A kind of aluminum oxide short fiber reinforced magnesium oxide base crucible and preparation method thereof

A magnesia-based and magnesia-based ceramic technology is applied in the field of alumina short fiber reinforced magnesia-based crucible and its preparation, magnesia-based crucible and its preparation, and magnesium and its alloy smelting fields, which can solve the problem of reducing magnesia ceramics. The problems of sintering temperature, chemical stability of inter-grain bonding, and sintering temperature of MgO foam ceramics are reduced to achieve the effect of improving mechanical properties and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

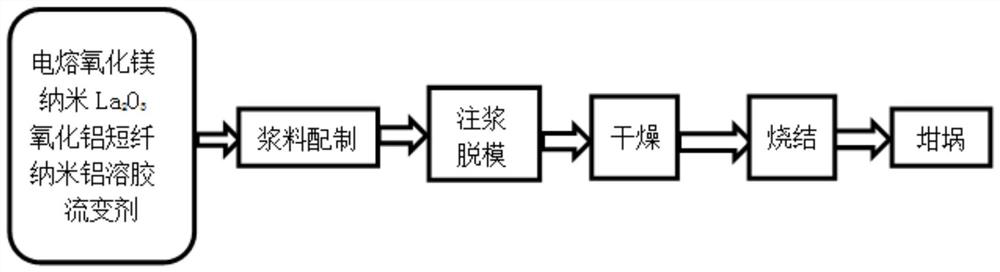

Method used

Image

Examples

Embodiment 1

[0055] According to the proportion of nano-lanthanum oxide in the mass percentage of ceramic powder as 1%, alumina short fiber as 1%, and the rest as fused magnesia, the nano-lanthanum oxide with a particle size of 60nm and the commercialized small aspect ratio polycrystalline Al 2 o 3 Short fibers (diameter 10μm-20μm, length 50μm-100μm) and particle size 250 mesh (median diameter d 50 The ceramic powder is prepared by mixing fused magnesia powder with a thickness of 58 μm; the rheological agent is prepared by mixing the mass ratio of polyvinyl alcohol and hydroxyethyl cellulose at a ratio of 2:3.

[0056] According to mass percentage, 15% of nano-alumina sol with a solid content of 20% (select a commercial nano-alumina sol with a nearly neutral pH value, the same below), 0.8% of rheological agent, and the rest are ceramic powders for batching. First, add the fused magnesia powder into the ball mill tank according to the proportion, and prepare the nano-aluminum sol, rheolog...

Embodiment 2

[0061] According to the ratio of nano-lanthanum oxide to the mass percentage of ceramic powder as 3%, alumina short fiber as 3%, and the rest as fused magnesia, the nano-lanthanum oxide with a particle size of 30nm and the commercialized small aspect ratio polycrystalline Al 2 o 3 Short fibers (diameter 10 μm ~ 20 μm, length 50 μm ~ 100 μm) and particle size 500 mesh (median diameter d 50 Mix and prepare ceramic powder with fused magnesia powder (25 μm); mix and prepare rheological agent according to the mass ratio of polyvinyl alcohol and hydroxypropyl cellulose at a ratio of 2:3.

[0062] According to mass percentage, 25% of nano-alumina sol with a solid content of 25%, 1.5% of rheological agent, and the rest are ceramic powder for batching. First, add the fused magnesia powder into the ball mill tank according to the proportion, prepare a solution from nano-aluminum sol, rheological agent and appropriate amount of deionized water, then add nano-lanthanum oxide and alumina...

Embodiment 3

[0067] According to the ratio of nano-lanthanum oxide to the mass percentage of ceramic powder as 2%, alumina short fiber as 2%, and the rest as fused magnesia, the nano-lanthanum oxide with a particle size of 45nm and the commercialized small aspect ratio polycrystalline Al 2 o 3 Short fibers (diameter 10μm-20μm, length 50μm-100μm) and particle size 325 mesh (median diameter d 50 Mix and prepare ceramic powder with fused magnesia powder (45 μm); mix and prepare rheological agent according to the mass ratio of polyvinyl alcohol and hydroxyethyl cellulose at a ratio of 2:3.

[0068] According to mass percentage, 20% of nano-alumina sol with a solid content of 22%, 1% of rheological agent, and the rest are ceramic powder for batching. First, add the fused magnesia powder into the ball mill tank according to the ratio, prepare a solution from nano-alumina sol, rheological agent and an appropriate amount of deionized water, then add nano-lanthanum oxide and alumina short fiber, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com