Electrolyte for low-corrosivity electrolytic condenser and method for making the same

An electrolytic capacitor, corrosive technology, applied in the field of electrolyte, can solve the problems of non-compliance, reduce the conductivity of the electrolyte, etc., and achieve the effect of preventing hydration reaction, strong anti-hydration ability, and inhibiting hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

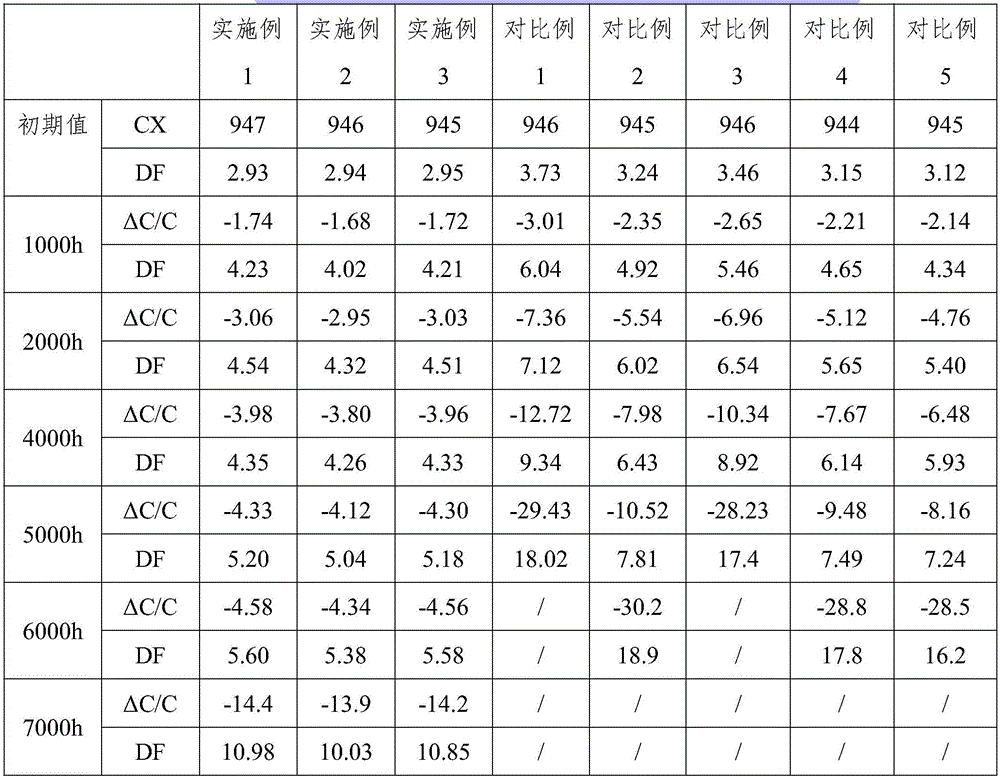

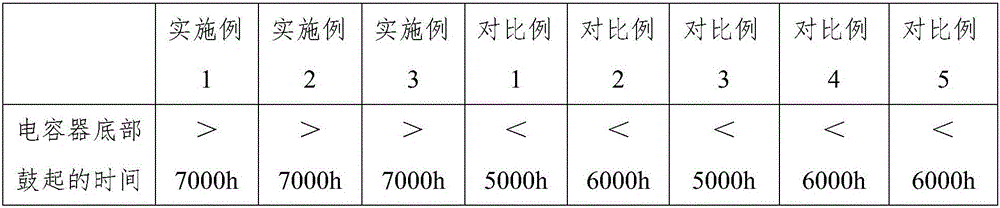

Examples

Embodiment 1

[0033] Embodiment 1, a kind of electrolytic solution for electrolytic capacitor of low corrosion

[0034] The electrolytic solution for the low-corrosion electrolytic capacitor consists of the following components and parts by weight thereof:

[0035] 120 parts of ethylene glycol, 16 parts of ammonium adipate, 12 parts of ammonium formate, 4 parts of additives and 30 parts of ultrapure water; Said additive consists of ethylene glycol 78%, diammonium hydrogen phosphate 2%, phosphoric acid 4%, para Nitrobenzoic acid 1%, ammonium p-nitrobenzoate 2%, complexing agent 4%, surfactant 3% and corrosion inhibitor 6% form; Described complexing agent is made up of ethylenediaminetetraacetic acid and citric acid by weight The composition ratio is 1:4; the surfactant is composed of polysorbate 80 and mannitol in a weight ratio of 0.5:5; the corrosion inhibitor is composed of 8-hydroxyquinoline and silicon dioxide in a weight ratio of 1:6.

[0036] Preparation:

[0037] S1: Add ammonium a...

Embodiment 2

[0039] Embodiment 2, a kind of electrolytic solution for electrolytic capacitor with low corrosion

[0040] The electrolytic solution for the low-corrosion electrolytic capacitor consists of the following components and parts by weight thereof:

[0041] 145 parts of ethylene glycol, 16 parts of ammonium adipate, 16 parts of ammonium formate, 7 parts of additives and 40 parts of ultrapure water, described additives are made of ethylene glycol 68%, diammonium hydrogen phosphate 4%, phosphoric acid 6%, Nitrobenzoic acid 2%, ammonium p-nitrobenzoate 3%, complexing agent 5%, surfactant 5% and corrosion inhibitor 7% form; Described complexing agent is made up of ethylenediaminetetraacetic acid and citric acid by weight The composition ratio is 2:3; the surfactant is composed of polysorbate 20 and mannitol in a weight ratio of 1:4; the corrosion inhibitor is composed of 8-hydroxyquinoline and silicon dioxide in a weight ratio of 2:5.

[0042] Preparation:

[0043] S1 Add ammonium a...

Embodiment 3

[0045] Embodiment 3, a kind of electrolytic solution for electrolytic capacitor with low corrosion

[0046] The electrolytic solution for the low-corrosion electrolytic capacitor consists of the following components and parts by weight thereof:

[0047] 150 parts of ethylene glycol, 20 parts of ammonium adipate, 18 parts of ammonium formate, 8 parts of additives and 60 parts of ultrapure water; Said additive consists of ethylene glycol 60%, diammonium hydrogen phosphate 5%, phosphoric acid 8%, para Nitrobenzoic acid 3%, ammonium p-nitrobenzoate 4%, complexing agent 6%, surfactant 6% and corrosion inhibitor 8% form; Described complexing agent is made up of ethylenediaminetetraacetic acid and citric acid by weight The composition ratio is 3:2; the surfactant is composed of polysorbate 20 and mannitol in a weight ratio of 2:3; the corrosion inhibitor is composed of 8-hydroxyquinoline and silicon dioxide in a weight ratio of 3:4.

[0048] Preparation:

[0049] S1 Add ammonium ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com