Patents

Literature

35results about How to "Strong resistance to hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

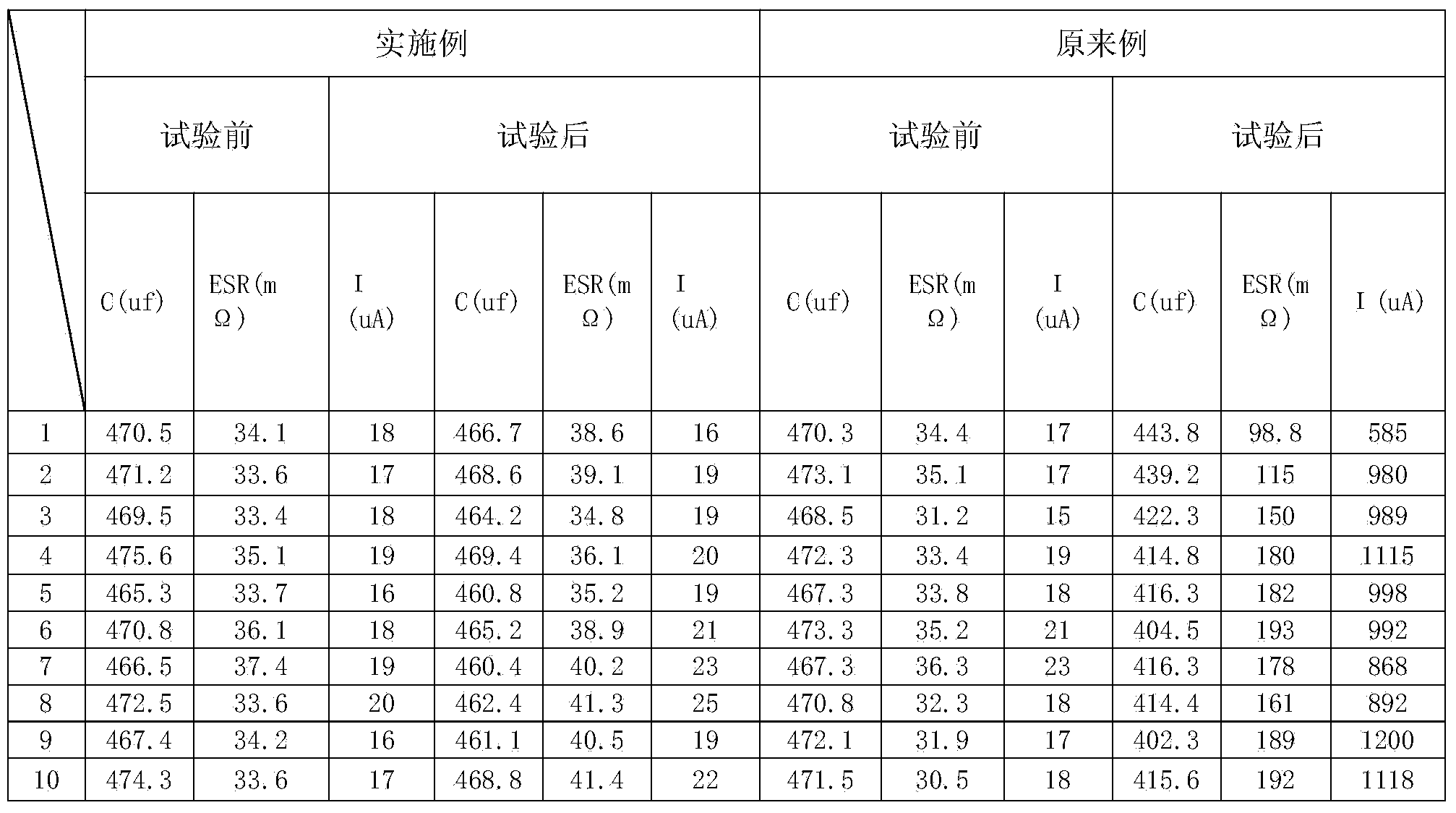

Magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter and preparation method thereof

ActiveCN108516803AAct as a binderAvoid damageFiltration separationCeramicwareOxide ceramicNano al2o3

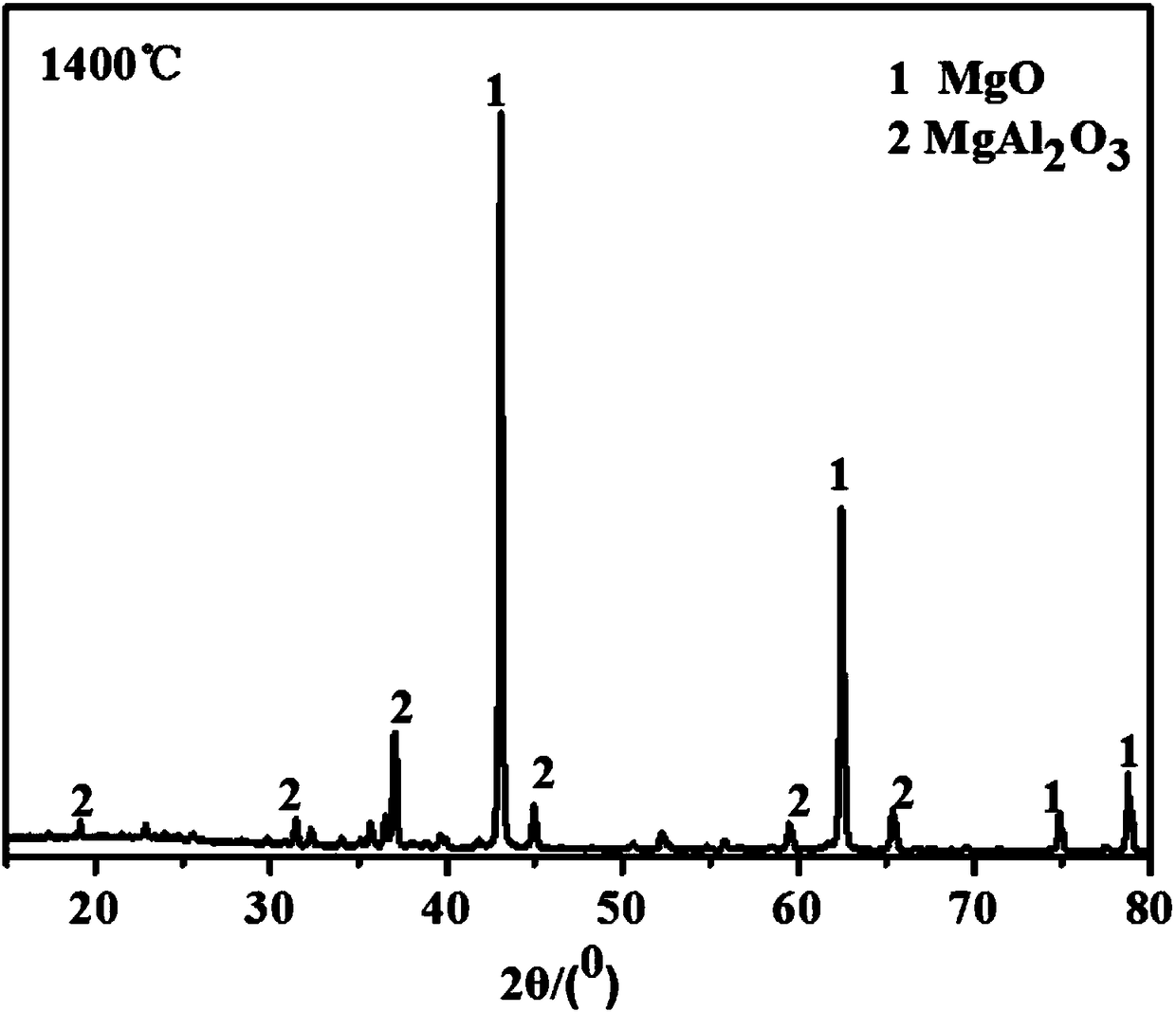

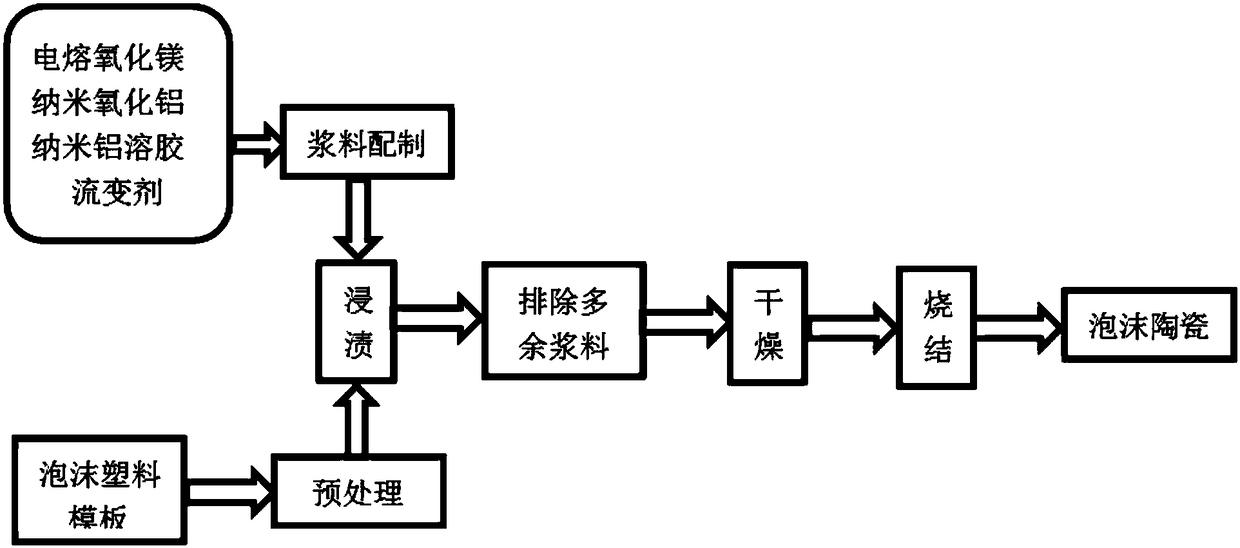

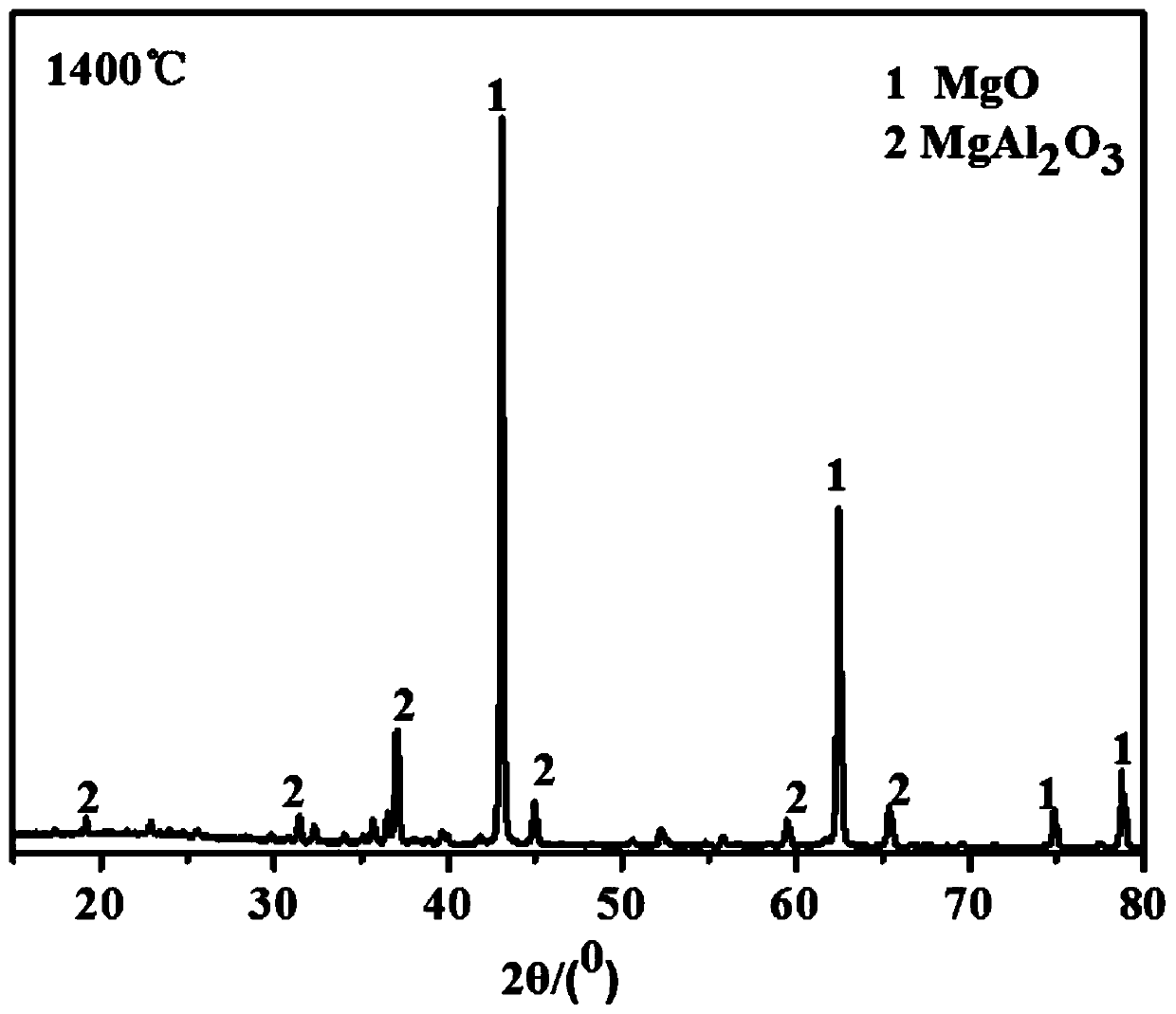

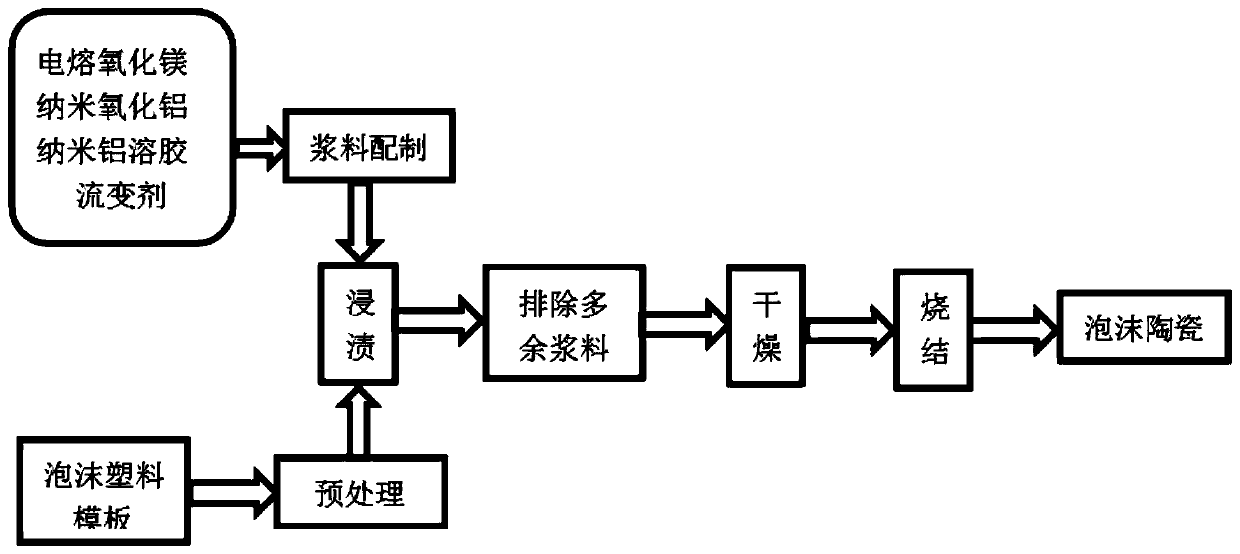

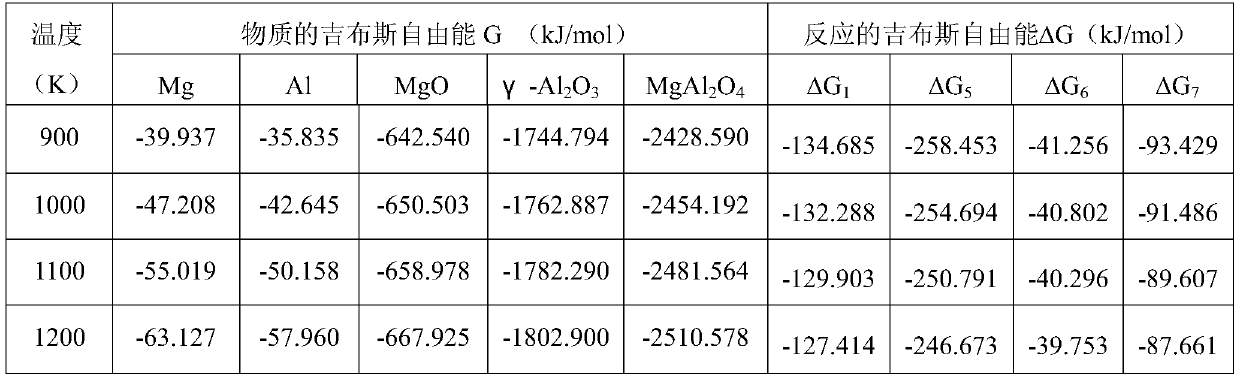

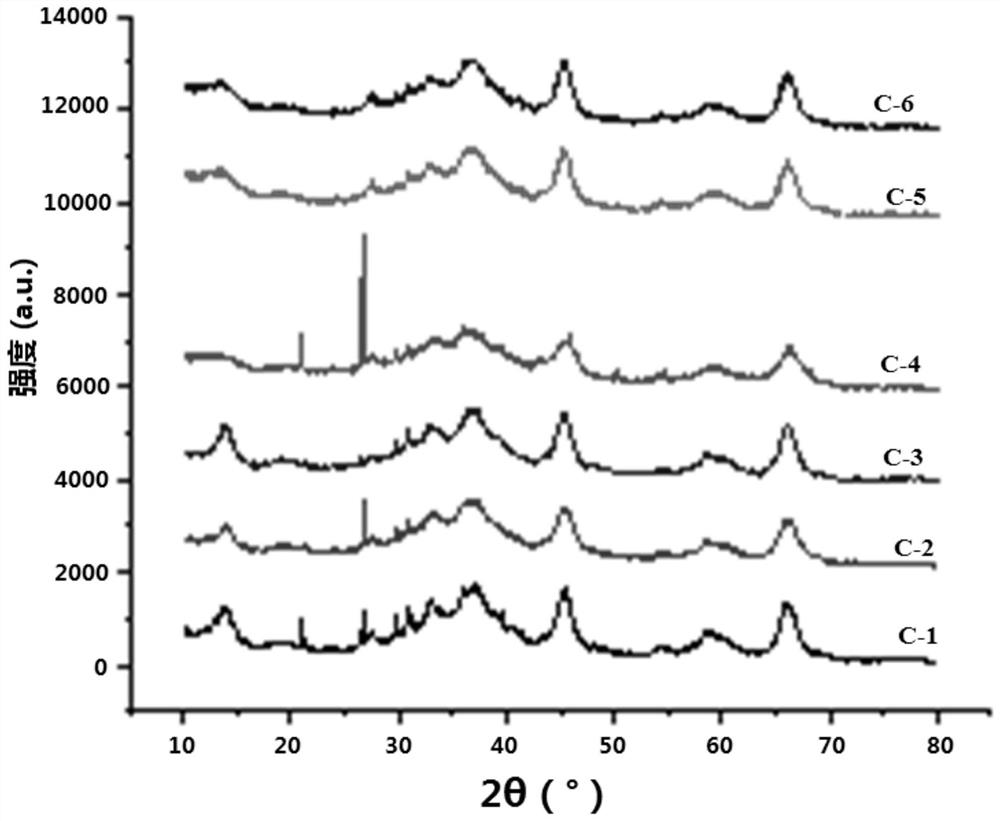

The invention discloses a magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter with capability of realizing sintering at low temperature, excellent chemical stability and excellentthermal shock resistant performance, and a preparation method thereof. The preparation method comprises the following steps that (1) 10 to 20 percent of nanometer alumina sol, 0.8 to 1.5 percent of rheological agents and the balance of magnesium oxide ceramic powder containing a nanometer aluminum oxide sintering aid are proportioned; deionized water is added; ball milling and uniform mixing areperformed; then, through vacuum exhaust, ceramic slurry with the solid content being 60 to 70 percent is prepared; (2) a polyurethane foamed plastic template is soaked into the ceramic slurry; the polyurethane foamed plastic template is extruded through a roller press for removing the redundant leaching hanging slurry; then, biscuit is prepared; then, the biscuit is heated to 80 to 120 DEG C for drying; (3) the dried biscuit is put into a sintering furnace; the temperature is raised to 1400 to 1600 DEG C; high-temperature sintering is performed; cooling is performed along with the furnace to room temperature; the magnesia-based foamed ceramic filter is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Nano-matrix-combined high-performance fused magnesium calcium brick and manufacturing method thereof

The invention provides a nano-matrix-combined high-performance fused magnesium calcium brick and a manufacturing method thereof. The fused magnesium calcium brick is prepared from 8-5mm high-calcium fused magnesium calcium sand, 5-2mm high-calcium fused magnesium calcium sand, 2-0mm high-calcium fused magnesium calcium sand, <=0.074mm high-calcium fused magnesium calcium sand, 8-5mm fused magnesite, 5-2mm fused magnesite, 2-0mm fused magnesite, <=0.074mm fused magnesite fine powder, nano sea water magnesia fine powder and a binder paraffin. The manufacturing method comprises the following steps: fine powder premixing, integral compounding, molding, drying, firing and the like. The product has the advantages of compact microstructure, fewer low-melting-point minerals, higher erosion resistance, higher scour resistance, higher stripping resistance and higher hydration resistance. The furnace life is prolonged by 30% above on average. Thus, the product satisfies the requirements of high efficiency, long service life and high cleanness for stainless steel and special steel smelting, and lowers the cost for the steel enterprises.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

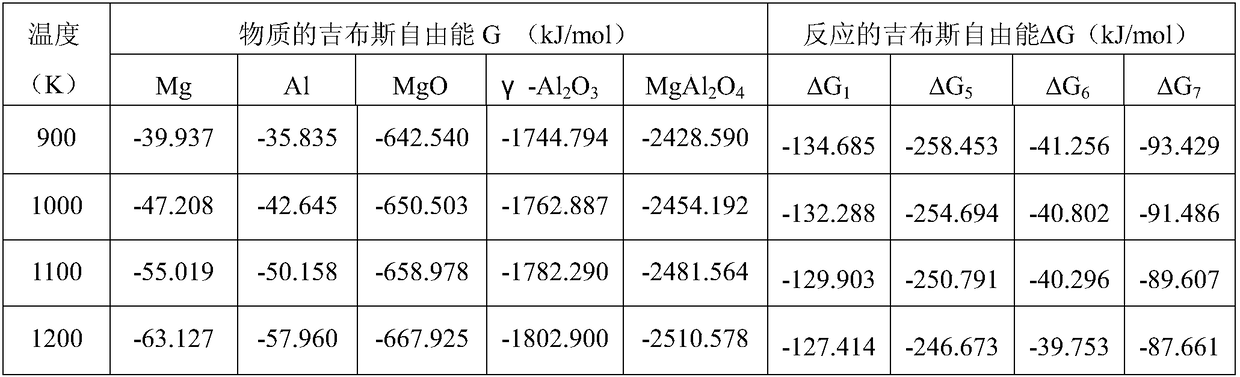

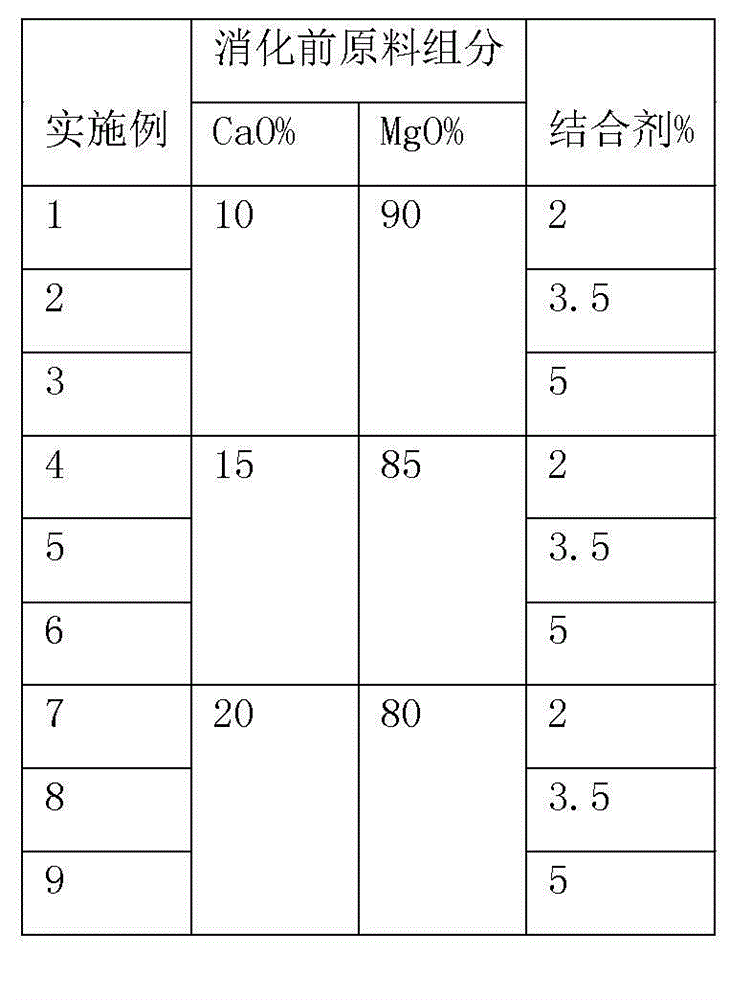

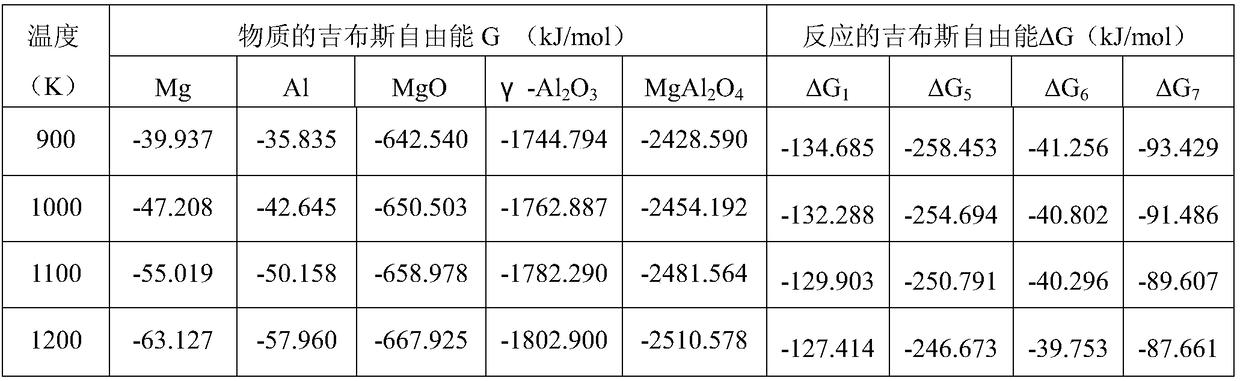

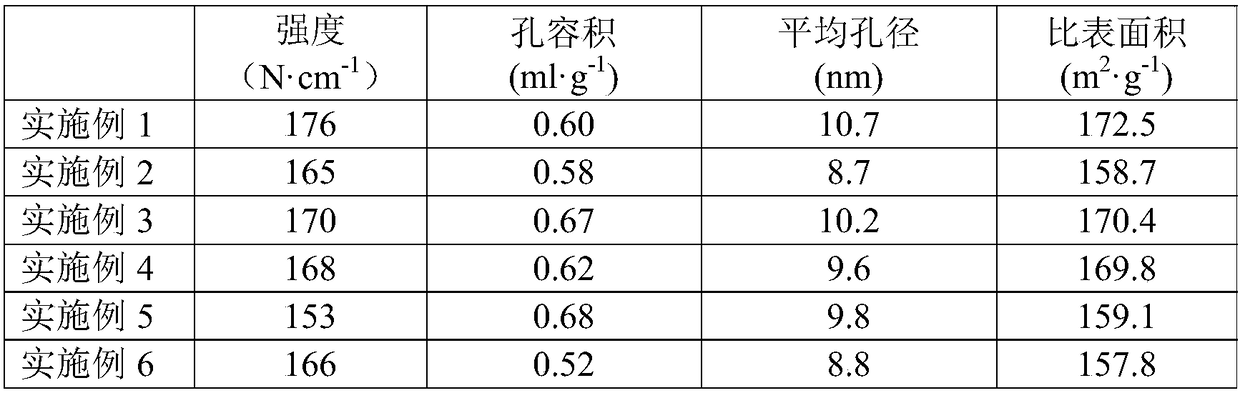

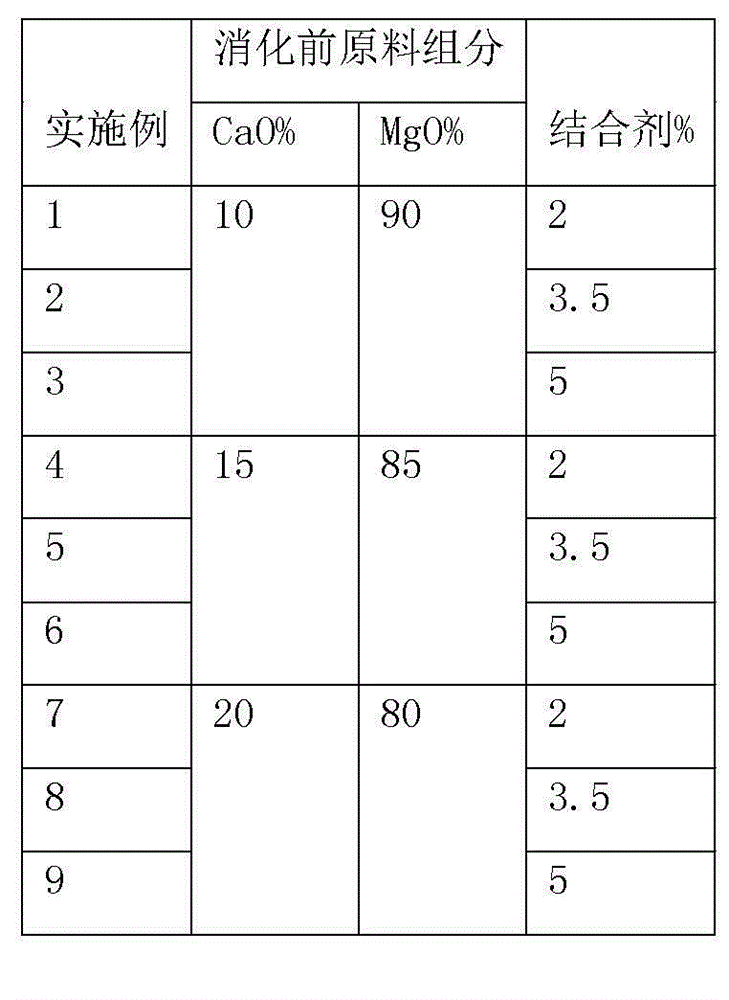

Method for preparing high-quality calcium magnesia by superhigh-temperature calcination

The invention relates to the field of preparation of refractory materials, particularly a method for preparing high-quality calcium magnesia by superhigh-temperature calcination, which is characterized by comprising the following steps: preparing dolomite and magnesite into a raw material in which the CaO content is 15-20 wt% and the MgO content is 80-85%; adding the raw material into a ball milling tank, grinding and mixing, and meanwhile, adding water to carry out slaking and slurrying; and drying the slurry, adding calcium lignosulphonate, evenly mixing, pressing into green bricks, and calcining. The calcination process comprises the following steps: heating to 1100 DEG C, keeping the temperature for 3-5 hours, heating to the final calcination temperature of 2000-2200 DEG C, keeping the temperature for 5-7 hours, vacuumizing, cooling with water to 1000 DEG C, introducing protective hydrogen, and continuing cooling with water to room temperature. Compared with the prior art, the calcium magnesia has the advantages of high hydration resistance and high corrosion resistance, thereby basically solving the problem of high hydration tendency in the magnesium-calcium refractory material, and facilitating the storage, transportation, building and the like in future.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Carbon monoxide conversion catalyst carrier, catalyst based on carrier, and preparation method thereof

ActiveCN105032497AImproves hydration resistanceHigh mechanical strengthHydrogenCatalyst carriersAluminum IonHigh absorption

The invention provides a catalyst carrier with conversion and adsorption purification performances. Modified bauxite added into the raw materials of the catalyst carrier has fluxing and pore-forming functions. Through modification, most of iron oxide in bauxite is removed, such that the modified bauxite contains a large amount of high-activity aluminosilicate compound. As a fluxing agent, during catalyst preparation, the aluminosilicate compound assists in significantly improving the migration rates of magnesium and aluminum ions during a roasting process, such that MgAl2O4 generation under low temperature is promoted. Therefore, the catalyst carrier provided by the invention has relatively high hydration resistance and mechanical strength. Also, with the modification treatment, modified bauxite is adopted as a macroporous hard template for preparing the catalyst. With a roasting treatment, macro-pores are formed in the catalyst carrier structure, such that the catalyst carrier has relatively high absorption purification capacity upon macromolecular particles such as oil and dust.

Owner:FUJIAN PROVINCE SINOGASHOLDER EQUIP INSTALLATION CO LTD

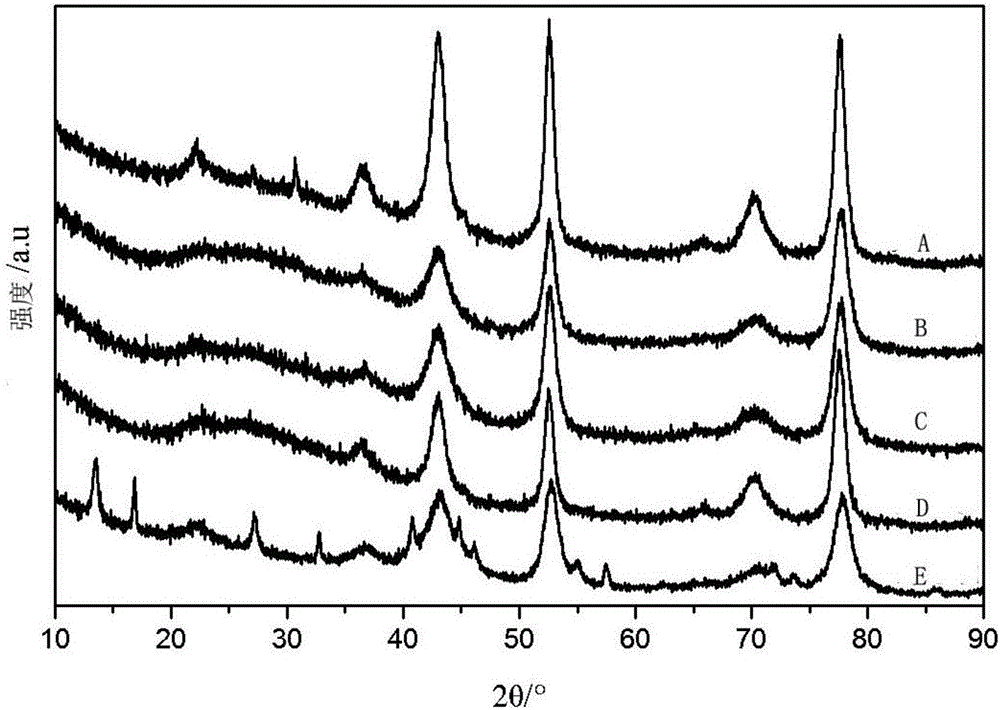

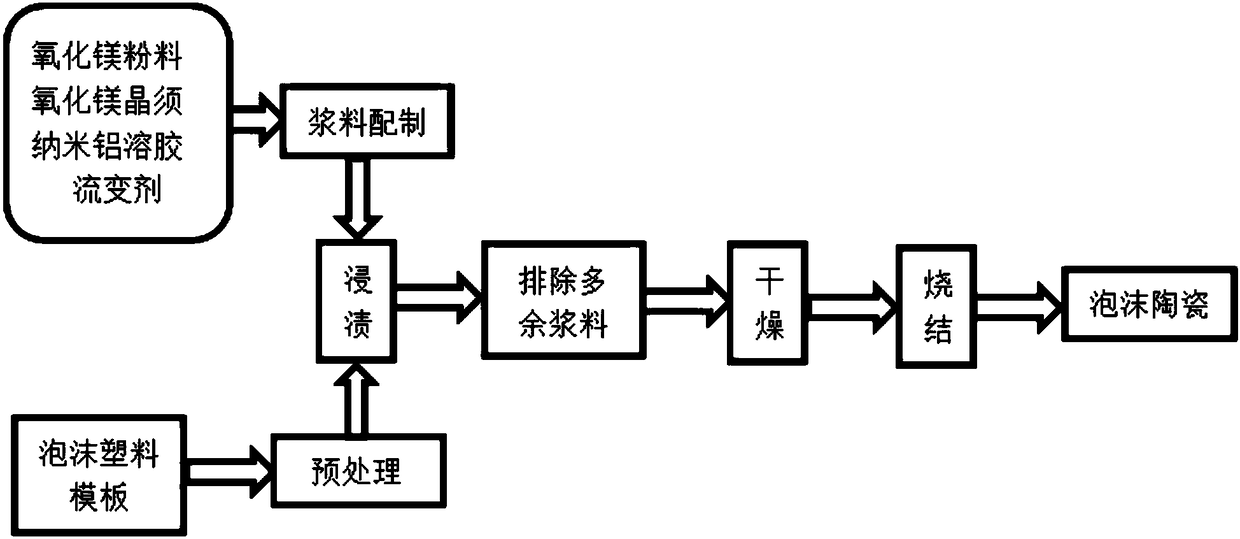

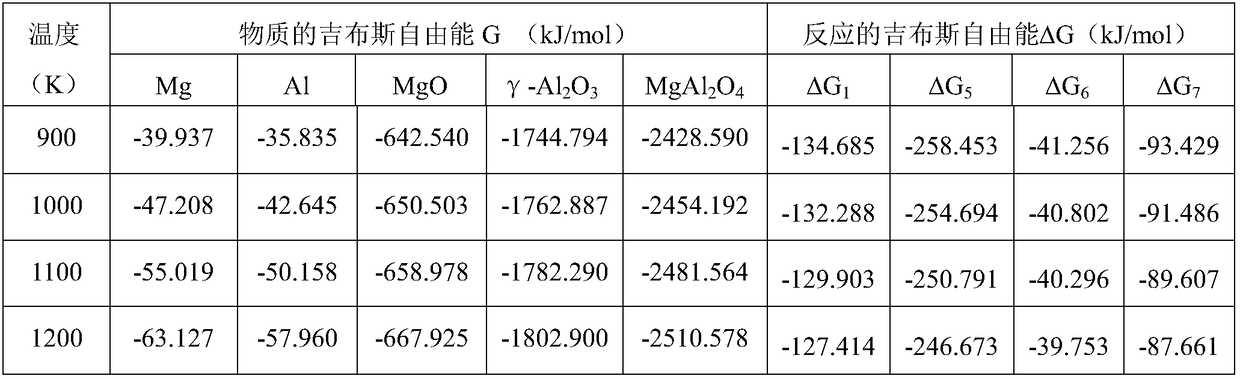

Magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter and preparation method thereof

ActiveCN108484182AAvoid obstructionAct as a binderFiltration separationCeramicwareRoom temperatureSlurry

The invention discloses a magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter with chemical stability and excellent thermal shock resistance capable of sintering in a low temperature and a preparation method thereof. The preparation method comprises the following steps: (1) according to a mass percent, compounding by 15%-25% of nano-aluminum sol, 0.8%-1.5% of rheological agent, and the balance of magnesia ceramics powder containing magnesium oxide whisker, adding deionized water, ball-milling, uniformly mixing, and preparing ceramic slurry of which the solid content is 60%-70% through vacuum exhaust; (2) immerging a polyurethane foamed plastic template in the ceramic slurry, extruding the polyurethane foamed plastic template through a roller press so as to remove redundant immerging slurry, preparing a biscuit, heating the biscuit to 80-120 DEG C, and drying; and (3) placing the dried biscuit in a sintering furnace, warming to 1400-1600 DEG C, and sintering in a high temperature, cooling to room temperature along with the furnace, to obtain the magnesium-oxide-based foam ceramic filter.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH +1

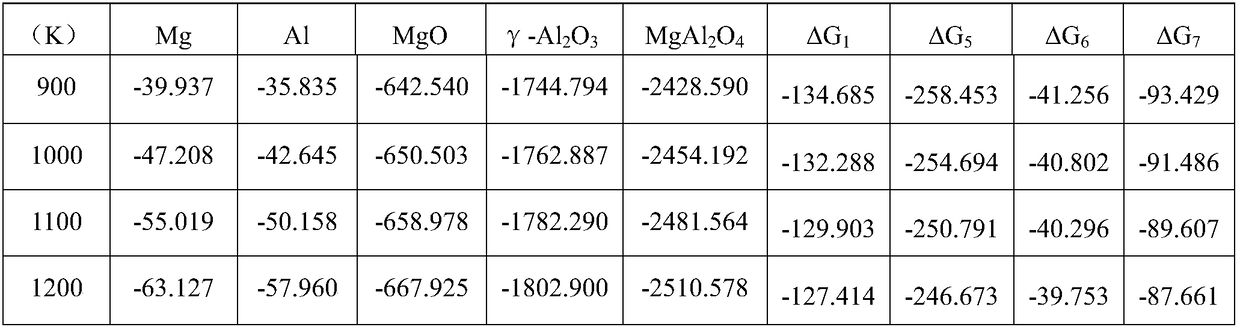

Preparation process of high-voltage anode foil for contracted ox horn type aluminum electrolytic capacitor

ActiveCN111599598ASimplify the configuration processEasy to operateElectrolytic capacitorsO-Phosphoric AcidPhysical chemistry

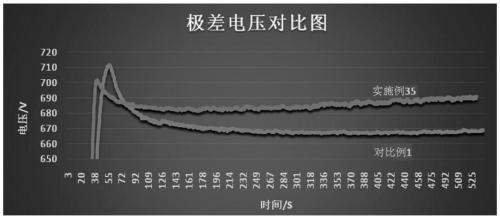

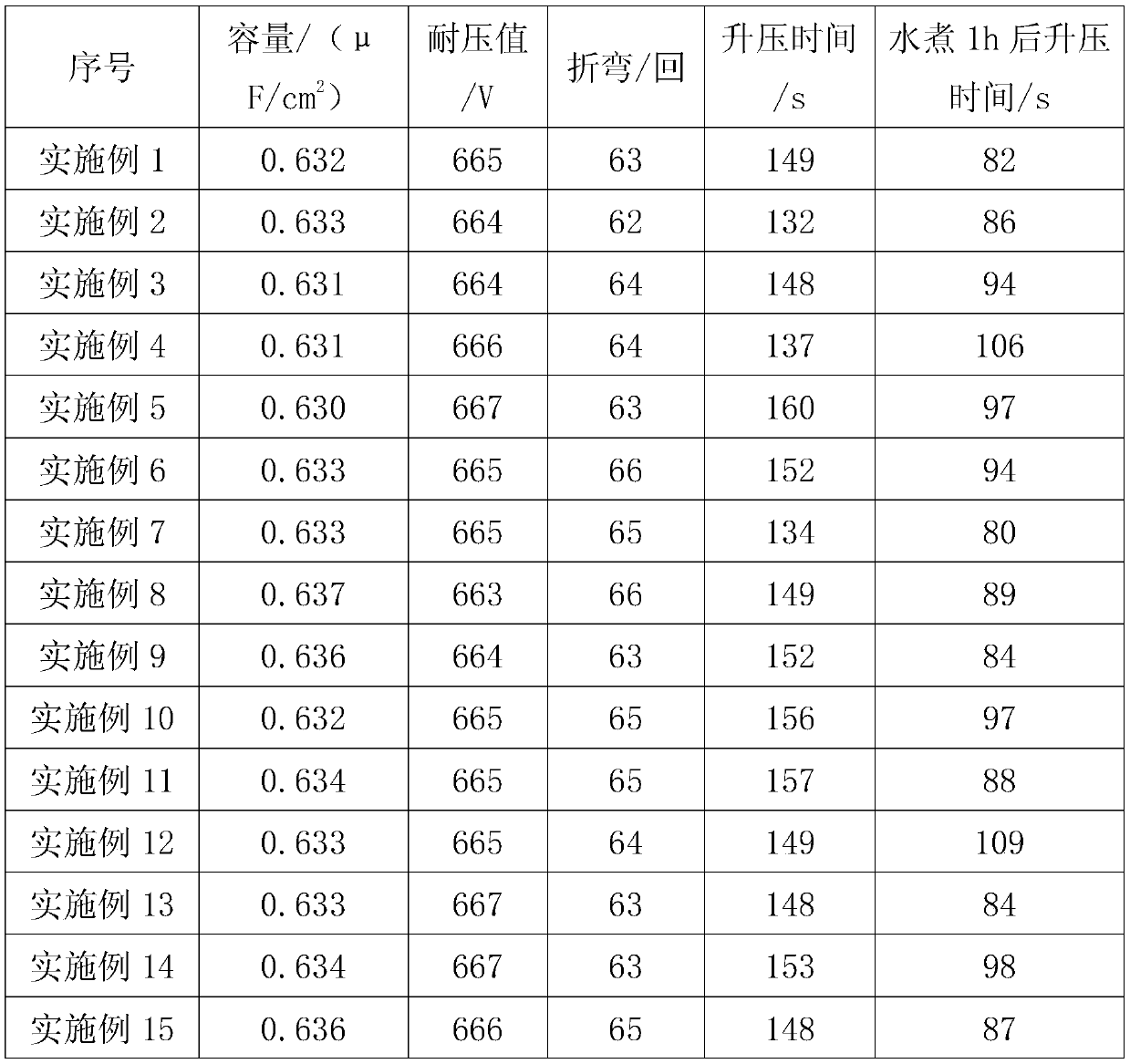

The invention relates to a preparation process of a high-voltage anode foil for a contracted ox horn type aluminum electrolytic capacitor. The preparation process comprises the following steps: (1) first-stage feeding; (2) high-temperature water boiling of an aluminum foil sheet; (3) first-stage formation; (4) second-stage formation; (5) second-stage feeding; (6) third-stage formation; (7) fourth-stage formation; (8) third-level feeding; (9) five-stage formation; (10) six-stage formation; (11) first phosphoric acid treatment; (12) first rear end repairing; (13) second phosphoric acid treatment; (14) second rear end repairing; (15) sheet firing; (16) third rear end repairing; (17) post-treatment; and (18) drying treatment. According to the preparation process of the high-voltage anode foilfor the contracted ox horn type aluminum electrolytic capacitor, the aluminum foil with high capacity, high strength, low electric leakage and high hydration resistance can be prepared.

Owner:XINJIANG JOINWORLD CO LTD

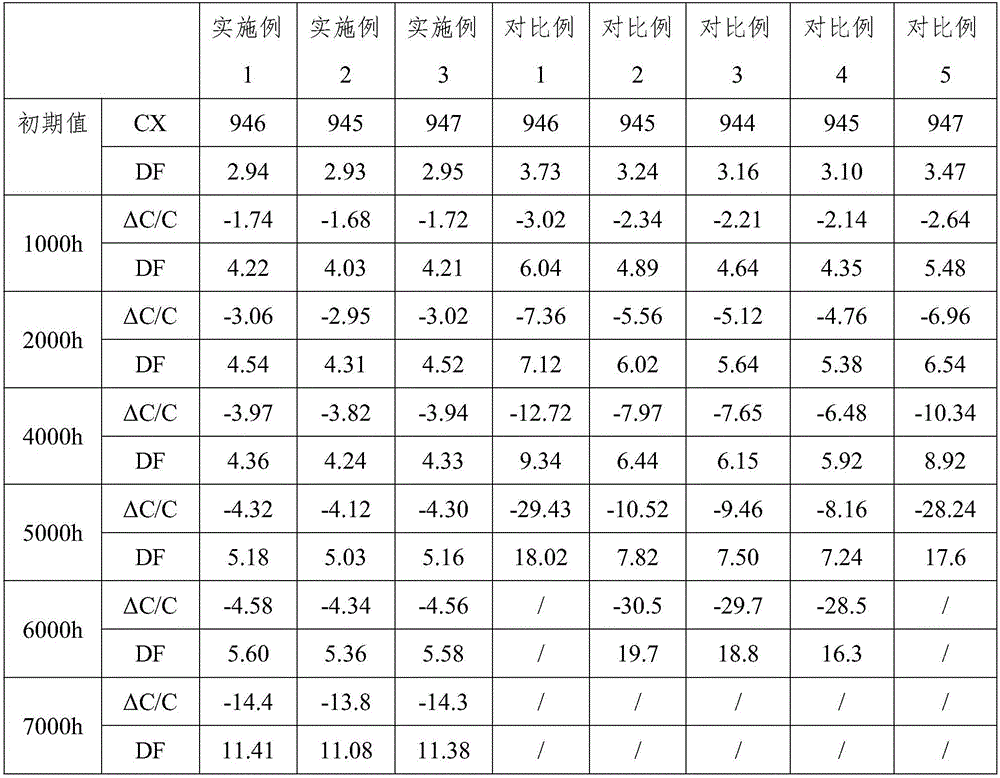

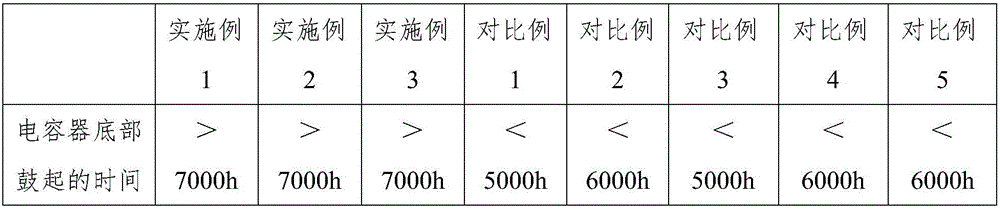

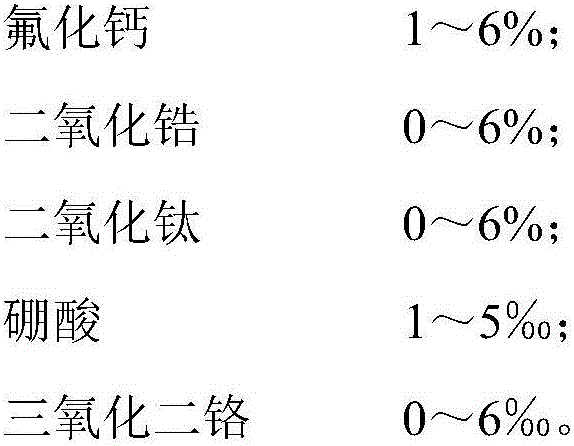

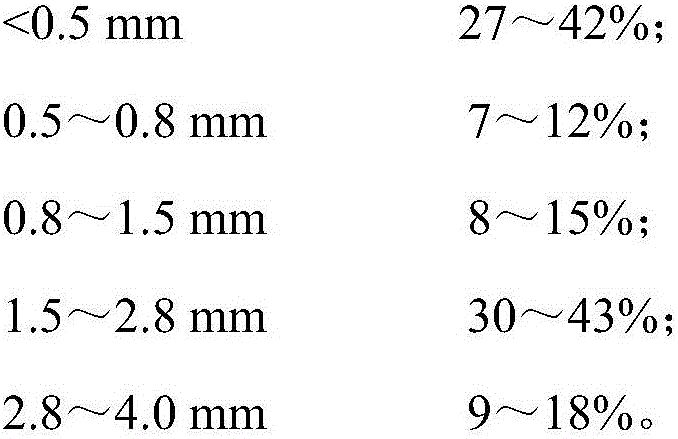

Electrolyte for low-corrosivity electrolytic condenser and method for making the same

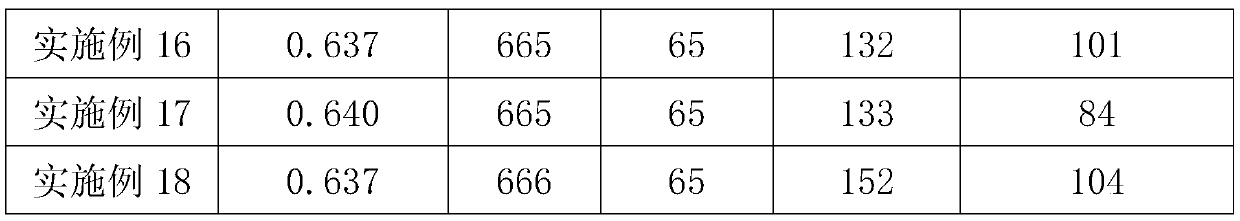

ActiveCN107527742AStable structureStrong resistance to hydrationElectrolytic capacitorsP-nitrobenzoic acidDegradation reaction

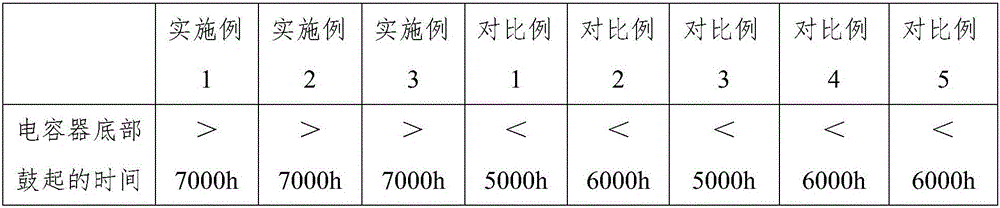

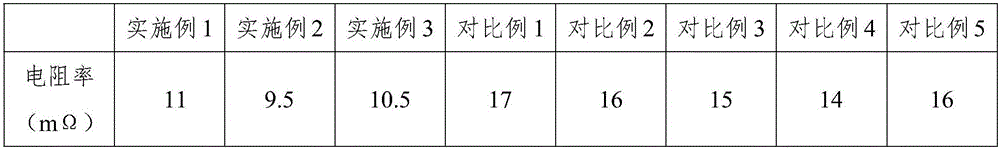

The invention, which belongs to the technical field of the electrolyte, particularly relates to an electrolyte for a low-corrosivity electrolytic condenser and a method for making the same. The electrolyte is mainly composed of ethylene glycol, ammonium adipate, ammonium formate, additives and ultrapure water. The additives consist of ethylene glycol, diammonium hydrogen phosphate, phosphoric acid, p-nitrobenzoic acid, ammonium 4-nitrobenzoate dihydrate, a complexing agent, an interfacial agent and a corrosion inhibitor. The electrolyte which is suitable for a low-voltage electrolytic condenser has advantages of high frequency, low impedance, low electric leakage, and low corrosivity. According to the electrolyte, the service life of the electrolytic condenser is prolonged effectively by suppressing a hydration degradation reaction of an electrode aluminum foil and re rising of leak currents; and with the electrolyte, bottom heaving of the electrolytic condenser is avoided and thus the safety of the electrolytic condenser is enhanced substantially.

Owner:东莞市承兴电子有限公司

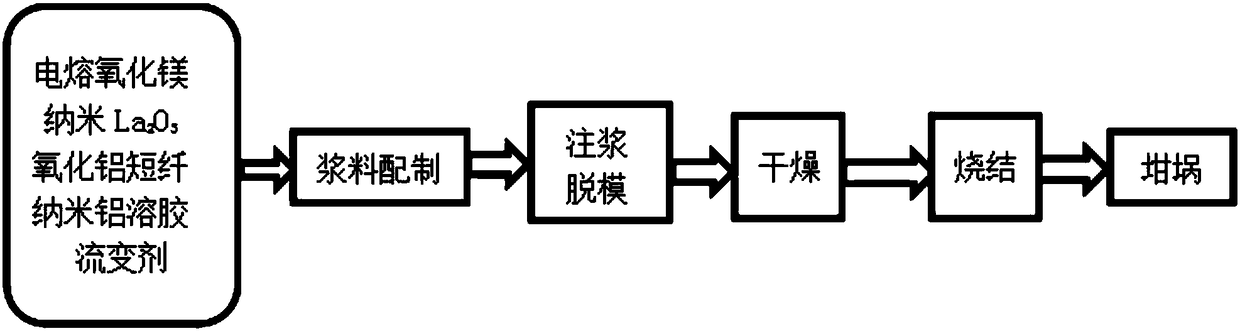

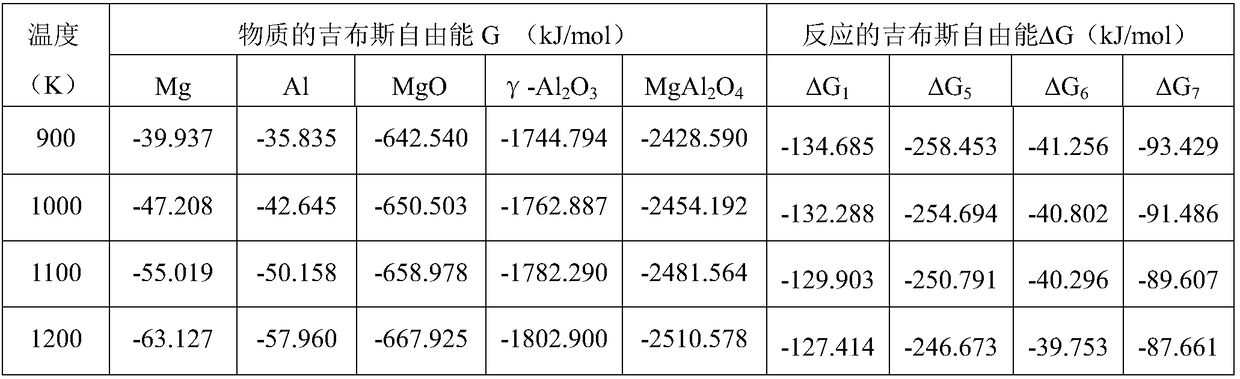

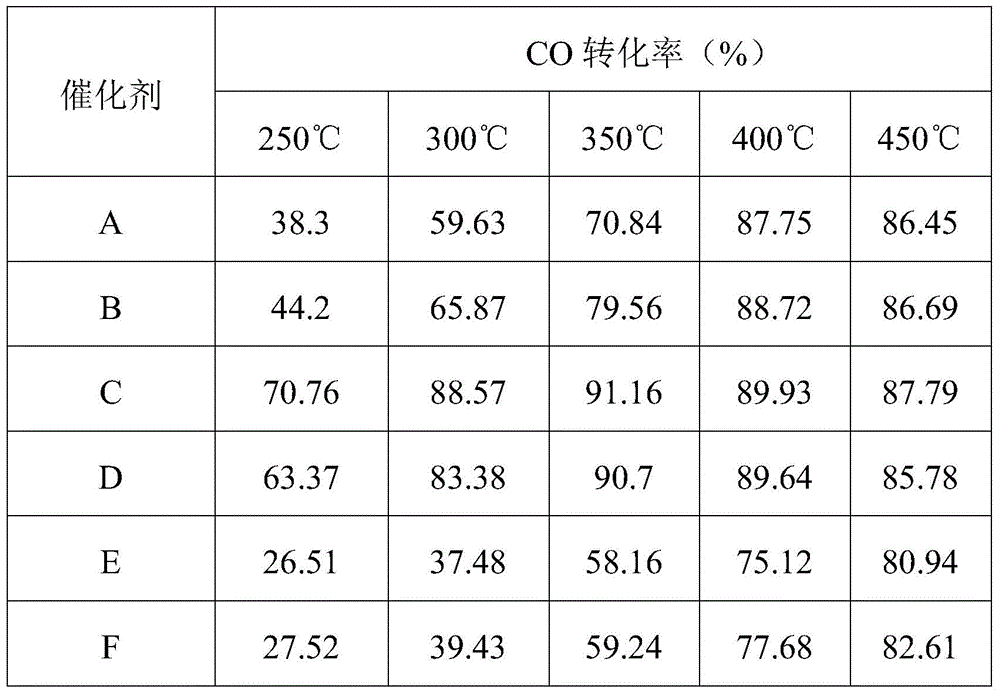

Alumina short fiber-reinforced magnesium oxide-based crucible and preparation method thereof

The invention discloses an alumina short fiber-reinforced magnesium oxide-based crucible which is excellent in chemical stability and thermal shock resistance, and can realize sintering at a low temperature and a preparation method thereof, the method comprises the following steps: (1) proportioning, by mass, 15% to 25% of nano-aluminum sol, 0.8% to 1.5% of a rheological agent, and balance of electro-fused magnesium oxide ceramic powder containing nano-lanthana and alumina short fiber, adding an appropriate amount of deionized water, uniformly mixing by ball milling, and vacuum degassing to obtain a ceramic slurry having a solid content of 70% to 80%; (2) preparing a crucible biscuit; (3) preparing a crucible blank; and (4) putting the magnesium oxide-based crucible blank in the aluminum sol for vacuum impregnation treatment, grinding the surface, drying, performing high-temperature secondary sintering at a temperature of 1400 to 1600 DEG C, and cooling in a furnace to room temperatureto obtain the magnesia-based crucible.

Owner:FENGYANG L S NET FORMING CO LTD +1

Low-resistivity electrolytic capacitor-used electrolyte and preparation method thereof

ActiveCN105990027AExtended service lifeInhibition of hydrationElectrolytic capacitorsPhosphorous acidElectrolysis

The invention belongs to the technical field of electrolytes, and particularly relates to a low-resistivity electrolytic capacitor-used electrolyte and a preparation method thereof. The low-resistivity electrolytic capacitor-used electrolyte provided by the invention is mainly composed of ethylene glycol, ammonium adipate, ammonium formate, additives and ultrapure water, wherein the additives comprises ethylene glycol, ammonium dihydrogen phosphate, phosphorous acid, silicon dioxide, a complexing agent, a surfactant and a hydrogen removing agent. The low-resistivity electrolytic capacitor-used electrolyte is applicable to a low-voltage electrolytic capacitor, and has the advantages of high frequency, low impedance, low electric leakage and low corrosivity; the electrolyte can restrain a hydration deterioration reaction of an electrode aluminum foil and rebound of leakage current, can also prevent an electrolytic capacitor floor heave phenomenon and can effectively prolong the service life of the electrolytic capacitor.

Owner:湖南建顺电子有限公司

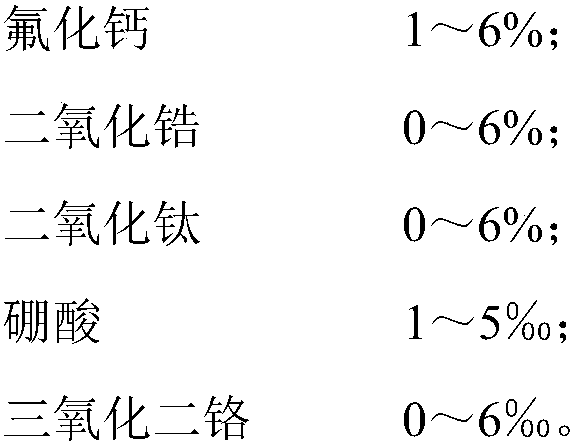

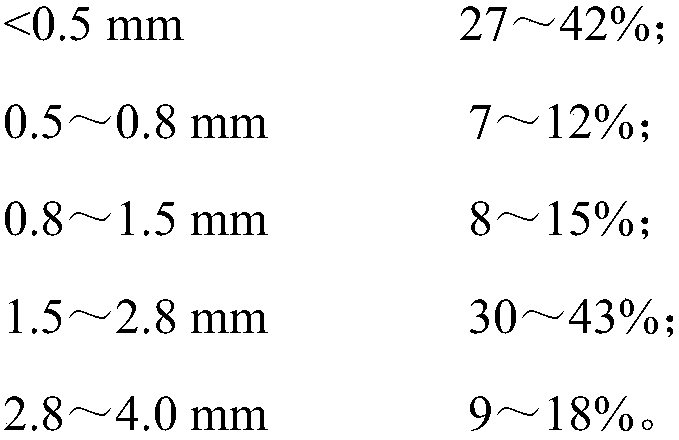

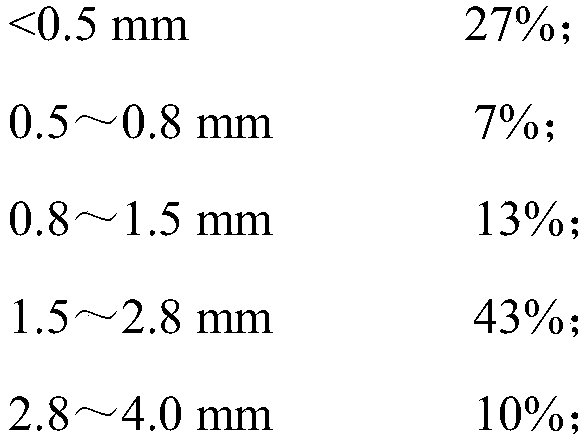

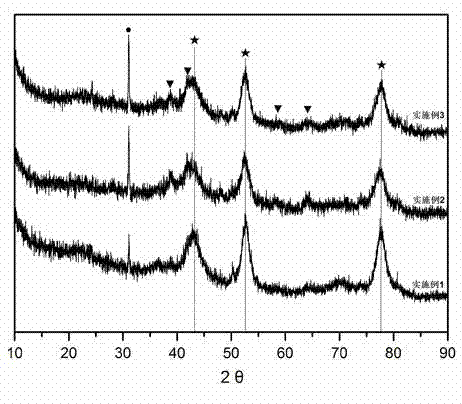

Method for preparing hydration-resistant and thermal-shock-resistant calcium oxide crucible by dry process

The invention discloses a method for preparing a hydration-resistant and thermal-shock-resistant calcium oxide crucible by a dry process. The method comprises the following steps: purifying quicklime lumps, and crushing and fining the quicklime lumps with calcium oxide purity higher than 96%; mixing the quicklime fines with additives so as to form a mixture, and then, pressing the mixture into brick-shaped products; carrying out first-time temperature-controlled sintering on the brick-shaped products; crushing the sintered material obtained after first-time sintering, carrying out screening, then, carrying out proportioning proportionally, and carrying out uniform mixing so as to form clinker; loading the clinker obtained through carrying out uniform mixing in the step (4) to a crucible die, carrying out compaction on a vibrating platform, and carrying out pressing by a cold isostatic press; and putting a calcium oxide crucible green body in an electric furnace, carrying out second-time temperature-controlled sintering according to a secondary temperature-control curve, thereby obtaining a calcium oxide crucible product. The calcium oxide crucible prepared by using the method has the advantages that the hydration resistance is higher, the thermal-shock resistance is better, the sintering is denser, and the strength of the crucible is good.

Owner:XI'AN PETROLEUM UNIVERSITY

Dolomite-periclase-calcium zirconate composite fireproof material and preparation method thereof

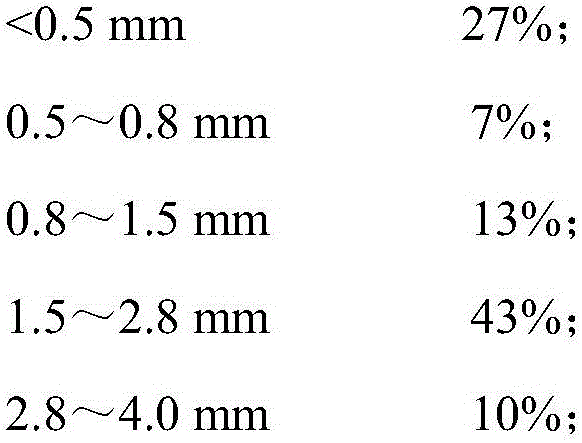

The invention relates to a high-quality dolomite-periclase-calcium zirconate composite fireproof material suitable for smelting stainless steel, special steel AOD furnace and refining ladles. The adopted raw materials mainly comprise, by weight, 8-10% of magnesium calcium sand with a particle size of 5-8 mm, 9-18% of magnesium calcium sand with a particle size of 3-5 mm, 10-22% of magnesium calcium sand with a particle size of 1-3 mm, 5-10% of calcium zirconate with a particle size of 0.5-1 mm, 5-10% of magnesia with a particle size of 0.5-1 mm, 3-10% of 600 mesh electric melting calcium zirconate, 15-24% of magnesia with a particle size of less than or equal to 0.5 mm, 3-10% of 400 mesh 98 large crystal magnesia, 1-3% of a binding agent, and 1-2% of a sintering agent, wherein the raw materials are subjected to mixing, molding, sintering, finished product inspection, package and other steps to prepare the material.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

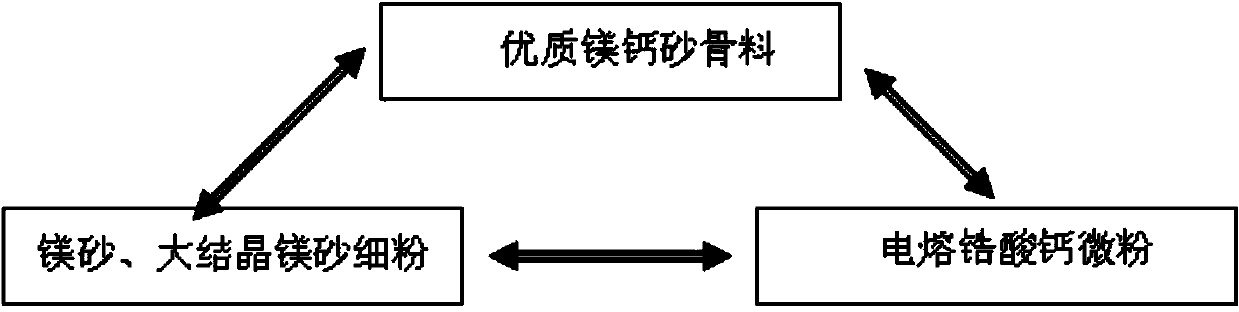

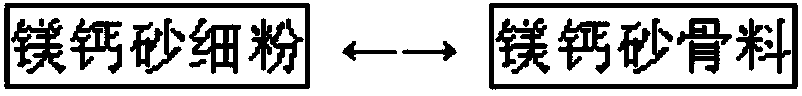

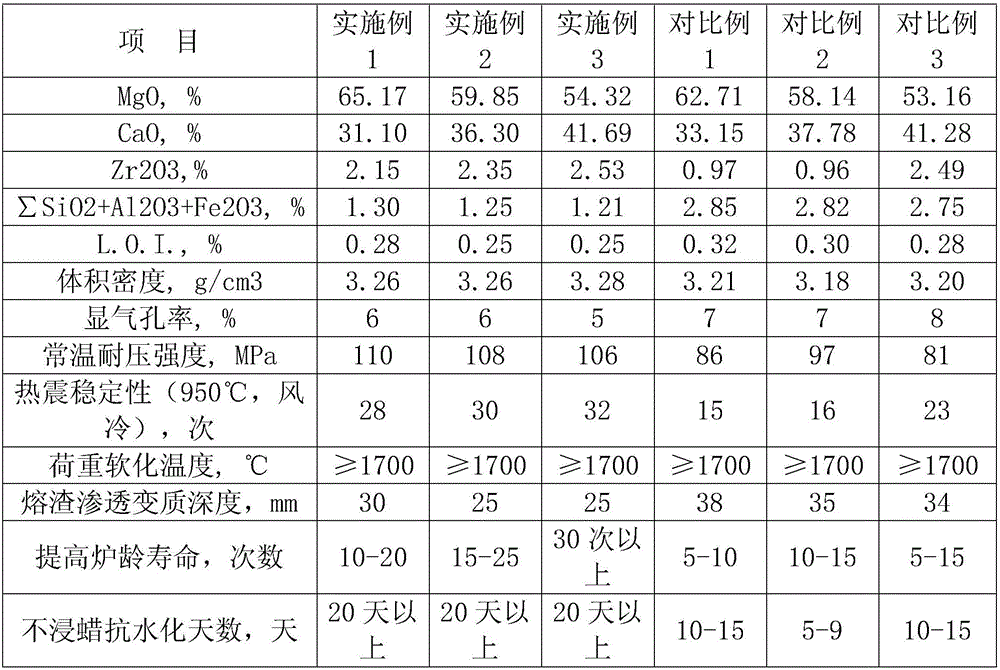

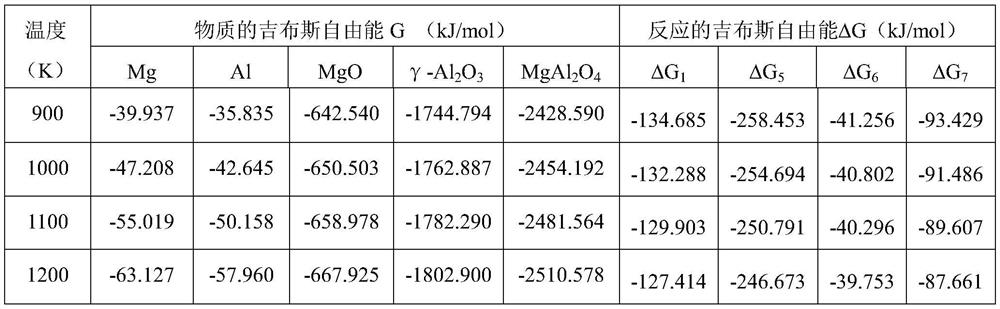

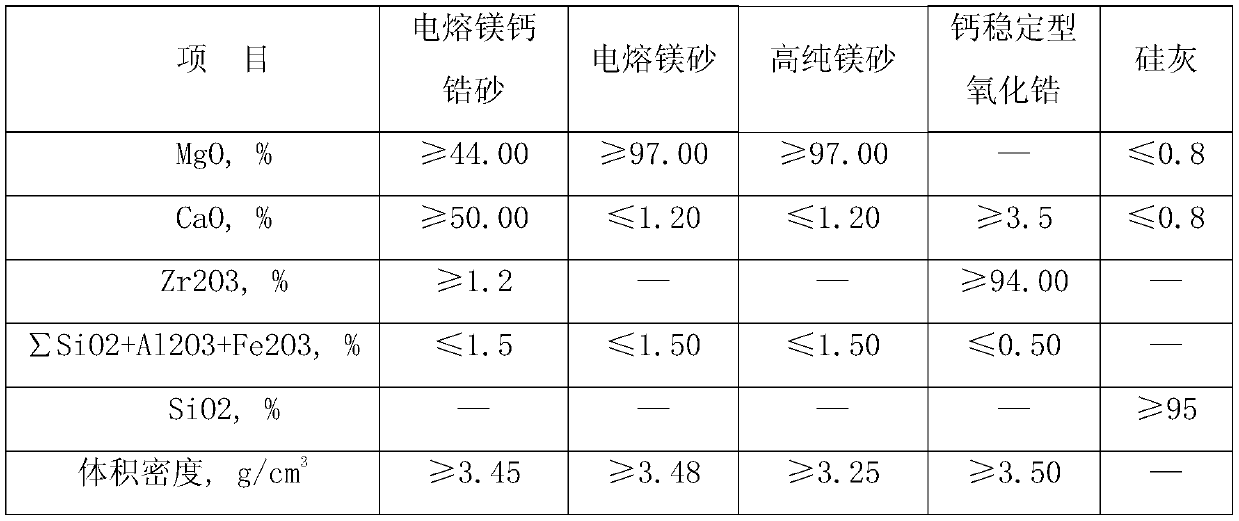

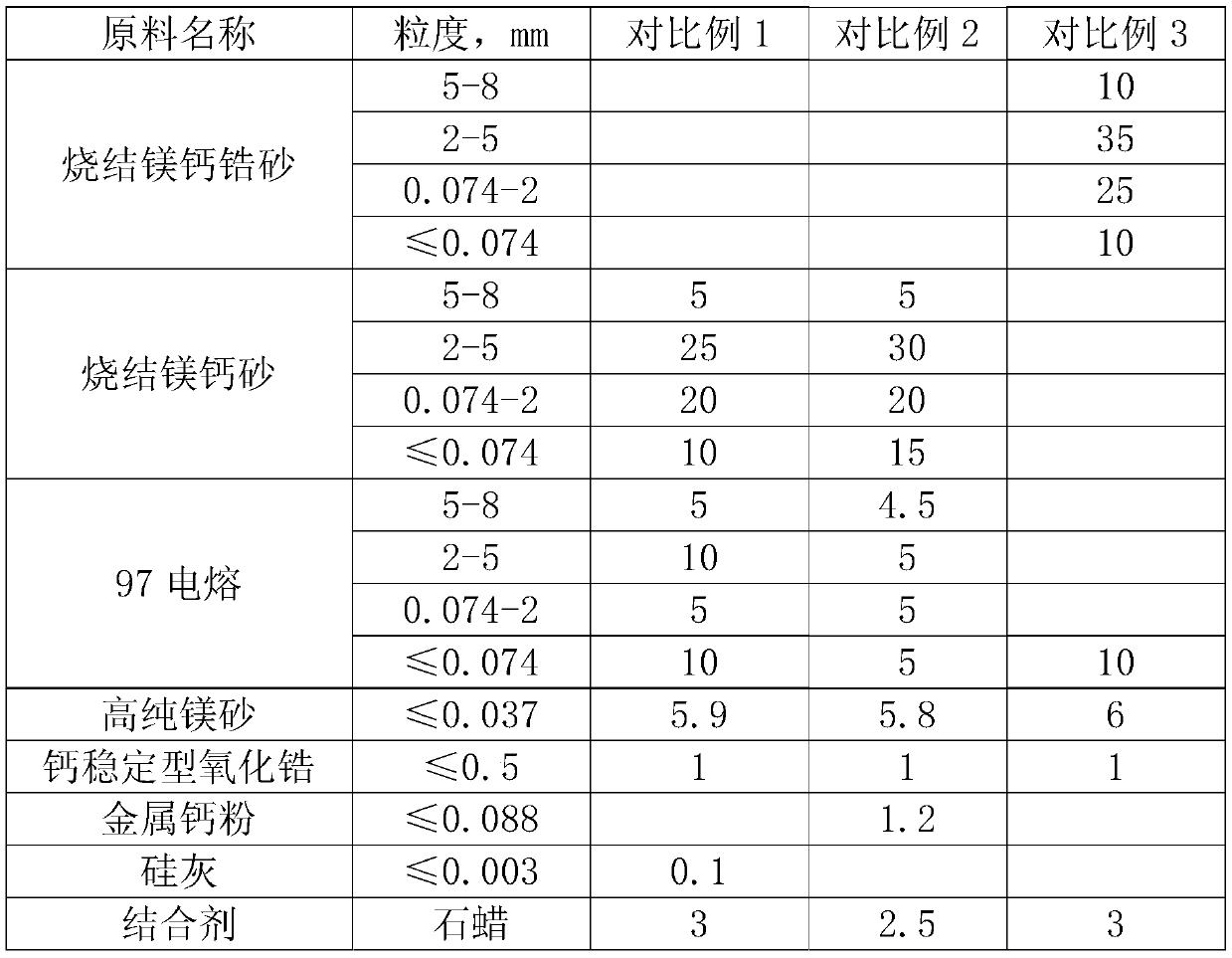

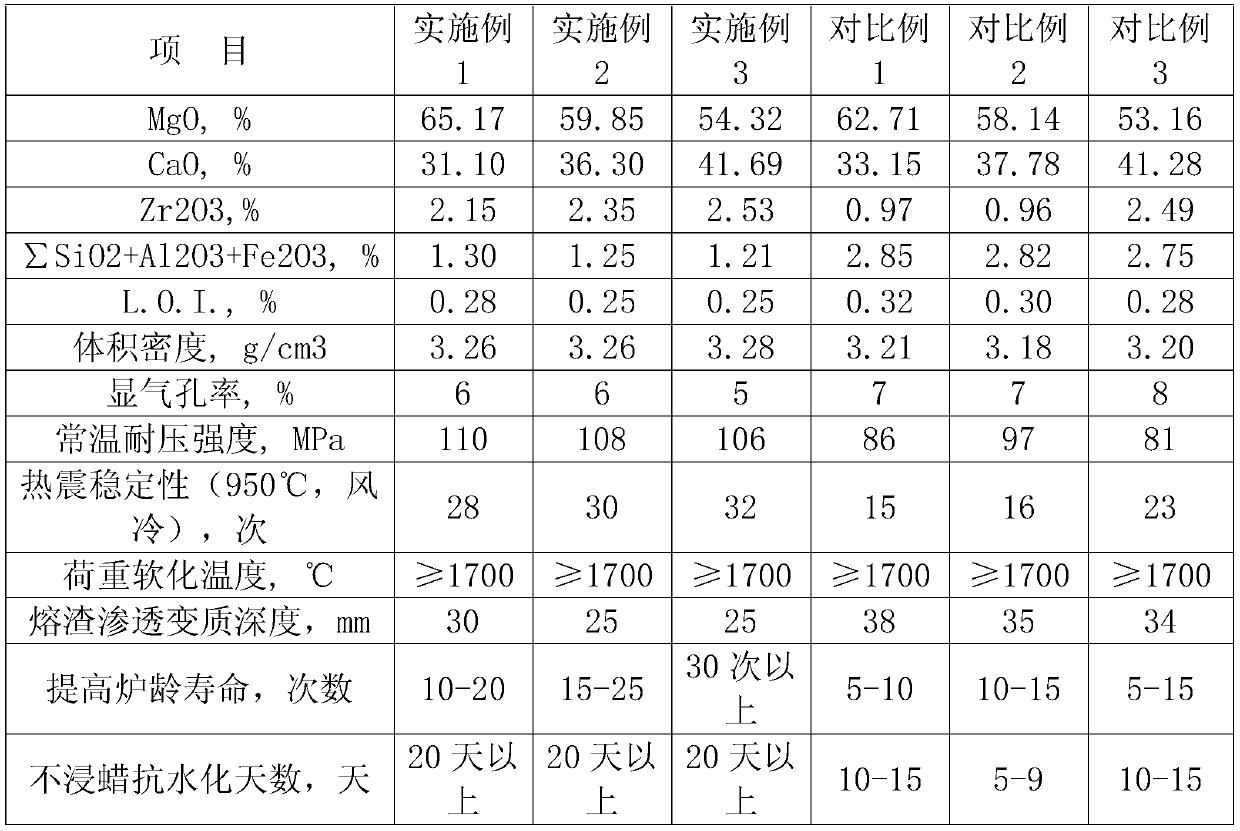

Zirconium composite high-performance electrofused magnesium-calcium zirconium brick and manufacturing method thereof

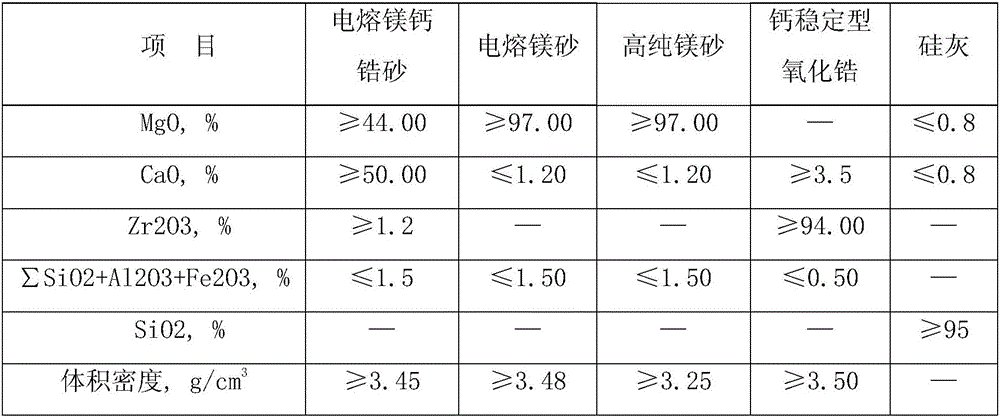

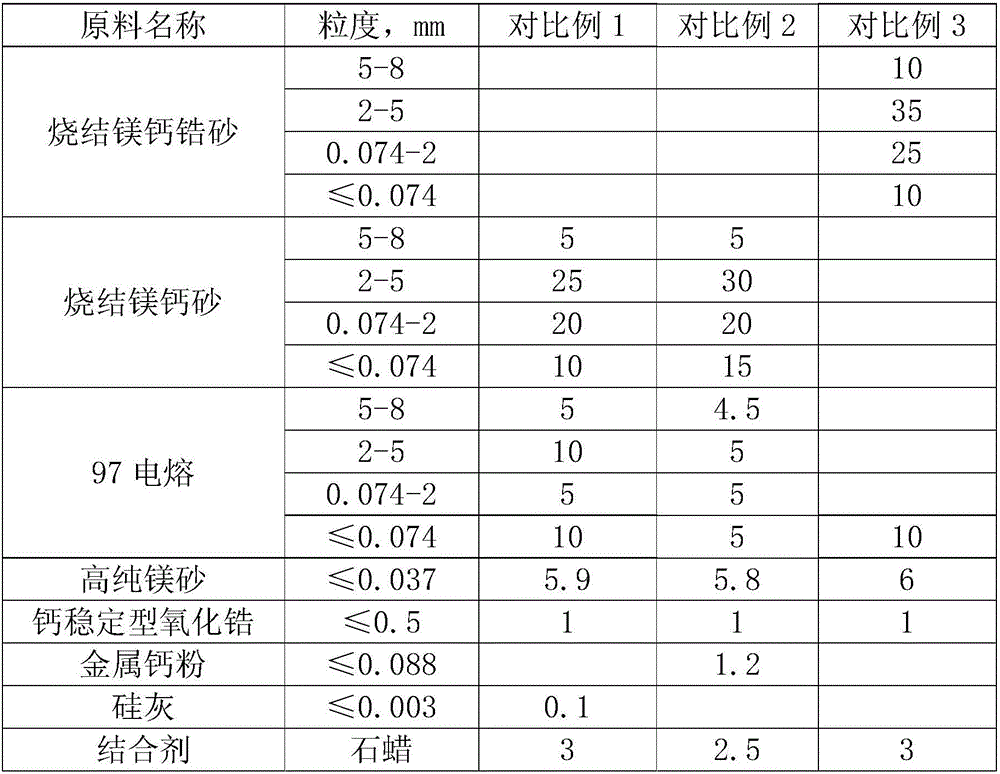

The invention belongs to the technical field of refractories for steel smelting furnaces, and in particular relates to a zirconium composite high-performance electrofused magnesium-calcium zirconium brick and a manufacturing method thereof; the zirconium composite high-performance electrofused magnesium-calcium zirconium brick comprises 5-10% of electrofused magnesium-calcium zirconium sand with a partical size of 5-8mm, 20-35% of electrofused magnesium-calcium zirconium sand with a partical size of 2-5mm, 20-30% of electrofused magnesium-calcium zirconium sand with a partical size of 2-0.074mm, 10-15% of electrofused magnesium-calcium zirconium sand fine powder with a partical size of 0.074mm or less, 1-5% of electrofused magnesium sand with a partical size of 5-8mm, 1-10% of electrofused magnesium sand with a partical size of 2-5mm, 1-5% of electrofused magnesium sand with a partical size of 2-0.074mm, 5-10% of electrofused magnesium sand fine powder with a partical size of 0.074mm or less, 5-10% of electrofused magnesium sand super-fine powder with a partical size of 0.037mm or less, 0.5-1.2% of calcium stabilized zirconia with a partical size of 0.5mm or less, 0.5-2% of metal calcium powder with a partical size of 0.088mm or less, 0.1-0.5% of silica fume with a partical size of 0.003mm or less and 2-5% of a binder. The method can obviously improve the physical and chemical performance indexes of the magnesium-calcium zirconium brick, anti-penetration, anti-erosion, anti-erosion and anti-spalling and other use performances of the magnesium-calcium zirconium brick can be improved, and most importantly, the magnesium-calcium zirconium brick can meet the requirements of current smelting conditions.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Magnesite dolomite dry ramming mix for medium-frequency induction furnace lining and preparation method of magnesite dolomite dry ramming mix

InactiveCN110183212AImprove high temperature structural strengthImprove thermal shock resistanceNon-metallic inclusionsMedium frequency

The invention relates to a magnesite dolomite dry ramming mix for a medium-frequency induction furnace lining. The product is a loose, dry and uniform aggregate, and components comprise calcined dolomite sand particles, fused magnesite and desiliconized fused zirconia. The product comprises the following components in parts by weight: 1-19 parts of dolomite sand having a particle size of more than3mm and less than or equal to 6mm, 20-30 parts of dolomite sand having a particle size of more than 1mm and less than or equal to 3mm, 0-13 parts of dolomite sand having a particle size of more than0.3mm and less than or equal to 1mm, 20-40 parts of fused magnesite having a particle size of more than 0mm and less than or equal to 1mm, 15-23 parts of fused magnesite having a particle size of morethan 0.074mm and less than or equal to 0.045mm, and 2-6.5 parts of 325-mesh desiliconized fused zirconia. The dry ramming mix disclosed by the invention has a desulfurization effect; nonmetallic inclusions in molten steel are removed, and the molten steel is purified; high-temperature performance is excellent; the thermal shock resistance is improved; and the refractoriness is high.

Owner:裘伟 +1

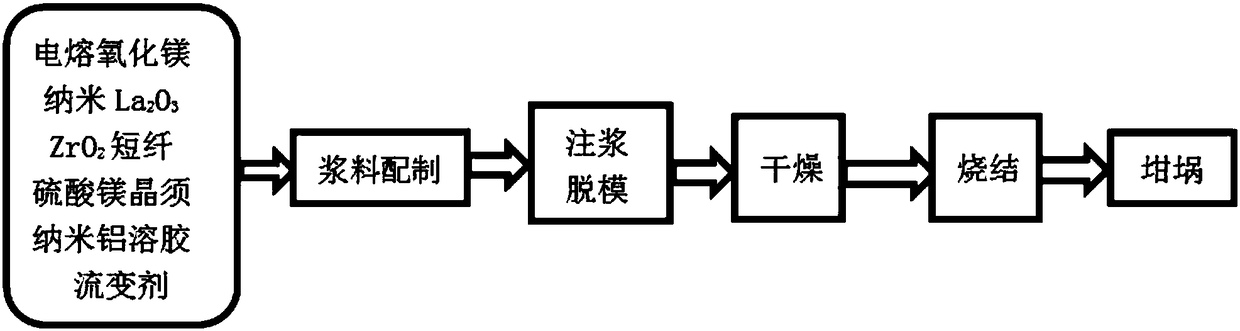

Zirconium dioxide short fiber and basic magnesium sulfate whisker composite enhanced magnesia-based crucible and preparation method thereof

The invention discloses a preparation method of a zirconium dioxide short fiber and basic magnesium sulfate whisker composite enhanced magnesia-based crucible which can be sintered at the low temperature and has excellent chemical stability and thermal shock resistance. The method comprises steps as follows: (1) 15%-25% of nano aluminum sol, 0.8%-1.5% of a rheological agent and the balance of fused magnesia ceramic powder containing nano lanthanum oxide, zirconium dioxide short fiber and basic magnesium sulfate whisker are prepared in percentage by mass, deionized water is added, the mixture is subjected to ball milling and mixed uniformly, then, vacuum exhausting is performed, and ceramic slurry with the solid content of 70%-80% is prepared; (2) a crucible biscuit is prepared; (3) the dried biscuit is put in a sintering furnace to be sintered at the high temperature and then cooled with the furnace, and a magnesia-based crucible blank is obtained; (4) the magnesia-based crucible blankis subjected to vacuum impregnation treatment in aluminum sol, then, surface polishing treatment is performed, high-temperature secondary sintering is performed after drying, a product is cooled withthe furnace to the room temperature, and the magnesia-based crucible is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Green low-creep MgO-C brick and preparation method thereof

InactiveCN110550922AImprove bindingImprove environmental protection effectParaffin waxHigh resistance

The invention relates to a green low-creep MgO-C brick and a preparation method thereof. The technical scheme of the preparation method comprises the steps: performing batching on fused magnesia finepowder, titanium diboride fine powder and triethanolamine at a mass ratio of 100:(2-4):(4-6), performing even mixing at 130-135 DEG C in a vertical heating mixer so as to obtain a mixed fine powder material, performing batching on fused magnesia particles, the mixed fine powder powder, flake graphite and boric anhydride at a mass ratio of 100:(40-45):(3-6):(2-3), performing even mixing at 140-150DEG C in the vertical heating mixer so as to obtain a premix, adding glycerin with an amount of 4-5% of the weight of the premix and liquid paraffin with an amount of 2-3% of the weight of the premixto the premix, performing mixing at 160-165 DEG C in the vertical heating mixer so as to obtain a mixed material, performing press forming on the mixed material under 55-65 MPa, and performing heat treatment at 220-250 DEG C for 60-90 minutes so as to obtain the green low-creep MgO-C brick. The process is simple and environmentally friendly, the prepared product has a good environmental protectioneffect, low creep at high temperature, hydration resistance and high resistance to slag corrosion.

Owner:WUHAN UNIV OF SCI & TECH +1

Method for manufacturing aluminum electrolytic capacitor with ultra-long service life special for LED drive circuit

ActiveCN103887072ALower impedanceStrong resistance to hydrationLiquid electrolytic capacitorsCapacitor electrodesPorous carbonEngineering

The invention discloses a method for manufacturing an aluminum electrolytic capacitor with the ultra-long service life special for an LED drive circuit. Leads are riveted to anode aluminum foil and cathode aluminum foil, a capacitor core packet is formed by isolating electrolytic paper in an isolating and winding mode, vacuum impregnation is carried out through low-impedance electrolyte, and the capacitor core packet is sealed through a sealing rubber plug and an aluminum packaging shell. The manufactured aluminum electrolytic capacitor can be widely applied to a high-frequency switch power source and a computer main board, especially the LED drive circuit, the capacitor is a winding type aluminum capacitor composed of the anode aluminum foil, the cathode aluminum foil, the isolating electrolytic paper, the leads, the sealing rubber plug, the aluminum packaging shell and other components after electrochemical treatment, the anode aluminum coil and the cathode aluminum coil of the capacitor are treated through a traditional electrochemical surface expansion corrosion formation process, then plasma chemical vapor deposition treatment is carried out, porous carbon nano films are formed on the surface of the anode aluminum foil and the surface of the cathode aluminum foil, therefore, the excellent hydration resisting capacity is obtained, and the capacitor has the advantages of being low in impedance and long in service life.

Owner:CHENGDU DAAISI ELECTRONICS

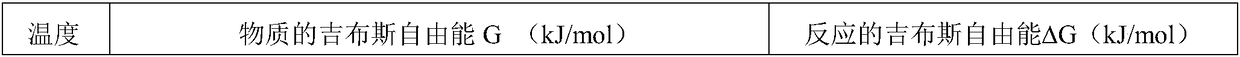

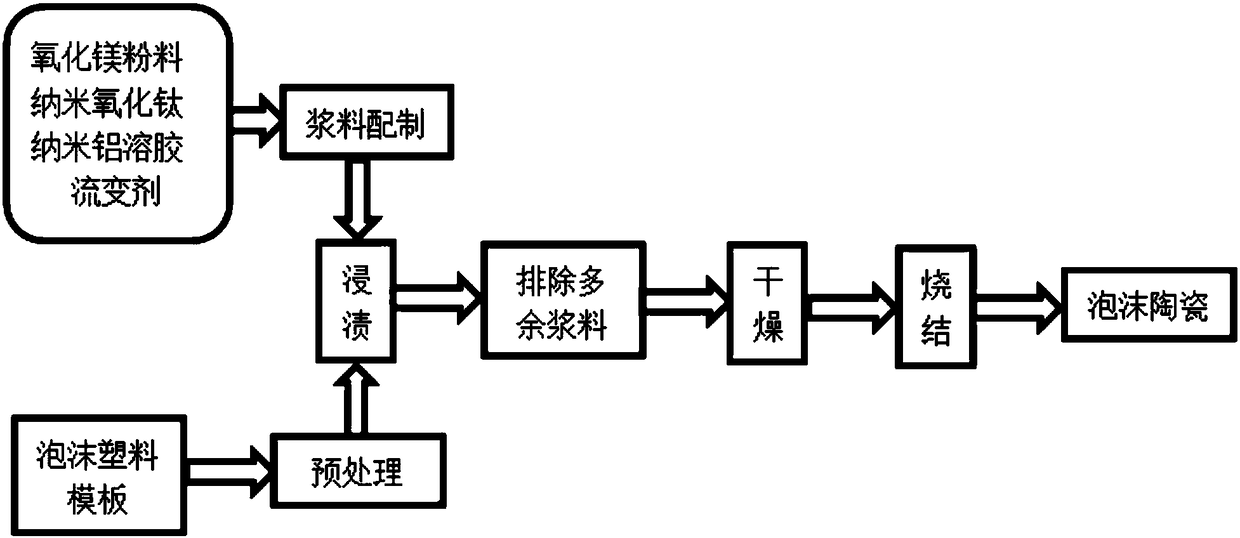

MA-M2T spinel solid liquor enhanced magnesium oxide based foam ceramic filter and preparation method thereof

ActiveCN108439957AAvoid damageIncrease vacanciesSemi-permeable membranesMembrane filtersOxide ceramicSlurry

The invention discloses an MA-M2T spinel solid liquor enhanced magnesium oxide based foam ceramic filter which can realize sintering at the low temperature and has excellent chemical stability and thermal shock resistance and a preparation method of the foam ceramic filter. The preparation method comprises steps as follows: (1) 15%-25% of nano aluminum sol, 0.8%-1.5% of a rheological agent and thebalance of magnesium oxide ceramic powder containing a nano titania sintering aid are prepared in percentage by mass, deionized water is added, the mixture is subjected to ball milling and uniform mixing, and ceramic slurry with the solid content of 60%-70% is prepared through vacuum exhausting; (2) a polyurethane foam plastic template is soaked in the ceramic slurry and is extruded by a roller press to remove redundant soaked hanging slurry, a biscuit is prepared, and the biscuit is heated to 80-120 DEG C and dried; (3) the dried biscuit is put in a sintering furnace, heated to 1,400-1,600 DEG C for high-temperature sintering and cooled to the room temperature with the furnace, and the magnesium oxide based foam ceramic filter is obtained.

Owner:FENGYANG L S NET FORMING CO LTD +2

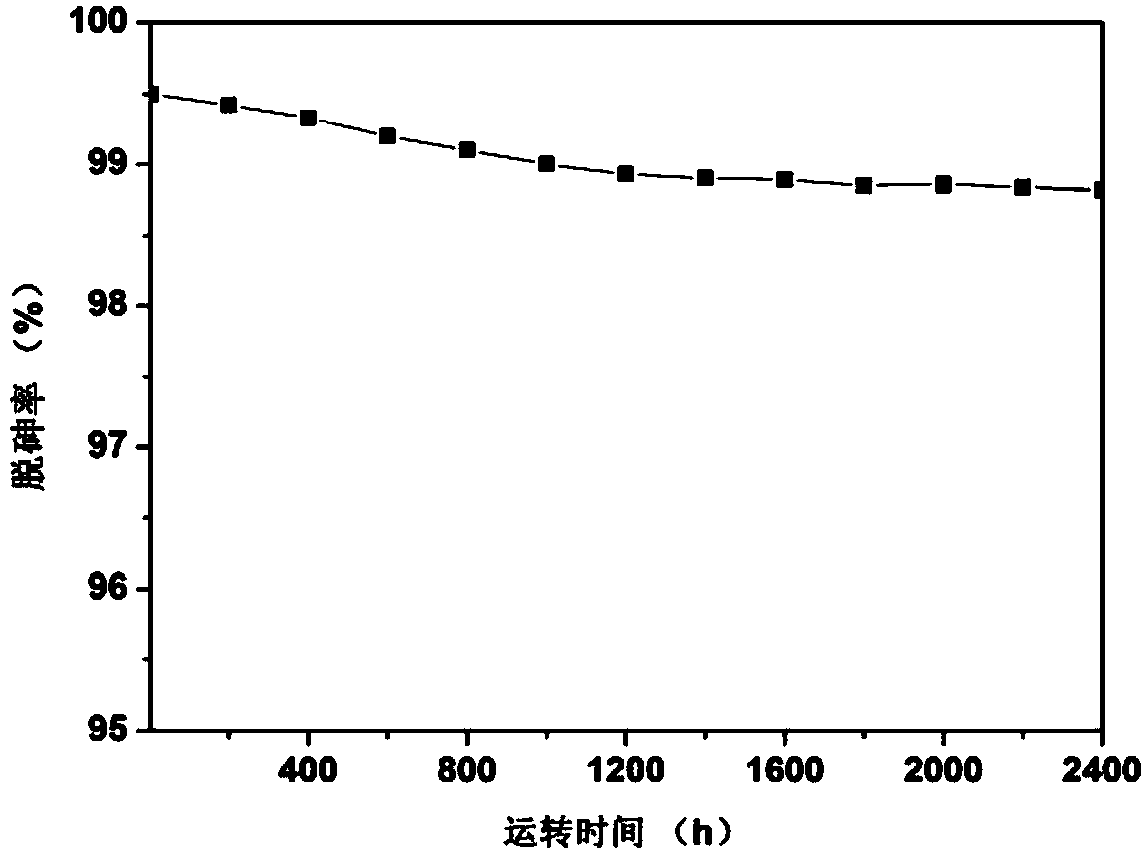

A kind of loaded arsenic removal agent and preparation method thereof

ActiveCN105536689BImprove performance and stabilityImprove adsorption capacityOther chemical processesWater contaminantsActive componentSpinel

The supported arsenic removal agent of the present invention includes a carrier and an active component loaded on the carrier; the carrier is porous amorphous magnesium aluminum spinel, and the active component is CuO and / or NiO. Since the carrier is porous amorphous magnesium-aluminum spinel with good crystallinity, the material is internally bound by strong Mg- and Al-O ionic bonds, which fundamentally effectively improves the strength and hydration resistance of the material. The preparation method of the load-type arsenic removal agent of the present invention has simple production process and low production cost.

Owner:FUZHOU UNIV ASSET MANAGEMENT CO LTD +1

Method for preparing high-quality calcium magnesia by superhigh-temperature calcination

The invention relates to the field of preparation of refractory materials, particularly a method for preparing high-quality calcium magnesia by superhigh-temperature calcination, which is characterized by comprising the following steps: preparing dolomite and magnesite into a raw material in which the CaO content is 15-20 wt% and the MgO content is 80-85%; adding the raw material into a ball milling tank, grinding and mixing, and meanwhile, adding water to carry out slaking and slurrying; and drying the slurry, adding calcium lignosulphonate, evenly mixing, pressing into green bricks, and calcining. The calcination process comprises the following steps: heating to 1100 DEG C, keeping the temperature for 3-5 hours, heating to the final calcination temperature of 2000-2200 DEG C, keeping the temperature for 5-7 hours, vacuumizing, cooling with water to 1000 DEG C, introducing protective hydrogen, and continuing cooling with water to room temperature. Compared with the prior art, the calcium magnesia has the advantages of high hydration resistance and high corrosion resistance, thereby basically solving the problem of high hydration tendency in the magnesium-calcium refractory material, and facilitating the storage, transportation, building and the like in future.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Low-temperature sulfur-tolerant shift catalyst and preparation method thereof

ActiveCN103769130BSimple structureImprove stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsActive componentEconomic benefits

The invention belongs to the technical field of coal chemical industry sulfur-tolerant shift, and particularly relates to a low temperature sulfur-tolerant shift catalyst and a preparation method thereof. The low temperature sulfur-tolerant shift catalyst comprises a carrier and an active component, and is characterized in that attapulgite clay is adopted as the carrier, the carrier is added with a magnesium-containing powdery solid compound and a titanium-containing powdery solid compound, the active component is a metal oxide of Co, Ni and Mo, and an active auxiliary agent is added. The low temperature sulfur-tolerant shift catalyst has characteristics of good structure stability, strong hydration resistance, good low temperature activity, good activity stability, low active component loss rate and long service life, and can meet requirements of the industrial sulfur-tolerant shift work section low temperature condition on the catalyst. In addition, the raw material adopts the attapulgite clay with characteristics of wide source and low cost so as to substantially reduce the catalyst preparation cost, provide an effective approach for comprehensive utilization of the attapulgite clay, and provide good economic benefits and good environmental protection benefits.

Owner:CHINA PETROLEUM & CHEM CORP

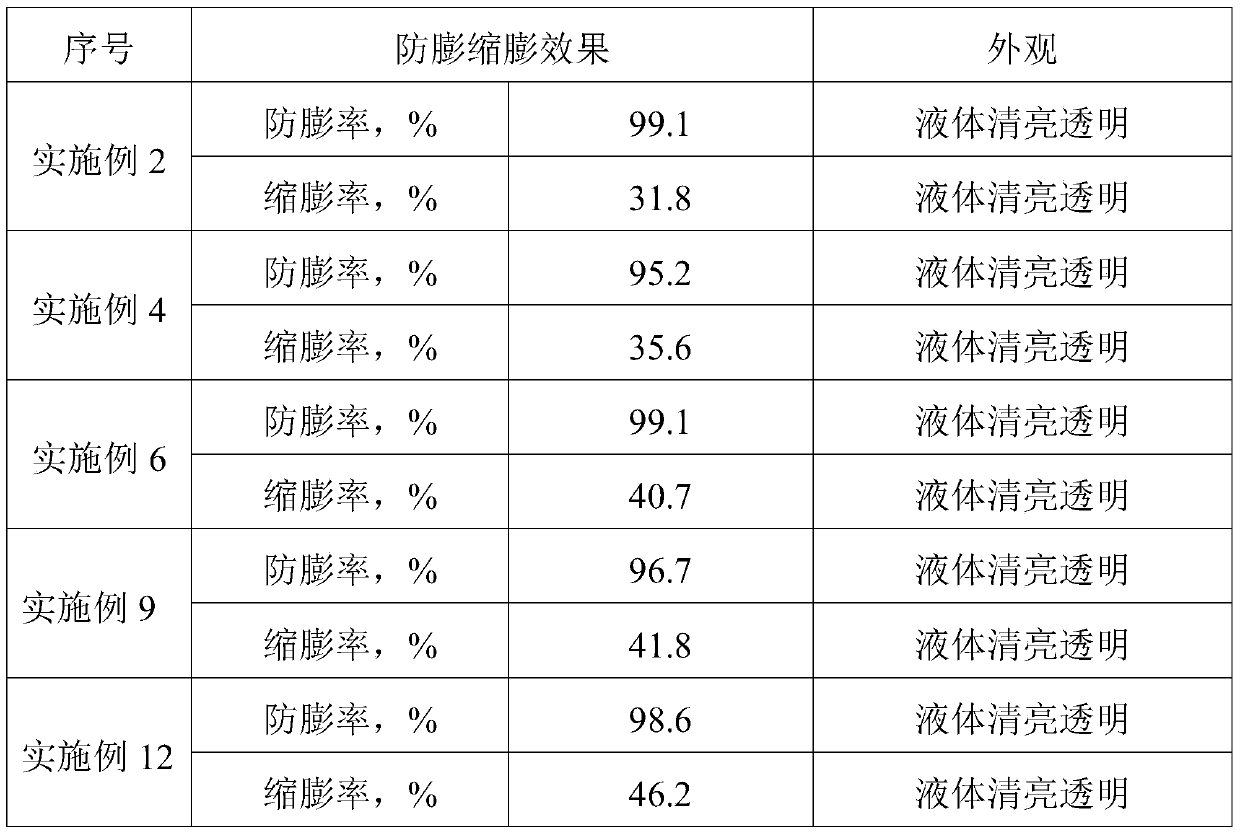

anti-expansion agent

ActiveCN105154034BGood anti-expansion and contraction effectFast convergenceDrilling compositionSuberedamine BEthylene diamine

The invention discloses an anti-swelling shrinking agent which is an ethylene diamine diacetate solution. This solution avoids the adverse factor that traditionally bridge blinding occurs in capturing of large cations, also overcomes the adverse factor that small cations are low in charge density and short in effective life, has a good clay stabilizing function and is also well capable of shrinking swelled clay. The anti-swelling shrinking agent composited by adding magnesium chloride and / or amino trimethylene phosphonic acid has better anti-swelling and shrinking effects. A liquid of the anti-swelling shrinking agent is clear and crystal, has anti-swelling agent higher than 95% and shrinking rate higher than 35%, and is applicable to preventing and solving the clay swelling problem caused in oilfield development.

Owner:XIAN AODE PETROCHEM ENG TECH CO LTD

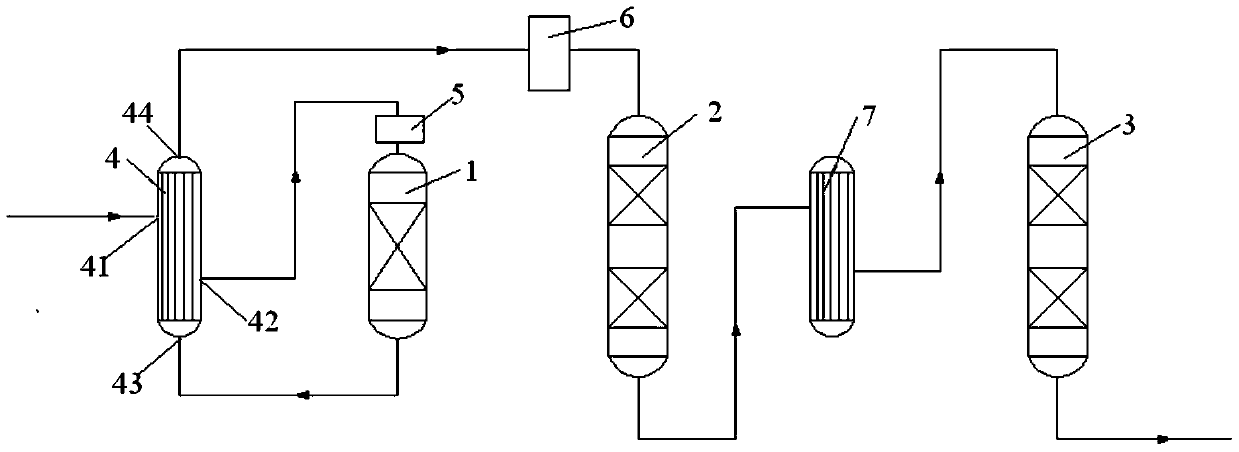

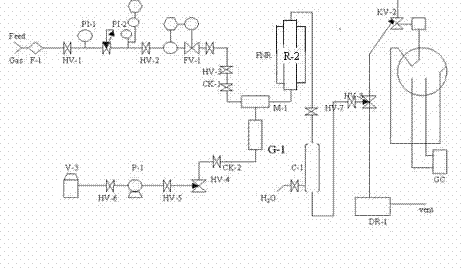

Sulfur-tolerant shift reaction equipment and sulfur-tolerant shift process method

ActiveCN105645354BLow sulfur resistance conversion performanceStrong resistance to hydrationHydrogenHydrogen/synthetic gas productionActive agentSulfur

The invention provides a sulfur-resistant shift reaction equipment and a sulfur-resistant shift process method. The sulfur-resistant shift reaction equipment includes a first-stage shift reactor, a second-stage shift reactor, and a third-stage shift reactor connected in series; wherein, the first-stage shift reactor is filled with MgAl2O4 as a carrier, and A catalyst with CoO and MoO3 as the main active components; the second-stage shift reactor is filled with a catalyst with MgAl2O4 as the carrier, CoO and MoO3 as the main active components, and rare earth oxides as active promoters; The three-stage shift reactor is loaded with a catalyst with MgAl2O4 or Al2O3 as the carrier, CoO and MoO3 as the main active components, and K2O as the active promoter. The sulfur-resistant shift reaction equipment provided by the invention can carry out sulfur-resistant CO shift for feed gas with high CO concentration, high steam-gas ratio, oil pollution and dust, and the sulfur-resistant shift process method provided by the invention has the advantages of simple design, safe operation, It is not easy to "fly temperature" and has the characteristics of low investment.

Owner:中琉科技有限公司

A kind of magnesia-aluminum spinel reinforced magnesia-based foam ceramic filter and preparation method thereof

ActiveCN108516803BAvoid obstructionAct as a binderFiltration separationCeramicwareOxide ceramicNano al2o3

The invention discloses a magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter with capability of realizing sintering at low temperature, excellent chemical stability and excellentthermal shock resistant performance, and a preparation method thereof. The preparation method comprises the following steps that (1) 10 to 20 percent of nanometer alumina sol, 0.8 to 1.5 percent of rheological agents and the balance of magnesium oxide ceramic powder containing a nanometer aluminum oxide sintering aid are proportioned; deionized water is added; ball milling and uniform mixing areperformed; then, through vacuum exhaust, ceramic slurry with the solid content being 60 to 70 percent is prepared; (2) a polyurethane foamed plastic template is soaked into the ceramic slurry; the polyurethane foamed plastic template is extruded through a roller press for removing the redundant leaching hanging slurry; then, biscuit is prepared; then, the biscuit is heated to 80 to 120 DEG C for drying; (3) the dried biscuit is put into a sintering furnace; the temperature is raised to 1400 to 1600 DEG C; high-temperature sintering is performed; cooling is performed along with the furnace to room temperature; the magnesia-based foamed ceramic filter is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A low-temperature sulfur-tolerant shift catalyst and its preparation method

ActiveCN107999084BKeep aliveSignificant resistance to sulfationHydrogenHydrogen/synthetic gas productionPtru catalystAqueous solution

The invention relates to the field of water vapor shift reactions, and particularly discloses a low-temperature sulfur-tolerant shift catalyst and a preparation method thereof. The preparation methodcomprises: (1) sequentially molding, drying and calcining the mixture of an aluminum source, a magnesium source and a cobalt source to obtain a primary carrier; and (2) impregnating the primary carrier by using a K2SiO3 aqueous solution, drying, calcining, impregnating with the aqueous solution of a molybdenum source, drying, and calcining. According to the present invention, the impregnating is performed sequentially with the K2SiO3 and the molybdenum source by using the step-by-step impregnation manner, such that the activity of the catalyst is ensured, and the stability of the catalyst is ensured.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A kind of preparation method of anti-hydration, anti-thermal shock dry calcium oxide crucible

Owner:XI'AN PETROLEUM UNIVERSITY

A kind of zrsio4-mgo material and preparation method thereof

The invention provides a ZrSiO4-MgO material and a preparation method thereof. According to a technical scheme in the invention, the preparation method comprises the following steps: placing magnesia fine powder and nickel-containing mixed liquor in a mass ratio of 1: 2 in a ball mill and carrying out mixing and milling for 0.5 to 6 h so as to obtain mixed slurry; draining the mixed slurry through filtering and then carrying out drying at 110 DEG C for 24 h so as to obtain a mixture block; and maintaining the mixture block at 1000 to 1400 DEG C for 1 to 6 h, then cooling the mixture block and carrying out ball milling until a particle size of 1 to 200 [mu]m is obtained so as to obtain the ZrSiO4-MgO material. A preparation method for the nickel-containing mixed liquor comprises the following steps: mixing silicon tetrachloride with a zirconium tetra-n-butoxide solution according to an atomic mol ratio of Si to Zr of 1: 1 so as to obtain a mixed solution; and adding nickel nitrate into the mixed solution according to a mass ratio of the mixed solution to nickel nitrate of 1: (0.001-0.2) and carrying out mixing so as to obtain the nickel-containing mixed liquor. The ZrSiO4-MgO material prepared in the invention has the characteristics of high refractoriness, good hydration resistance, high wear and corrosion resistance, good erosion resistance and excellent slag penetration resistance.

Owner:WUHAN UNIV OF SCI & TECH

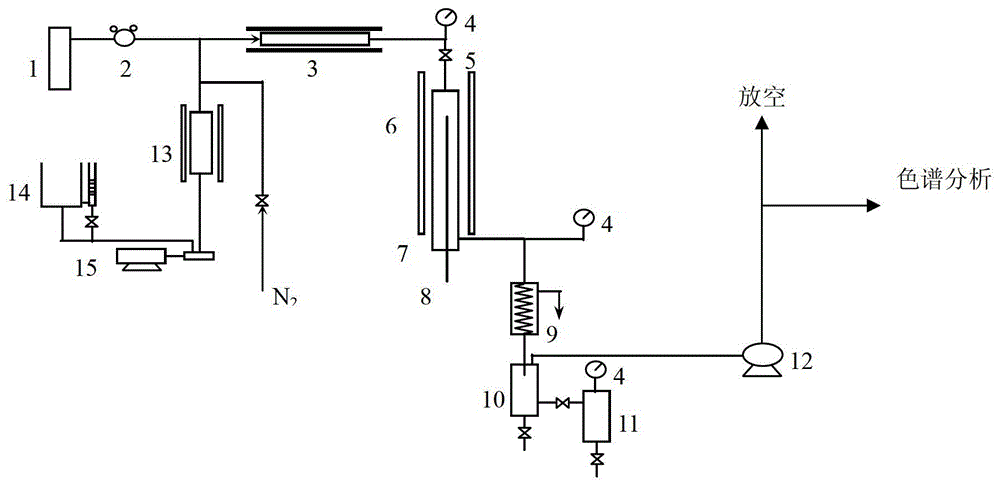

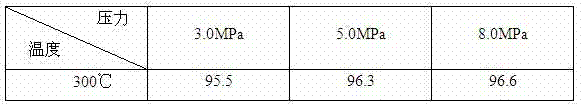

CO (carbon monoxide) sulfur tolerant shift catalyst applicable to high pressure process and preparation method thereof

ActiveCN102240556BImprove thermal stabilityEasy to makeCombustible gas catalytic treatmentMetal/metal-oxides/metal-hydroxide catalystsHydration reactionPseudoboehmite

The invention relates to a CO (carbon monoxide) sulfur tolerant shift catalyst applicable to a high pressure process and a preparation method thereof. The CO sulfur tolerant shift catalyst applicable to the high pressure process comprises a carrier and a catalyst active component, wherein the carrier is prepared from the following materials by mass percent: 5-40% of modified bauxite powder, 20-60% of pseudoboehmite or aluminum nitrate, and 10-40% of magnesium oxide or magnesium hydroxide; the catalyst active component comprises CoO, MoO3 and CeO2; and CoO is 0.5-5% of the weight of the catalyst, MoO3 is 1.0-15% of the weight of the catalyst and CeO2 is 0.3-2% of the weight of the catalyst. The preparation method comprises the following steps: raw materials mixing; kneading; strip extruding; roasting; isometric impregnation, and the like. The preparation process is simple and no waste water is discharged. The prepared catalyst carrier has excellent hydration resisting property and strength. The activating temperature of the catalyst is low. Under the conditions of high pressure, high gas to steam ratio and high temperature, the catalyst has excellent thermal stability.

Owner:福建三聚福大化肥催化剂国家工程研究中心有限公司

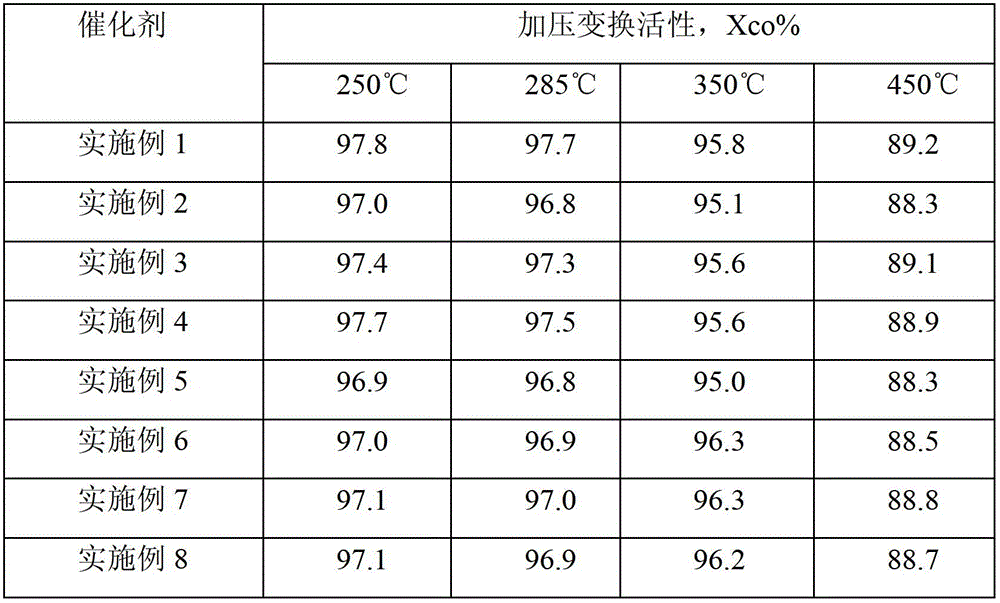

Shift catalyst using cobalt-magnesium-aluminum hydrotalcite as precursor and preparation method thereof

ActiveCN105251512BHigh low temperature activityImprove thermal stabilityPhysical/chemical process catalystsHydration reactionPtru catalyst

The invention provides a sulfur-tolerant shift catalyst using cobalt-magnesium-aluminum hydrotalcite as a precursor, using CoMgAl-LDO as a carrier, and using MoO3 as an active component. The carrier CoMgAl-LDO is based on cobalt-magnesium-aluminum hydrotalcite. The precursor is prepared after roasting, and has the characteristics of uniform cobalt dispersion, suitable surface alkalinity and uniform distribution of pore structure. The catalyst prepared by further using the carrier CoMgAl-LDO to impregnate the Mo active component can make the Co and Mo components All are highly dispersed, in which the Co component is evenly distributed in the interior and surface of the catalyst carrier, and a good interaction is formed between Co and Mo, and the catalyst has high catalytic activity in a wide temperature range of 250-450°C , high thermal stability, strong hydration resistance, not only suitable for high temperature, high pressure and high steam-gas ratio conversion conditions, but also suitable for medium pressure and low temperature conversion process.

Owner:中琉科技有限公司

A kind of aluminum oxide short fiber reinforced magnesium oxide base crucible and preparation method thereof

The invention discloses an alumina short fiber-reinforced magnesium oxide-based crucible which is excellent in chemical stability and thermal shock resistance, and can realize sintering at a low temperature and a preparation method thereof, the method comprises the following steps: (1) proportioning, by mass, 15% to 25% of nano-aluminum sol, 0.8% to 1.5% of a rheological agent, and balance of electro-fused magnesium oxide ceramic powder containing nano-lanthana and alumina short fiber, adding an appropriate amount of deionized water, uniformly mixing by ball milling, and vacuum degassing to obtain a ceramic slurry having a solid content of 70% to 80%; (2) preparing a crucible biscuit; (3) preparing a crucible blank; and (4) putting the magnesium oxide-based crucible blank in the aluminum sol for vacuum impregnation treatment, grinding the surface, drying, performing high-temperature secondary sintering at a temperature of 1400 to 1600 DEG C, and cooling in a furnace to room temperatureto obtain the magnesia-based crucible.

Owner:FENGYANG L S NET FORMING CO LTD +1

A zirconium composite high-performance fused magnesia-calcium-zirconium brick and its manufacturing method

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com