Lightweight high-strength refractory castable

A refractory castable, high-strength technology, applied in the field of refractory materials, can solve problems such as increased consumption, easy breakage, and fluctuations in the mechanical properties of castables, and achieve the effects of reducing heat loss, reducing bulk density, and improving high-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

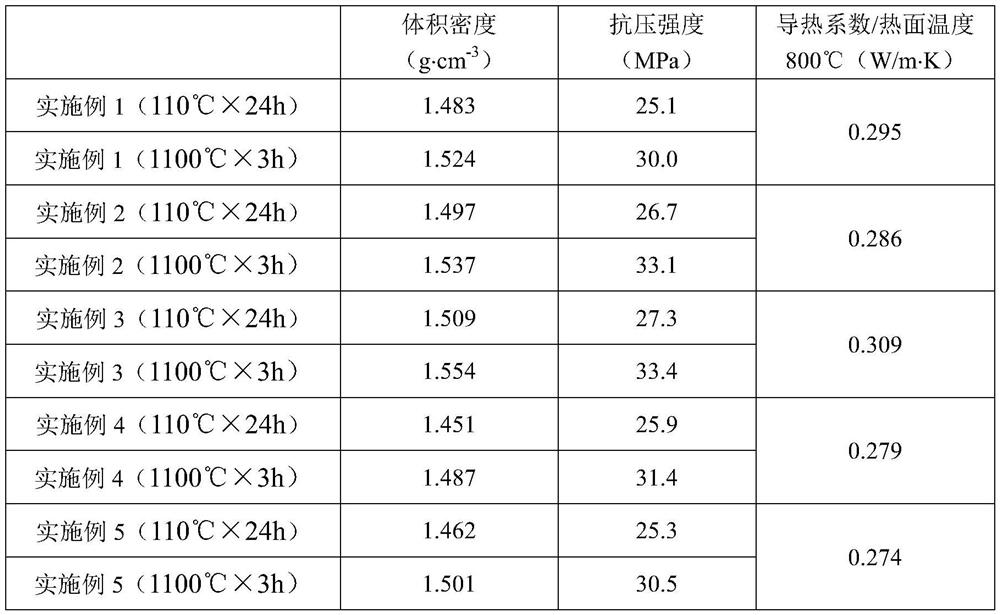

Examples

Embodiment 1

[0034] A light-weight high-strength refractory castable, its raw material composition and weight percentage content are: 25% light-weight high-strength microporous bauxite aggregate, 35% aluminum oxide hollow balls, 3% floating beads with a particle size of 200 mesh, and 3% with a particle size of 5% of 120 mesh kyanite powder, 6.88% of cooked bauxite fine powder with a particle size of 200 mesh, 8% of silicon micropowder with a particle size of ≤500 mesh, α-Al with a particle size of ≤500 mesh 2 o 3 Micropowder 9%, alumina cement 5%, refractory fiber 3%, composite water reducer 0.1%, commercially available RK-720F silicon polyether defoamer 0.02%.

[0035] Wherein, the light-weight high-strength microporous alumina aggregate is graded, specifically including light-weight high-strength microporous alumina aggregate with 15% by weight of 5mm≤particle size3 , the total porosity ≥ 65%, the average pore diameter of micropores ≤ 10μm.

[0036] The alumina hollow spheres are partic...

Embodiment 2

[0040] A light-weight high-strength refractory castable, its raw material composition and weight percentage content are: 30% light-weight high-strength microporous bauxite aggregate, 30% aluminum oxide hollow balls, 4% floating beads with a particle size of 180 mesh, and 4% with a particle size of 6% of 120 mesh kyanite powder, 5.32% of cooked bauxite fine powder with a particle size of 200 mesh, 6% of silicon micropowder with a particle size of ≤500 mesh, α-Al with a particle size of ≤500 mesh 2 o 3 Micro powder 8%, alumina cement 6.5%, refractory fiber 4%, composite water reducer 0.15%, commercially available RK-720F silicon polyether defoamer 0.03%.

[0041] Wherein, the light-weight high-strength microporous alumina aggregate is graded, specifically including light-weight high-strength microporous alumina aggregate with 15% by weight of 5mm≤particle size3 , the total porosity ≥ 65%, the average pore diameter of micropores ≤ 10μm.

[0042] The alumina hollow spheres are pa...

Embodiment 3

[0046] A light-weight high-strength refractory castable. Its raw material composition and weight percentage content are: 28% light-weight high-strength microporous bauxite aggregate, 25% aluminum oxide hollow balls, 5% floating beads with a particle size of 160 mesh, and 5% floating beads with a particle size of 80 mesh kyanite powder 6.82%, 180 mesh cooked bauxite fine powder 8%, silicon micropowder ≤500 mesh 6%, α-Al particle size ≤500 mesh 2 o 3 Micropowder 9%, alumina cement 7%, refractory fiber 5%, composite water reducer 0.15%, commercially available RK-720F silicon polyether defoamer 0.03%.

[0047] Wherein, the light-weight high-strength microporous alumina aggregate is graded, specifically including light-weight high-strength microporous alumina aggregate with 18% by weight of 5mm≤particle size3 , the total porosity ≥ 65%, the average pore diameter of micropores ≤ 10μm.

[0048] The alumina hollow spheres are graded, specifically including 17% by weight of alumina ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com