Magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter and preparation method thereof

A technology of magnesium oxide-based ceramics and magnesium oxide whiskers, which is applied in the field of metal materials and metallurgy, can solve the problems of reduced chemical stability of bonding between grains, increased lattice distortion of matrix magnesium oxide, and operational limitations, and achieves excellent chemical stability. The effect of stability, simple process and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

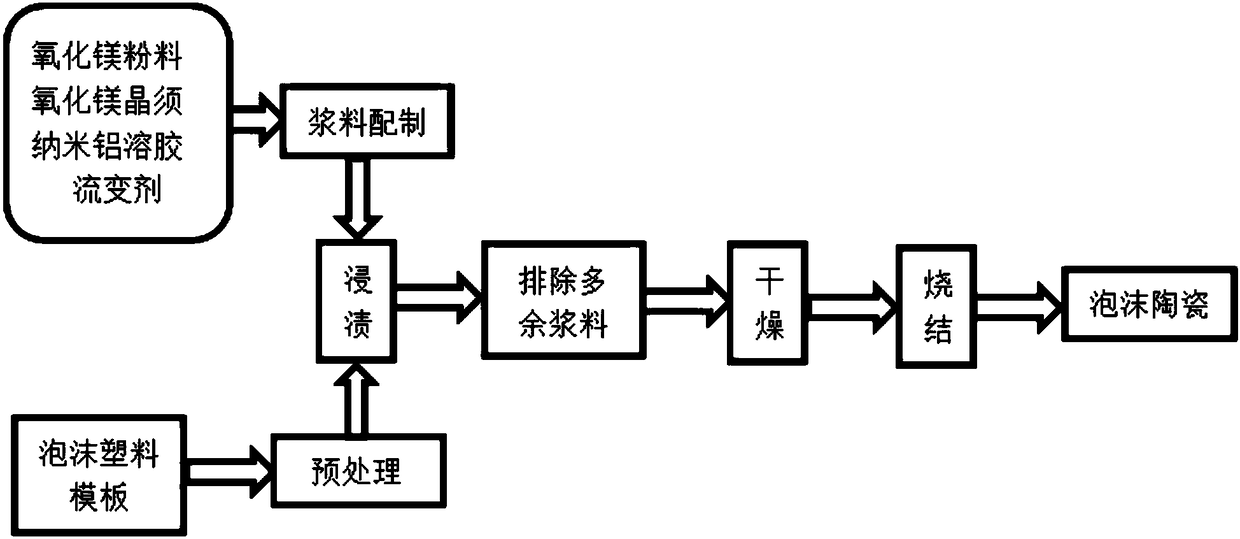

Method used

Image

Examples

Embodiment 1

[0048] Account for the proportioning of 1% of the quality of the ceramic powder according to the magnesia whiskers, weighing the commercial magnesia whiskers and particle diameter is 250 orders (median diameter d 50 Prepare ceramic powder for 58 μm) fused magnesia powder; mix and prepare rheological agent according to the mass ratio of urea-formaldehyde resin and hydroxyethyl cellulose at a ratio of 1:4.

[0049] According to mass percentage, 15% of nano-alumina sol with a solid content of 20% (select a commercial nano-alumina sol with a nearly neutral pH value, the same below), 0.8% of rheological agent, and the rest are ceramic powders for batching. First, add the fused magnesia powder into the ball mill tank according to the proportion, and prepare the nano-aluminum sol, rheological agent and appropriate amount of deionized water (the amount to be added according to the solid content of the ceramic slurry, the same below) to prepare a solution Add magnesium oxide whisker po...

Embodiment 2

[0053] According to the proportion that magnesium oxide whiskers account for 2% of the mass of ceramic powder, weigh commercial magnesium oxide whiskers (with a diameter of 2 to 5 μm and a length of 200 μm to 1000 μm) and a particle size of 500 mesh (median diameter d 50 Prepare ceramic powder for fused magnesia powder (25 μm); mix and prepare rheological agent according to the mass ratio of urea-formaldehyde resin and hydroxypropyl methylcellulose at a ratio of 1:4.

[0054] According to mass percentage, 20% of nano-aluminum sol with a solid content of 25%, 1.5% of rheological agent, and the rest are ceramic powder for batching. First, add the fused magnesia powder into the ball mill tank according to the ratio, prepare the nano-aluminum sol, rheological agent and appropriate amount of deionized water into a solution, add the magnesia whisker powder, and ultrasonically treat the magnesia whiskers for 45 minutes to make the magnesia whiskers After the powder is fully dispersed...

Embodiment 3

[0058]Account for the proportioning of 1.5% of the ceramic powder quality according to the magnesia whiskers, weighing the commercial magnesia whiskers and particle diameter is 325 orders (middle diameter d 50 Prepare ceramic powder for fused magnesia powder (45 μm); mix and prepare rheological agent according to the mass ratio of urea-formaldehyde resin and hydroxyethyl cellulose at a ratio of 1:4.

[0059] According to mass percentage, 25% of nano-alumina sol with a solid content of 22%, 1.0% of rheological agent, and the rest are ceramic powder for batching. First, add the fused magnesia powder into the ball mill tank according to the ratio, prepare a solution of nano-alumina sol, rheological agent and an appropriate amount of deionized water, add magnesia whiskers powder, and ultrasonically treat magnesia whiskers for 60 minutes to make the magnesia whiskers After the powder is fully dispersed in the solution, add it to the ball mill tank, and then add corundum balls accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com