Nanometer silicon nitride bearing material for machinery and preparation method thereof

A nano-silicon nitride and bearing material technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of insufficient service life, poor load-carrying capacity, low elastic modulus, etc., so as to prolong the service life and improve the mechanical strength , reduce the effect of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

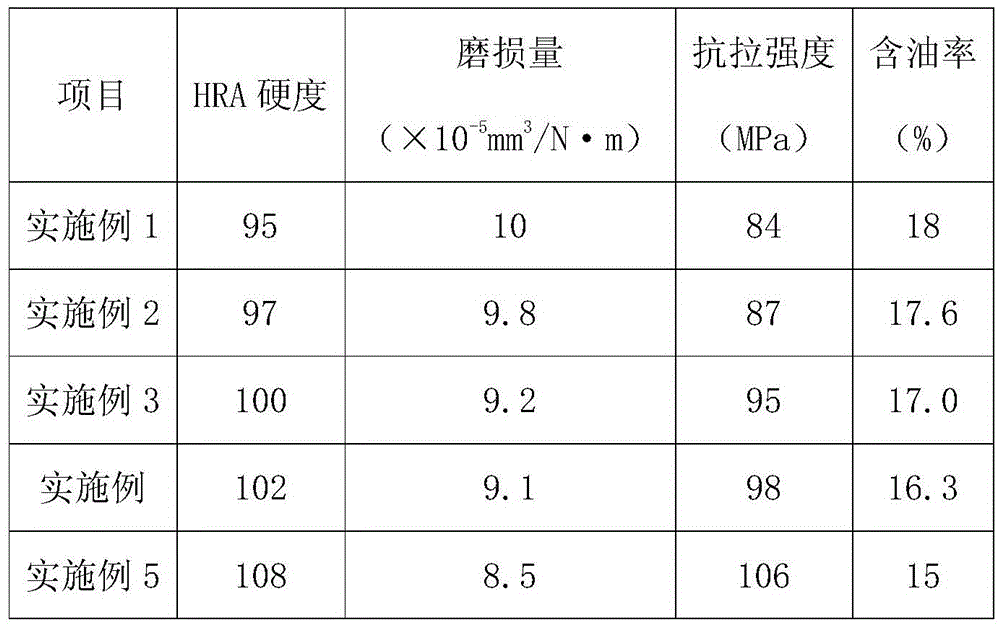

Examples

Embodiment 1

[0021] In the embodiment of the present invention, a nano-silicon nitride bearing material for machinery is made of the following raw materials in parts by weight: 14 parts of nano-silicon nitride, 62 parts of zirconia, 9 parts of silicon, 2 parts of nickel, magnesium 3 parts, germanium 1.8 parts, polytetrafluoroethylene powder 5 parts, polyvinyl alcohol 3.4 parts, bamboo charcoal powder 0.4 parts, oleic acid 5 parts, calcium stearate 0.8 parts, alumina 7 parts, bentonite 1.5 parts, triphenyl phosphate 2.5 parts of ester.

[0022] The preparation method of the nano-silicon nitride bearing material for machinery comprises the following steps:

[0023] (1) Pour nano-silicon nitride, zirconia, silicon, nickel, magnesium, germanium and aluminum oxide into a mortar, grind and mix evenly, then add the mixed powder to a ball mill for wet ball milling for 16 hours, and the ball milling medium is Zirconium balls, the solvent is absolute ethanol, mixed powder: absolute ethanol: zirconi...

Embodiment 2

[0030] In the embodiment of the present invention, a nano-silicon nitride bearing material for machinery is made of the following raw materials in parts by weight: 18 parts of nano-silicon nitride, 58 parts of zirconia, 13 parts of silicon, 1 part of nickel, magnesium 4 parts, germanium 1.2 parts, polytetrafluoroethylene powder 7 parts, polyvinyl alcohol 2.8 parts, bamboo charcoal powder 0.8 parts, oleic acid 3 parts, calcium stearate 1.2 parts, aluminum oxide 5 parts, bentonite 2.5 parts, triphenyl phosphate 1.5 parts of ester.

[0031] The preparation method of the nano-silicon nitride bearing material for machinery is the same as that in Example 1.

Embodiment 3

[0033] In the embodiment of the present invention, a nano-silicon nitride bearing material for machinery is made of the following raw materials in parts by weight: 15 parts of nano-silicon nitride, 62 parts of zirconia, 9 parts of silicon, 1.6 parts of nickel, magnesium 3.4 parts, germanium 1.6 parts, polytetrafluoroethylene powder 5.5 parts, polyvinyl alcohol 3.2 parts, bamboo charcoal powder 0.5 parts, oleic acid 4.2 parts, calcium stearate 0.9 parts, alumina 6.2 parts, bentonite 2.0 parts, triphenyl phosphate 2.2 parts of ester.

[0034] The preparation method of the nano-silicon nitride bearing material for machinery comprises the following steps:

[0035] (1) Pour nano-silicon nitride, zirconia, silicon, nickel, magnesium, germanium and aluminum oxide into a mortar, grind and mix evenly, then add the mixed powder to a ball mill for wet ball milling for 24 hours, and the ball milling medium is Zirconium balls, solvent is absolute ethanol, mixed powder: absolute ethanol: z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com