Porous silicon material and preparation method thereof

A technology of porous silicon and organosilicon, which is applied in the direction of halosilane and silicon halide compounds, can solve the problems of high production cost of porous silicon materials, polluting industrial production, and complicated processes, and achieves low production costs, uniform pore size, and high process efficiency. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

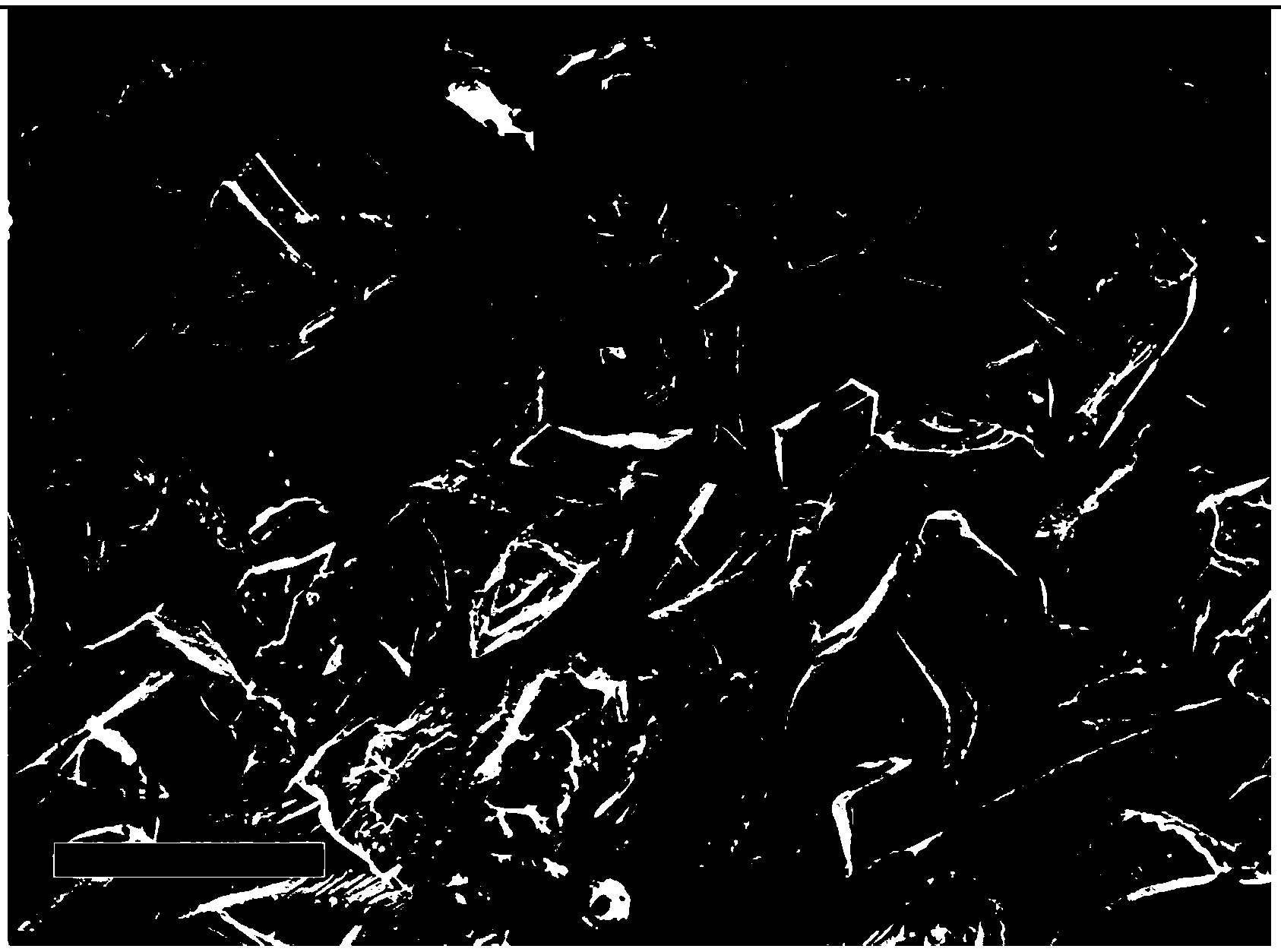

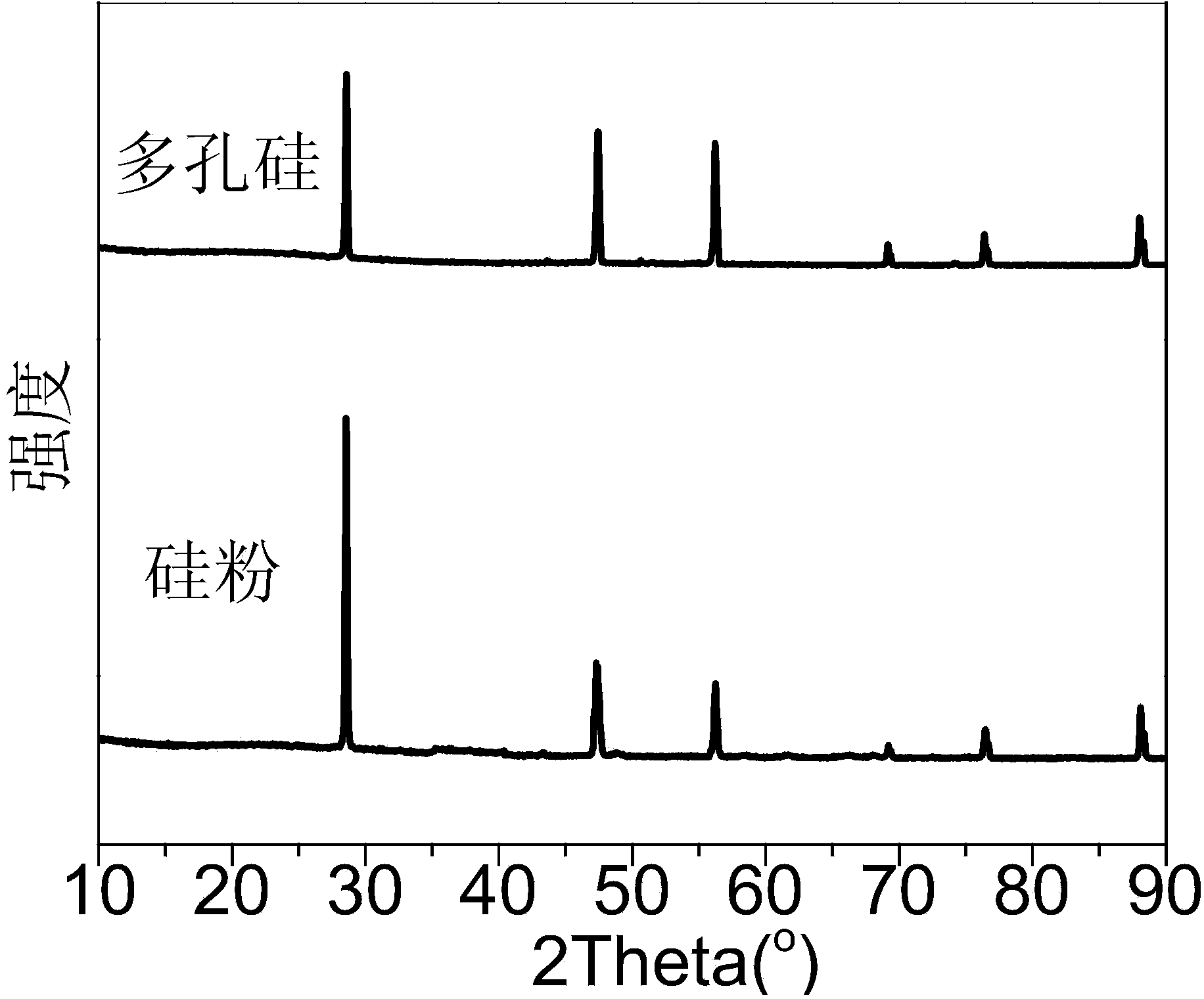

Embodiment 1

[0041] Mix 10 g of commercially purchased silicon fume raw material (particle size range 10-100 μm) with commercially purchased Cu 2 10 grams of O powder (as a copper-based catalyst, particle size range 1-5 microns), 1 gram of zinc powder, mixed and ground evenly, then packed into a fixed-bed reactor, fed with methyl chloride gas (gas velocity is 30ml / min), adjusted The pressure is 0.3MPa. After preheating, the temperature is raised to 410°C. After 18 hours of reaction, it is cooled to room temperature. The gaseous product in the reaction process becomes a mixture of organosilicon monomers after condensation, and can be separated into chemicals by rectification later. Unreacted methyl chloride can be recycled. The solid residue after the reaction contains silicon and a solid copper-based catalyst. Air is introduced into a tube furnace (gas velocity: 100ml / min) and the temperature is raised to 500°C for 1 hour to remove carbon deposits, cooled to room temperature, and heated to...

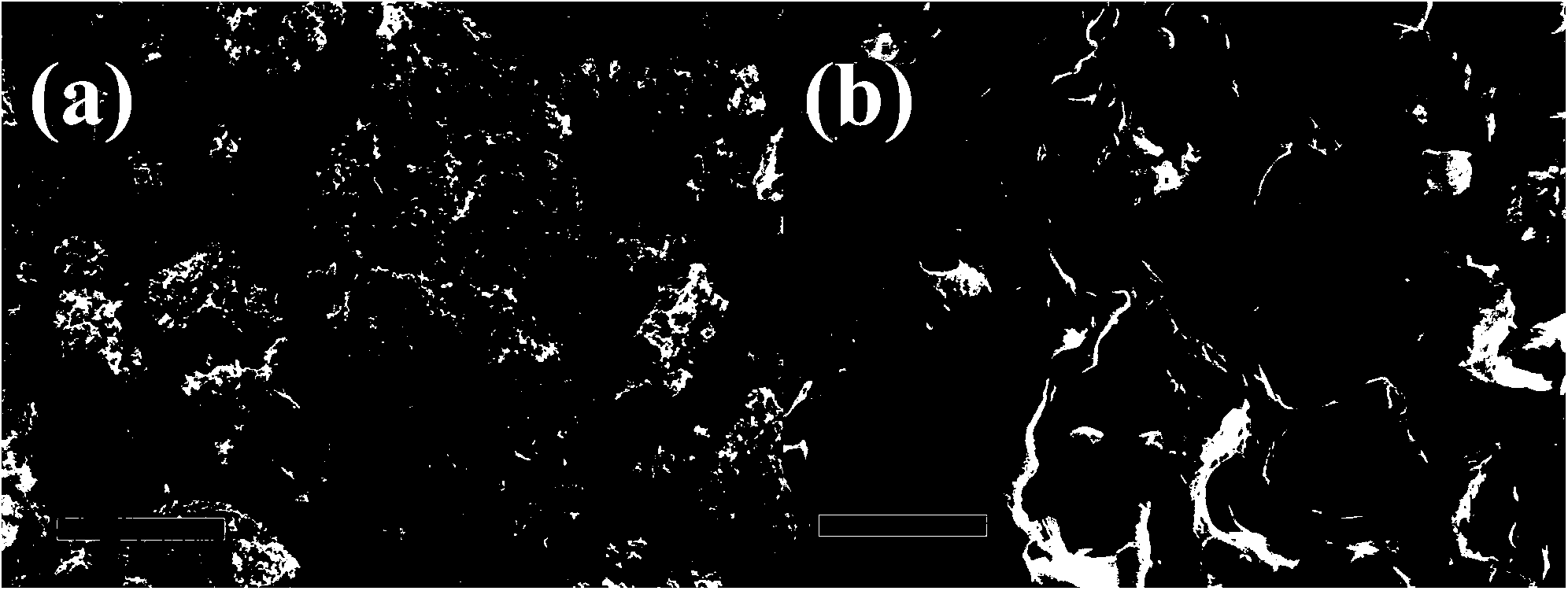

Embodiment 2

[0049] Mix and grind 8 grams of commercially purchased silicon powder raw materials (with a particle size range of 5-50 microns), 5 grams of self-made Cu powder (as a copper-based catalyst, with a particle size range of 0.1-1 microns), and 0.2 grams of zinc powder. The fixed bed reactor is fed with methyl chloride gas (gas velocity is 30ml / min), and the pressure is adjusted to 1MPa. After preheating, the temperature is raised to 420°C. After 24 hours of reaction, it is cooled to room temperature, and the gaseous products in the reaction process are condensed Afterwards, it becomes a mixture of organosilicon monomers, which can be separated into chemicals by rectification in the later stage, and unreacted monochloromethane can be recycled. The solid residue after the reaction contains silicon and a solid copper-based catalyst. Air is introduced into the tube furnace (gas velocity is 200ml / min) and the temperature is raised to 600°C for 2 hours to remove carbon deposits, cooled t...

Embodiment 3

[0052] Combine 20 grams of commercially purchased silicon powder raw material (particle size range 1-20 microns) with commercially purchased Cu-CuCl powder 15 grams (as a copper-based catalyst, particle size range 0.1-10.0 microns), 2.0 grams of zinc powder, tin powder Mix and grind 0.05 grams evenly and put them into a fixed-bed reactor, feed in methyl chloride gas (gas velocity: 50ml / min), adjust the pressure to 0.6MPa, preheat, heat up to 480°C, react for 12 hours, and cool to room temperature , the gaseous product in the reaction process becomes a mixture of organosilicon monomers after condensation, which can be separated into chemicals by rectification in the later stage, and unreacted monochloromethane can be recycled. The solid residue after the reaction contains silicon and a solid copper-based catalyst. Air is introduced into a tube furnace (gas velocity: 100ml / min) and the temperature is raised to 500°C for 1 hour to remove carbon deposits, cooled to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com