A zirconium composite high-performance fused magnesia-calcium-zirconium brick and its manufacturing method

An fused magnesia-calcium-zirconium brick, a high-performance technology, is applied in the field of refractory materials for steel smelting furnaces, and can solve the problem of unsatisfactory erosion resistance and erosion resistance, poor erosion resistance of magnesia-calcium bricks, and insignificant effect of purifying molten steel. and other problems, to achieve the effect of improving thermal shock stability, improving toughness and spalling resistance, and improving thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

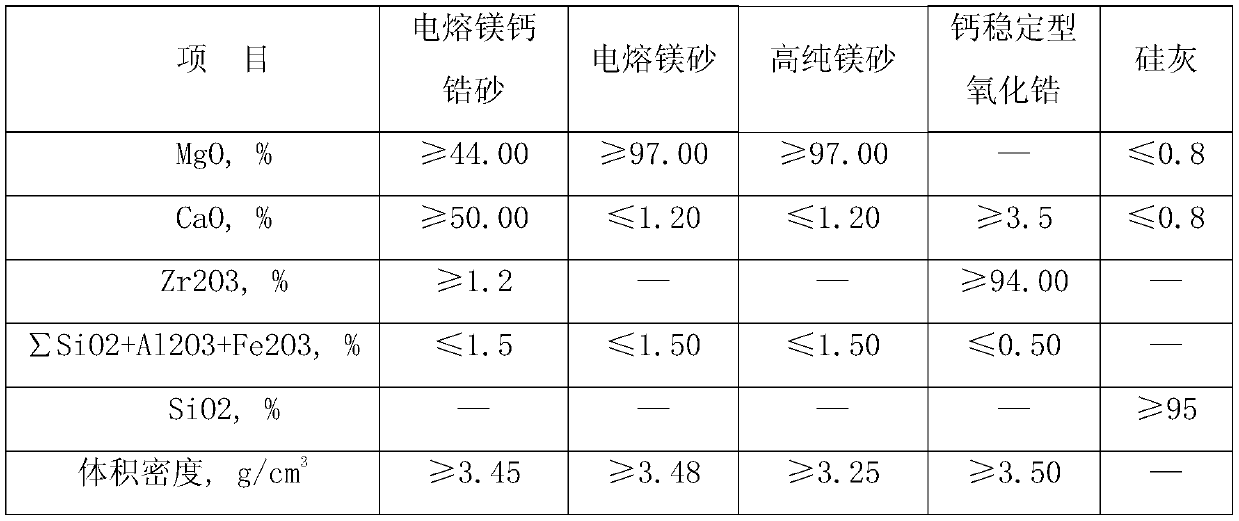

Method used

Image

Examples

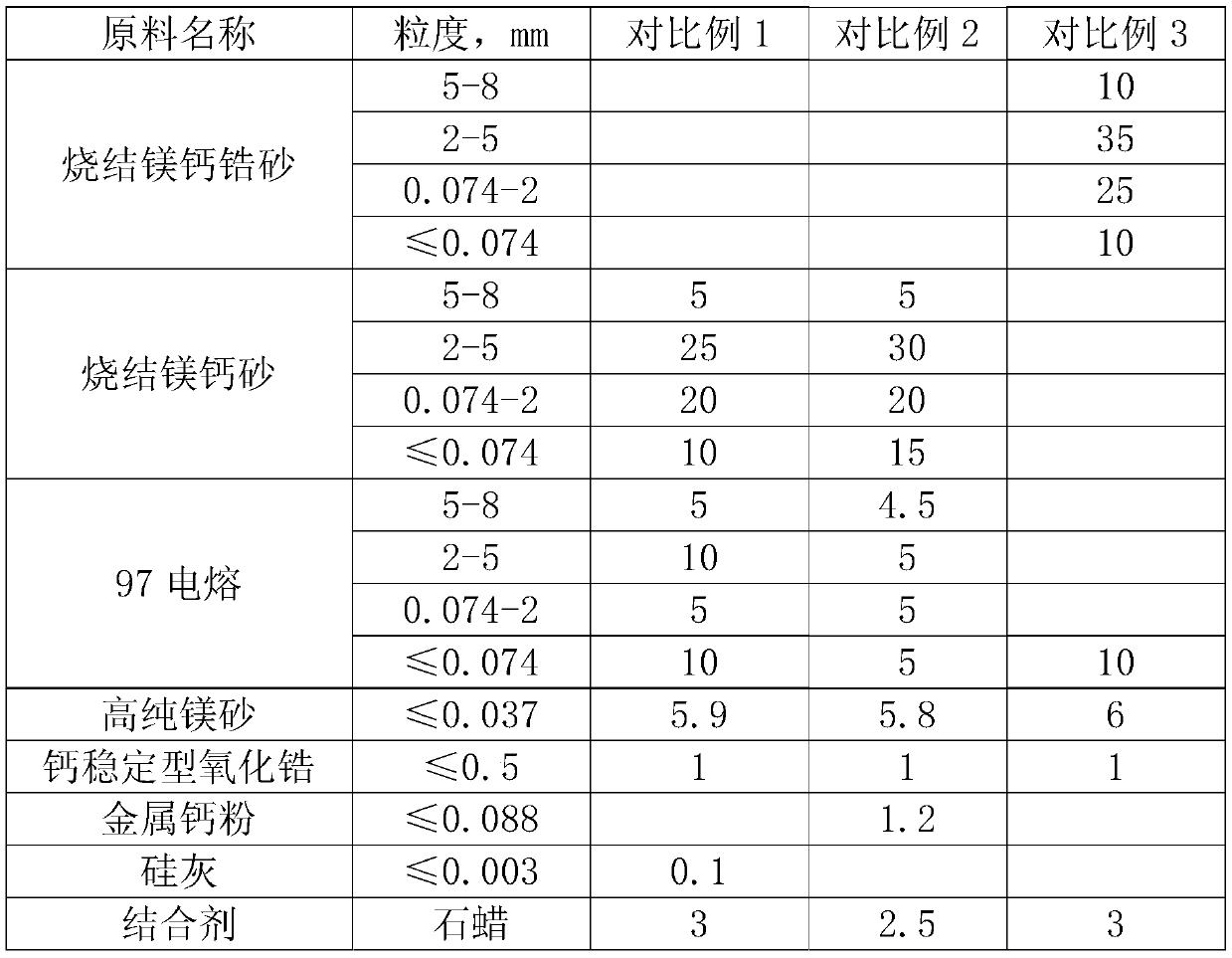

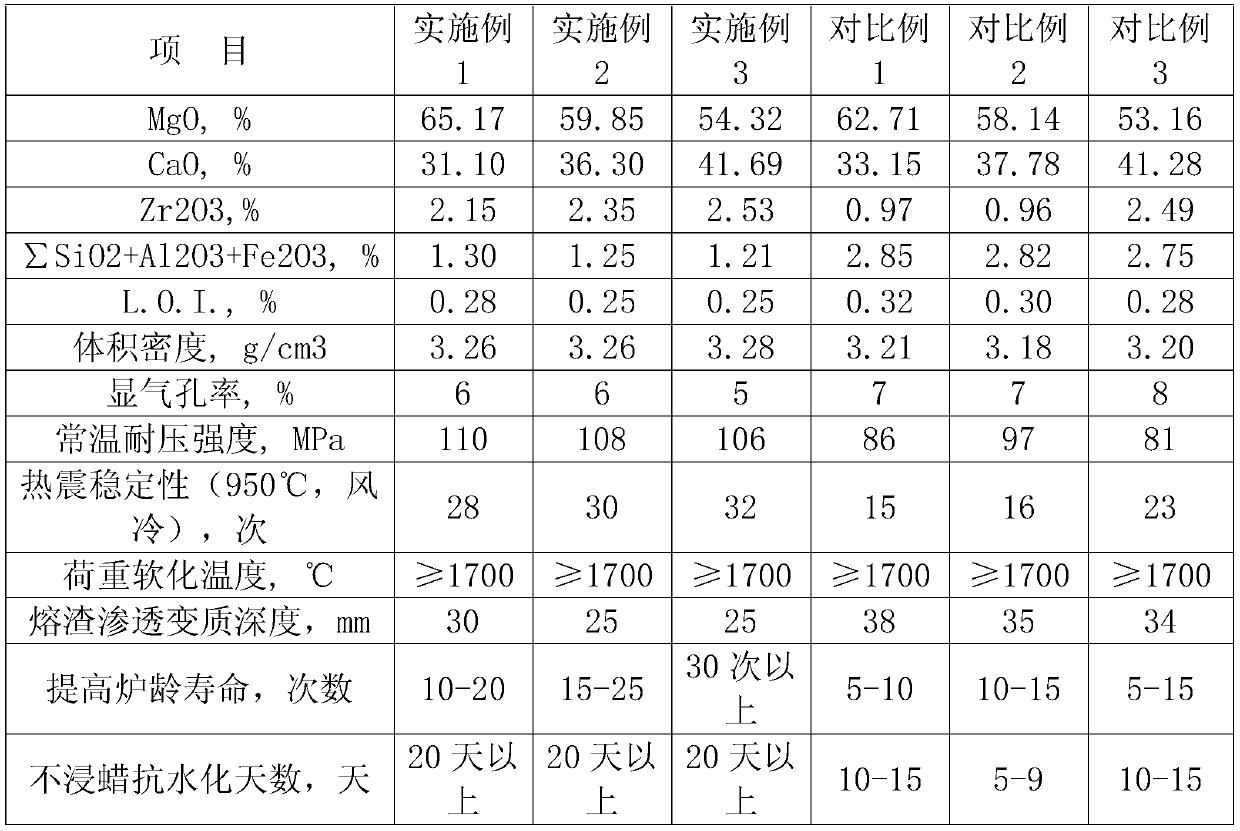

Embodiment 1

[0028] A zirconium composite high-performance fused magnesia-calcium-zirconium brick is made of the following raw materials in proportion by weight: 5% fused magnesia-calcium-zirconium sand with a particle size of 5-8mm, fused magnesia with a particle size of 2-5mm Calcium-zirconium sand 25%, particle size 2-0.074mm fused magnesia-calcium-zirconium sand 20%, particle size not greater than 0.074mm fused magnesia-calcium-zirconium sand fine powder 10%, particle size 5-8mm fused magnesia 5% 10% of fused magnesia with a particle size of 2-5mm, 5% of fused magnesia with a particle size of 2-0.074mm, 10% of fused magnesia fine powder with a particle size of no more than 0.074mm, high-purity magnesia with a particle size of no more than 0.037mm 6% ultra-fine powder, 1% calcium-stabilized zirconia with a particle size not greater than 0.5mm, 0.9% calcium metal powder with a particle size not greater than 0.088mm, 0.1% silica fume with a particle size not greater than 0.003mm, and 2% pa...

Embodiment 2

[0041] A zirconium composite high-performance fused magnesia-calcium-zirconium brick is made of the following raw materials in proportion by weight: 5% fused magnesia-calcium-zirconium sand with a particle size of 5-8mm, fused magnesia with a particle size of 2-5mm Calcium-zirconium sand 30%, particle size 2-0.074mm fused magnesia-calcium-zirconium sand 20%, particle size not greater than 0.074mm fused magnesia-calcium-zirconium sand powder 15%, particle size 5-8mm fused magnesia 4.5% 5% fused magnesia with a particle size of 2-5mm, 5% fused magnesia with a particle size of 2-0.074mm, 5% fused magnesia fine powder with a particle size not greater than 0.074mm, high-purity magnesia with a particle size not greater than 0.037mm 5.7% ultrafine powder, 1% calcium stabilized zirconia with a particle size not larger than 0.5mm, 1.2% metallic calcium powder with a particle size not larger than 0.088mm, 0.1% silica fume with a particle size not larger than 0.003mm, and 2.5% paraffin. ...

Embodiment 3

[0044] A zirconium composite high-performance fused magnesia-calcium-zirconium brick is made of the following raw materials in proportion by weight: 6% fused magnesia-calcium-zirconium sand with a particle size of 5-8mm, fused magnesia with a particle size of 2-5mm Calcium-zirconium sand 33%, particle size 2-0.074mm fused magnesia-calcium-zirconium sand 24%, particle size not greater than 0.074mm fused magnesia-calcium-zirconium sand fine powder 10%, particle size 5-8mm fused magnesia 3% 2% fused magnesia with a particle size of 2-5mm, 1% fused magnesia with a particle size of 2-0.074mm, 10% fused magnesia fine powder with a particle size not greater than 0.074mm, high-purity magnesia with a particle size not greater than 0.037mm 5.4% ultrafine powder, 1% calcium-stabilized zirconia with a particle size not greater than 0.5mm, 1.5% calcium metal powder with a particle size not greater than 0.088mm, 0.1% silica fume with a particle size not greater than 0.003mm, and 3% paraffin....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com