Application of mixed cellulose ester film, prepared battery and preparation method

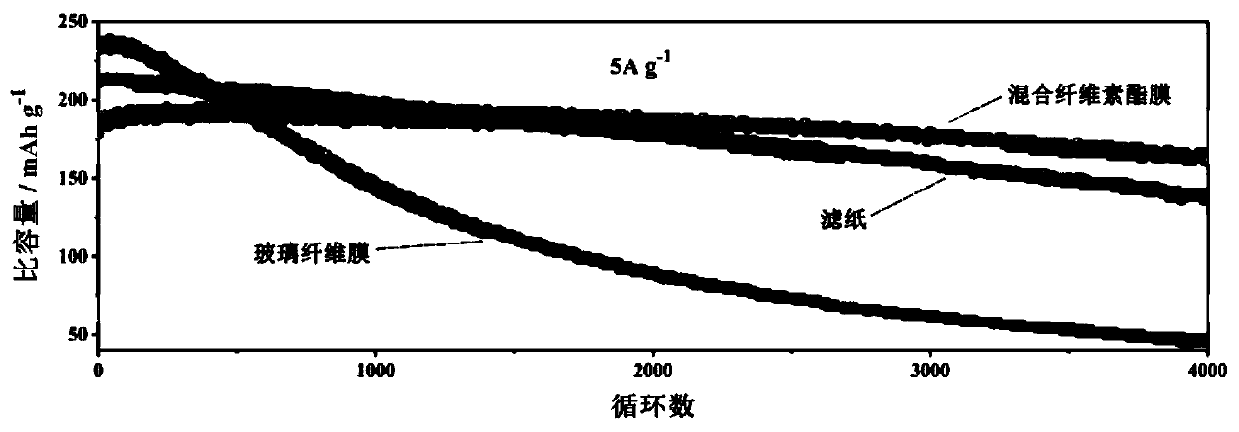

A technology of mixing cellulose and ester film, used in secondary battery manufacturing, secondary battery, battery pack parts and other directions, can solve the problem of high porosity, achieve low cost, prolong cycle life, and widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

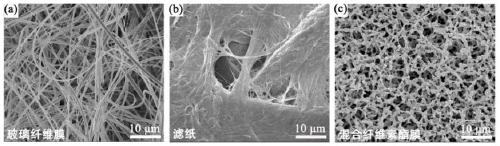

[0031] The separator of this embodiment is a mixed cellulose ester membrane with a pore size of 0.8 μm and a thickness of 130 μm, and is not infiltrated in the electrolyte containing zinc salt before the battery is assembled.

[0032] The CR2025 button battery is used to assemble the water-based zinc-ion battery for testing. The assembly process is as follows: first place the negative electrode shell, then place the shrapnel and gasket in turn, place the metal zinc sheet as the negative electrode in the middle of the gasket, and mix the cellulose ester film (The pore size is 0.8μm, the thickness is 130μm) is placed on top of the metal zinc sheet, and three drops of electrolyte are added to the membrane. The composition of the electrolyte is 3mol L -1 The zinc trifluoromethanesulfonate aqueous solution, and then the sodium vanadate positive sheet is placed in the middle of the membrane, and finally the positive shell is added to it, and the battery packer is used for sealing. The a...

Embodiment 2

[0034] The separator of this embodiment is a mixed cellulose ester membrane with a pore size of 1.2 μm and a thickness of 130 μm, and it is not infiltrated in the electrolyte containing zinc salt before the battery is assembled.

[0035] The CR2025 button battery is used to assemble the water-based zinc-ion battery for testing. The assembly process is as follows: first place the negative electrode shell, then place the shrapnel and gasket in turn, place the metal zinc sheet as the negative electrode in the middle of the gasket, and mix the cellulose ester film (The pore size is 1.2μm, the thickness is 130μm) is placed on top of the metal zinc sheet, and three drops of electrolyte are added to the membrane. The composition of the electrolyte is 3mol L -1 The zinc trifluoromethanesulfonate aqueous solution, and then the sodium vanadate positive sheet is placed in the middle of the membrane, and finally the positive shell is added to it, and the battery packer is used for sealing. Th...

Embodiment 3

[0037] The separator in this embodiment is a mixed cellulose ester membrane with a pore size of 2.0 μm and a thickness of 130 μm, and it is not infiltrated in the electrolyte containing zinc salt before the battery is assembled.

[0038] The CR2025 button battery is used to assemble the water-based zinc-ion battery for testing. The assembly process is as follows: first place the negative electrode shell, then place the shrapnel and gasket in turn, place the metal zinc sheet as the negative electrode in the middle of the gasket, and mix the cellulose ester film (The pore size is 2.0μm, the thickness is 130μm) is placed on top of the metal zinc sheet, and three drops of electrolyte are added on the membrane. The composition of the electrolyte is 3mol L -1 The zinc trifluoromethanesulfonate aqueous solution, and then the sodium vanadate positive sheet is placed in the middle of the membrane, and finally the positive shell is added to it, and the battery packer is used for sealing. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com