Battery diaphragm, preparation method thereof, lithium ion battery and electric vehicle

A battery diaphragm and base film technology, which is applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of uneven distribution of pore structure, poor thermal shrinkage resistance of the diaphragm, and low surface porosity of the battery diaphragm, and achieve Low shrinkage, prevent short circuit of positive and negative electrodes of battery, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In a second aspect, the present invention also provides a method for preparing a battery separator, wherein the method includes the following steps:

[0045] (1) carry out surface modification to polyethylene terephthalate, make it contain hydroxyl group and / or carboxyl group, or make it have carbon-carbon double bond, obtain modified polyethylene terephthalate;

[0046] (2) The modified polyethylene terephthalate is mixed with an acrylic polymer for melt spinning to form a polymer fiber layer.

[0047] According to the present invention, the above method for modifying polyethylene terephthalate has been fully introduced, and will not be repeated here in order to avoid unnecessary repetition.

[0048] Wherein, in step (1), the weight ratio of the silane coupling agent to polyethylene terephthalate is 0.05:1-0.5:1, and the silane coupling agent and polyethylene terephthalate The weight ratio of the alcohol ester is controlled in the above range, and the modified polyeth...

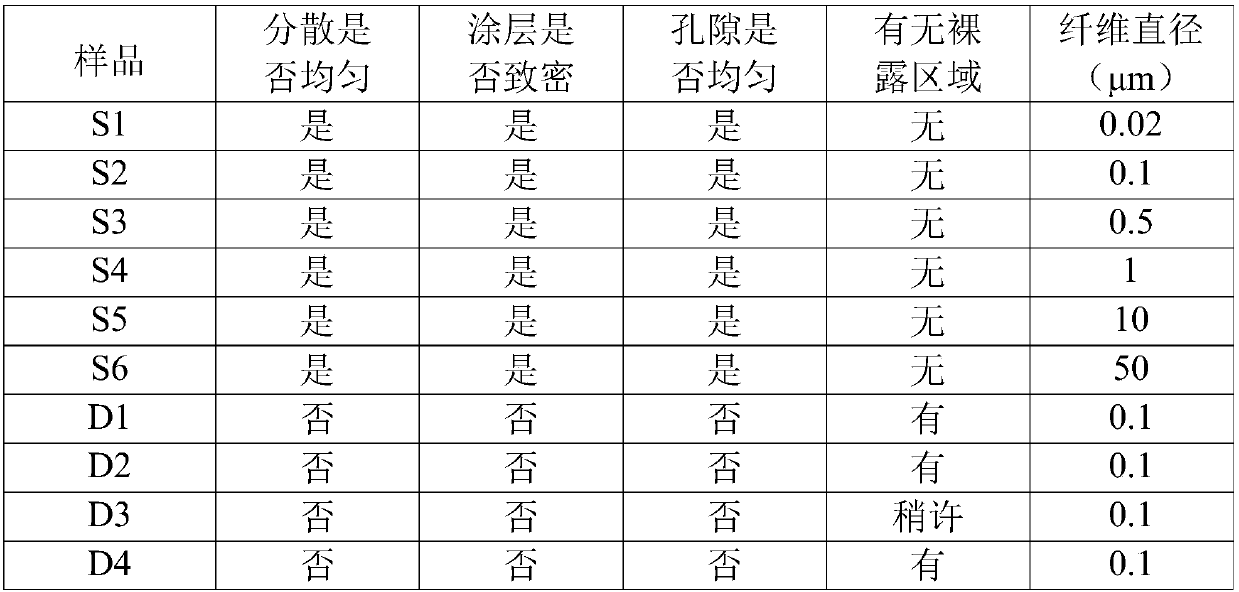

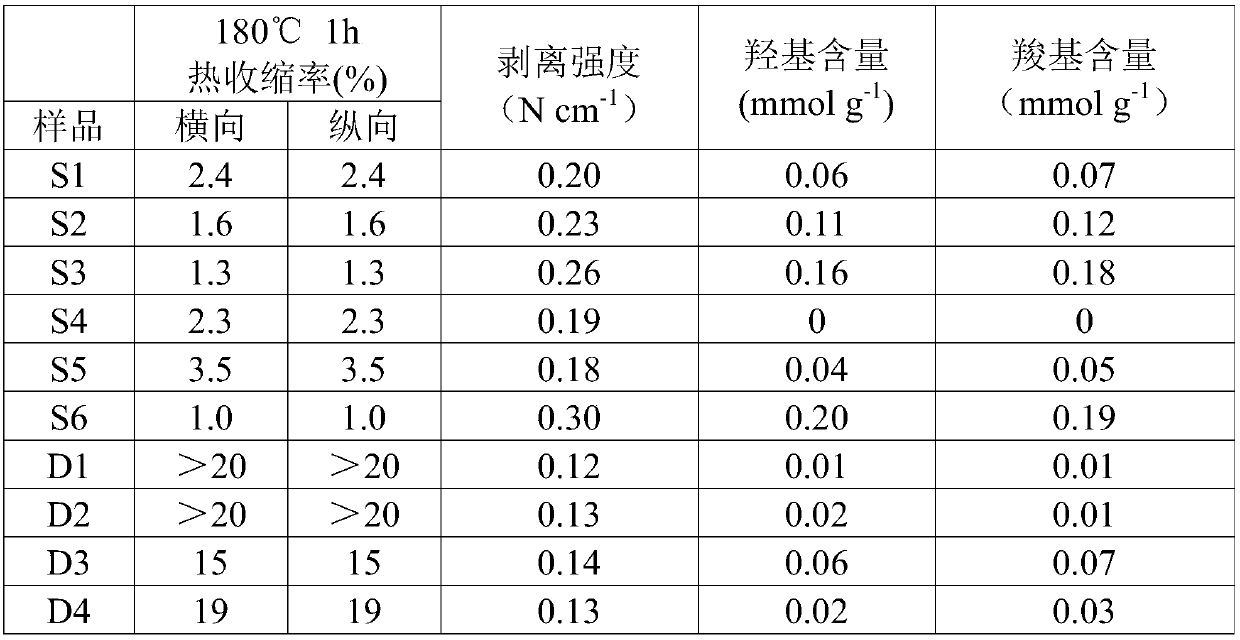

Embodiment 1

[0083] Prepare battery separators as follows:

[0084](1) First use N,N-dimethylformamide solution of 0.1mol / L silane coupling agent 3-acryloyloxypropyltrimethoxysilane to polyethylene terephthalate at 60°C After 2 hours of treatment, modified polyethylene terephthalate was obtained. The amount of the silane coupling agent is such that the hydroxyl content and carboxyl content on the surface of polyethylene terephthalate are shown in Table 2.

[0085] (2) Mix the modified polyethylene terephthalate prepared in step (1) with butyl acrylate-hydroxyethyl acrylate copolymer to obtain a polymer fiber layer composition. Among them, the content of modified polyethylene terephthalate was 90% by weight, and the content of butyl acrylate-hydroxyethyl acrylate copolymer was 10% by weight. Heated and melted at 200°C, then electrospun on one side of the PE base film, dried at 60°C for 2 hours, spun on the other side by the same method after drying, and dried at 60°C for 24 hours to obtai...

Embodiment 2

[0088] (1) earlier polyethylene terephthalate is used the N of the silane coupling agent 3-methacryloxypropyltrimethoxysilane of 0.2mol / L, N-dimethylformamide solution at 50 Treat at ℃ for 3h to obtain modified polyethylene terephthalate. The amount of the silane coupling agent is such that the hydroxyl content and carboxyl content on the surface of polyethylene terephthalate are shown in Table 2.

[0089] (2) The modified polyethylene terephthalate prepared in step (1) is mixed with butyl acrylate-hydroxyethyl acrylate copolymer and sodium hexametaphosphate, wherein the modified polyethylene terephthalate The content of the ethylene glycol ester was 85% by weight, the content of the polybutyl acrylate-hydroxyethyl acrylate copolymer was 10% by weight, and the content of the dispersant was 5% by weight. Then heat and melt at 200°C, and perform electrospinning on one side of the PE base film, dry at 60°C for 2 hours, spin on the other side in the same way after drying, and dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com