Phosphorus tailing/polyvinyl chloride composite material and preparation method thereof

A technology of polyvinyl chloride and composite materials, applied in the field of composite materials, can solve the problems of restricting the development of PVC, low impact strength, insufficient heat resistance, etc., to improve processing rheological properties, improve interface bonding, and improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

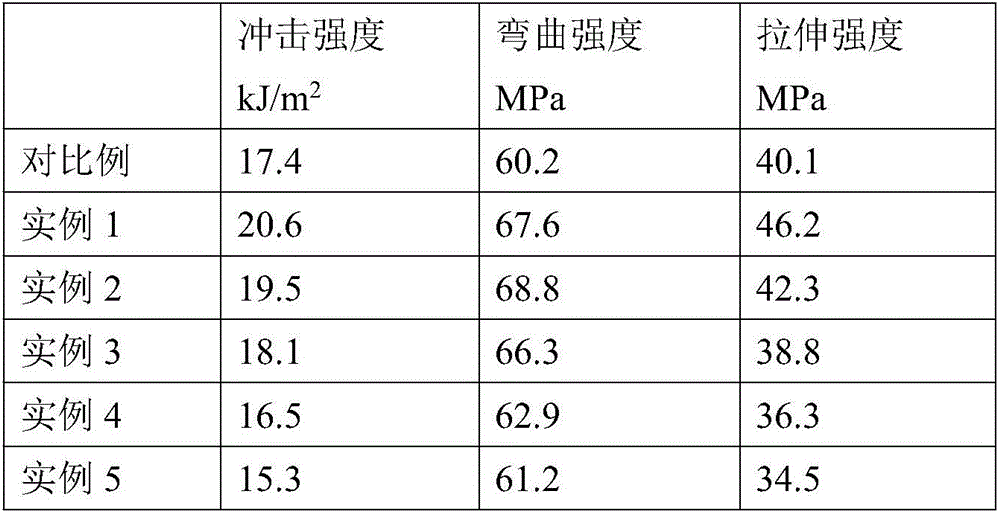

Examples

preparation example Construction

[0030] The preparation process of the phosphate tailings / polyvinyl chloride composite material of the present invention:

[0031] Step 1: Dry the phosphorus tailings in a drying box;

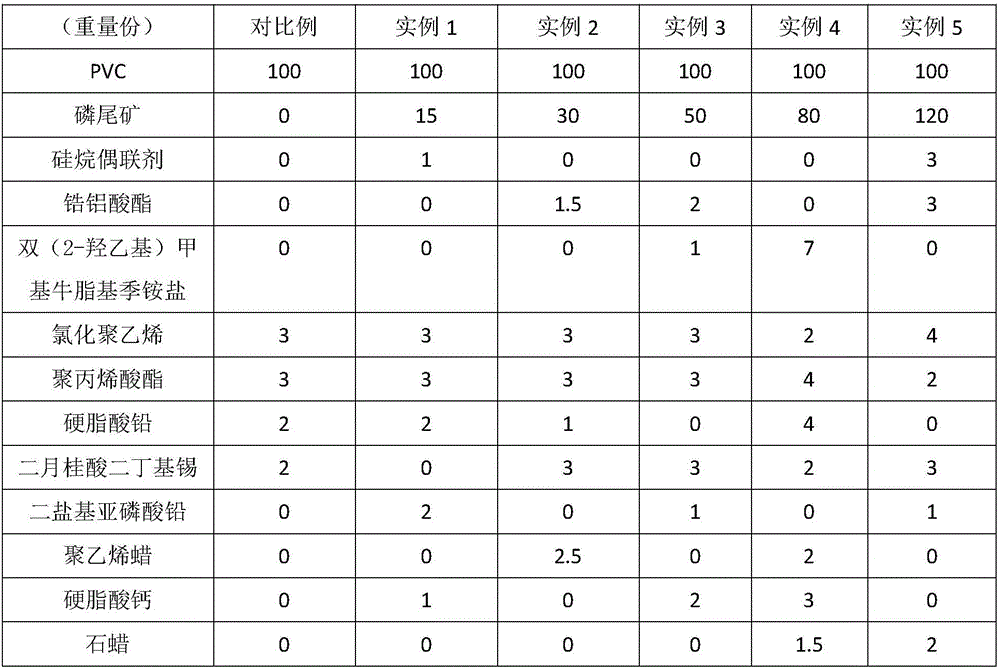

[0032] Step two, premix the dried phosphate tailings and polyvinyl chloride according to the formula ratio, so that the raw materials are initially mixed uniformly to obtain a premix, wherein the formula is composed of the following raw materials: 100 parts of PVC, 80-200 phosphate tailings Parts, 2-7 parts of surface modifier, 5-10 parts of polymer modifier, 4-9 parts of heat stabilizer, 3-7 parts of lubricant.

[0033] Step three, add the premix obtained in step two into a twin-screw extruder for melt extrusion, where: the twin-screw extruder is an in-phase parallel twin-screw with a length-to-diameter ratio of 32:1 to 48:1; The speed of the machine is 30~50r / min; the processing temperature is controlled within 160~185℃.

Embodiment 1

[0039] Raw material composition: 100 parts of PVC, 15 parts of phosphate tailings, 1 part of surface modifier, 6 parts of polymer modifier, 4 parts of heat stabilizer, 1 part of lubricant.

[0040] The twin-screw extruder used has a diameter of 25cm, a length-to-diameter ratio of 32:1, a rotation speed of 30r / min, and a processing temperature of 160±5°C in the first zone, 165±5°C in the second zone, 170±5°C in the third zone, and four zones 180±5℃, machine head 170±5℃.

[0041] The phosphate tailings / polyvinyl chloride composite material of this embodiment was prepared according to the above preparation method.

Embodiment 2

[0043] Raw material composition: 100 parts of PVC, 30 parts of phosphate tailings, 1.5 parts of surface modifier, 6 parts of polymer modifier, 4 parts of heat stabilizer, 2.5 parts of lubricant.

[0044] The twin-screw extruder used has a diameter of 30cm, a length-to-diameter ratio of 32:1, a speed of 30r / min, and a processing temperature of 160±5℃ in the first zone, 165±5℃ in the second zone, 170±5℃ in the third zone, and four zones 180±5℃, machine head 170±5℃.

[0045] The phosphate tailings / polyvinyl chloride composite material of this embodiment was prepared according to the above preparation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com