Glass fiber impregnating compound high in permeating speed and application thereof in producing twistless roving

A sizing and lubricant technology, applied in the direction of yarn, textiles and paper making, can solve the problems of poor bonding between white silk, glass fiber and resin, affecting the appearance and strength of FRP products, etc., and achieve the effect of fast soaking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

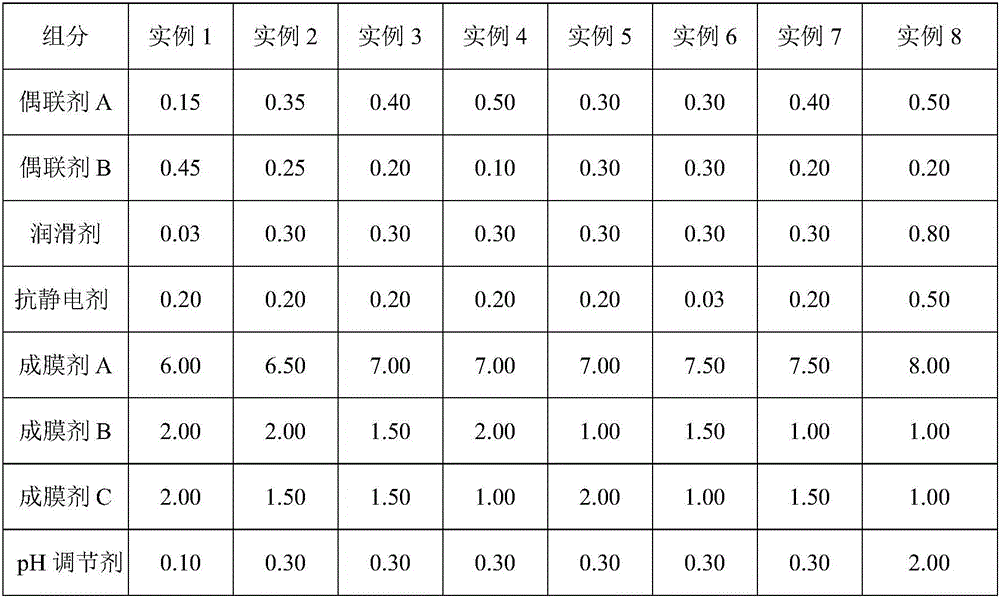

[0051] The technical scheme of the present invention will be further described below with specific examples, but protection scope of the present invention is not limited to this:

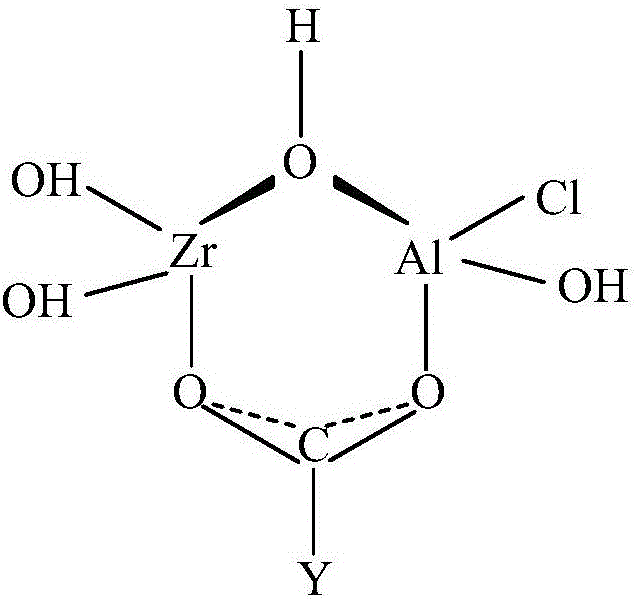

[0052] See Table 1. In these examples, in order to meet the requirements that the glass fiber can be quickly soaked by the matrix resin, improve the chopping property, and improve the production efficiency, we use nano-silica-modified polyester emulsion and (denoted as emulsion film-forming agent A ) and homopolymeric PVAc (referred to as emulsion film former B) and polyurethane modified epoxy resin emulsion (referred to as emulsion film former C) mixed as film former. Emulsion film-forming agent A is a polyester emulsion modified by nano-silica, which uses JS-131 raw material from COIM Company, which is about 0.5% to 3% polyester emulsion modified by nano-silica, Tg The particle size of the emulsion is between 0.3 and 0.8 microns between 4 and 30°C, it can quickly dissolve styrene, the Tg is betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com