Novel hydrophobic modification system p-carboxyl MWCNT/PVDF blend membrane surface modification method

A hydrophobic modification and surface modification technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problem that the hydrophobicity and permeation flux of super-hydrophobic membrane materials cannot be increased at the same time, and achieve short time and high pore size. The effect of uniform structure distribution, reducing energy consumption and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for modifying the surface of a carboxylated MWCNT / PVDF blend membrane by a new hydrophobic modification system, the method steps are as follows,

[0033] (1) Preparation of MWCNT / PVDF blend membrane:

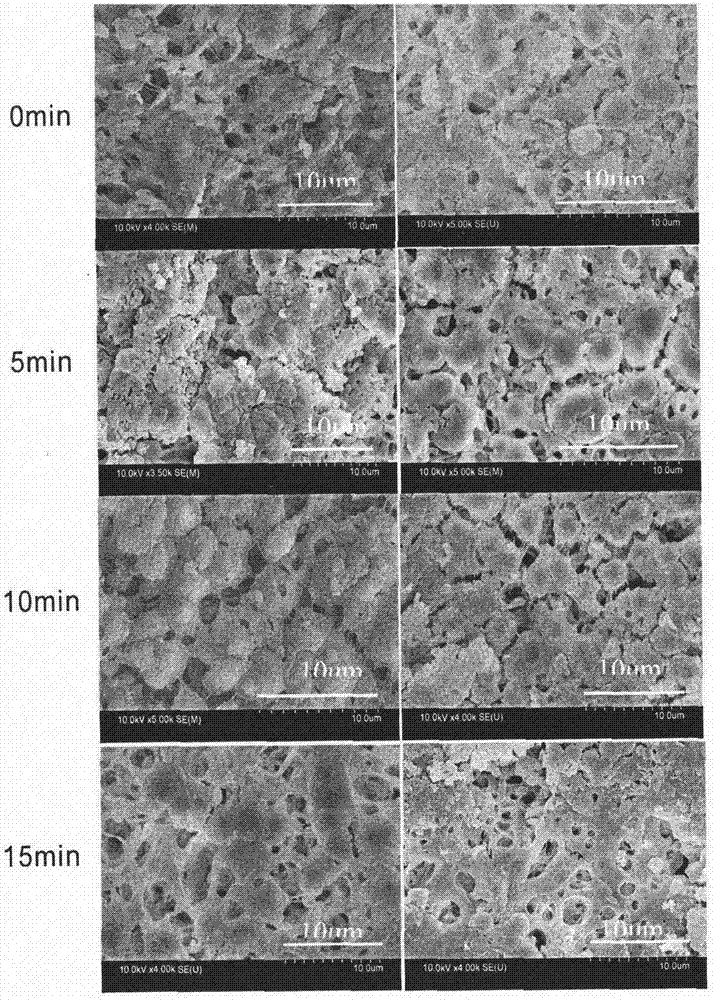

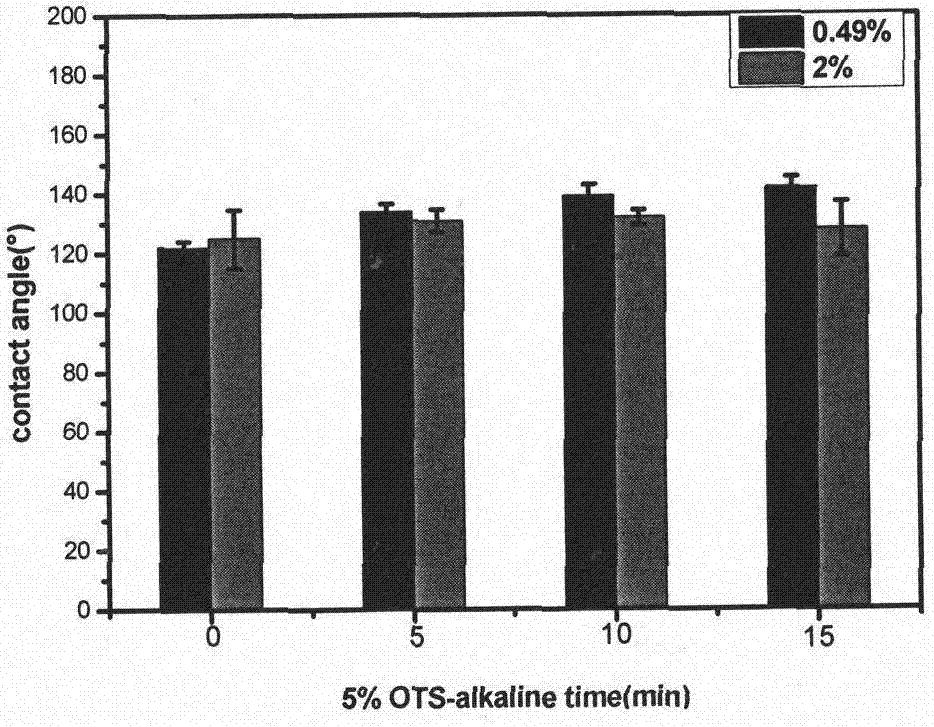

[0034] 0.05g MWCNTs-COOH (0.49%, 2%), 30ml DMF, ultrasonic 40min to fully disperse MWCNTs-COOH, add 5g PVDF powder and stir vigorously in a constant temperature water bath at 70°C for 4h to make a casting solution;

[0035] (2) Alkali pretreatment:

[0036] Wet the MWCNT / PVDF blend membranes with different carboxylation contents with ethanol, and then soak them in NaOH solution (pH=10) for alkali treatment for 0, 5, 10, 15 min;

[0037] (3) Silanization modification:

[0038] 98% OTS and 90% (w / w) ethanol / water were formulated into silane coupling agent solutions with a concentration of 2%, 5%, and 7%, respectively, and the blended membrane after alkali treatment was immersed and placed on a vibrating shaker Medium reaction for 4 hours;

[0039] (4) Post-proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com