Preparing method of antibacterial porous titanium alloy

A titanium alloy, ascorbic acid technology, applied in metal processing equipment, nanotechnology for materials and surface science, nanotechnology, etc., to achieve the effects of strong controllability, convenient operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

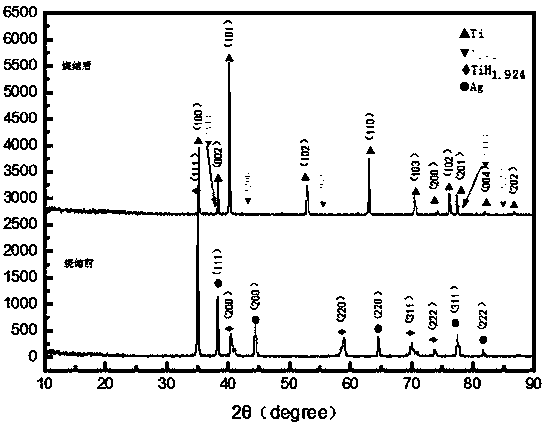

Image

Examples

Embodiment 1

[0032] A kind of preparation method of antibacterial porous titanium alloy, concrete steps are as follows:

[0033] (1) Weigh TiH 2 Powder, the powder purity is greater than or equal to 99.0%, put the powder into the ball mill tank according to the ball-to-material ratio of 4:1, the charging volume is 40%, use a planetary ball mill, set the ball mill speed to 150r / min, and the ball mill time to 150min. When the particle size is less than 45um, it is for use;

[0034] (2) Weigh silver nitrate and add deionized water to make a silver nitrate solution with a concentration of 0.1mol / L, add dispersant PVP, fully dissolve, and record it as solution A 1 , the amount of dispersant added is solution A 1 5% of silver nitrate mass in medium;

[0035] (3) Weigh the reducing agent ascorbic acid and add deionized water to make reducing agent solution A with a concentration of 0.2mol / L 2 ;

[0036] (4) Add solution A 1 and solution A 2 Put it in a water bath, heat it to the reaction t...

Embodiment 2

[0042] A kind of preparation method of antibacterial porous titanium alloy, concrete steps are as follows:

[0043](1) According to the required composition ratio of Ti-13Nb-13Zr alloy standard, weigh TiH 2 Powder, Nb powder, Zr powder, powder purity greater than or equal to 99.0%, put the powder into the ball mill tank according to the ball-to-material ratio of 4:1, the charging volume is 40%, use a planetary ball mill, set the ball mill speed to 150r / min, The ball milling time is 150min, until the particle size is less than 45um, and set aside;

[0044] (2) Weigh silver nitrate and add deionized water to make a silver nitrate solution with a concentration of 0.5mol / L, add dispersant PVP, fully dissolve, and record it as solution A 1 , the amount of dispersant added is solution A 1 10% of the mass of silver nitrate in medium;

[0045] (3) Weigh the reducing agent ascorbic acid and add deionized water to make reducing agent solution A with a concentration of 1mol / L 2 ;

...

Embodiment 3

[0051] A kind of preparation method of antibacterial porous titanium alloy, concrete steps are as follows:

[0052] (1) According to the required composition ratio of Ti(3-6)Zr(2-4)Mo(24-27)Nb (TLE, a multi-purpose near-β-type medical titanium alloy developed by Northwest Nonferrous Metal Research Institute) alloy standard, Weigh TiH 2 Powder, Zr powder, Mo powder, Nb powder, powder purity greater than or equal to 99.0%, put the powder into the ball mill tank according to the ball-to-material ratio of 4:1, the charging volume is 40%, use a planetary ball mill, set the ball mill speed to 150r / min, the ball milling time is 150min, the ball milling until the particle size is less than 45um, and it is ready for use;

[0053] (2) Weigh silver nitrate and add deionized water to make a silver nitrate solution with a concentration of 2mol / L, add dispersant PVP, fully dissolve, and record it as solution A 1 , the amount of dispersant added is solution A 1 15% of silver nitrate mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com