Method for manufacturing aluminum electrolytic capacitor with ultra-long service life special for LED drive circuit

An aluminum electrolytic capacitor, LED driving technology, applied in liquid electrolytic capacitors, capacitor electrodes, capacitor parts and other directions, can solve the problems of capacitor failure, premature appearance, incompetence of aluminum electrolytic capacitors, etc., to reduce contact resistance, low ESR effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

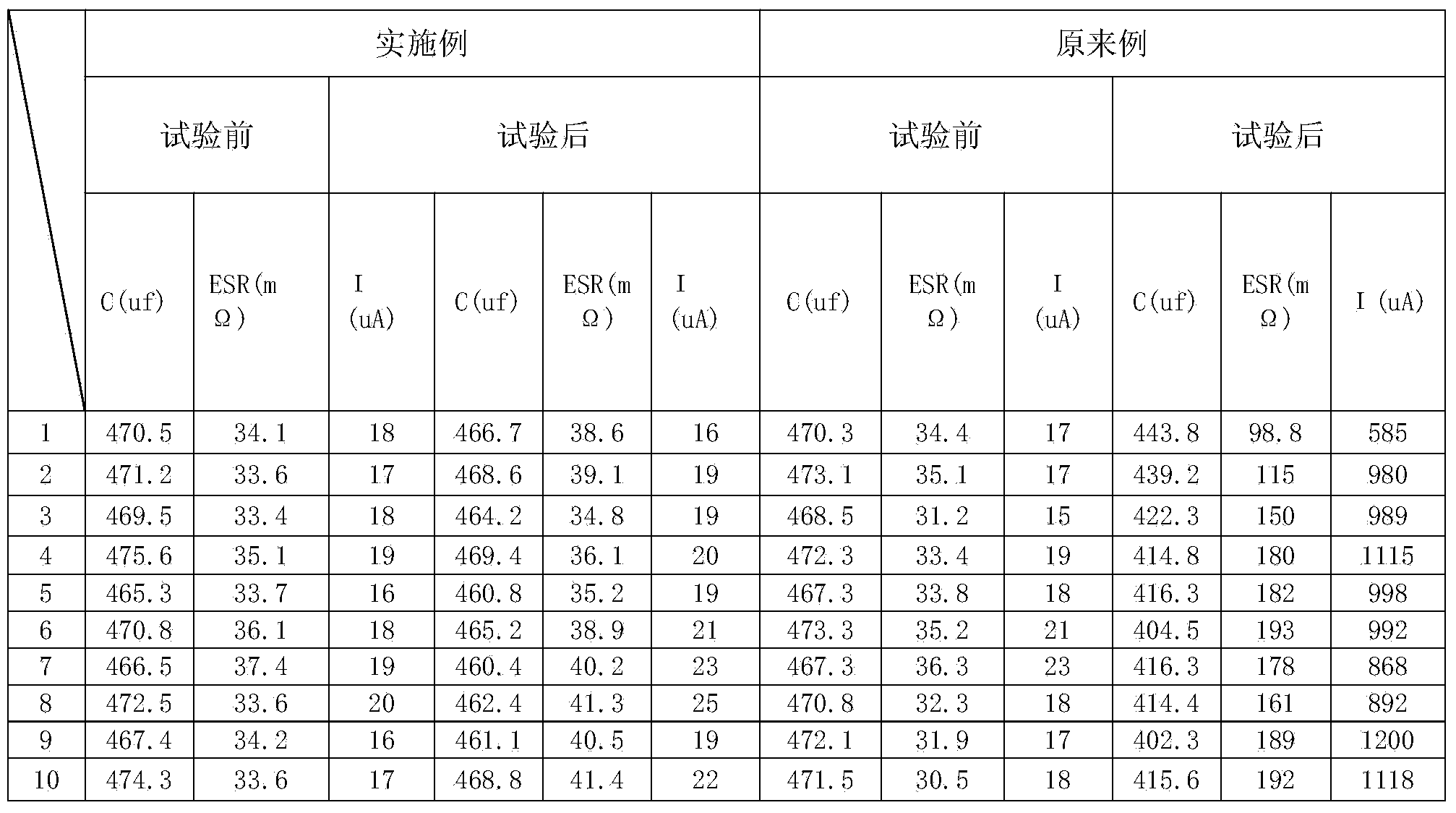

[0032] With the enabling voltage of 33Vf, the specific volume is 50uf / cm 2 the anode foil and C 50 Thick, specific volume 500uf / cm 2 For the above cathode foils, use nitrogen as carrier gas and methane as reaction gas respectively, and plasma chemical vapor deposition for 10 minutes, form porous carbon nanotube films on the anode and cathode electrode foils, then cut into 9mm wide, riveting positive and negative leads , separated by Kane SM260-40 electrolytic paper, wound into a capacitor core package, dried and vacuum-impregnated with an electrolyte with a conductivity of 40,000ms / cm (30°C) and a water content of 55%, with butyl rubber and aluminum The shell is packaged into a 25V470uf capacitor with a volume of φ10×17. After testing, the capacitor product with qualified electrical parameters is obtained, and a ripple current of 680mA / pc is applied at 105°C. Using the same raw materials and preparation process as in the example, the anode and cathode aluminum foils have not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com