Shift catalyst using cobalt-magnesium-aluminum hydrotalcite as precursor and preparation method thereof

A technology of cobalt-magnesium-aluminum and hydrotalcite is applied in the field of sulfur-resistant shift catalyst and its preparation, which can solve the problems of inapplicability of low-temperature shift process and poor low-temperature activity, achieve uniform distribution of surface alkalinity, improve low-temperature activity, and resist hydration strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

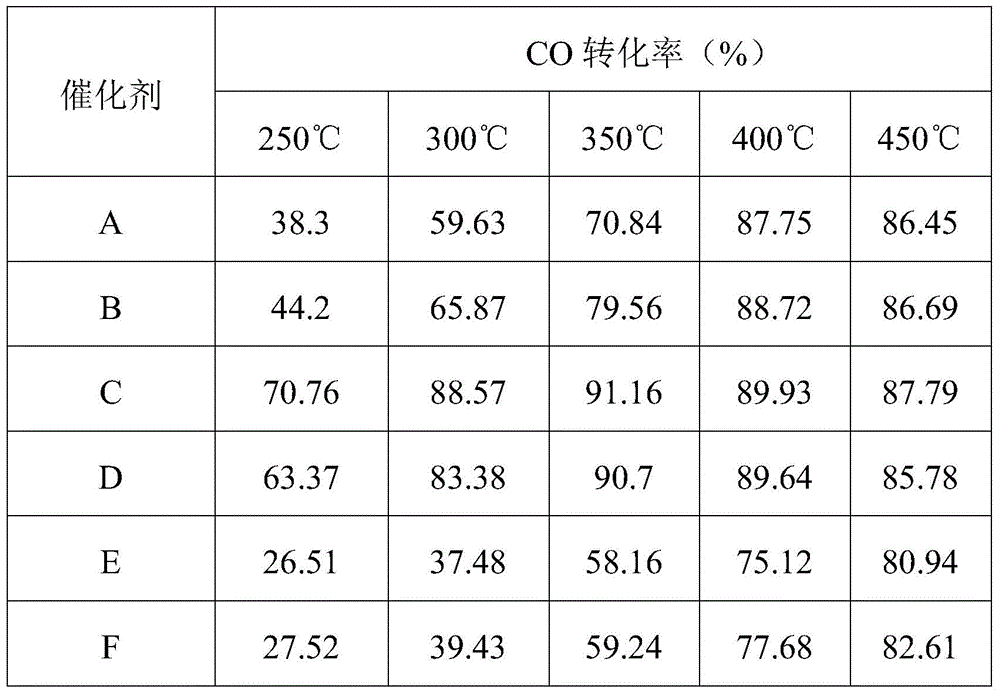

Examples

Embodiment 1

[0028] This embodiment provides a sulfur-tolerant shift catalyst using cobalt-magnesium-aluminum hydrotalcite as a precursor, which uses CoMgAl-LDO as a carrier and MoO 3 It is the active component, and the active component after sulfidation is Co-Mo-S phase.

[0029] The preparation method of the sulfur-resistant shift catalyst using cobalt-magnesium-aluminum hydrotalcite as a precursor comprises the following steps:

[0030] (1) Weigh 9.3783g of Al(NO 3 ) 2 9H 2 O, 0.1455g of Co(NO 3 ) 2 ·6H 2 O, 12.6923g of Mg(NO 3 ) 2 ·6H 2 O and mix it evenly, fully dissolve it in 250ml deionized water, and ultrasonically disperse it for 10min after dissolving to form the first mixed solution. 2+ and Mg 2+ The sum of the amount of substance and Al 3+ The ratio of the amount of substance is 2:1, and Co 2+ and Mg 2+ The sum of the amount of substance and Co 2+ The ratio of the amount of substances is 100:1;

[0031] (2) Weigh 6.4g sodium hydroxide and 2.65g sodium carbonate r...

Embodiment 2

[0036] This embodiment provides a sulfur-tolerant shift catalyst using cobalt-magnesium-aluminum hydrotalcite as a precursor, which uses CoMgAl-LDO as a carrier and MoO 3 It is the active component, and the active component after sulfidation is Co-Mo-S phase.

[0037] The preparation method of the sulfur-resistant shift catalyst using cobalt-magnesium-aluminum hydrotalcite as a precursor comprises the following steps:

[0038] (1) Weigh 4.5268g of AlCl respectively 3 ·6H 2 O, 0.7749g of 2CoCO 3 3Co(OH) 2 , 13.4479g of MgSO 4 ·7H 2 O and mix it evenly, fully dissolve it in 250ml deionized water, and ultrasonically disperse it for 10min after dissolving to form the first mixed solution. 2+ and Mg 2+ The sum of the amount of substance and Al 3+ The ratio of the amount of substance is 2:1, and Co 2+ and Mg 2+ The sum of the amount of substance and Co 2+ The ratio of the amount of substances is 100:3;

[0039] (2) Weigh 6.4g sodium hydroxide and 2.65g sodium carbonate r...

Embodiment 3

[0044] This embodiment provides a sulfur-tolerant shift catalyst using cobalt-magnesium-aluminum hydrotalcite as a precursor, which uses CoMgAl-LDO as a carrier and MoO 3 It is the active component, and the active component after sulfidation is Co-Mo-S phase.

[0045] The preparation method of the sulfur-resistant shift catalyst using cobalt-magnesium-aluminum hydrotalcite as a precursor comprises the following steps:

[0046] (1) Weigh 12.4953g of Al respectively 2 (SO 4 ) 3 18H 2 O, 0.4621 g of (HCOO) 2 Co 2H 2 O, 10.8632 g of MgCl 2 ·6H 2 O and mix it evenly, fully dissolve it in 250ml deionized water, and ultrasonically disperse it for 10min after dissolving to form the first mixed solution. 2+ and Mg 2+ The sum of the amount of substance and Al 3+ The ratio of the amount of substance is 2:1, and Co 2+ and Mg 2+ The sum of the amount of substance and Co 2+ The ratio of the amount of substances is 100:5;

[0047] (2) Weigh 6.4g sodium hydroxide and 2.65g sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com