Manufacturing process of girder of overhead or gantry crane

A crane and process technology, applied in the manufacturing process of the main beam of the gantry crane and the field of bridge type, can solve the problems of the lower deflection of the main beam of the crane, the lowering of the lifting weight, endangering the safety, etc. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

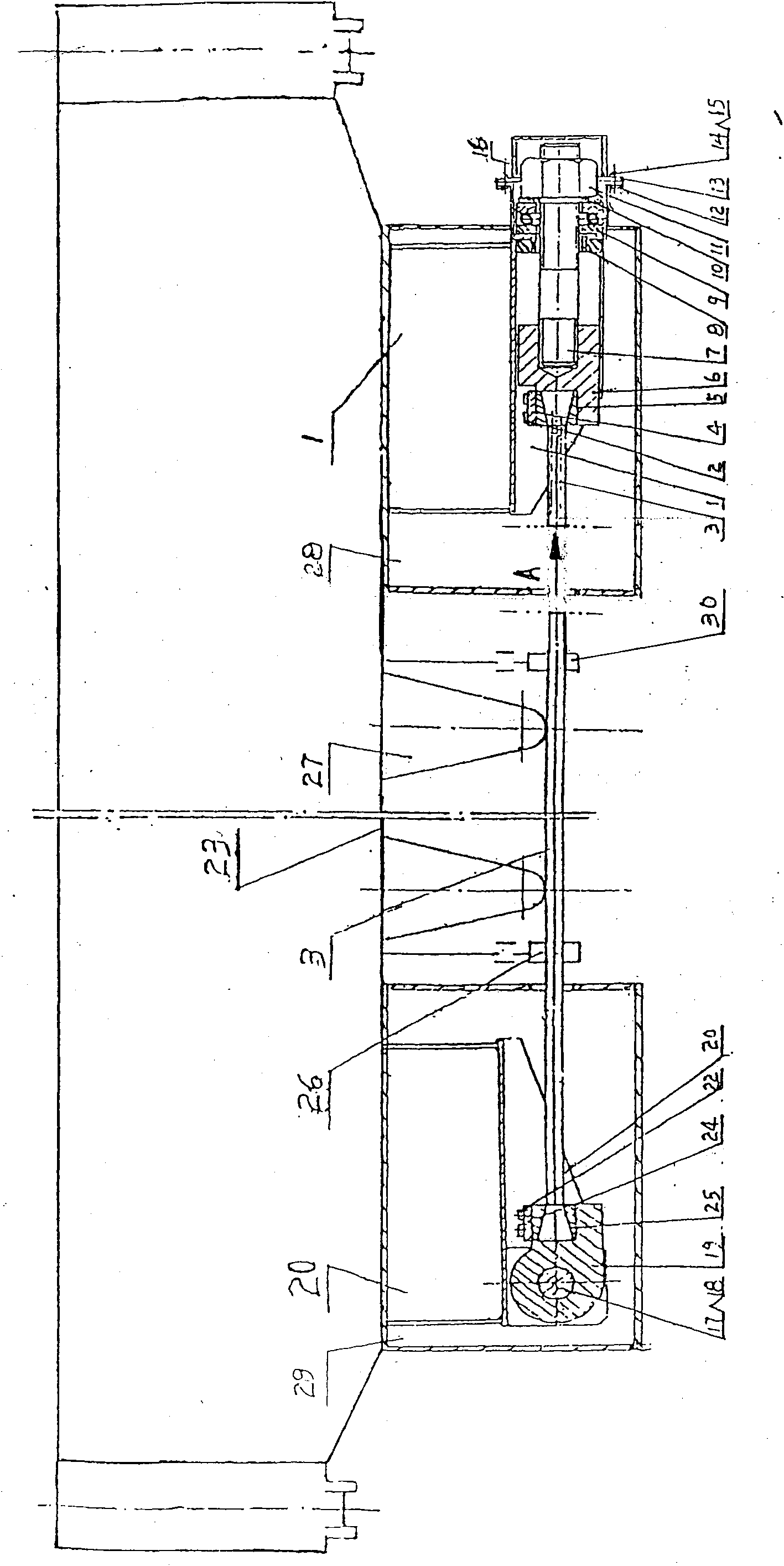

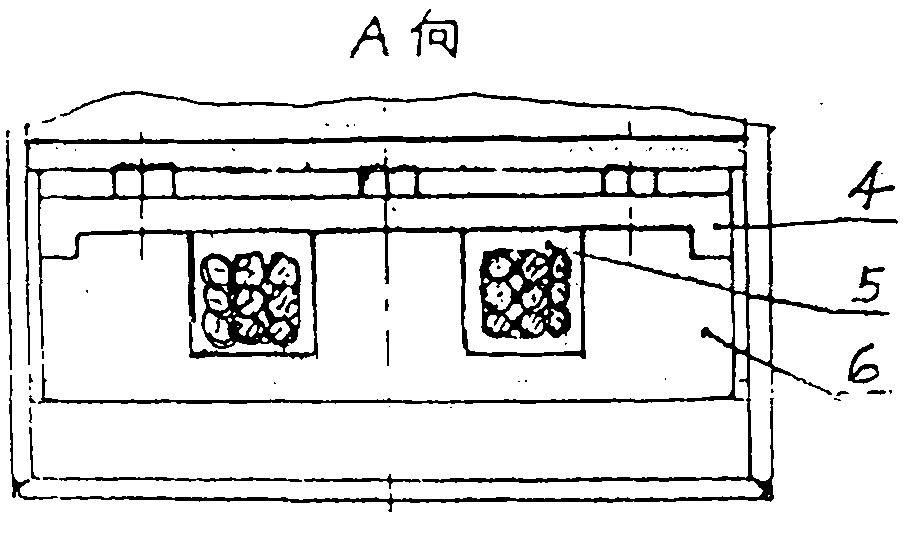

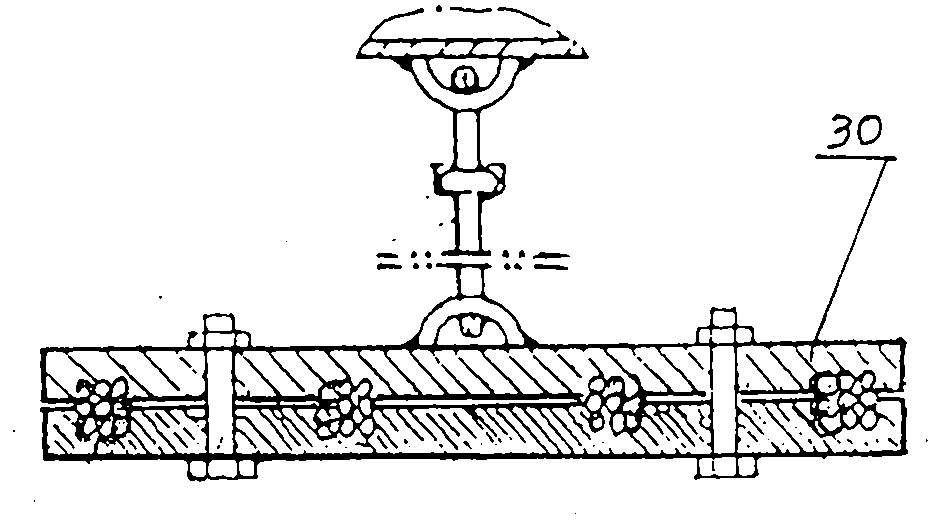

[0015] The implementation of the present invention will be described in detail below with reference to the drawings.

[0016] The first step: preparation process:

[0017] The crane main girder, which has been completed according to the crane main girder manufacturing drawings and process, is hoisted, so that the lower cover plate is positioned at a height of 1.4-1.6 meters from the ground, at the bottom of the end girder and the four planes without the wheel support , Support the main beam and the end beam with a support frame or pad to make it fall stably.

[0018] Step 2: Welding process:

[0019] Place the tensioner box 1 in the outer box 28 of the additional rectangular parallelepiped tensioner, set up a number of reinforcing ribs as required through the transition plate, and weld them into a whole piece, and then weld the whole piece to the lower cover of the main beam 23 At one end of the plate, the rope joint hinge support 20 is placed in the additional rectangular box body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com