Copper-based wide-temperature-range liquid-solid synergistic self-lubricating composite material with controllable porosity and preparation method of copper-based wide-temperature-range liquid-solid synergistic self-lubricating composite material

A composite material and wide temperature range technology, which is applied in the field of copper-based wide temperature range liquid-solid synergistic self-lubricating composite materials and its preparation, can solve the problems of poor bonding between ferrous sulfide and copper matrix, low mechanical strength of composite materials, and continuous matrix Improve the mechanical strength and tribological properties, improve the liquid-solid synergistic lubrication performance, and improve the lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

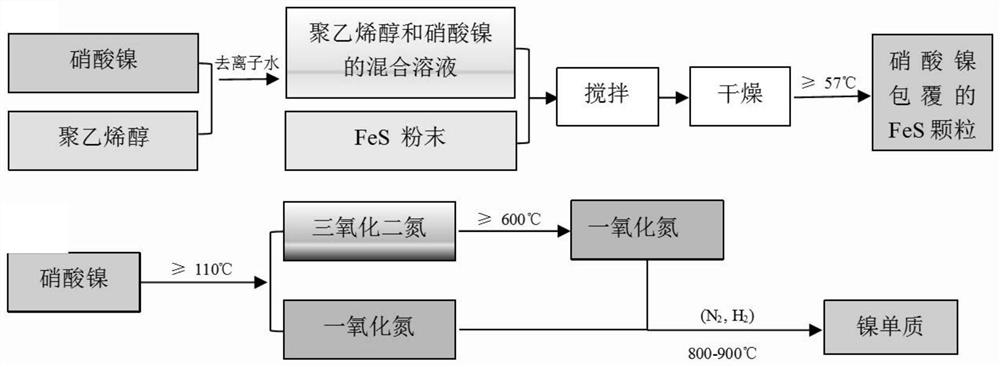

[0050] The operation steps for preparing the copper-based wide temperature range liquid-solid synergistic self-lubricating composite material with controllable porosity are as follows:

[0051] 1. Preparation of ferrous sulfide powder coated with nickel nitrate with a mass fraction of 85%

[0052] Cleaning: Ultrasonic dispersion of FeS powder in absolute ethanol for 15-20 minutes, remove the absolute ethanol and put it in a drying oven at 50-80°C for 1-2 hours;

[0053] Adhesive solution preparation: take 5g of polyvinyl alcohol and add it into 95g of pure water, fully dissolve it under the condition of heating in a water bath (95°C), and prepare a polyvinyl alcohol aqueous solution with a mass fraction of 5%.

[0054] Mixed solution preparation: 10 g of nickel nitrate was added to 5% polyvinyl alcohol solution for thorough stirring and dissolution to prepare a mixed solution.

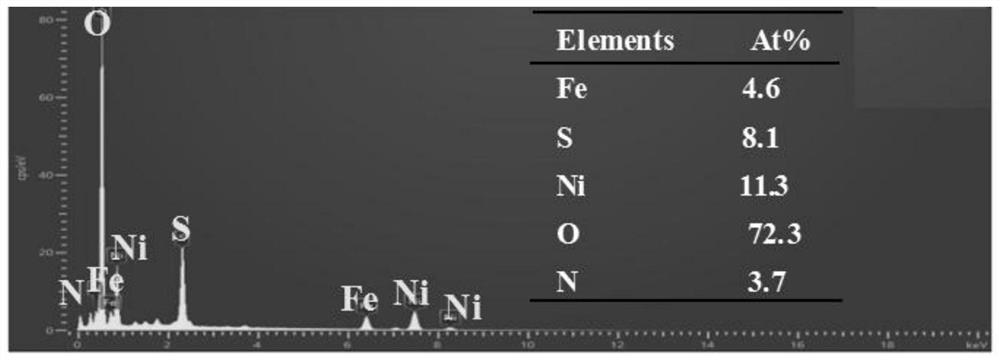

[0055] Nickel nitrate coating: Add 85g of FeS powder into the mixed solution of polyvinyl alcohol ...

Embodiment 2

[0068] The operation steps for preparing the copper-based wide temperature range liquid-solid synergistic self-lubricating composite material with controllable porosity are as follows:

[0069] 1. Preparation of ferrous sulfide powder coated with nickel nitrate with a mass fraction of 70%

[0070] Cleaning: Place 70g of FeS powder in absolute ethanol for ultrasonic dispersion for 15-20min, remove the absolute ethanol and put it in a drying oven at 50-80°C for 1-2 hours;

[0071] Adhesive solution preparation: take 5g of polyvinyl alcohol and add it into 95g of pure water, fully dissolve it under the condition of heating in a water bath (95°C), and prepare a polyvinyl alcohol aqueous solution with a mass fraction of 5%.

[0072] Mixed solution preparation: 25g of nickel nitrate was added to 5% polyvinyl alcohol solution for thorough stirring and dissolution to prepare a mixed solution.

[0073] Nickel nitrate coating: Add 70g of FeS powder into the mixed solution of polyvinyl ...

Embodiment 3

[0080] Embodiment 3: the difference with embodiment 1 is that the FeS without coating nickel nitrate is directly added

[0081] The operation steps for preparing copper-based wide temperature range liquid-solid synergistic self-lubricating composite material not coated with nickel nitrate are as follows:

[0082] 1. Add copper-tin alloy with a particle size of 200 mesh, ferrous sulfide powder with a particle size of 100 mesh, and bismuth powder with a particle size of 200 mesh into the planetary ball mill tank at a mass ratio of 85:9:6, and grind it at a low speed in an argon atmosphere. After ball milling for 6 hours, the rotating speed of the ball milling tank was 150r / min, and the ball-to-material ratio was 10:1 to obtain a mixed powder in which nickel nitrate-coated FeS and Bi powder were uniformly dispersed and embedded on flaky CuSn10 flakes.

[0083] The mixed powder was subjected to high-speed ball milling (450 rpm) for 1 h again to obtain a layered granular mixed powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com