A kind of preparation method of low-frequency sound-absorbing material

A sound-absorbing material and low-frequency technology, which is applied in the field of preparation of low-frequency sound-absorbing materials, can solve problems such as low low-frequency sound-absorbing performance, inability to meet the use requirements of electronic components, and restrict large-scale applications, and achieve high-strength, sound-absorbing performance Excellent, solve the effect of poor sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

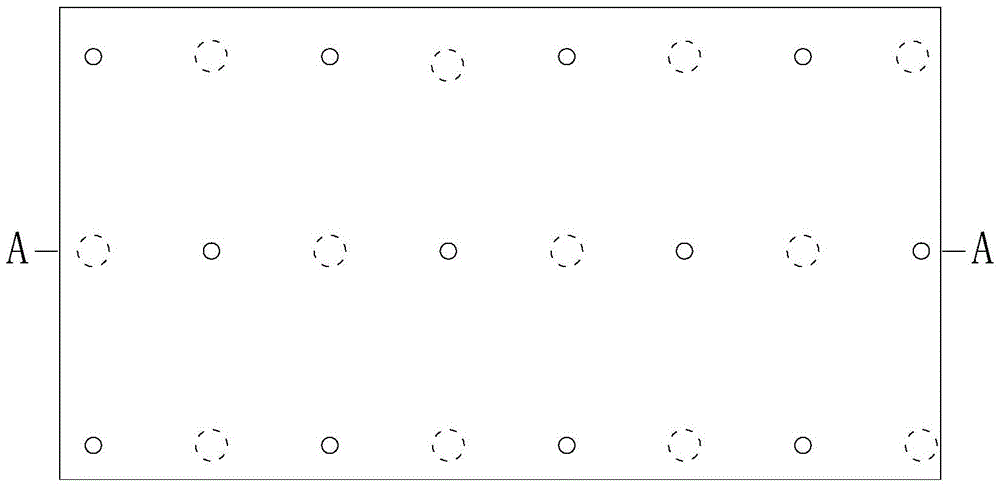

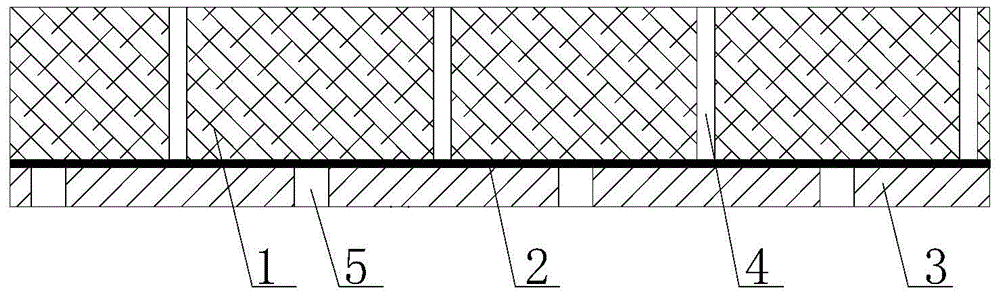

[0036] combine figure 1 and figure 2 , the preparation method of the low-frequency sound-absorbing material of this embodiment includes the following steps:

[0037] Step 1, adding copper powder with a particle size of 10 μm into polyvinyl alcohol aqueous solution and mixing uniformly to obtain a slurry; the mass percentage of copper powder in the slurry is 8%, and the balance is polyvinyl alcohol aqueous solution; The mass percentage concentration of polyvinyl alcohol aqueous solution is 2%;

[0038] Step 2, uniformly coating the slurry described in step 1 on the surface of the dense metal plate, then placing the dense metal plate coated with the slurry in a drying oven to dry, and obtaining a powder coating on the surface of the dense metal plate; The drying temperature is 120°C, and the drying time is 1 hour; the thickness of the powder coating is 0.1 mm; the material of the dense metal plate is stainless steel;

[0039] Step 3. Lay the metal fiber made of stainless ste...

Embodiment 2

[0043] combine figure 1 and figure 2 , the preparation method of the low-frequency sound-absorbing material of this embodiment includes the following steps:

[0044]Step 1, adding copper powder with a particle size of 20 μm into polyvinyl alcohol aqueous solution and mixing uniformly to obtain a slurry; the mass percentage of copper powder in the slurry is 10%, and the balance is polyvinyl alcohol aqueous solution; The mass percentage concentration of polyvinyl alcohol aqueous solution is 3%;

[0045] Step 2, uniformly coating the slurry described in step 1 on the surface of the dense metal plate, then placing the dense metal plate coated with the slurry in a drying oven to dry, and obtaining a powder coating on the surface of the dense metal plate; The drying temperature is 120°C, and the drying time is 2 hours; the thickness of the powder coating is 0.15 mm; the material of the dense metal plate is iron-chromium-aluminum alloy;

[0046] Step 3. Lay metal fibers made of i...

Embodiment 3

[0050] combine figure 1 and figure 2 , the preparation method of the low-frequency sound-absorbing material of this embodiment includes the following steps:

[0051] Step 1, adding copper powder with a particle size of 45 μm into polyvinyl alcohol aqueous solution and mixing uniformly to obtain a slurry; the mass percentage of copper powder in the slurry is 12%, and the balance is polyvinyl alcohol aqueous solution; The mass percent concentration of the polyvinyl alcohol aqueous solution is 5%.

[0052] Step 2, uniformly coating the slurry described in step 1 on the surface of the dense metal plate, then placing the dense metal plate coated with the slurry in a drying oven to dry, and obtaining a powder coating on the surface of the dense metal plate; The drying temperature is 120°C, and the drying time is 1.5h; the thickness of the powder coating is 0.2mm; the material of the dense metal plate is Fe-Cr-Al alloy;

[0053] Step 3. Lay metal fibers made of iron-chromium-alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com