Loop heat pipe and preparation method of porous silicon nitride ceramics

A technology of silicon nitride ceramics and porous ceramics, applied in the field of porous ceramics, can solve the problems of high temperature stability, wear resistance and corrosion resistance that cannot meet the application requirements of aerospace, and achieve high bending strength, uniform distribution of pore structure, and high porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

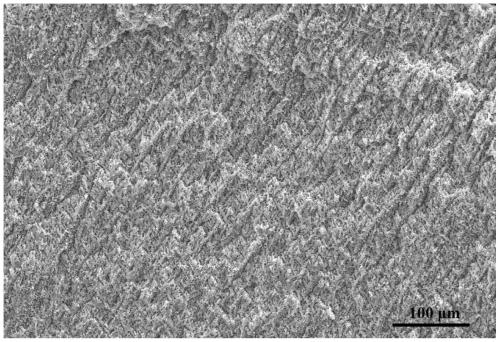

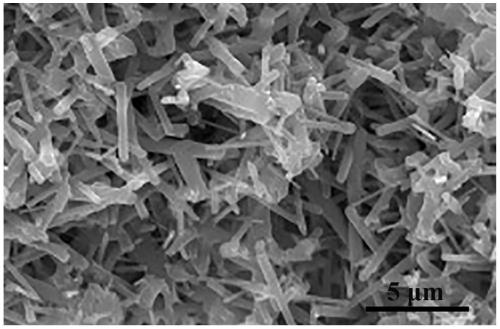

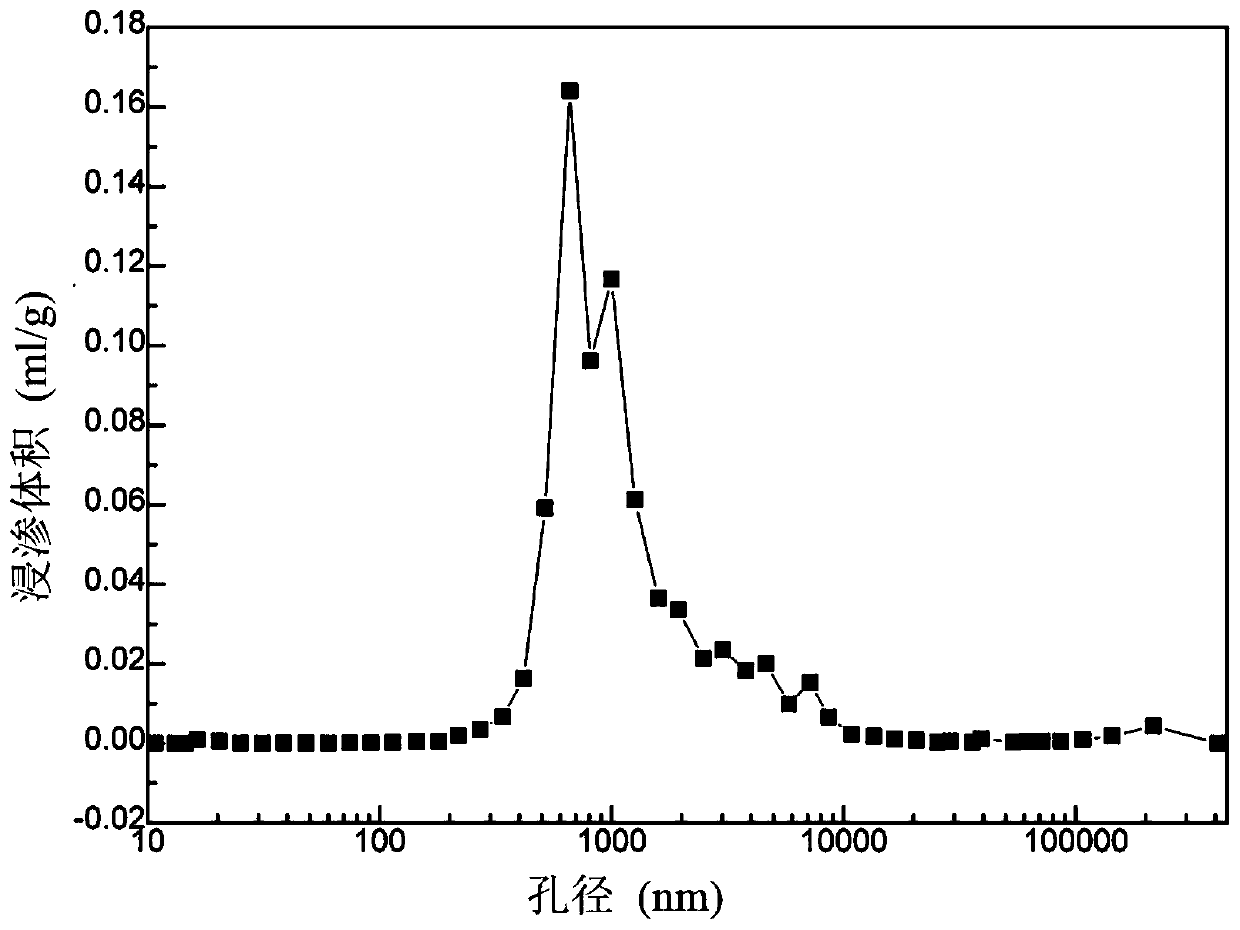

[0026] Step S1, preparation of slurry: using silicon nitride powder of 0.5-5 microns and 85-95% purity as raw material, adding sintering aid Y 2 o 3 , Si 3 N 4 Powder: Y 2 o 3 The weight ratio is shown in Table 1, and other binders, bulking agents and defoamers are added, which are PVA, glycerin and NH 4 PAA, with absolute ethanol as dispersant, with Si 3 N 4 Balls are used for mechanical wet mixing to form a well-dispersed, uniform and stable ceramic slurry.

[0027] Step S2, preparing the green body: after the slurry is defoamed and vacuum degassed, it is poured into a mold with a certain shape for freezing, and the slurry is frozen at a low temperature to ensure that the slurry is completely solidified, and the solidified sample is demolded.

[0028] Step S3, then quickly transfer to a freeze dryer, and dry under vacuum at low temperature.

[0029]Step S4, removing organic matter from the green body: put the dried green body into a muffle furnace, raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com