Application of alpha-molybdenum carbide and metal-modified alpha-molybdenum carbide catalyst to reaction for preparing carbon monoxide through hydrogenation of carbon dioxide

A metal modification, carbon dioxide technology, applied in the directions of carbon monoxide, physical/chemical process catalyst, chemical/physical process, etc., can solve problems that have not yet been seen, achieve high and low temperature activity and CO selectivity, solve thermal sintering and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

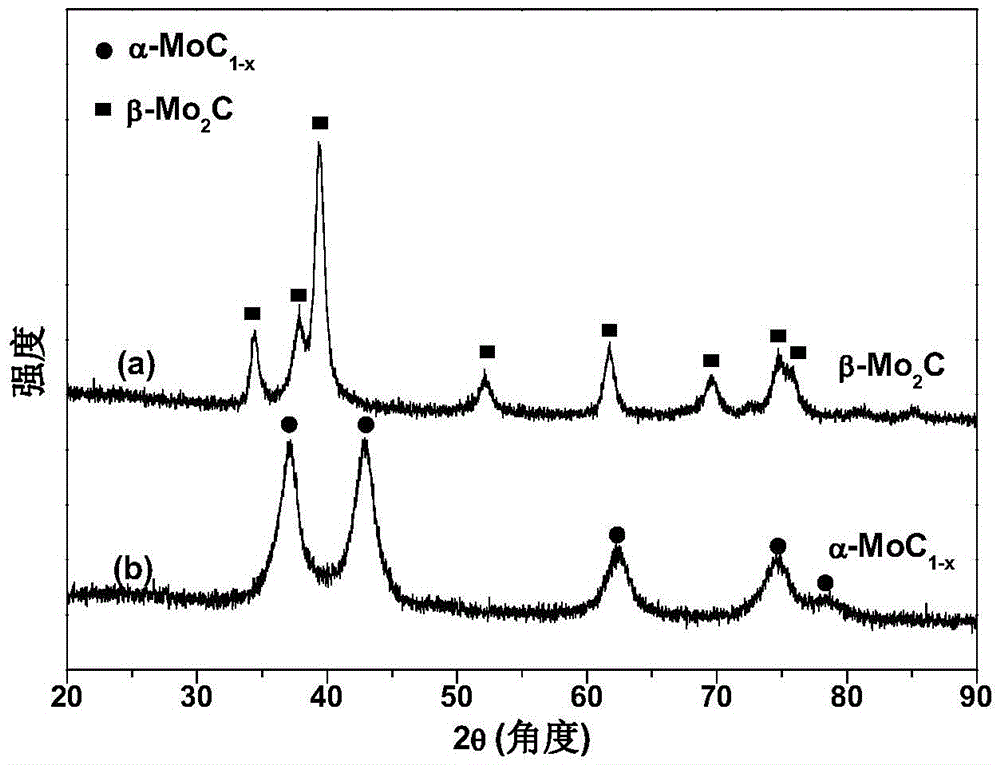

[0037] Example 1α-MoC 1-x preparation and activity evaluation

[0038] (1) Preparation

[0039] Take 1.2gMoO 3 (40-60 mesh) samples are placed in a quartz reactor, and 150ml / min of pure NH 3 Atmosphere, from room temperature to the final nitriding temperature of 700 °C at a heating rate of 5 °C / min, and kept for 2 hours, then cooled to room temperature, and the reaction gas was switched to 20% CH 4 / H 2 (150mL / min) mixed gas, and then raised to the final carbonization temperature of 700°C at a heating rate of 5°C / min, and kept for 2h. Then after cooling down to room temperature, in 1% O 2 / Ar atmosphere passivation for 12h to obtain α-MoC 1-x Catalyst samples.

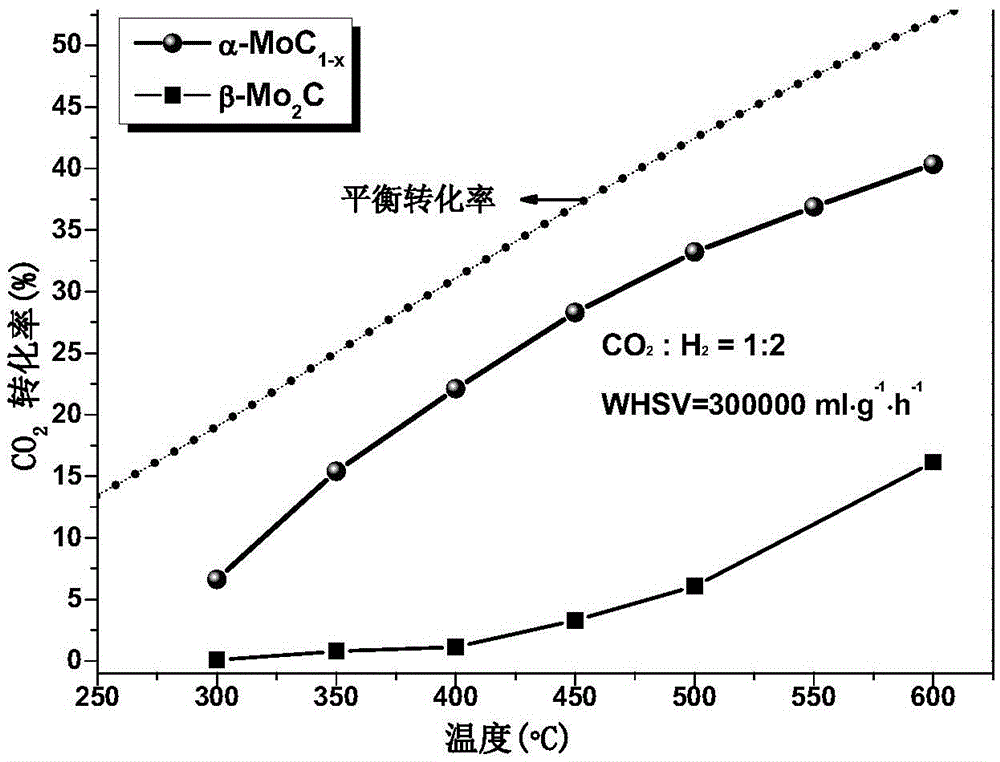

[0040] (2) Activity evaluation test

[0041] The carbon dioxide hydrogenation to carbon monoxide reaction is carried out in a quartz tube fixed-bed reactor with an inner diameter of 4mm. The flow rate of each gas required for the experiment is regulated and controlled by a mass flow meter, and flows into the r...

Embodiment 2

[0048] Example 2α-MoC 1-x stability test

[0049] This example is α-MoC 1-x The 40h stability test of the catalyst, the catalyst preparation and activity evaluation test conditions during the process were the same as those in Example 1, except that the stability test temperature was 600°C. It can be seen that within 40 hours, the reaction activity of the catalyst only decreased by about 5%, and it has better thermal stability than the commercial Cu-Zn-Al catalyst.

Embodiment 31

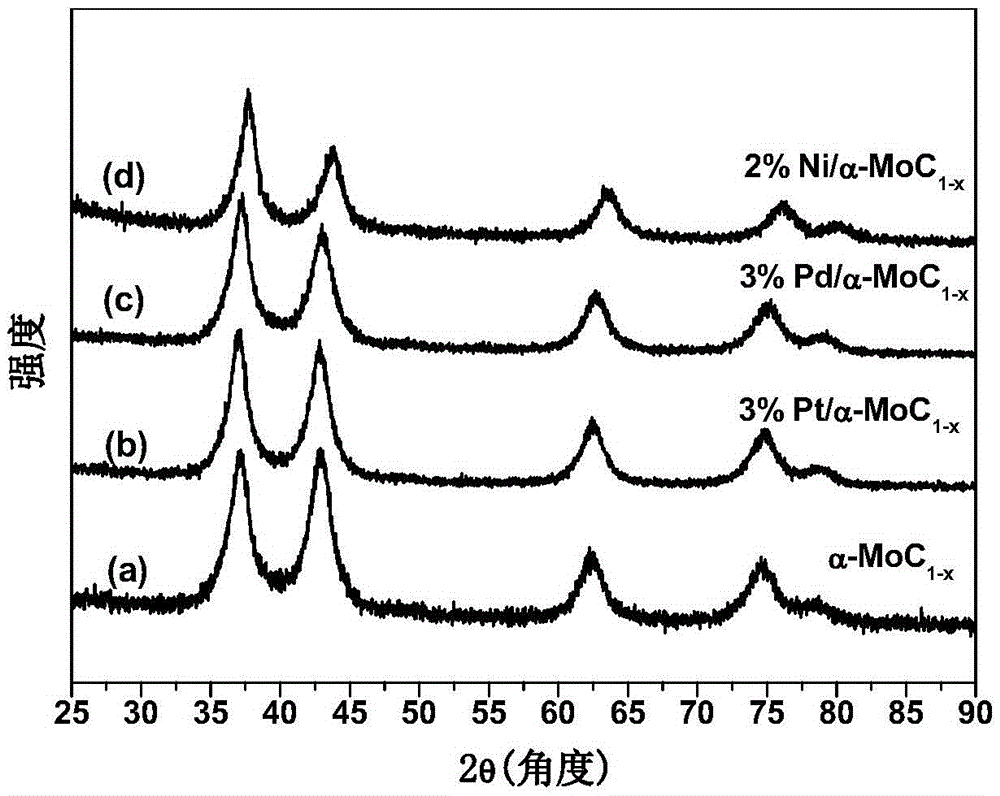

[0052] Example 31%Pt / α-MoC 1-x preparation and activity evaluation

[0053] (1) Preparation

[0054] 3%Pt / α-MoC Prepared by Isovolumetric Impregnation Method 1-x Catalyst: Weigh 3g of α-MoC prepared in Example 1 at room temperature 1-x The carrier is mixed with a certain concentration of chloroplatinic acid solution (the mass of chloroplatinic acid is 0.0796g, the volume of deionized water is 4.2ml), the impregnated product is left to stand overnight, and dried in a vacuum oven at 60°C for 12h to obtain 1% Pt / α-MoC 1-x catalyst;

[0055] (2) Activity evaluation test

[0056] The carbon dioxide hydrogenation to carbon monoxide reaction is carried out in a quartz tube fixed-bed reactor with an inner diameter of 4 mm. The flow rate of each gas required for the experiment is regulated and controlled by a mass flow meter, and flows into the reactor after mixing.

[0057] Weigh 30mg of 1%Pt / α-MoC 1-x (40-60 mesh) catalyst and 0.12g of quartz sand (40-60 mesh) are placed in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com