Recycled composite material for enhancing modified waste polypropylene by using waste printed circuit board powder/glass fiber and preparation method of recycled composite material

A technology of composite materials and waste polypropylene, which is applied in the direction of chemical recycling, can solve problems such as environmental hazards and loss of useful resources, and achieve the effects of reducing machine wear, good social and economic benefits, and strong market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

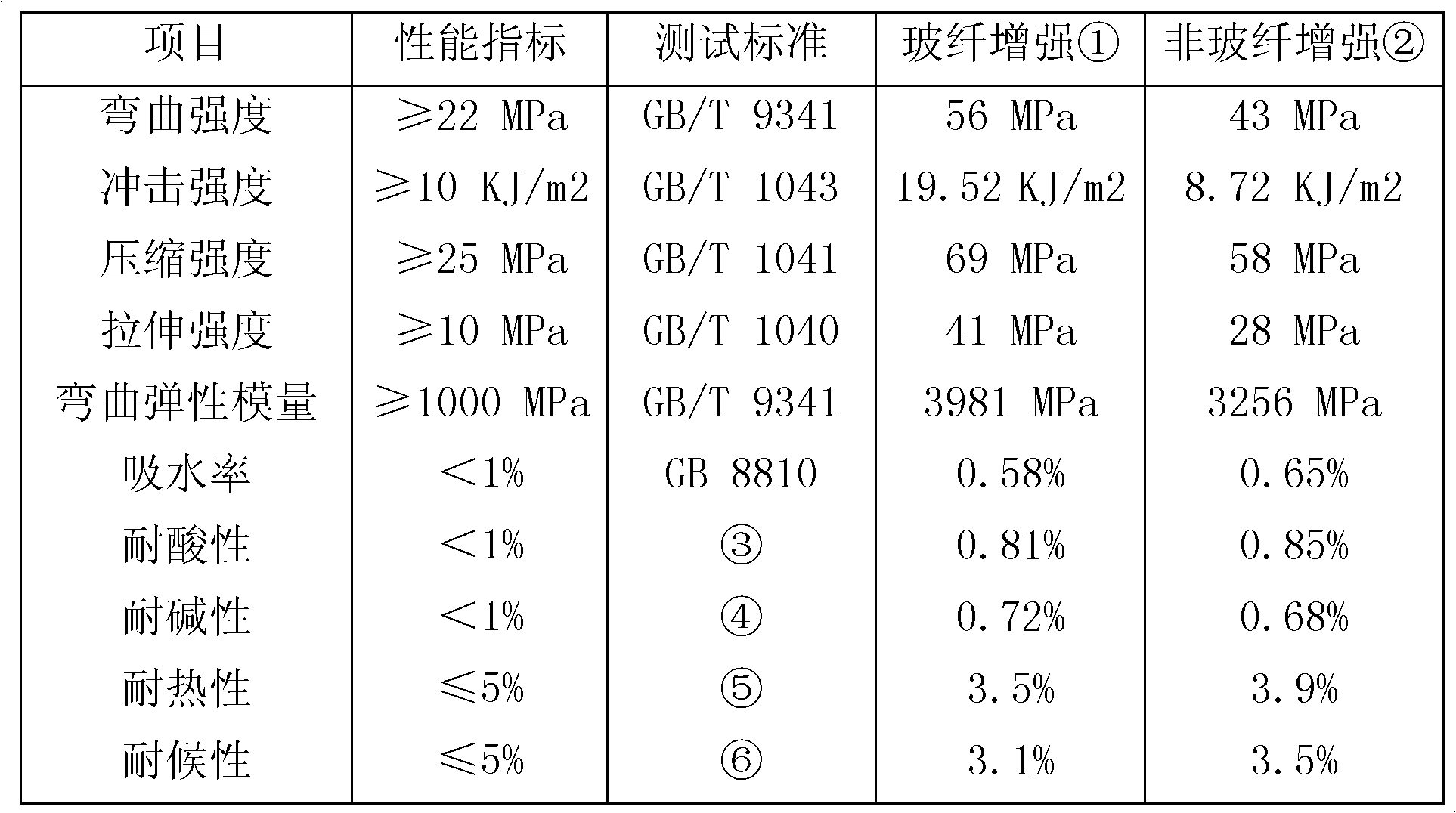

Image

Examples

example 1

[0023] The waste circuit board is crushed and sieved to obtain a powder of more than 100 mesh. The metal and non-metal powders are separated by conventional electrostatic and winnowing processes, and the non-metal powders are dried for use. Mix the materials according to the following proportions: 100 parts of waste polypropylene (PP), 100 parts of waste circuit board powder, 10 parts of compatibilizer PP-g-MAH, antioxidant four [β-(3,5-di 1 part of tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol and tris(2,4-di-tert-butylphenyl) phosphite in a ratio of 1:1.

[0024] During the screw extrusion of the twin-screw extruder, as the screw speed increases, the shear force on the melt in the barrel increases, and the friction between the glass fiber and the barrel and the screw increases, resulting in a large number of fibers being twisted by the screw. , the average length of the fiber becomes smaller, but the speed is too small and the mixing effect will be affected. The c...

example 2

[0027] The preparation method and steps are the same as in Example 1, and the material ratio is changed as follows: 100 parts of waste PP, 200 parts of waste circuit board powder, 15 parts of compatibilizer PP-g-MAH, antioxidant tetrakis [β-(3,5-ditert Butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester and tris(2,4-di-tert-butylphenyl)phosphite were compounded in 2 parts at a ratio of 1:3. A quantitative 10 parts of alkali-free glass fiber was added from the fourth zone of the extruder process.

example 3

[0029] The preparation method and steps are the same as Example 1, and the material ratio is changed as follows: 100 parts of waste PP, 150 parts of waste circuit board powder, 10 parts of compatibilizer PP-g-AA, antioxidant tetrakis [β-(3,5-ditert Butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and tris (2,4-di-tert-butylphenyl) phosphite are mixed in 1 part at a ratio of 1:1. A quantitative quantity of 8 parts of alkali-free glass fibers was added from the extruder processing zone 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com