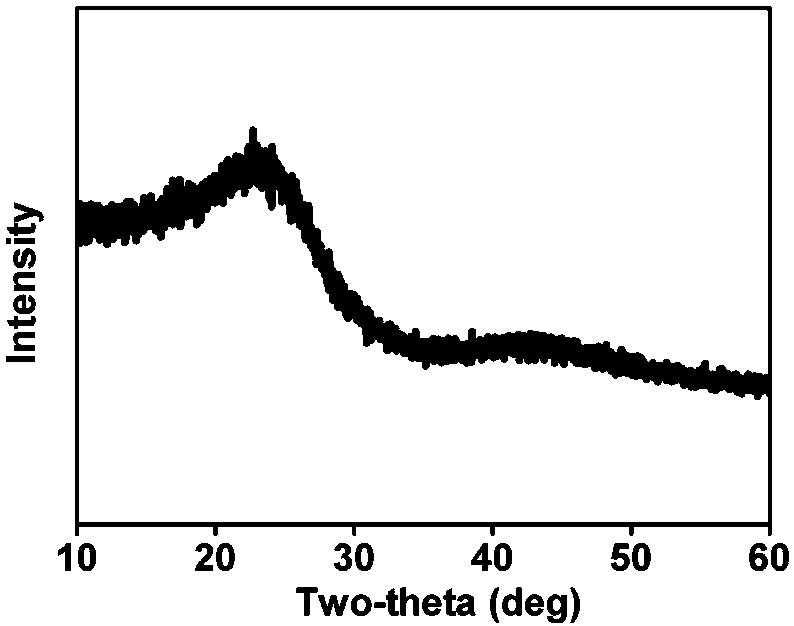

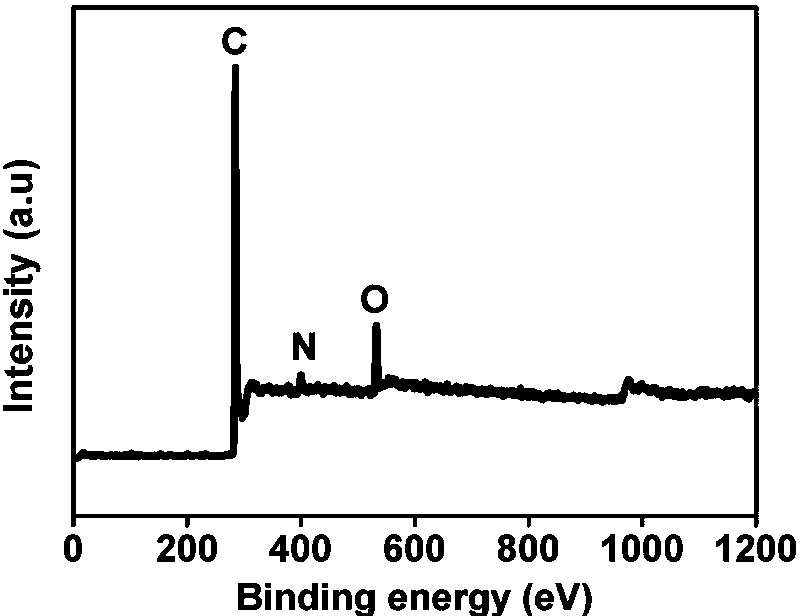

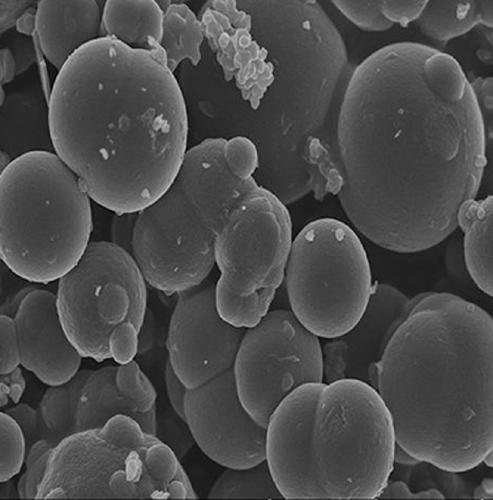

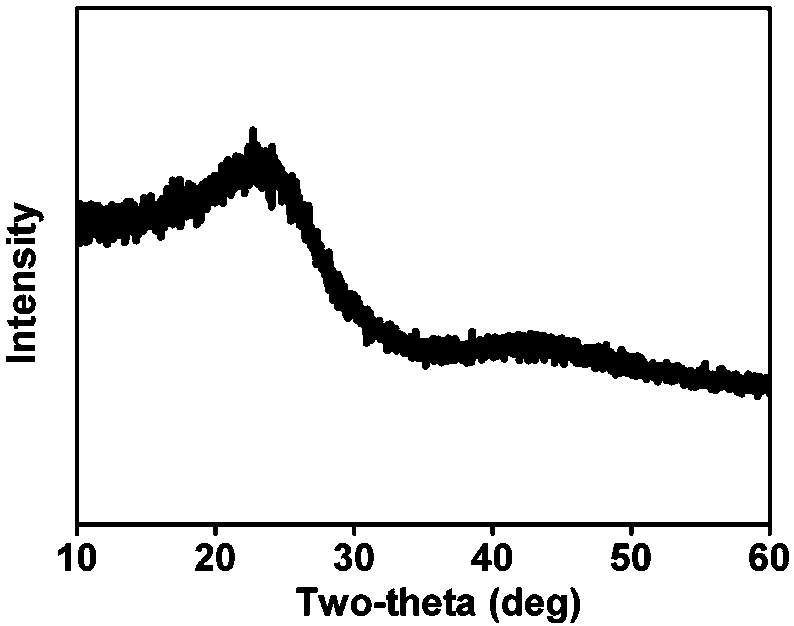

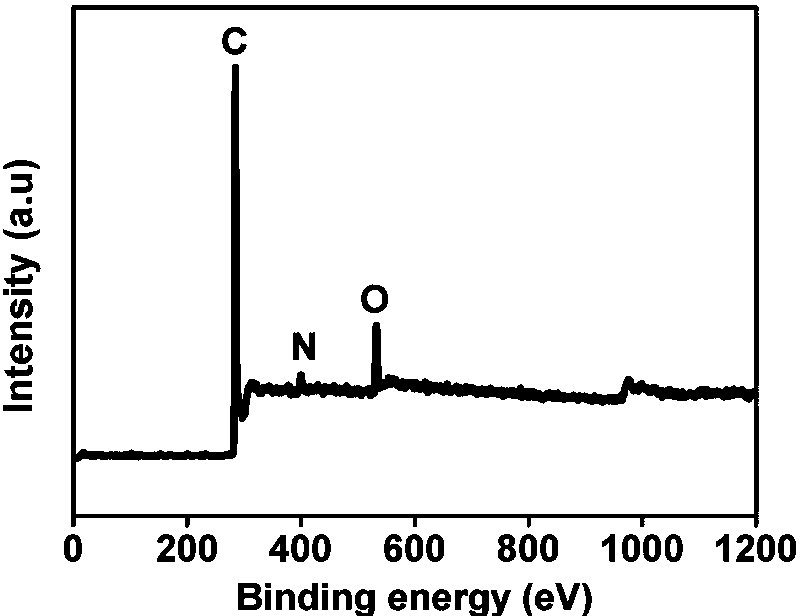

High specific surface area coal-based nitrogen-doped activated carbon sphere electrode material and preparation method thereof

ActiveCN108428560AHigh yieldEvenly distributed pore structureHybrid capacitor electrodesHybrid/EDL manufactureMicro nanoCarbonization

The invention relates to the technical field of electrode materials for supercapacitors, and discloses a high specific surface area coal-based nitrogen-doped activated carbon sphere electrode materialand a preparation method thereof. The high specific surface area coal-based nitrogen-doped activated carbon sphere electrode material is prepared according to the steps of enabling pulverized coal tobe reacted with a strong oxidant solution, performing hydrothermal reaction on obtained oxidized coal and glucosamine, mixing a powdered product obtained by washing and drying to obtain with potassium hydroxide, carrying out carbonization treatment, washing and drying an obtained mixed product to acquire a high specific surface area coal-based nitrogen-doped activated carbon sphere electrode material. According to the invention, the glucosamine is adopted to serve as a nitrogen source, the oxidized coal is adopted to serve as a carbon source, so that the yield of coal-based nitrogen-doped carbon spheres is effectively improved, and the high specific surface area coal-based nitrogen-doped activated carbon sphere electrode material is prepared. The high specific surface area coal-based nitrogen-doped activated carbon sphere electrode material has micro-nano morphology, is uniform in pore structure distribution and has excellent specific capacity and high-current charging and dischargingperformance when serving as a supercapacitor electrode material.

Owner:XINJIANG UNIVERSITY

Asphalt concrete using alkaline slag regeneration micro powder as filling materials and preparation method thereof

The invention relates to asphalt concrete using alkaline slag regeneration micro powder as filling materials and a preparation method thereof. The asphalt concrete is formed by mixing the following ingredients in percentage by weight: 8 to 12 percent of alkaline slag, 0 to 2 percent of mineral powder, 50 to 54 percent of clastic rock, 10 to 12 percent of stone chips, 21 to 23 percent of sand and 4 to 6 percent of asphalt, and the total percent is 100 percent. The method comprises the steps of material pretreatment, material preparation, material stirring and asphalt concrete forming. The industrial alkaline slag micro powder is used as asphalt concrete regeneration filling materials; the bonding force of the asphalt concrete can be effectively improved, so that the intensity of the asphalt concrete can be improved; the anti-peeling performance is improved; the stability flowing value is superior to that of ordinary asphalt concrete; the stability degree of the asphalt concrete can be greatly improved; the resource utilization of the industrial solid waste slag can be realized.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY +1

Porous vegetation concrete for road slope ecological protection and preparation method thereof

ActiveCN107311688AGuaranteed stabilityUniform pore structureBio-organic fraction processingWaste based fuelPorosityEvaporation

The invention relates to a porous vegetation concrete for road slope ecological protection and a preparation method thereof. The porous vegetation concrete comprises the following components by weight: 100 parts of gravel aggregate, 5.0-8.0 parts of soil, 10-12 parts of cement, 5.0-8.0 parts of papermaking black liquid black concentrated modified liquid, 2.0-3.0 parts of an organic fertilizer, and 4.5-6.0 parts of water. The preparation method includes: evaporating and concentrating papermaking black liquid, then adding a formaldehyde solution, conducting mixing and raising the temperature to 80-85DEG C for reaction, then performing cooling, and conducting evaporation and concentration again. A porous concrete layer formed by pouring of the porous vegetation concrete has a pH value of only about 9.0, and belongs to a low alkali environment suitable for vegetation growth, the porous vegetation concrete has large porosity and high water permeability coefficient, is suitable for plants to take root and the root system to pass through and reach the subsoil, has high compressive strength, and can guarantee the long-term stability of road slopes, thus being suitable for ecological protection of road slopes.

Owner:江西天丰建设集团有限公司

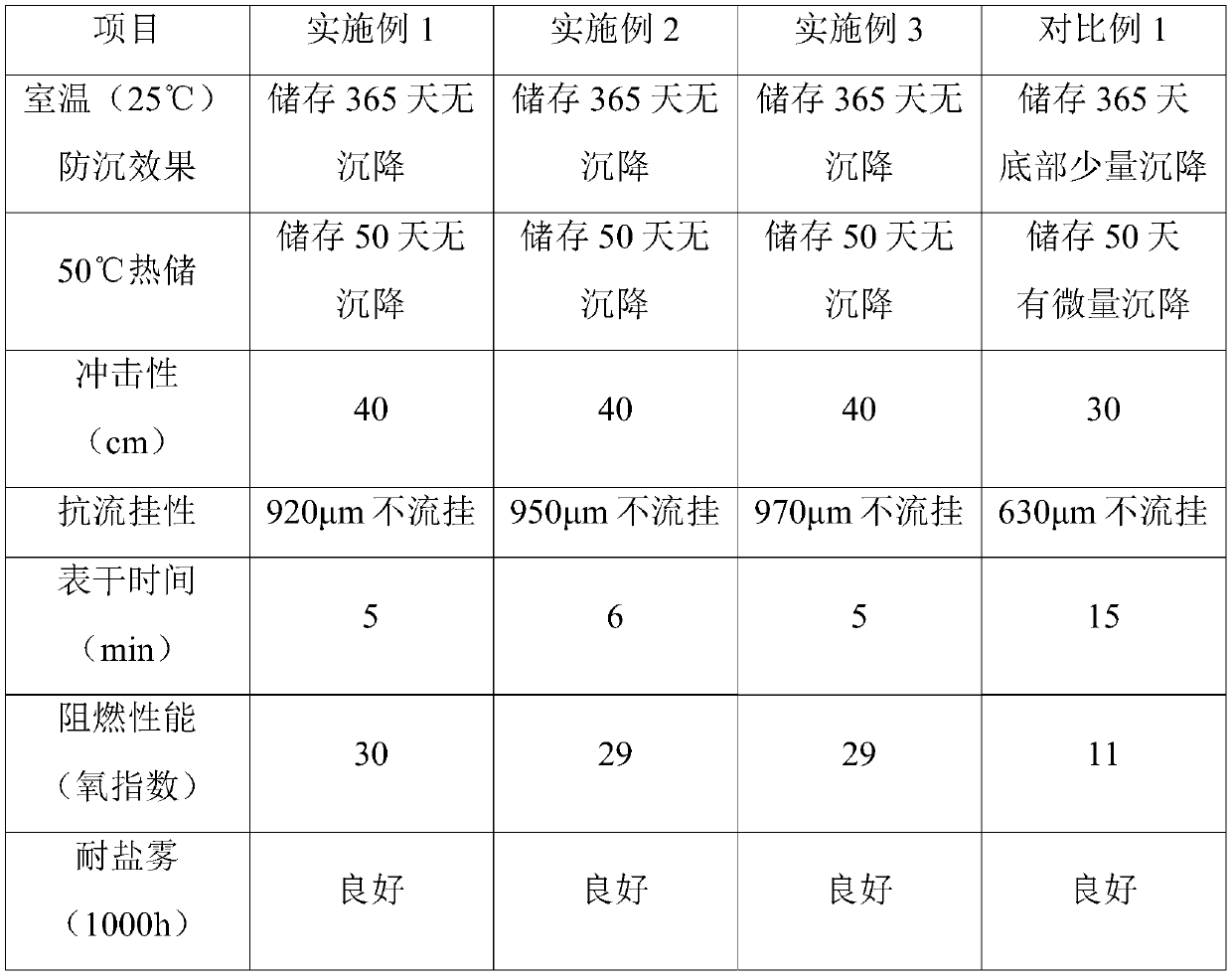

Water-based primer and preparation method thereof

InactiveCN110358405AImprove rust resistanceFix stability issuesFireproof paintsAnti-corrosive paintsWater basedSilicon alloy

The invention relates to the technical field of coatings, and concretely discloses a water-based primer and a preparation method thereof. The water-based primer comprises a component A and a componentB; the component A comprises, by mass, an epoxy resin, an epoxy reactive diluent, a dispersant, a defoamer, a film forming aid, zinc powder, aluminum-silicon alloy powder, ferrophosphorus powder, expanded graphite, silica, a flash rust inhibitor and zirconium phosphate; the component B includes, by mass, a curing agent, and the balance of deionized water; and a mass ratio of the component A to the component B is (4-6):1. The water-based primer of the invention has the advantages of good stability, good impact resistance, good sag resistance, good drying speed, good salt spray resistance, goodflame retardant performance, simple preparation process, convenience in construction, and low production cost.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Negative electrode material, negative electrode slurry, battery cell, fast charging battery and preparation method thereof

PendingCN113517419AReduce conductivityImprove ionic conductivityNegative electrodesSecondary cellsSolid state electrolyteFast charging

The invention discloses a negative electrode material, negative electrode slurry, a battery cell, a fast charging battery and a preparation method thereof, and belongs to the field of lithium ion batteries. The negative electrode material comprises a negative electrode active material and an inorganic solid electrolyte, the negative electrode active material comprises hard carbon and artificial graphite which are mixed, the weight ratio of the hard carbon in the negative electrode active material is 10-90%, and the content of the inorganic solid electrolyte is 2-10% of the weight of the hard carbon. A porous negative electrode dressing area is prepared by adding the solid electrolyte, mixing the solid electrolyte with hard carbon in the artificial graphite and mixing materials with different particle sizes, so that the problems of non-uniform current density distribution and poor dynamic performance caused by violent change of the porosity of a pole piece and non-uniform pore distribution after rolling of a traditional artificial graphite negative electrode are solved. The hard carbon material is a porous material, and through combination with the graphite and the solid electrolyte, the pore structure distribution is more uniform.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

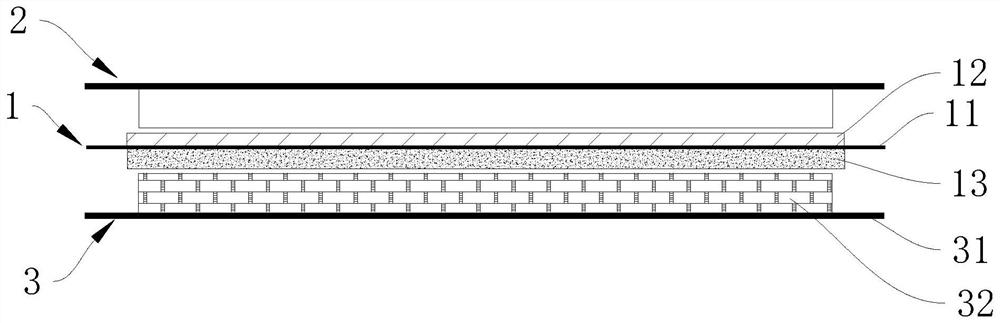

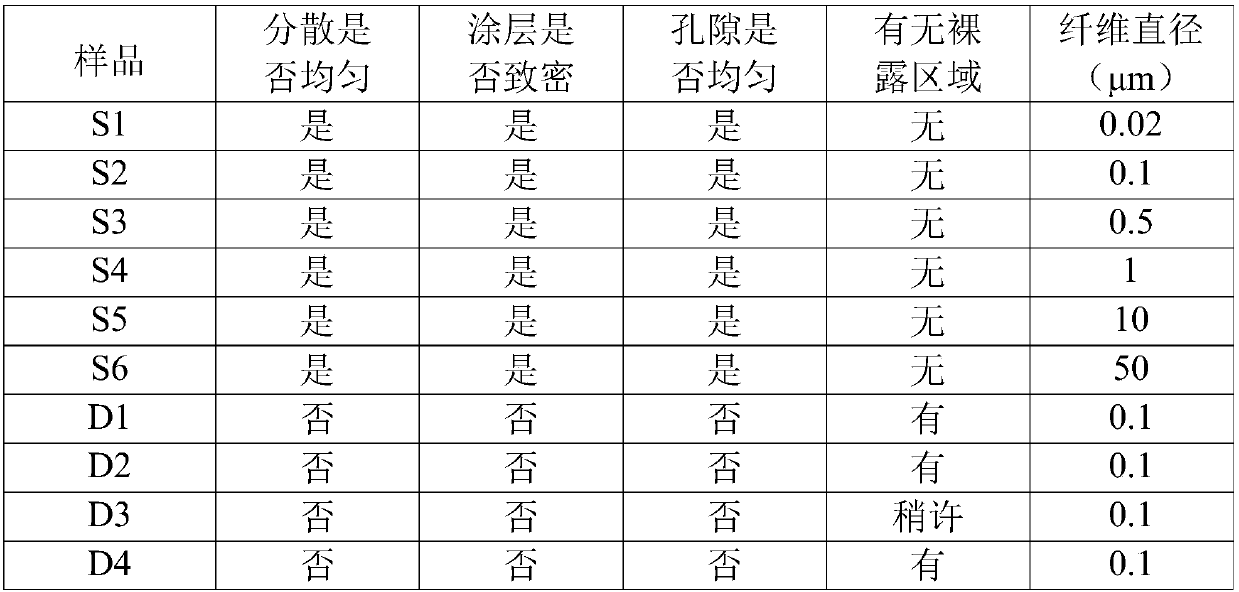

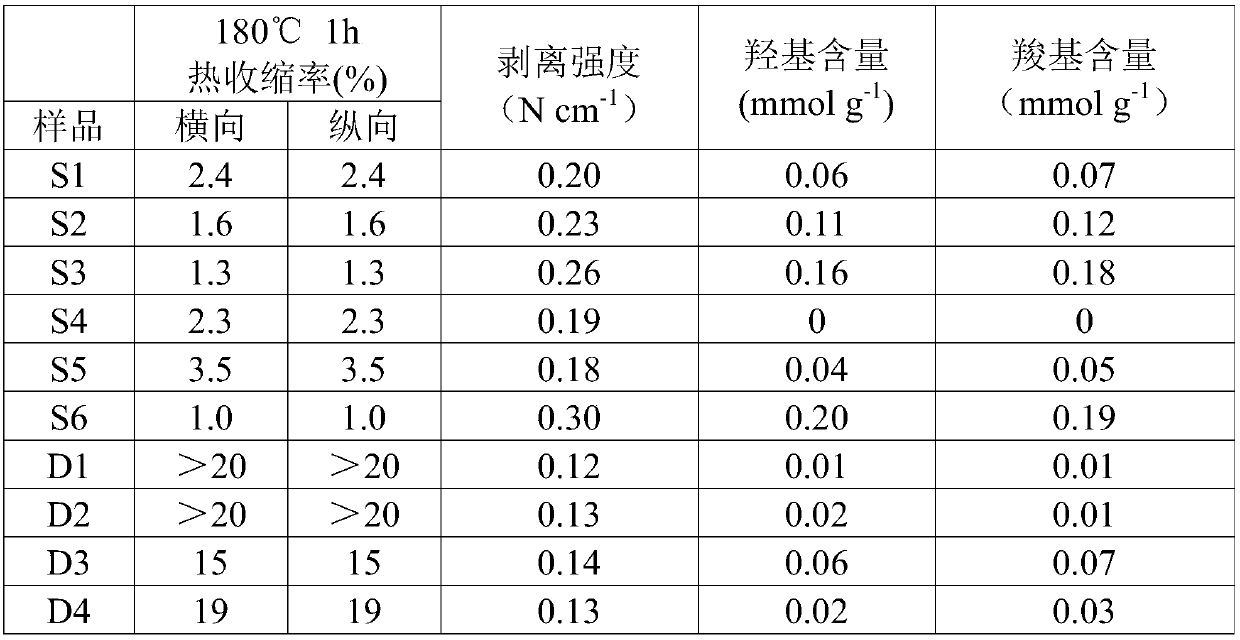

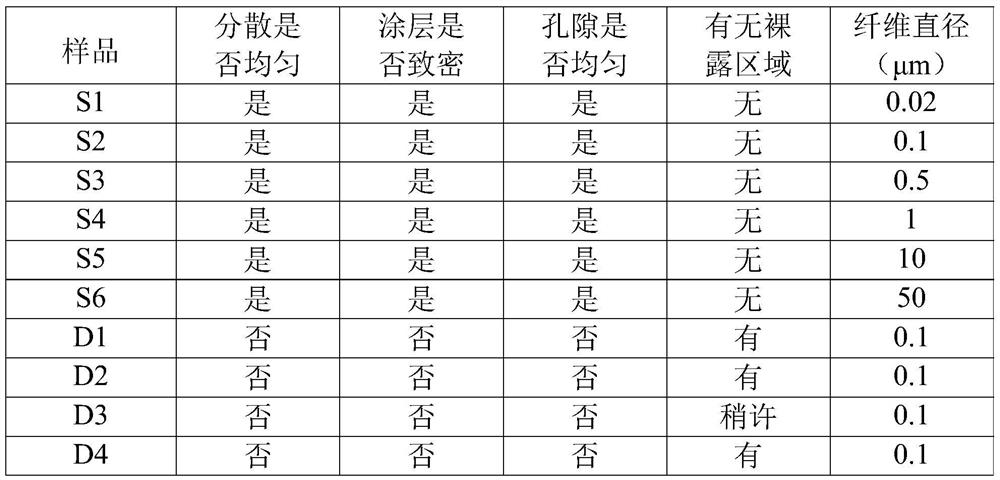

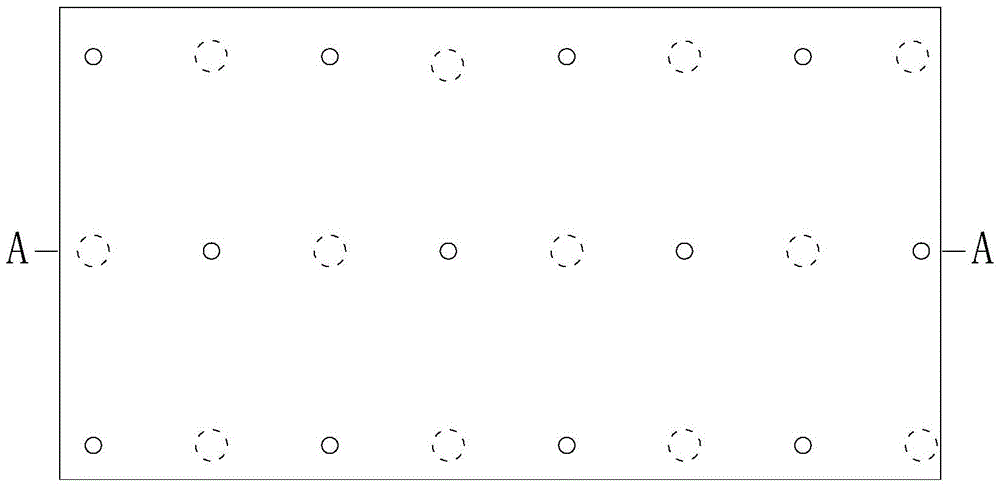

Battery diaphragm, preparation method thereof, lithium ion battery and electric vehicle

ActiveCN110660947AHigh strengthGood heat resistanceSecondary cellsCell component detailsCarboxylic groupLithium electrode

The invention relates to the technical field of battery materials, and discloses a battery diaphragm, a preparation method thereof, a lithium ion battery and an electric vehicle. The battery diaphragmcomprises a polymer fiber layer, wherein the polymer fiber layer contains polymer fibers, the polymer fibers contain a cross-linked polymer, and the cross-linked polymer is obtained by cross-linkingmodified polyethylene glycol terephthalate and an acrylate polymer; the modified polyethylene glycol terephthalate contains hydroxyl and / or carboxyl, or the modified polyethylene glycol terephthalatehas carbon-carbon double bonds. The battery diaphragm provided by the invention has good thermal shrinkage resistance, more uniformly distributed pores and good air permeability, and can meet the safety and electrochemical performance requirements of a lithium battery.

Owner:BYD CO LTD

Battery diaphragm and preparation method thereof, lithium ion battery and electric vehicle

ActiveCN110660947BHigh strengthUniform pore structureSecondary cellsCell component detailsFiberPolyethylene terephthalate glycol

Owner:BYD CO LTD

A kind of preparation method of low-frequency sound-absorbing material

The invention provides a preparation method of a low-frequency sound absorbing material. The preparation method of the low-frequency sound absorbing material comprises the following steps: 1) adding copper powder into polyvinyl alcohol aqueous solution and performing uniform mixing to obtain slurry; 2) uniformly coating the slurry on the surface of a compact metal plate and performing drying to obtain a powder coating layer; 3) laying metal fibers on the compact metal plate, performing pressing and then performing sintering to obtain a metal fiber porous composite material; 4) punching holes in the metal fiber porous composite material to obtain the low-frequency sound absorbing material. The average sound absorbing coefficient of the low-frequency sound absorbing material prepared by using the preparation method provided by the invention at frequency of 500Hz-1000Hz reaches 0.20-0.35, the sound absorbing performance is excellent, and the low-frequency sound absorbing material can be widely applied to the fields of precise electronic parts and components having low-frequency sound absorbing requirements or other sound silencing places.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of micron-aperture foamy copper

The invention relates to a preparation method of foamy copper with a micron aperture, and belongs to the technical field of foam metal. The method comprises the following steps: firstly, mixing pure copper particles or copper oxide particles with a solvent to prepare slurry; coating the pure copper slurry or the copper oxide slurry on a carrier; and drying the slurry, and then carrying out heat treatment or heat reduction treatment to obtain the foamy copper with the micron aperture. The foamy copper has the advantages of being complete in structure, uniform in pore structure distribution, micron in pore diameter and controllable in thickness.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Lithium ion battery separator and preparation method thereof, and lithium ion battery

ActiveCN104157812BRequirements to ensure the strength of the diaphragmMeet the requirements of diaphragm strengthCell seperators/membranes/diaphragms/spacersSecondary cellsPorosityPower flow

The invention provides a lithium ion battery diaphragm, a preparation method of the lithium ion battery diaphragm and a lithium ion battery. The lithium ion battery diaphragm comprises a support layer, wherein either or both of a dense layer or an inorganic coating are compounded on the support layer; the average quantity of the lithium ion battery diaphragm is 8-25g / m<2>, the thickness is 15-60 mu m, the average aperture is 50-500nm, and the porosity is 78-82%. The lithium ion battery diaphragm provided by the invention is good in isolating property and excellent in electrolyte absorbing property, is further relatively high in tension strength, is capable of realizing high power capacity of a battery, and can meet the requirement of rapid large-current charge and discharge of the lithium ion battery.

Owner:SOUTH CHINA UNIV OF TECH

Concrete with alkali slag as admixture and preparation method thereof

The invention discloses a concrete containing alkali residue as an admixture and a preparation method thereof. The concrete is prepared by mixing the following components in percentage by weight: 45%-49% of pebble, 25%-29% of sand, 10%-14% of cement, 5%-10% of alkali residue and 5.5%-8% of water. The preparation method comprises the following steps of: drying industrial alkali residues in the sun; drying the industrial alkali residues for 4-6 hours at 105 DEG C in an oven and crushing the industrial alkali residues; cleaning the pebbles; drying pebbles at 105 DEG C for 4-6 hours; screening and taking out flake-like and needle-like pebbles; drying the sand for 4-6 hours at 105 DEG C; weighing solid materials in percentage by weight; completely stirring all the solid materials for 3-5 minutes in a stirrer; slowly adding running water in percentage by weight into the stirrer; and continuously stirring for 2-3 minutes to obtain a commercial concrete. As industrial waste residues are used as a concrete admixture, the concrete is light and hard; endurance characteristics, such as high compressive strength, frost resistance and wearing resistance meet the standard requirements; the shrinkage performance of the concrete is superior to that of a common concrete; and the heat insulation performance of the concrete can be greatly improved.

Owner:深圳市固亿建材水泥制品有限公司

Preparation method of nano pearl powder/c-ha composite scaffold

ActiveCN107185048BEvenly distributed pore structureImprove wettabilityTissue regenerationProsthesisFreeze-dryingEthylic acid

The invention discloses a preparation method of nano-pearl powder / C-HA composite scaffold. The preparation method comprises the following steps: firstly, dissolving chitosan and hyaluronic acid into an acetic acid solution with concentration of 1% respectively, stirring at 2000rpm for 5min, placing at room temperature for 24 hours, and obtaining a chitosan acetic acid solution and a hyaluronic acid acetic acid solution; secondly, 24 hours later, mixing the chitosan acetic acid solution and the hyaluronic acid acetic acid solution, and stirring at 2000rpm for 5 min; thirdly, adding the nano-pearl powder with the weight percentage of 1 to 25%, stirring at 2000 rpm for 5min; fourthly, putting into a -20 DEG C refrigerator for 24h, then freeze drying for 24h, and obtaining the composite scaffold. The technical problem to be solved by the invention is to provide a preparation method of nano-pearl powder / C-HA composite scaffold which has a suitable pore structure, is advantageous for cell proliferation, blood vessel growth and transport of nutrients, has good biological activity, biocompatibility and biodegradability, and can adapt to the specific shape of bone defects.

Owner:海口市人民医院

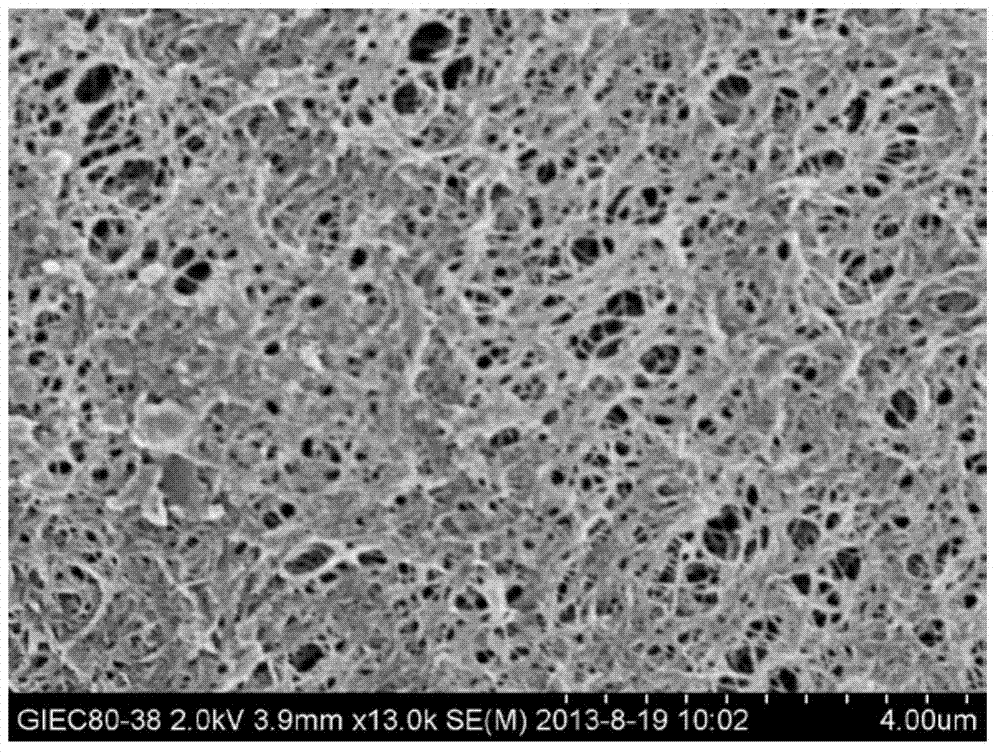

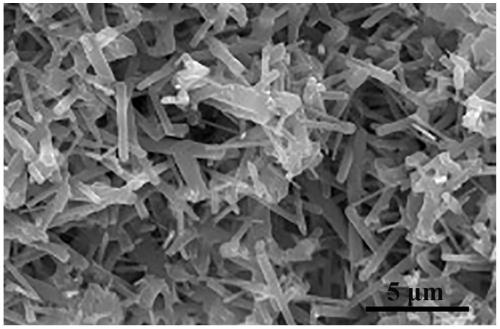

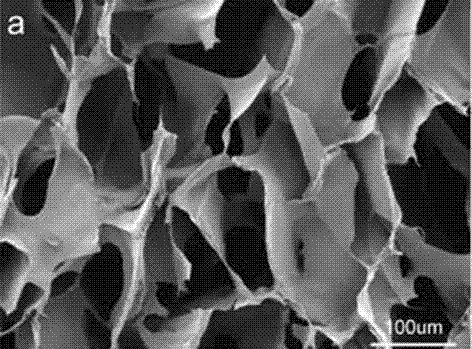

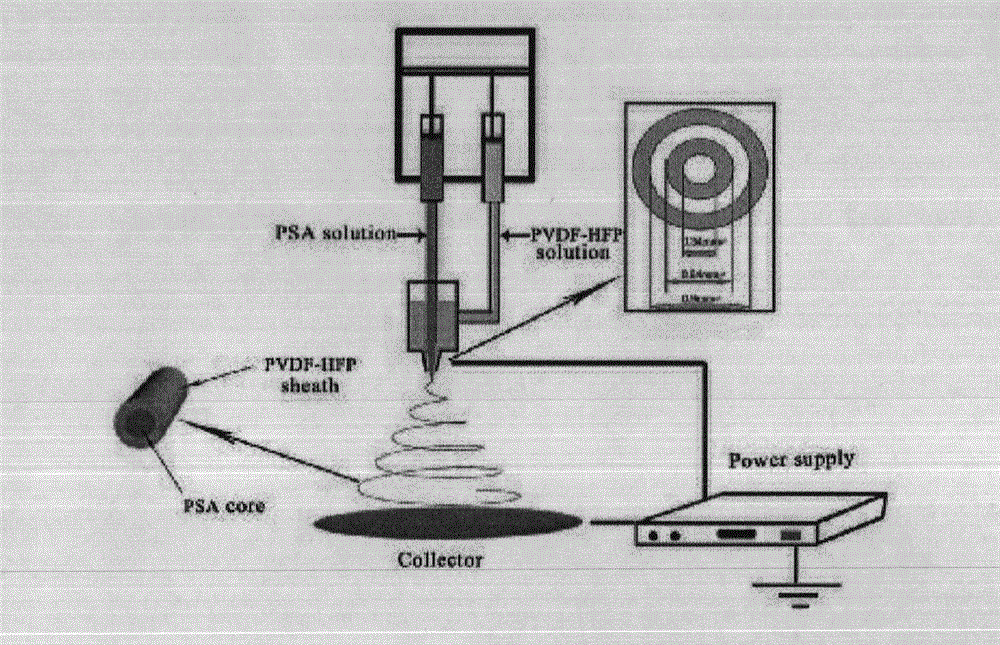

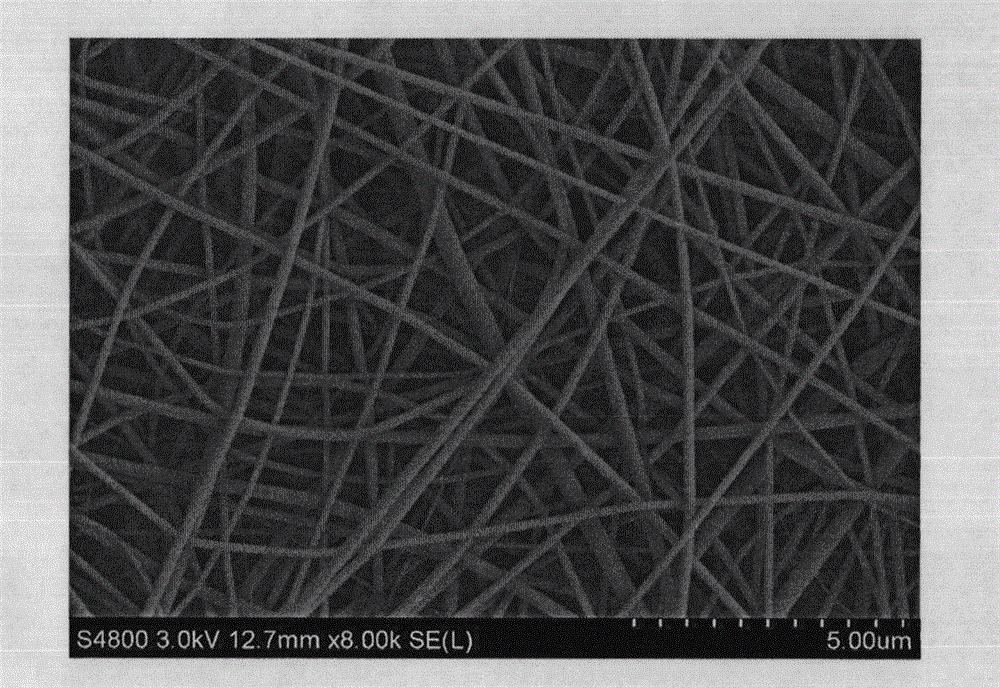

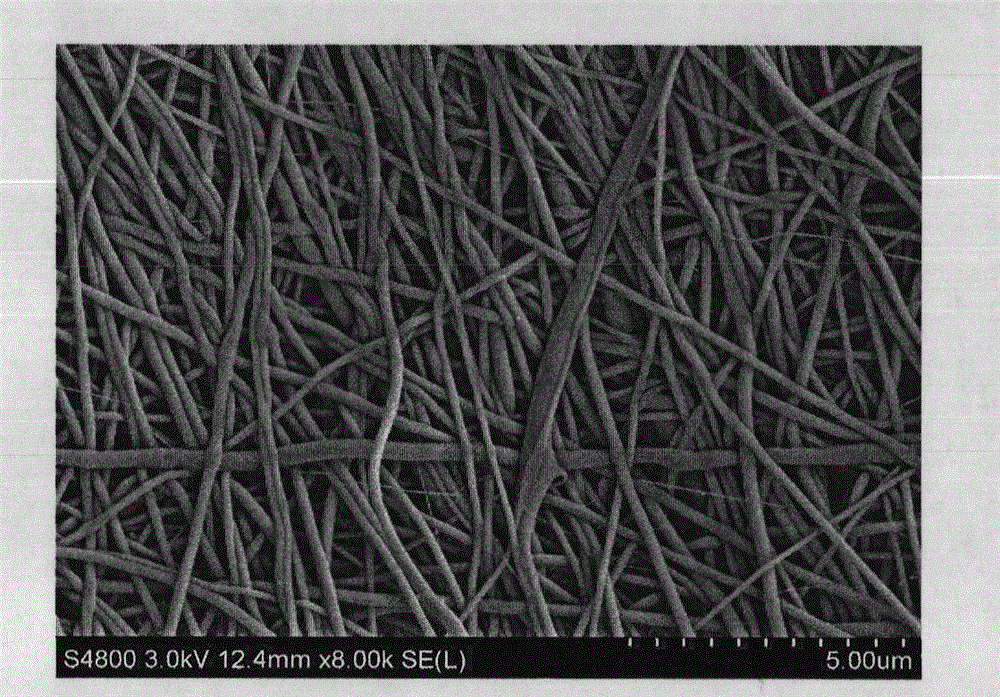

A high-temperature-resistant polyarylsulfone amide-based lithium-ion battery separator

ActiveCN102969471BEasy to manufactureEvenly distributed pore structureFilament/thread formingCell component detailsPorosityPolyolefin

The invention belongs to the technical field of lithium ion battery diaphragm, and provides a high-temperature resistant aromatic polysulfonamide base lithium ion battery diaphragm. The battery diaphragm is characterized in that the battery diaphragm has fiber diameter of 30-800nm, diaphragm thickness of 15-80 mum and membrane permeability of 3-100 s; pores on the upper and lower surface of the membrane and in the membrane are symmetrically and uniformly distributed, and have average pore size of 50-800nm; besides, the membrane has porosity of 70%-90%, and tensile strength of 10-50 MPa. The invention also discloses a preparation method of the aromatic polysulfonamide base diaphragm. Compared with a traditional polyolefin diaphragm, the aromatic polysulfonamide base diaphragm provided by the invention has good electrolyte wettability, excellent flame retardant performance and high temperature resistance performance. A lithium ion battery assembled from the diaphragm does not generate short circuit phenomenon under high temperature of 120 DEG C, and can charge and discharge quickly. Therefore, the high-temperature battery diaphragm provided by the invention is particularly applicable to the fields of power lithium ion battery and high temperature lithium ion battery.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

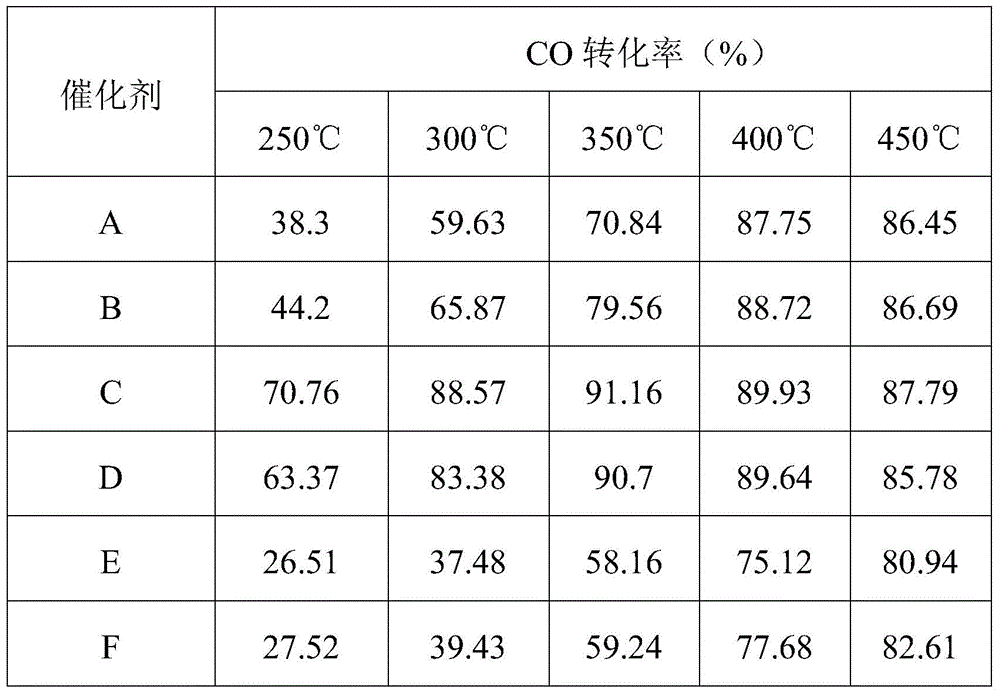

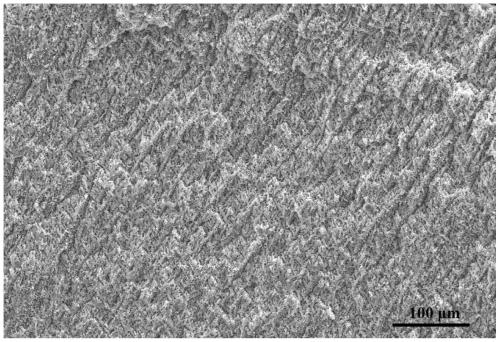

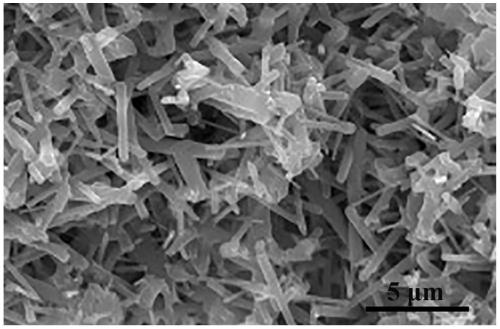

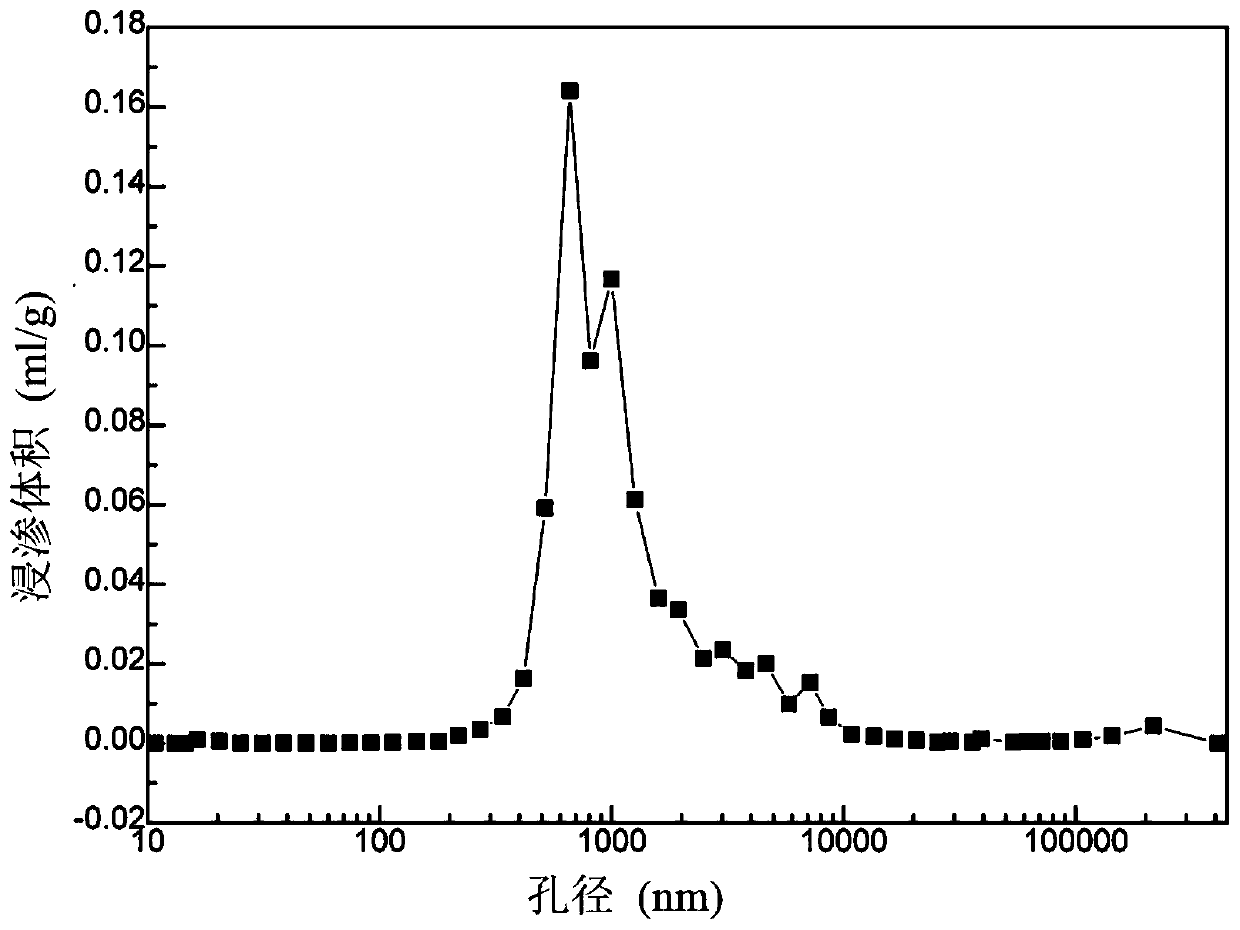

Shift catalyst using cobalt-magnesium-aluminum hydrotalcite as precursor and preparation method thereof

ActiveCN105251512BHigh low temperature activityImprove thermal stabilityPhysical/chemical process catalystsHydration reactionPtru catalyst

The invention provides a sulfur-tolerant shift catalyst using cobalt-magnesium-aluminum hydrotalcite as a precursor, using CoMgAl-LDO as a carrier, and using MoO3 as an active component. The carrier CoMgAl-LDO is based on cobalt-magnesium-aluminum hydrotalcite. The precursor is prepared after roasting, and has the characteristics of uniform cobalt dispersion, suitable surface alkalinity and uniform distribution of pore structure. The catalyst prepared by further using the carrier CoMgAl-LDO to impregnate the Mo active component can make the Co and Mo components All are highly dispersed, in which the Co component is evenly distributed in the interior and surface of the catalyst carrier, and a good interaction is formed between Co and Mo, and the catalyst has high catalytic activity in a wide temperature range of 250-450°C , high thermal stability, strong hydration resistance, not only suitable for high temperature, high pressure and high steam-gas ratio conversion conditions, but also suitable for medium pressure and low temperature conversion process.

Owner:中琉科技有限公司

Loop heat pipe and preparation method of porous silicon nitride ceramics

ActiveCN109956751BHigh porosityImprove flexural strengthIndirect heat exchangersCeramicwareSlurryPore diameter

The invention discloses a loop heat pipe and a preparation method of porous silicon nitride ceramic. The loop heat pipe is prepared from porous silicon nitride ceramic, of which the porosity is 50-70%, the strength is 10-30 MPa, and the average pore diameter is 0.5-1 [mu]m. The method comprises the following steps: with Si3N4 powder as a raw material, adding a sintering aid, and carrying out uniform mechanical wet ball milling mixing to form slurry; defoaming and degassing the slurry, freezing and curing the slurry at low temperature in a mold, and drying the material; putting the material into a muffle furnace for heat preservation to remove organic matter impurities; and finally, sintering the material in a sintering furnace at a high temperature to obtain the Si3N4 porous ceramic tube.The ceramic tube has the characteristics of high porosity, high strength, uniform pore structure distribution and the like, and can replace a metal loop heat tube to meet the use in the fields of loopheat tubes under a high-temperature condition and the like.

Owner:CENT SOUTH UNIV

Coal-based nitrogen-doped activated carbon spherical electrode material with high specific surface area and preparation method thereof

ActiveCN108428560BHigh yieldEvenly distributed pore structureHybrid capacitor electrodesHybrid/EDL manufacturePotassium hydroxideCarbonization

The invention relates to the technical field of electrode materials for supercapacitors, and discloses a high specific surface area coal-based nitrogen-doped activated carbon sphere electrode materialand a preparation method thereof. The high specific surface area coal-based nitrogen-doped activated carbon sphere electrode material is prepared according to the steps of enabling pulverized coal tobe reacted with a strong oxidant solution, performing hydrothermal reaction on obtained oxidized coal and glucosamine, mixing a powdered product obtained by washing and drying to obtain with potassium hydroxide, carrying out carbonization treatment, washing and drying an obtained mixed product to acquire a high specific surface area coal-based nitrogen-doped activated carbon sphere electrode material. According to the invention, the glucosamine is adopted to serve as a nitrogen source, the oxidized coal is adopted to serve as a carbon source, so that the yield of coal-based nitrogen-doped carbon spheres is effectively improved, and the high specific surface area coal-based nitrogen-doped activated carbon sphere electrode material is prepared. The high specific surface area coal-based nitrogen-doped activated carbon sphere electrode material has micro-nano morphology, is uniform in pore structure distribution and has excellent specific capacity and high-current charging and dischargingperformance when serving as a supercapacitor electrode material.

Owner:XINJIANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com