Preparation method of catalytic material mixed by copper and cerium oxide

A catalytic material, cerium oxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., to achieve the effects of simple operation, high pore volume, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

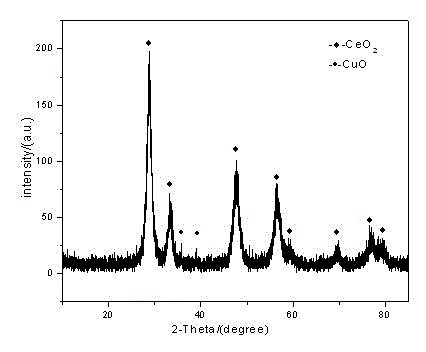

[0032] (a) Take 0.06318g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) Dissolve in deionized water and stir continuously for 0.5h; the concentration of Cu ions is 0.00872mol / mL;

[0033] (b) According to the liquid-solid ratio of 8:1, add the mesoporous ceria powder into the copper salt solution obtained in step (a), after dissolving, let stand for 24 hours, and stir occasionally during the period;

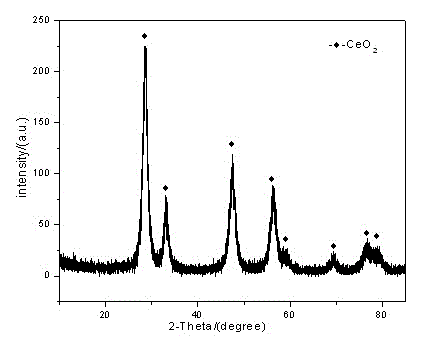

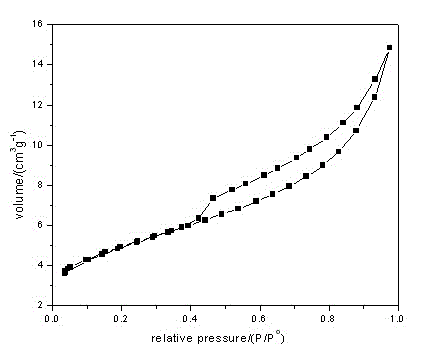

[0034] (c) Put the mixed solution of step (b) in a constant temperature drying oven to dry at 110°C for 10 hours, then grind it and place it in a muffle furnace for sintering at 300°C for 2 hours to obtain a copper-doped cerium oxide catalytic material, which The specific surface area is 154.289m 2 / g, the pore volume is 0.975cm 3 / g.

[0035] Wherein, the mesoporous ceria powder is prepared through the following steps:

[0036] (1) Take 52.240g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) and 5.2510 g of citric acid were dissolved in deionized water, and continuously stirred for 0.5 h to...

Embodiment 2

[0043] (a) Take 0.1972g copper nitrate (Cu(NO 3) 2 ·3H 2 O) Dissolve in deionized water and stir continuously for 0.8h; the concentration of Cu ions is 0.02616mol / mL;

[0044] (b) According to the liquid-solid ratio of 10:1, add the mesoporous ceria powder into the copper salt solution obtained in step (a), after dissolving, let stand for 36 hours, and stir occasionally during the period;

[0045] (c) Put the mixed solution of step (b) in a constant temperature drying oven to dry at 120°C for 12h, and then put it in a muffle furnace and bake at 280°C for 3h after grinding to obtain a copper-doped cerium oxide catalytic material, which The specific surface area is 150.976m 2 / g, the pore volume is 0.879cm 3 / g.

[0046] Wherein, the mesoporous ceria powder is prepared through the following steps:

[0047] (1) Take 17.3652g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) and 1.72812g of citric acid were dissolved in deionized water and stirred continuously for 0.5h to obtain a cit...

Embodiment 3

[0054] (a) Take 0.3235g copper nitrate (Cu(NO 3 ) 2 ·3H 2 O) Dissolve in deionized water and stir continuously for 1h; the concentration of Cu ions is 0.0436mol / mL;

[0055] (b) According to the liquid-solid ratio of 6:1, add the mesoporous ceria powder into the copper salt solution obtained in step (a), after dissolving, let stand for 48 hours, and stir occasionally during the period;

[0056] (c) Put the mixed solution in step (b) in a constant temperature drying oven to dry at 120°C for 10 hours, and then grind it and place it in a muffle furnace and bake it at 200°C for 2.5 hours to obtain a copper-doped cerium oxide catalytic material. Its specific surface area is 147.630m 2 / g, the pore volume is 0.859cm 3 / g.

[0057] Wherein, the mesoporous ceria powder is prepared through the following steps:

[0058] (1) Take 30.8873g cerium nitrate (Ce(NO 3 ) 3 ·6H 2 O) and 3.1002g of citric acid were dissolved in deionized water, and continuously stirred for 0.8h to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com