Water-based primer and preparation method thereof

A technology of water-based primer and active diluent, which is applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., and can solve problems such as stability, impact resistance, sag resistance, drying speed, salt spray resistance, and poor flame retardancy. , to achieve good anti-settling effect, good adhesion performance and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

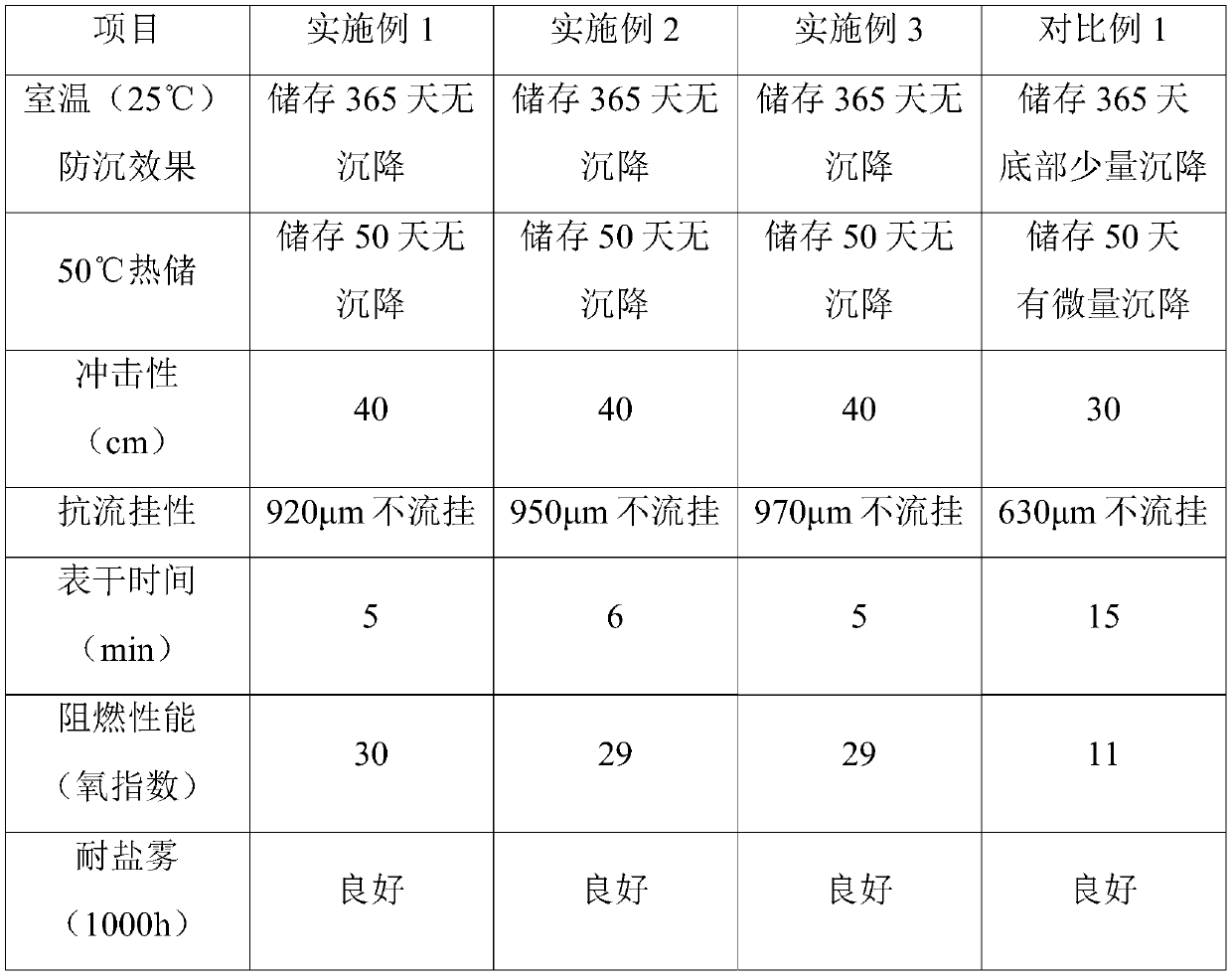

Examples

Embodiment 1

[0028] A water-based primer, comprising A component and B component;

[0029] Described A component comprises the component of following mass percentage:

[0030] raw material Proportion (%) epoxy resin 10 Epoxy Reactive Diluent 1 Dispersant 0.5 Defoamer 0.1 Coalescent 1 Zinc powder 53.6 Al-Si Alloy Powder 12 Ferrophosphorus powder 20 expanded graphite 1 silica 0.2 Anti-flash rust agent 0.1 Zirconium phosphate 0.5

[0031] Described B component comprises the component of following mass percentage:

[0032] raw material Proportion (%) Hardener 70 Deionized water 30

[0033] The mass ratio of the A component to the B component is 4:1.

[0034] Among them, the epoxy resin is selected from Shandong Mingda New Material Co., Ltd. F0704; the epoxy reactive diluent is selected from Nanya epoxy reactive diluent 692; the dispersant is selected from Nanjing Quanxi Chemical ...

Embodiment 2

[0040] A water-based primer, comprising A component and B component;

[0041] Described A component comprises the component of following mass percentage:

[0042] raw material Proportion (%) epoxy resin 20 Epoxy Reactive Diluent 2 Dispersant 0.4 Defoamer 0.3 Coalescent 3 Zinc powder 46 Al-Si Alloy Powder 8 Ferrophosphorus powder 15 expanded graphite 2 silica 1 Anti-flash rust agent 0.3 Zirconium phosphate 2

[0043] Described B component comprises the component of following mass percentage:

[0044] raw material Proportion (%) Hardener 80 Deionized water 20

[0045] The mass ratio of the A component to the B component is 5:1.

[0046]Among them, the epoxy resin is selected from Shandong Mingda New Material Co., Ltd. F0704; the epoxy reactive diluent is selected from Nanya epoxy reactive diluent 692; the dispersant is selected from Nanjing Quanxi Chemical Co., Ltd...

Embodiment 3

[0052] A water-based primer, comprising A component and B component;

[0053] Described A component comprises the component of following mass percentage:

[0054]

[0055]

[0056] Described B component comprises the component of following mass percentage:

[0057] raw material Proportion (%) Hardener 90 Deionized water 10

[0058] The mass ratio of the A component to the B component is 6:1.

[0059] Among them, the epoxy resin is selected from Shandong Mingda New Material Co., Ltd. F0704; the epoxy reactive diluent is selected from Nanya epoxy reactive diluent 692; the dispersant is selected from Nanjing Quanxi Chemical Co., Ltd. A-171; the defoamer is selected by quality Composed of phospholipid hydrophobic defoamer and silicone defoamer at a ratio of 3:1, the phosphate hydrophobic defoamer is 941PL from MOUSSEX, and the silicone defoamer is BYK- 028; the film-forming aid is propylene glycol methyl ether; the zinc powder is F1000 from Dali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com