Graphene in-situ modified nylon 6 composite and preparation method and application thereof

A composite material and polylactam technology, which is applied in the field of graphene in-situ modified polylactam composite materials, can solve the problems of unstable material performance, poor interface adhesion, and poor dispersion of modifier graphene , to achieve the effects of reduced friction coefficient, improved anti-wear performance, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

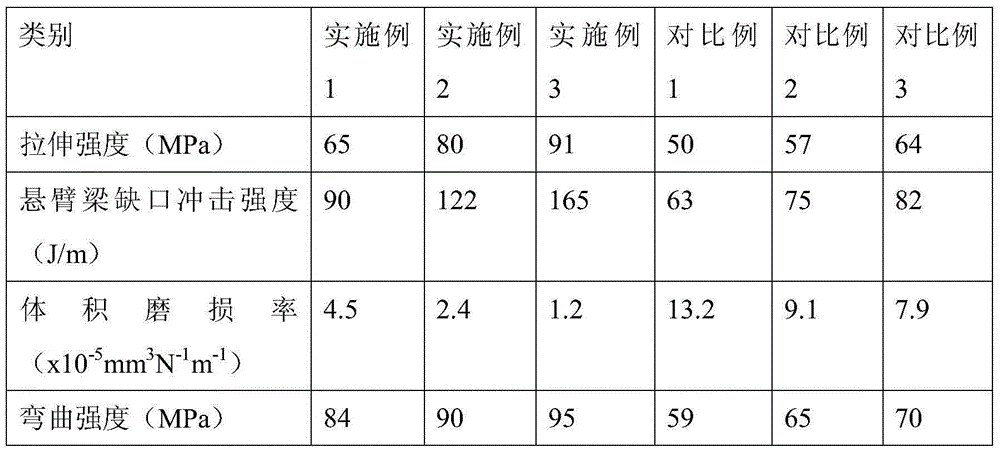

Examples

Embodiment 1

[0031] Graphite is pretreated by the Hummer method, that is, 1g graphite, 1gNaNO 3 , 3ml of H with a mass concentration of 98% 2 SO 4 were placed in three-necked flasks and stirred for 5min, then slowly added 4gKMnO 4 , reacted at room temperature for 10min, slowly added 50ml deionized water and 10gH 2 o 2 , at a temperature of 70°C, stirred and refluxed for 10 hours, then filtered with a microporous membrane while hot, washed 3 times with 5% HCl, and then repeatedly washed with distilled water until the filtrate was neutral, and then placed in Dry in a vacuum oven at 40°C for 24 hours to obtain graphene oxide. Disperse 1 g of graphene oxide in anhydrous DMF, ultrasonically disperse for about 1 h, add 1 g of isocyanate, heat and stir, react for 6 h, remove the product, and extract with anhydrous DMF for 6 h to obtain modified graphene oxide. Disperse 1g of modified graphene oxide in anhydrous DMF, add 1g of caprolactam, stir and heat at 130°C for 3h, then extract the prod...

Embodiment 2

[0033] Graphite is pretreated by the Hummer method, that is, 1g graphite, 2gNaNO 3 , 10ml mass concentration of 97% H 2 SO 4 were placed in three-necked flasks and stirred for 10min, then slowly added 6gKMnO 4 , reacted at room temperature for 15min, slowly added 100ml deionized water and 15gH 2 o 2, at a temperature of 85°C, stirred and refluxed for 8 hours, then filtered with a microporous membrane while hot, washed 4 times with 5% HCl, and then repeatedly washed with distilled water until the filtrate was neutral, and then placed in Dry in a vacuum oven at 50°C for 18 hours to obtain graphene oxide. Disperse 1 g of graphene oxide in anhydrous DMF, ultrasonically disperse for about 2 hours, add 2 g of isocyanate to heat and stir, react for 4 hours, remove the product, and extract with anhydrous DMF for 9 hours to obtain modified graphene oxide. Disperse 1 g of modified graphene oxide in anhydrous DMF, add 2 g of decanolactam, stir and heat at 120°C for 4 hours, then ext...

Embodiment 3

[0035] Graphite is pretreated by the Hummer method, that is, 1g graphite, 4gNaNO 3 , 6ml mass concentration of 96% H 2 SO 4 were placed in three-necked flasks and stirred for 20min, then slowly added 8gKMnO 4 , react at room temperature for 30min, slowly add 200ml deionized water and 30gH 2 o 2 , at a temperature of 110°C, stirred and refluxed for 6 hours, then filtered through a microporous membrane while hot, washed 5 times with 5% HCl, and then repeatedly washed with distilled water until the filtrate was neutral, and then placed in Dry in a vacuum drying oven at 70°C for 12 hours to obtain graphene oxide. Disperse 1 g of graphene oxide in anhydrous DMF, ultrasonically disperse for about 3 hours, add 3 g of isocyanate, heat and stir, react for 3 hours, remove the product, and extract with anhydrous DMF for 12 hours , to obtain modified graphene oxide. Disperse 1 g of modified graphene oxide in anhydrous DMF, add 3 g of laurolactam, stir and heat to 100 ° C for 6 h, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com