Patents

Literature

95results about How to "Increase lifting weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

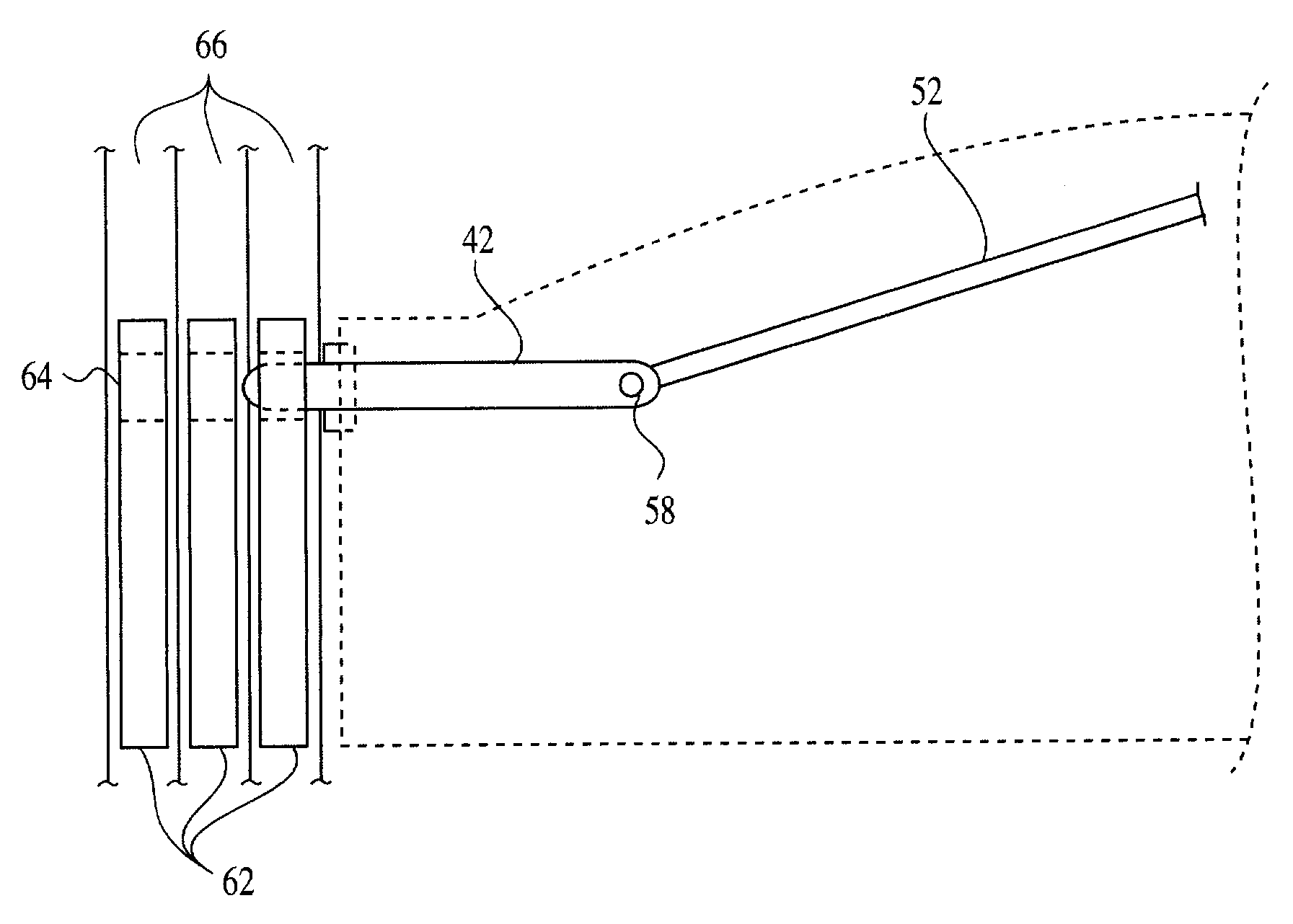

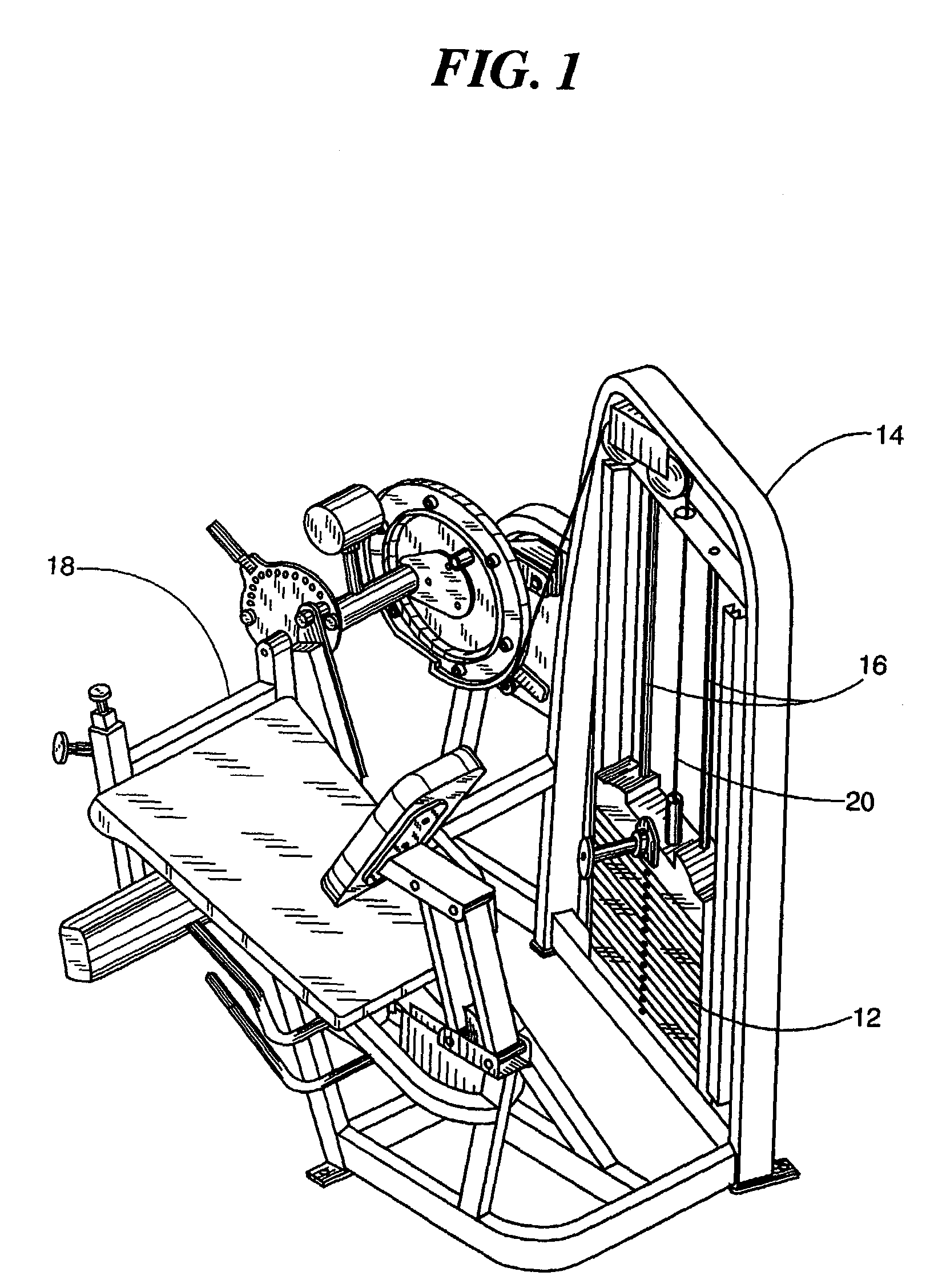

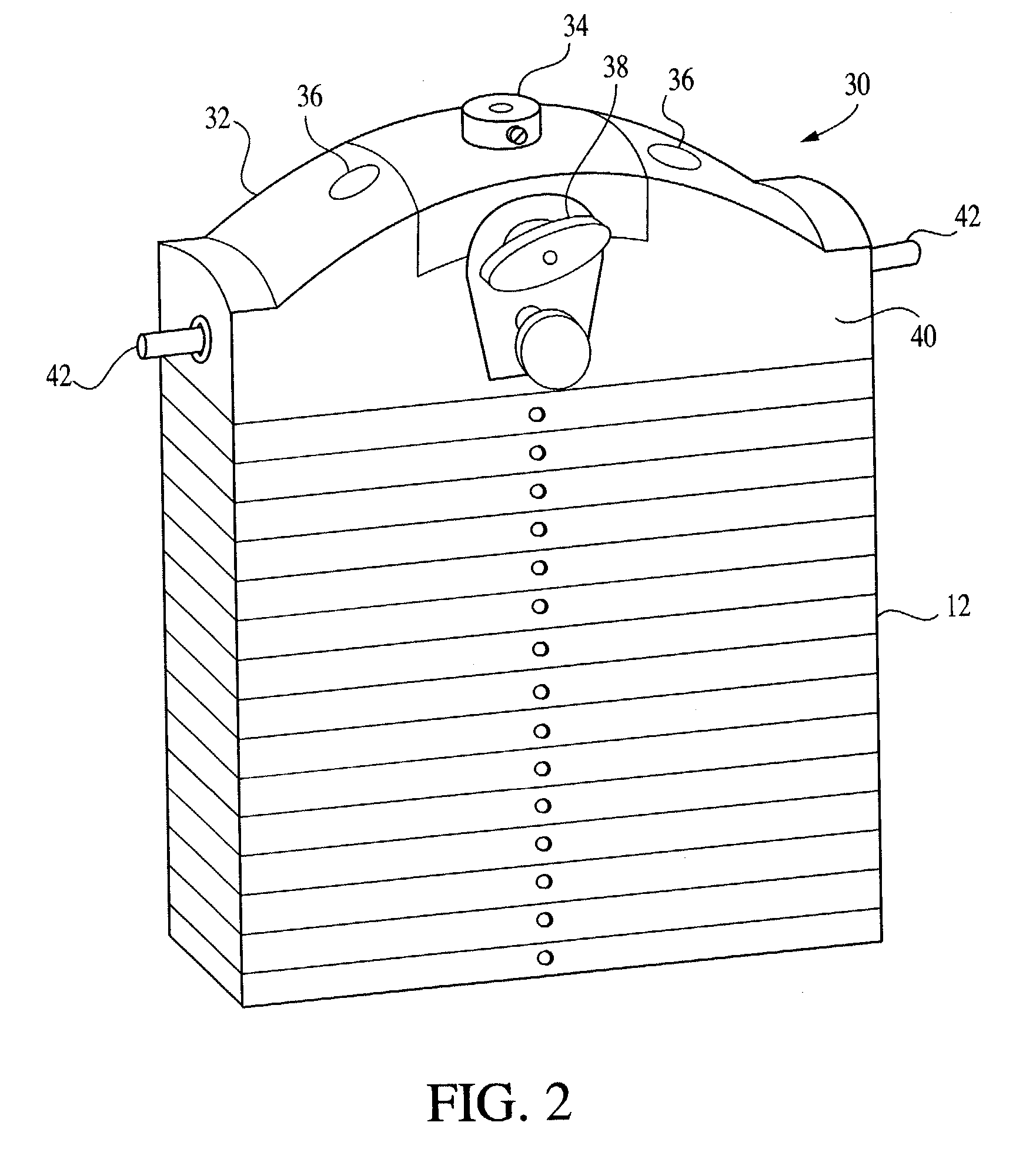

Incremental weight system

ActiveUS7335139B2Increase lifting weightWeight increaseMuscle exercising devicesEngineeringExercise machine

The present invention provides an incremental weight system for use with a weight stack of an exercise machines. As described herein, the incremental weight system enables users to incrementally increase the lifting weight, by adding weights that weigh less then the weight of a weight block. The incremental weight system is integrated onto the top of the weight stack, having a weight selector handle operable connected to a pair of engagement pins. The weight selector handle enables the engagement pins to be extended from and retracted into the assembly housing as the weight selector handle is rotated. Incremental weights are disposed at opposite ends of the weight stack. By rotating the weight selector handle, the engagement pins are extended from the assembly housing and engage the increment weights. The engagement pins engage the incremental weight by being inserted through the incremental weight receiving slots, such that, as the weight stack moves up and down, any selected incremental weights move in unison with the weight stack. If an incremental weight is not engaged by the engagement pin, the incremental weight will remain in position, while the rest of the selected incremental weights move unison with the weight stack.

Owner:CYBEX INTERNATIONAL

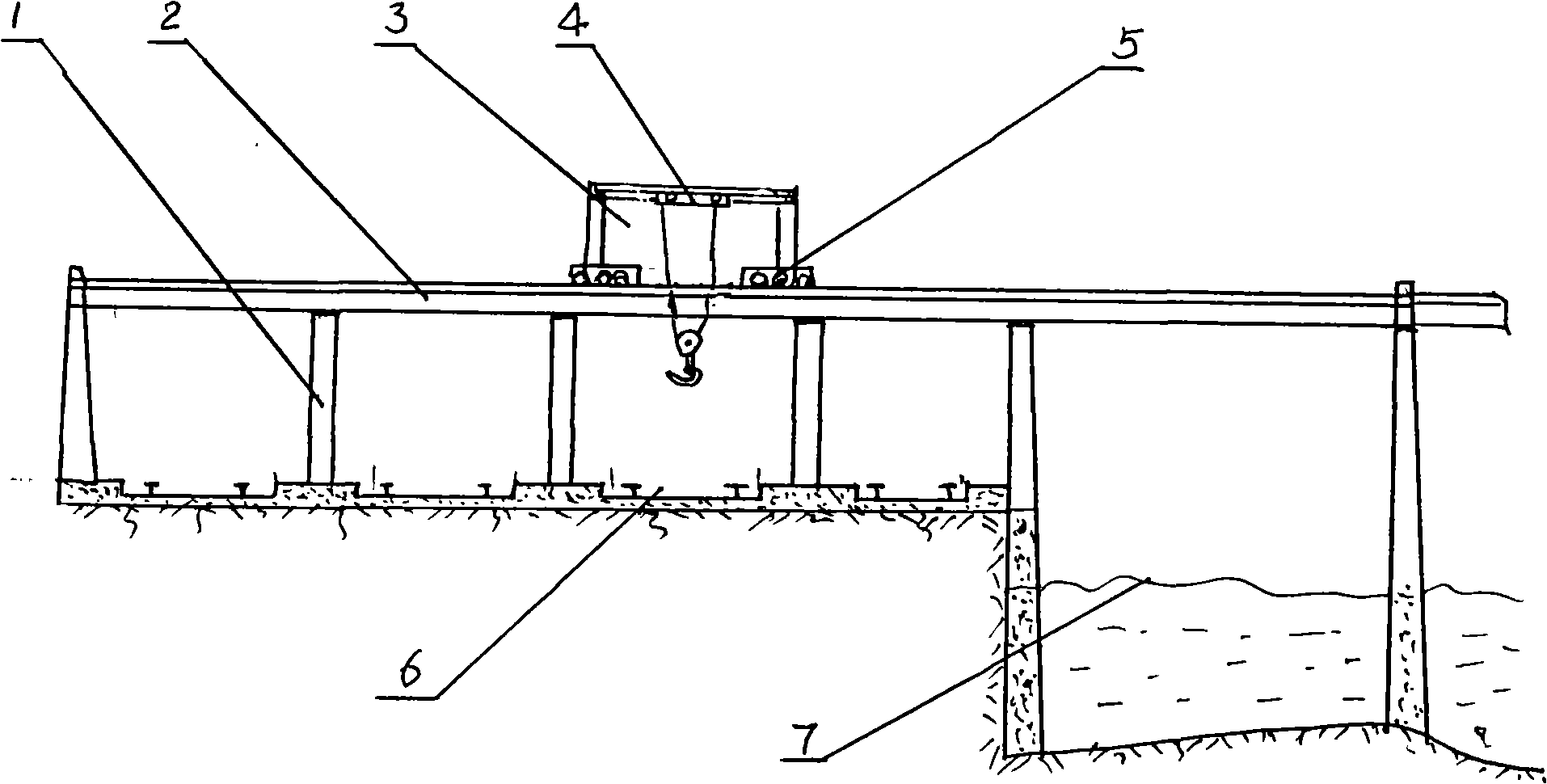

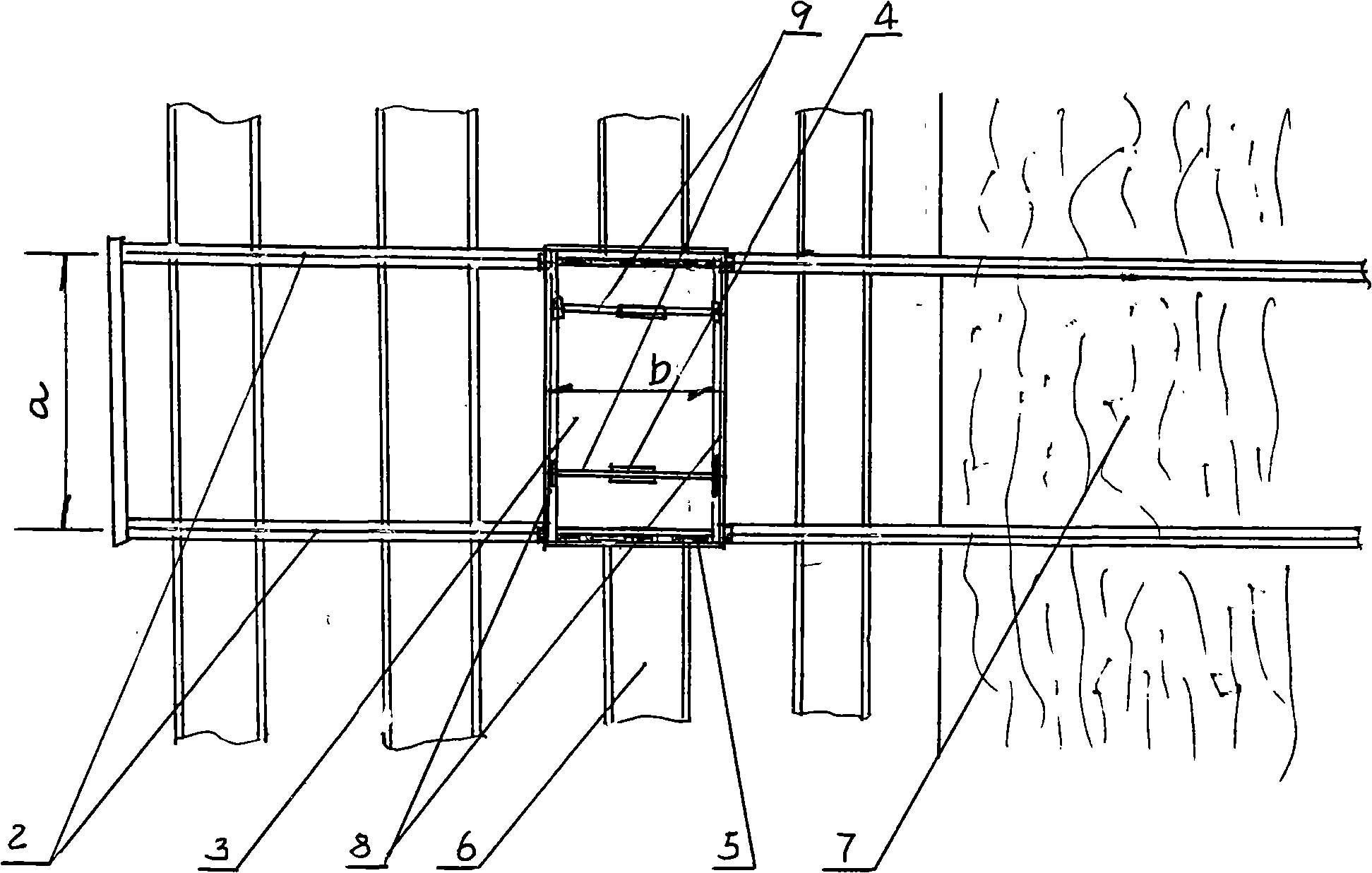

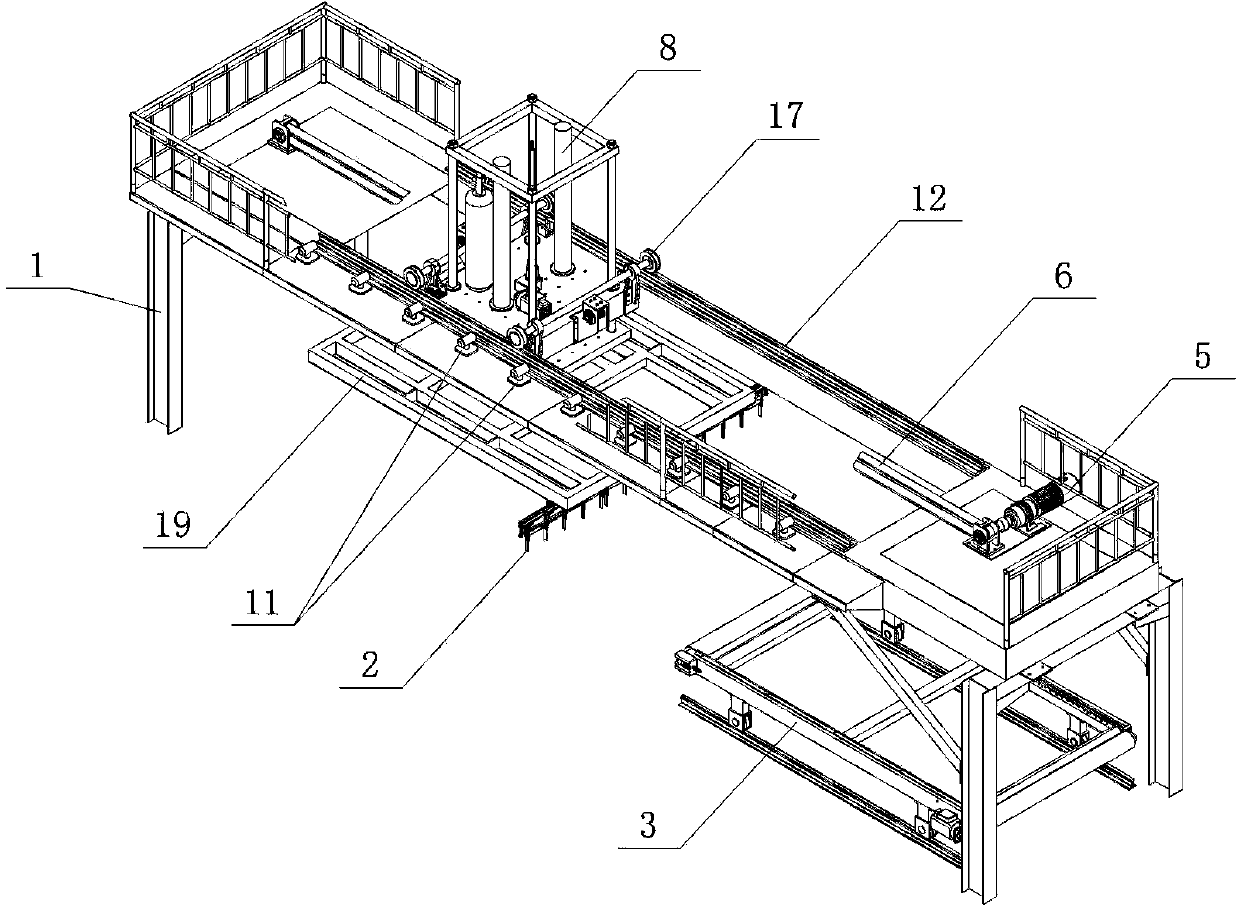

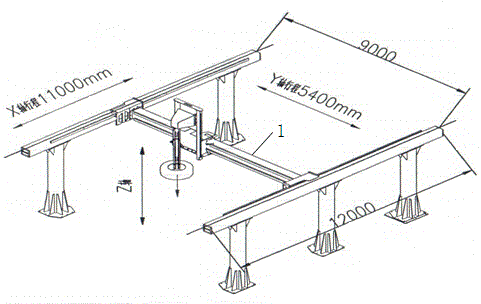

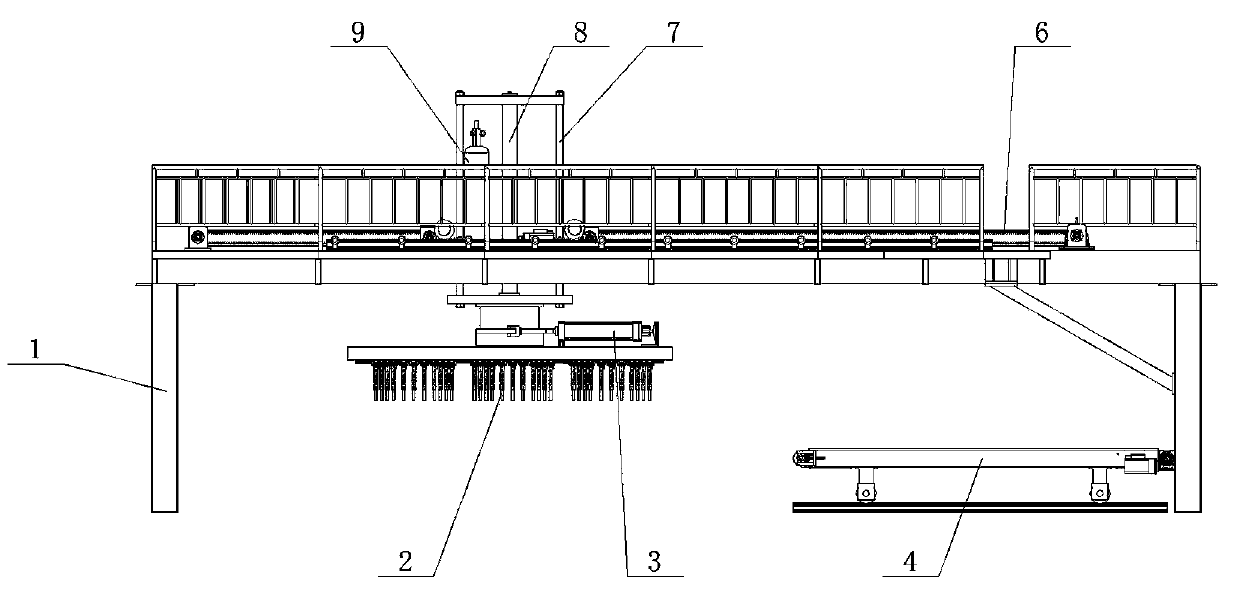

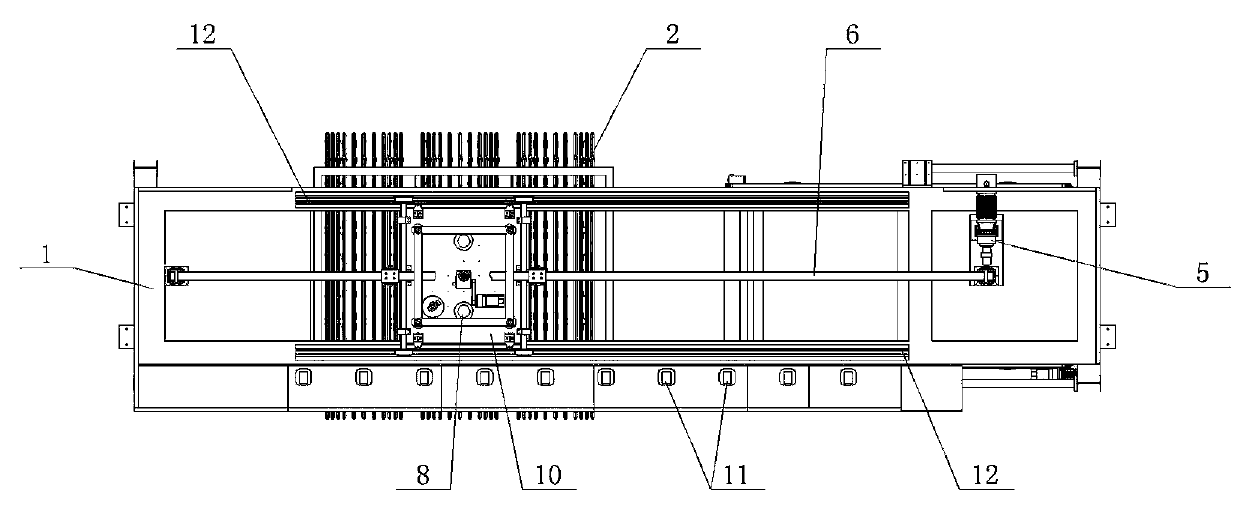

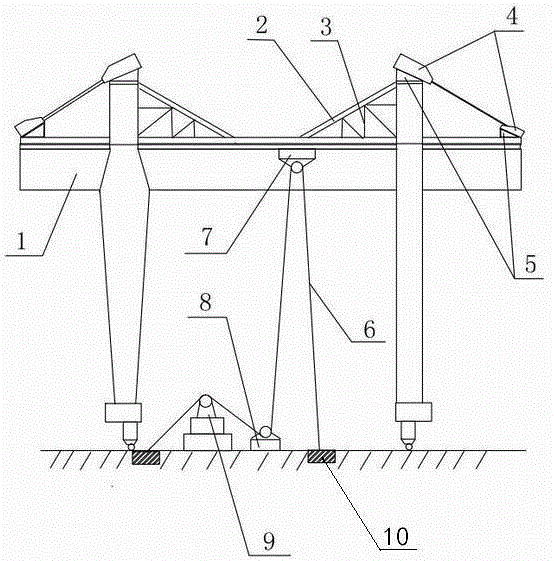

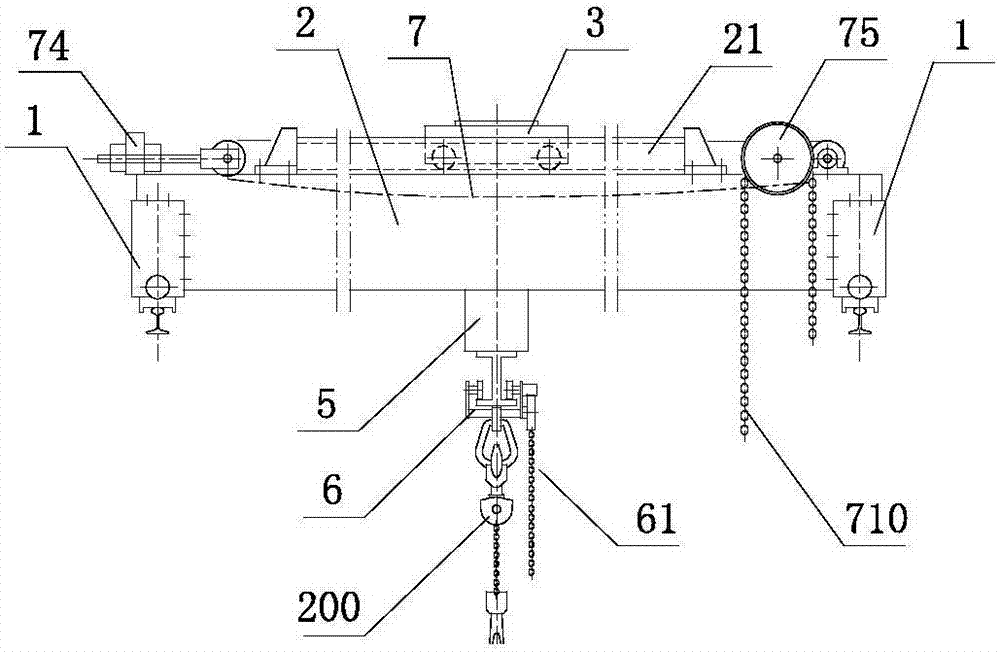

Double girder overhead viaduct type crane

InactiveCN101327892AAchieve passthroughReduce intermediate operationsTrolley cranesVehicle frameOverhead crane

The present invention discloses a twin-beam viaduct type crane, which is mainly used for directly loading and unloading goods at long distance. The crane consists of two rail main beams, a large car frame, a large car operation mechanism, a small rail car, a lifting mechanism, an operating chamber, and a electronically controlled device, wherein the two rail main beams are arranged in parallel; the large car frame consists of two rail beams; the large car operation mechanism is fixed to the two ends of the large car frame; the small rail car is arranged on the large car frame; the lifting mechanism is fixed to the small rail car; and, the operating chamber and the electronically controlled device are fixed to the large car frame. The rail main beams span over a railway, and extend to a cargo work position. A rail longeron is arranged on the rail beam. Longeron operating mechanisms are respectively arranged on the two ends of the rail longeron. The small rail car is arranged on the rail longeron operating mechanism. The crane achieves the straight communication between the materials of a train and a ship. The middle operation is reduced and the handling speed is improved. The berthing of the chip can be far away from a port. The handling can be realized in the sea. The throughput of the port is increased. The crane is suitable for the handling of heavy materials and largetonnage ships.

Owner:徐西元

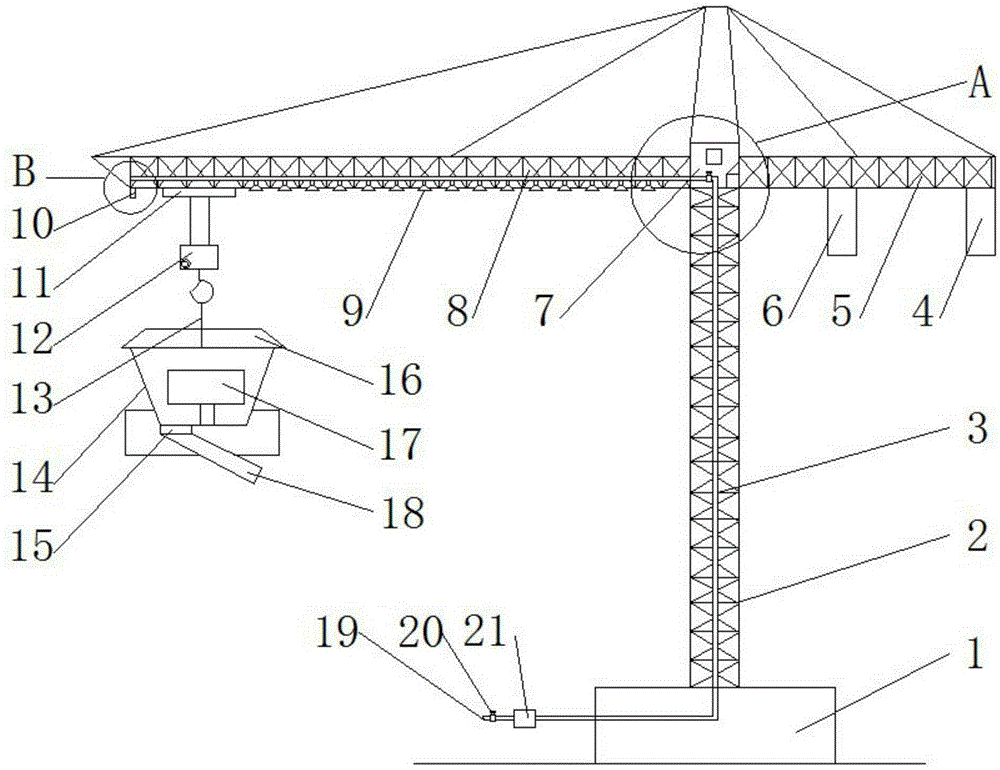

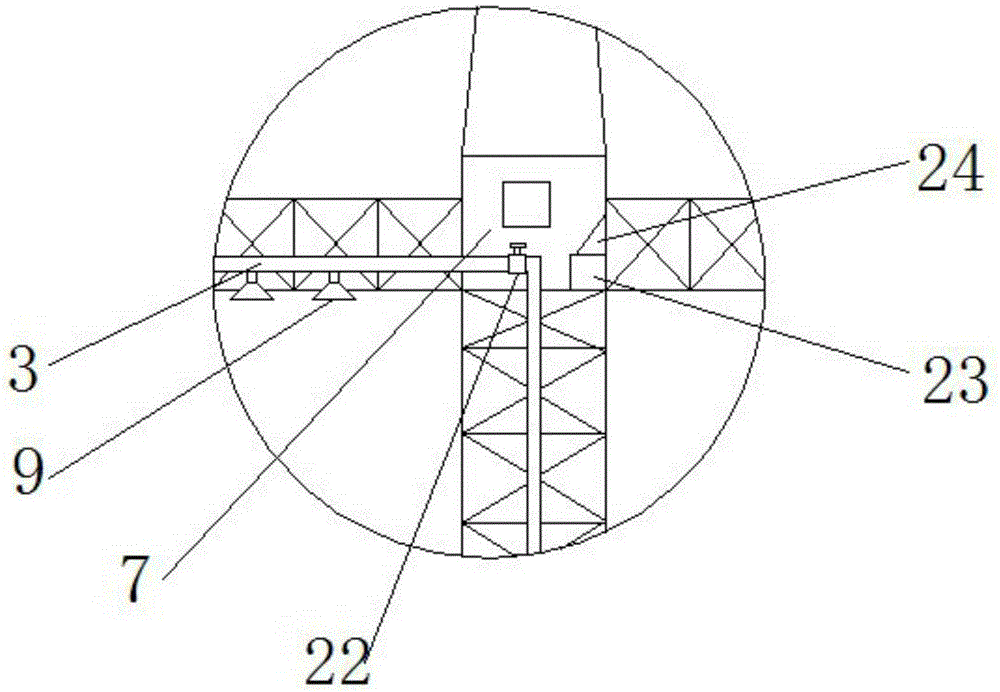

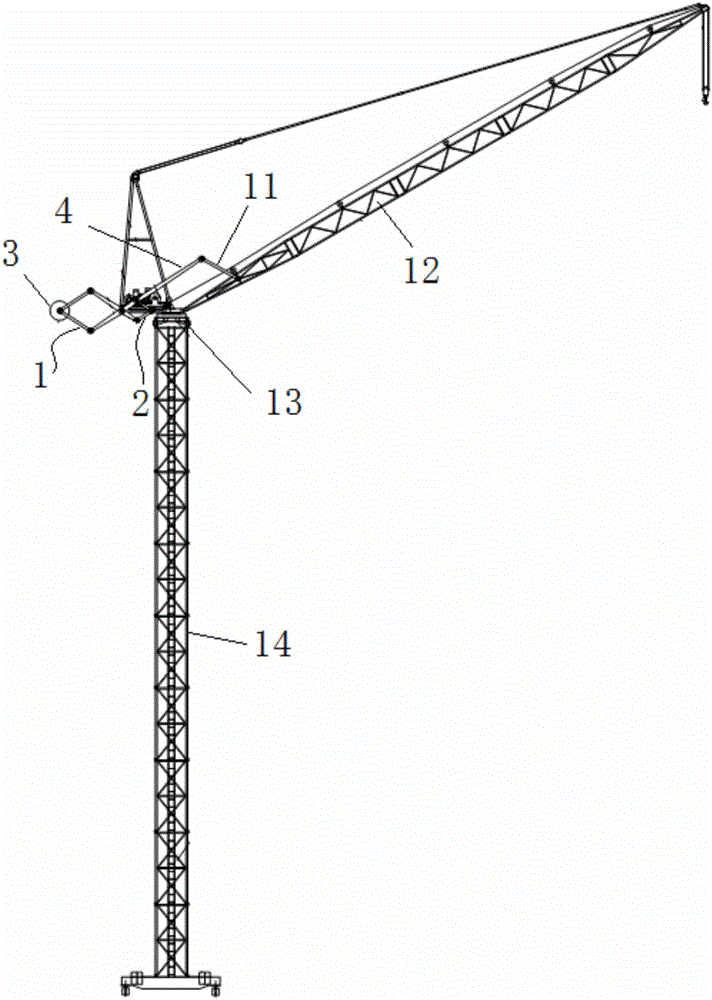

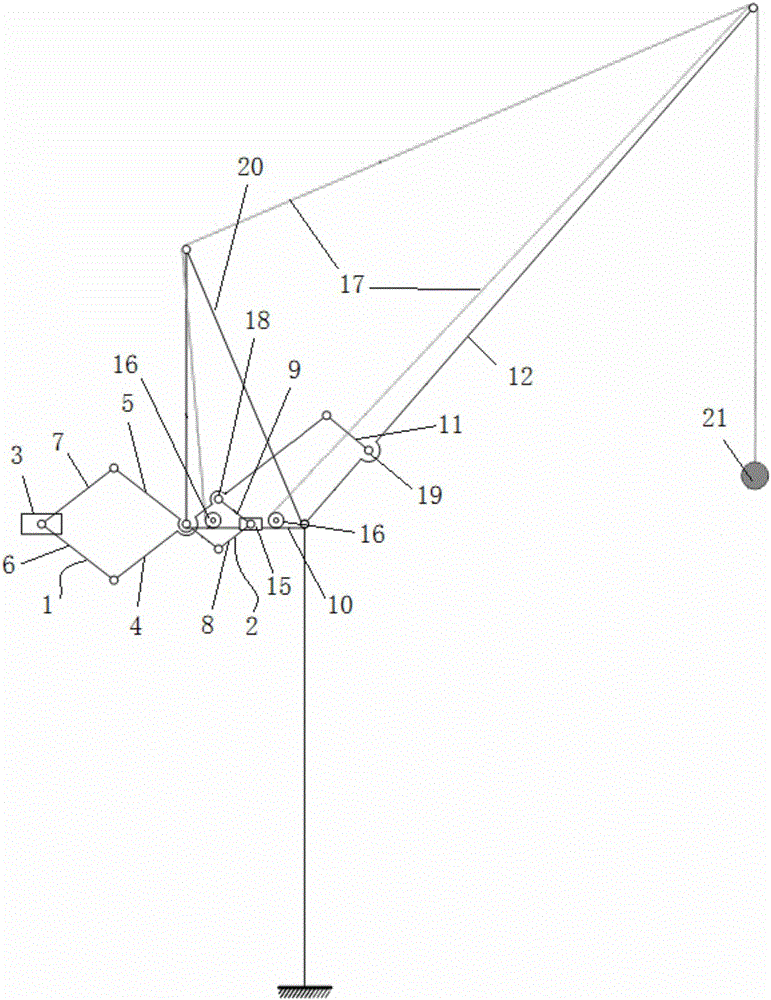

Construction method of multifunctional tower crane used for building construction

InactiveCN105668425AHelp outputPrevent compactionBuilding material handlingCranesSpray nozzleArchitectural engineering

The invention discloses a construction method of a multifunctional tower crane used for building construction. The multifunctional tower crane comprises a base, a hanging rack, a balancing arm, an operation room and a cargo boom. The balancing arm and the cargo boom are erected on the two sides of the hanging rack correspondingly in a balanced mode. A water pipe is vertically arranged in the hanging rack. A water pipe is transversely arranged in the cargo boom. A plurality of spray nozzles are uniformly distributed in the water pipe transversely arranged in the cargo boom. A sliding device is arranged on a front boom body of the cargo boom. A lifting hook is arranged below the sliding device. A cable is arranged below the lifting hook. The cable is connected with a concrete stirring box. Monitoring probes are arranged at the tail end of the cargo boom and the lifting hook. By the adoption of the construction method of the multifunctional tower crane used for building construction, a lifting and conveying function is achieved, and poured concrete can be wet and cooled through watering by spraying water mist, or dust removal can be achieved through mist spraying.

Owner:SUZHOU HUICHENG ZHIZAO IND DESIGN

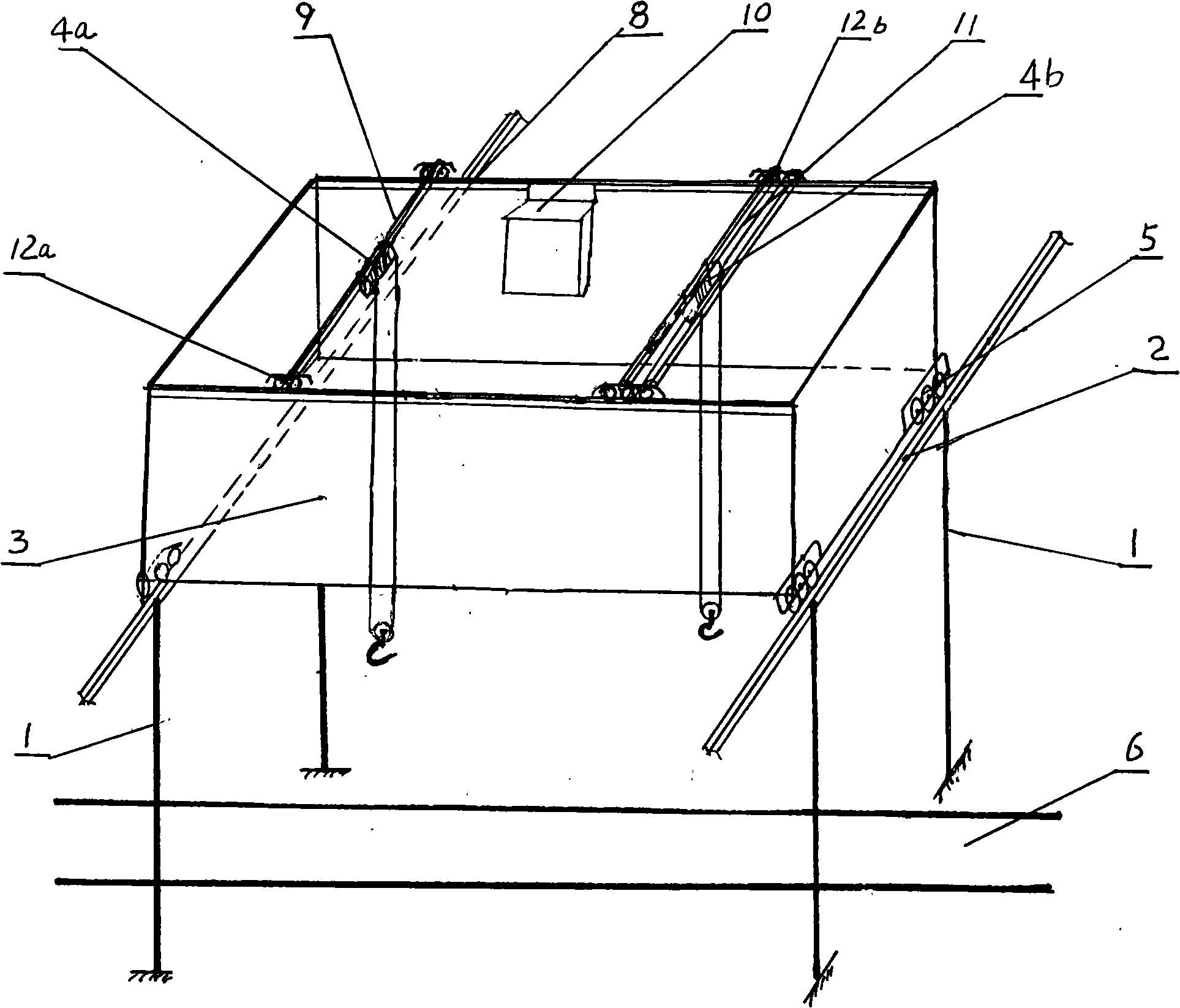

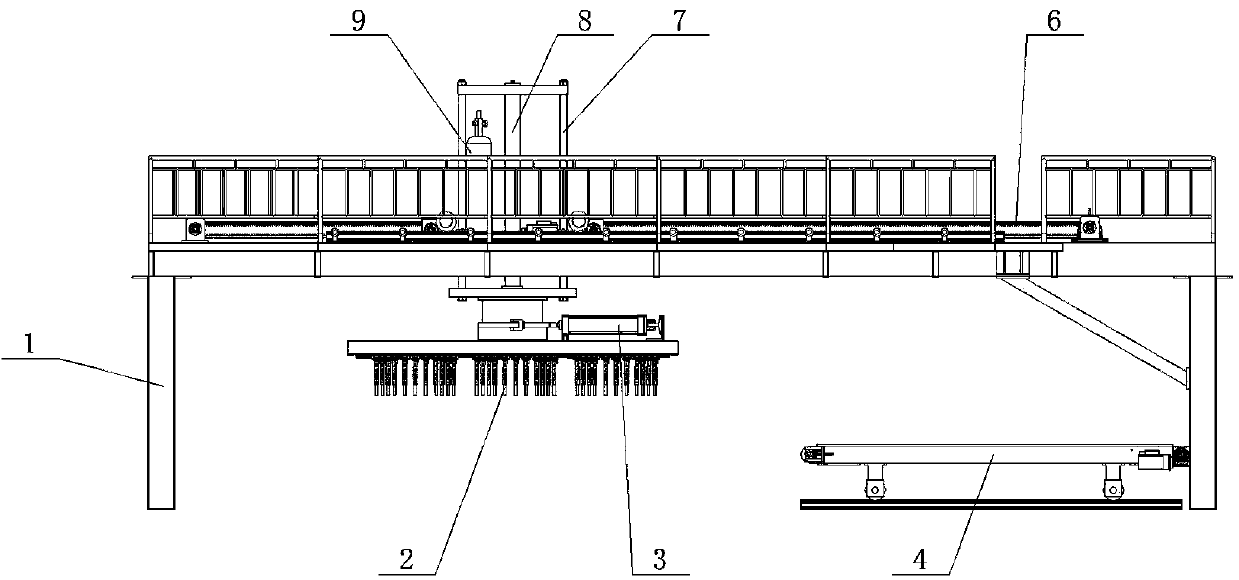

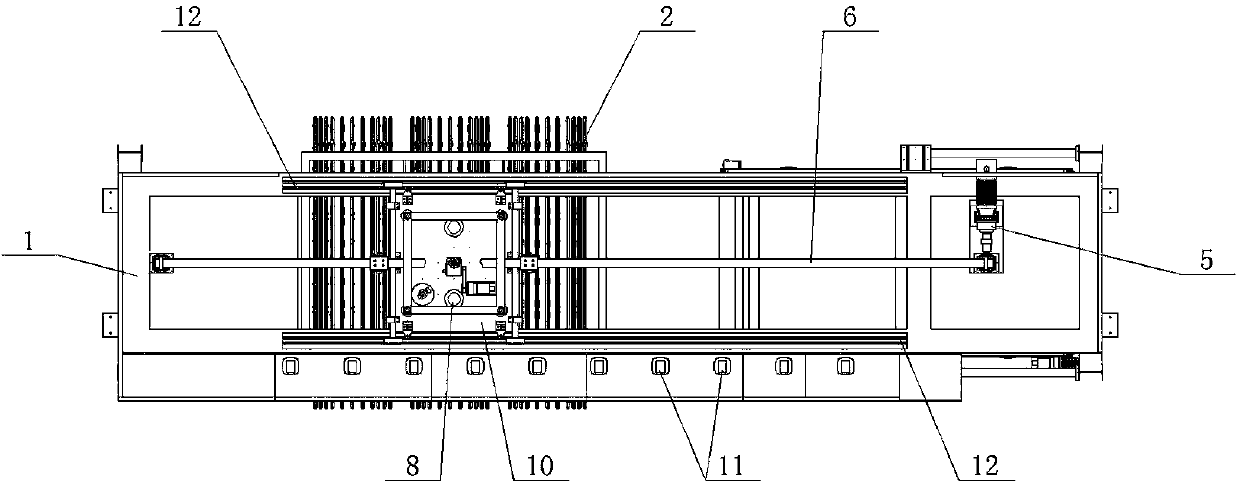

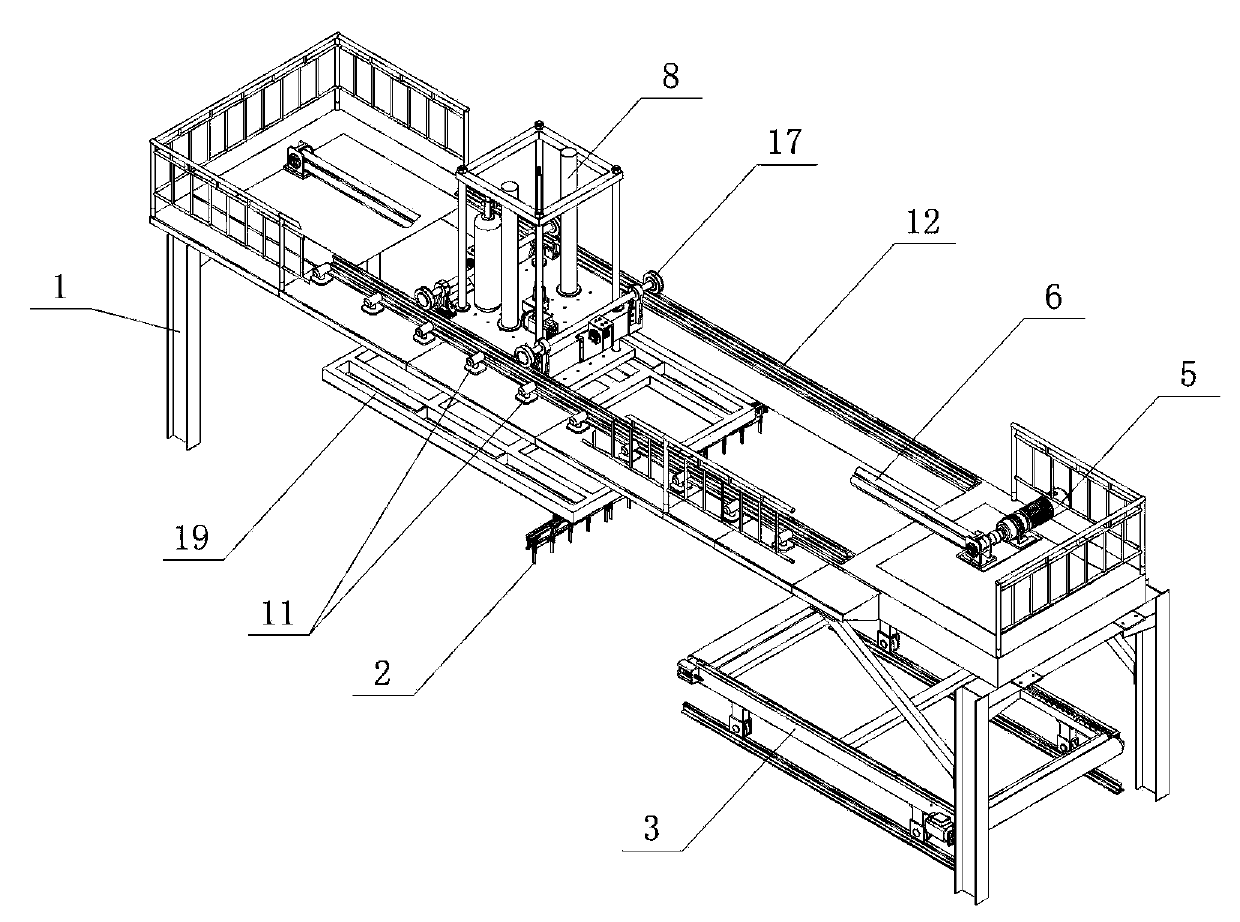

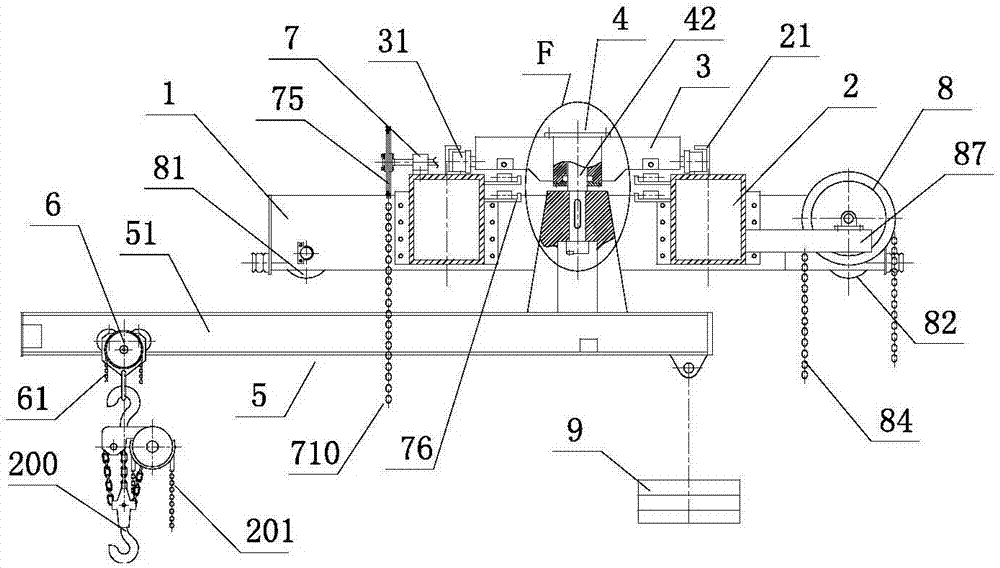

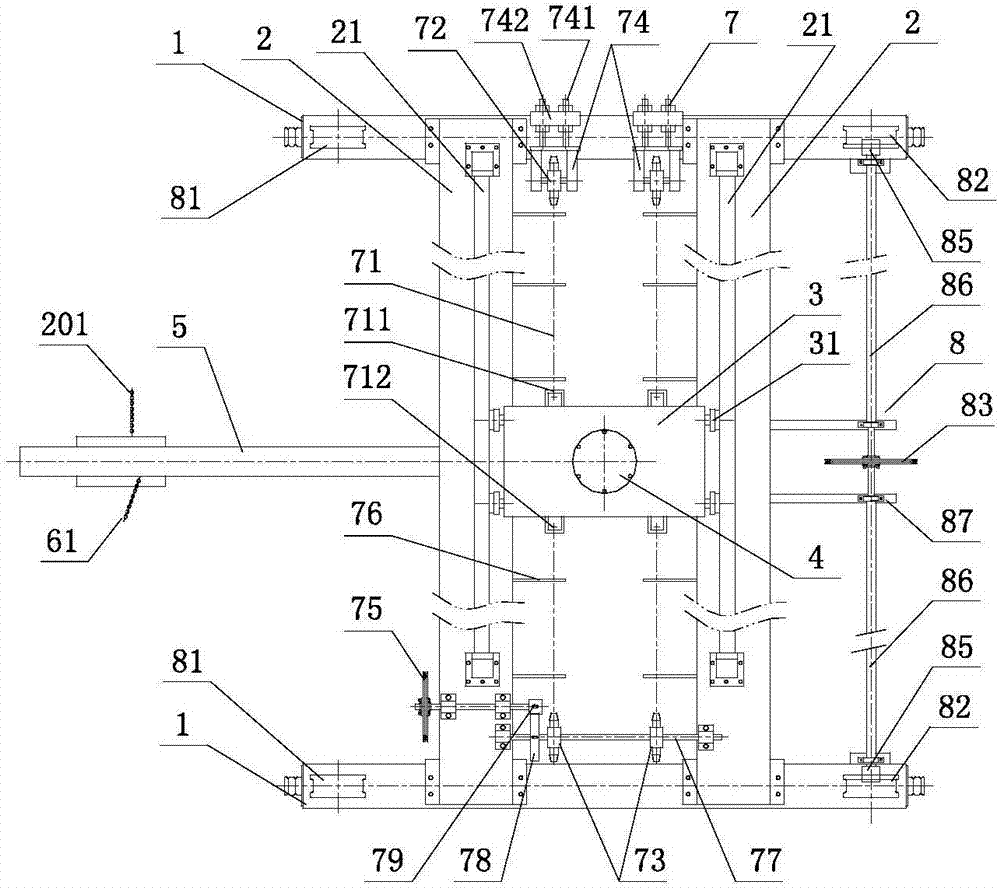

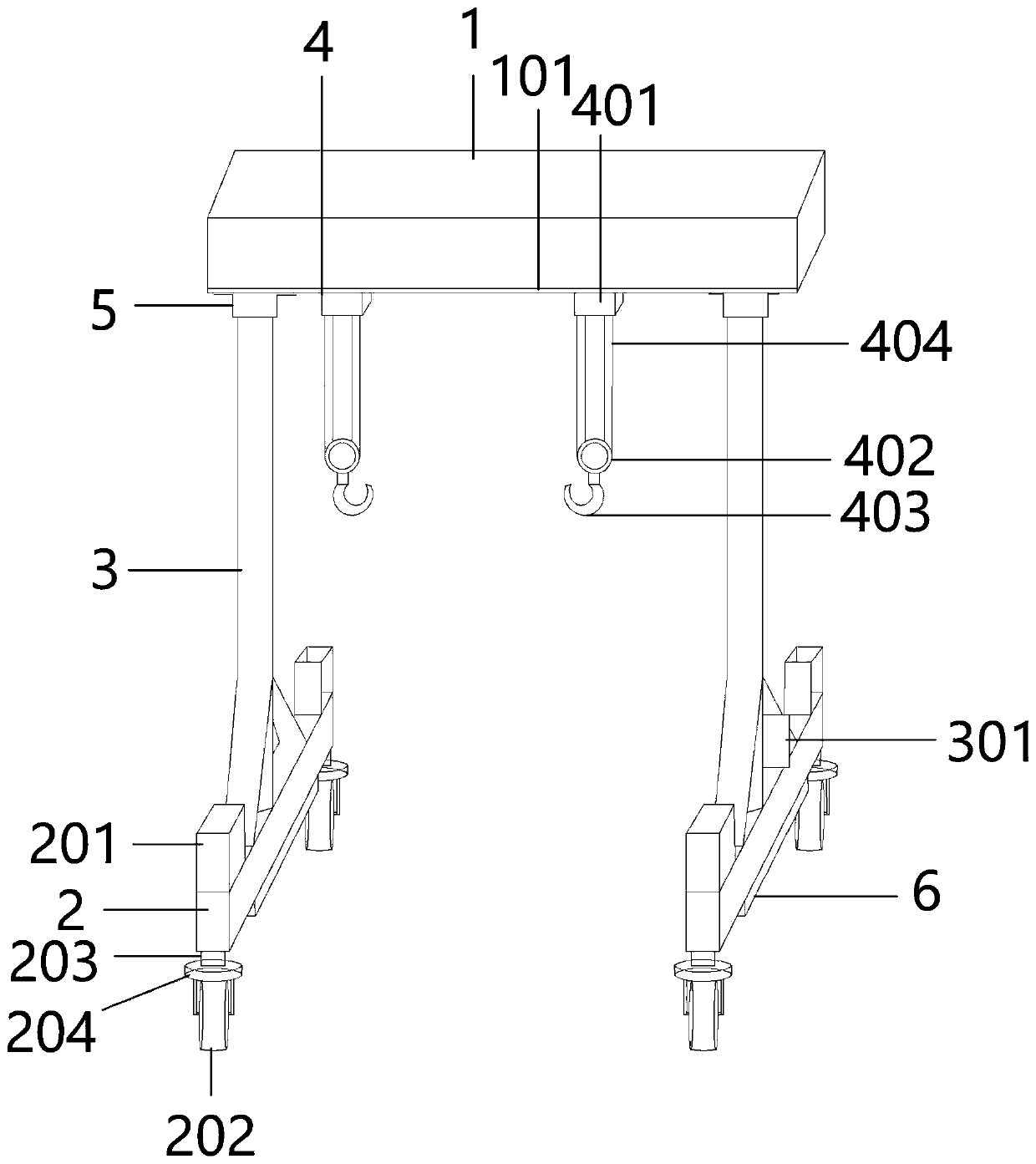

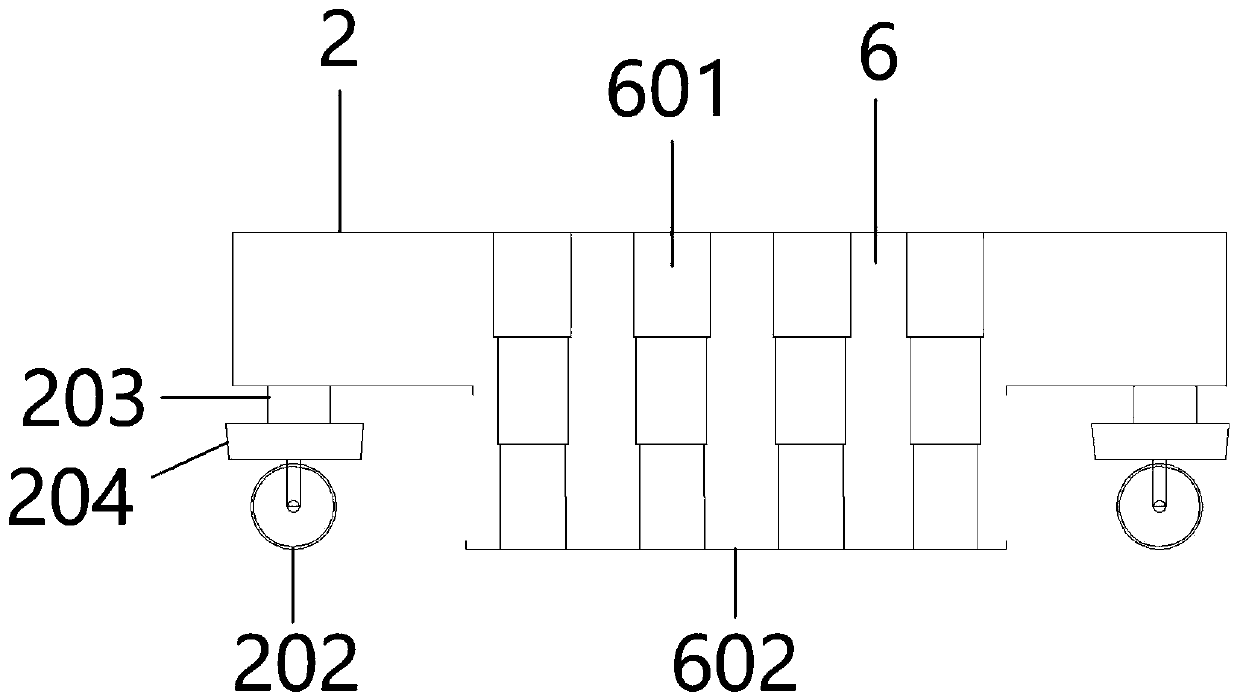

Automatic brick setting machine

InactiveCN103466335AEasy to controlEliminate transmission backlashStacking articlesDe-stacking articlesBrickEngineering

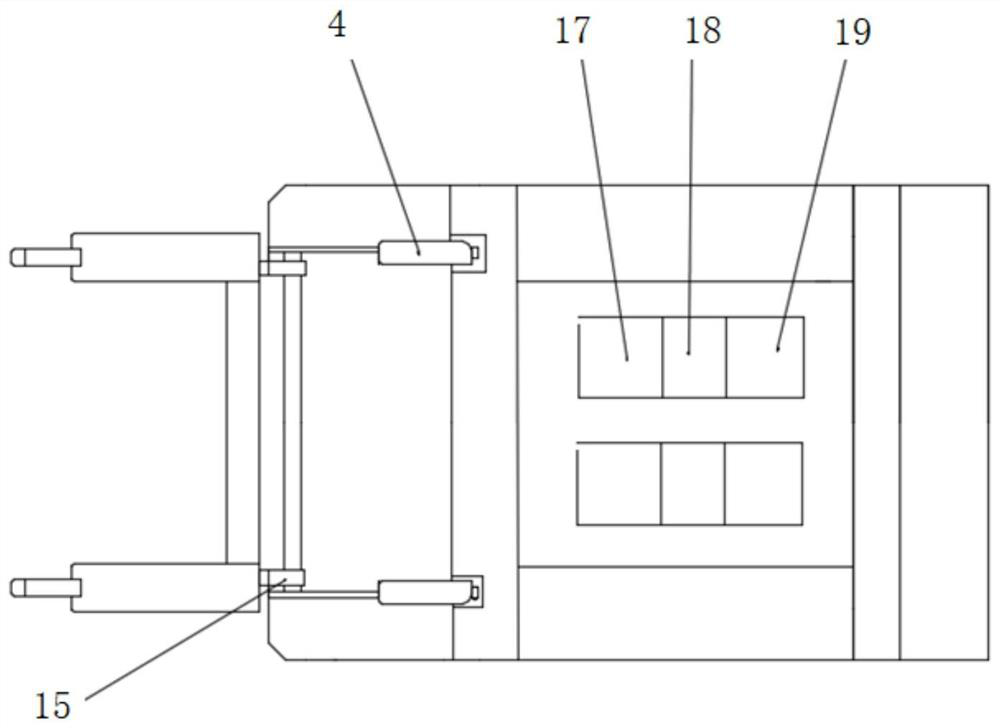

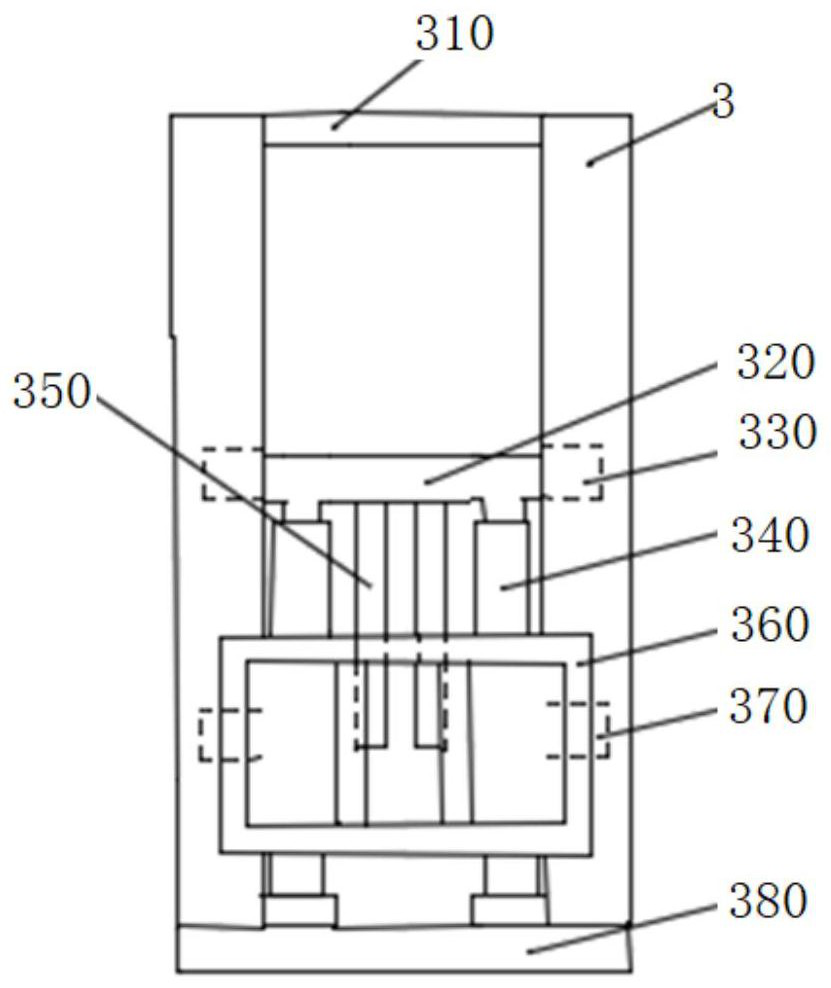

The invention discloses an automatic brick setting machine which comprises a portal frame. A slidable lifting mechanism is arranged on the portal frame and comprises a sliding platform and a lifting platform, a plurality of green brick fixtures are arranged below the lifting platform and mounted on a base, a slewing mechanism is arranged between the base and the lifting platform and comprises a slewing bearing and a cylinder, the slewing bearing is lifted by a connecting sleeve below the lifting platform, the cylinder is arranged between the slewing bearing and the base, the base is lifted by the slewing bearing and can be driven by the cylinder to horizontally rotate, and a deceleration buffering device and a rotation limiting device are matched with the slewing bearing. The slewing mechanism is driven by the cylinder, transmission gap is eliminated, rotation precision is improved, and rotation speed and angle are effectively controlled by the deceleration buffering device and the rotation limiting device of the slewing mechanism.

Owner:赵培龙

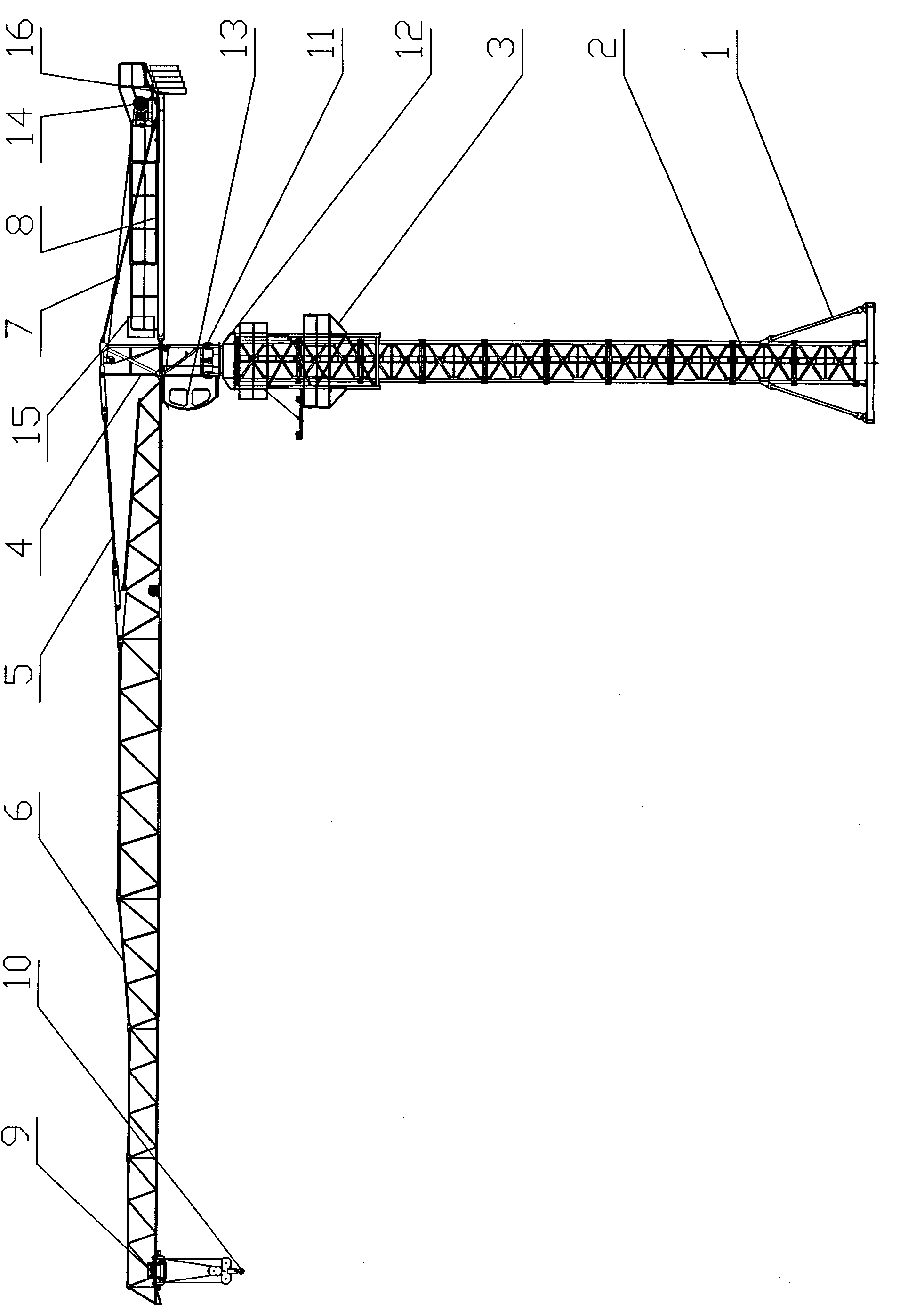

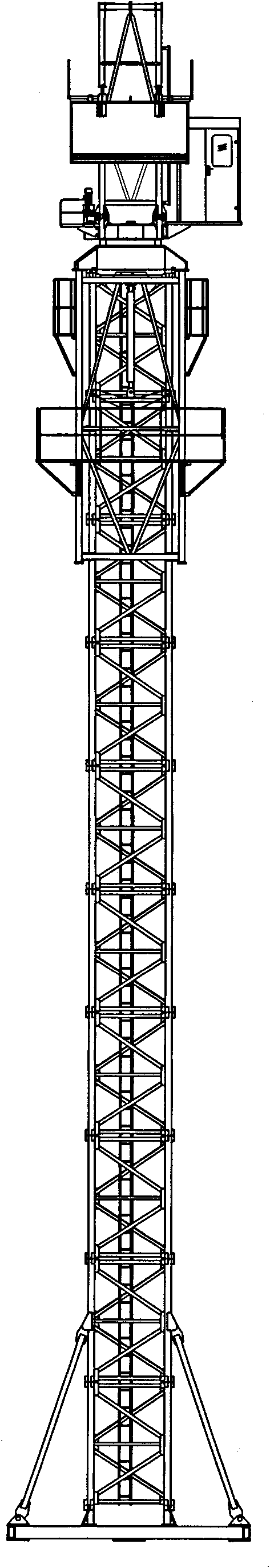

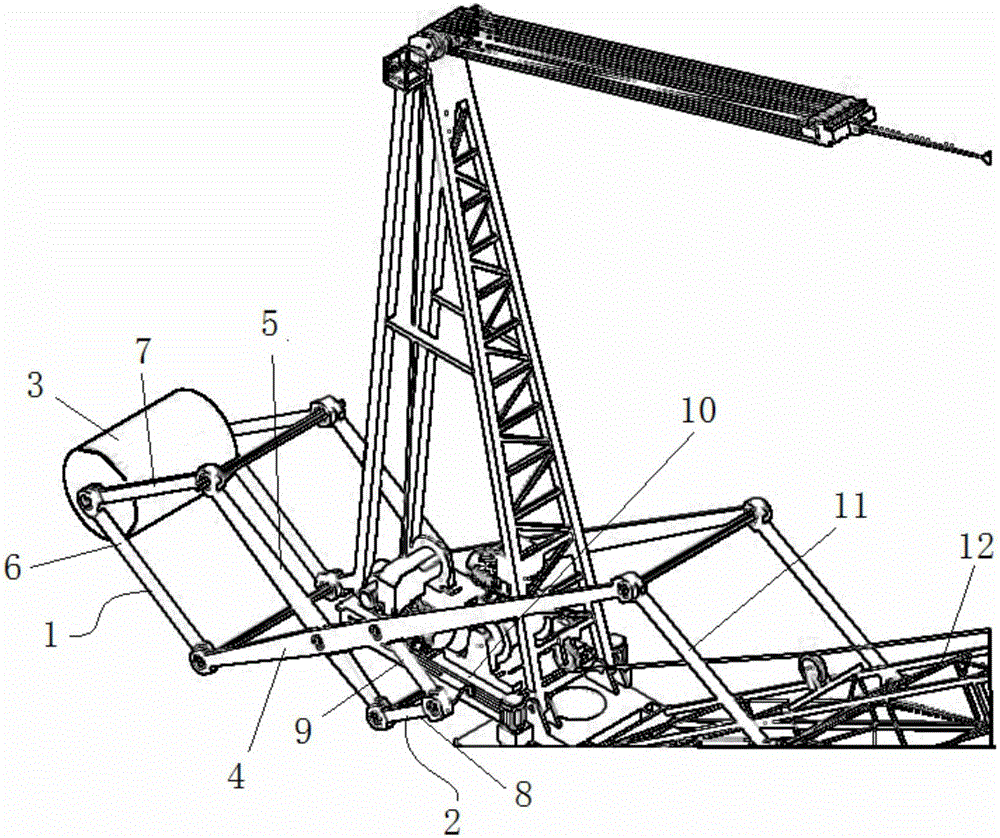

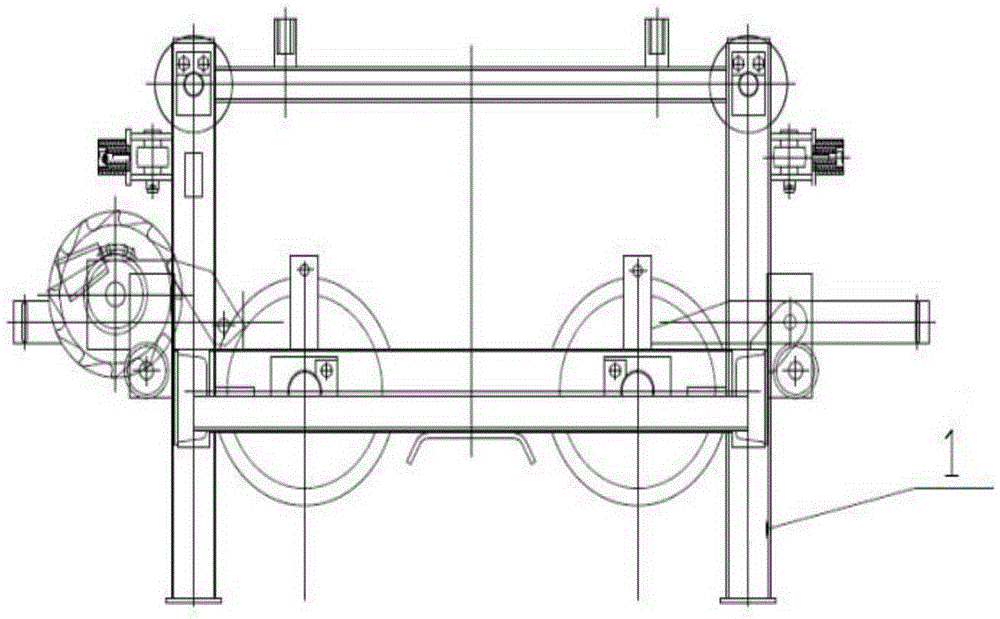

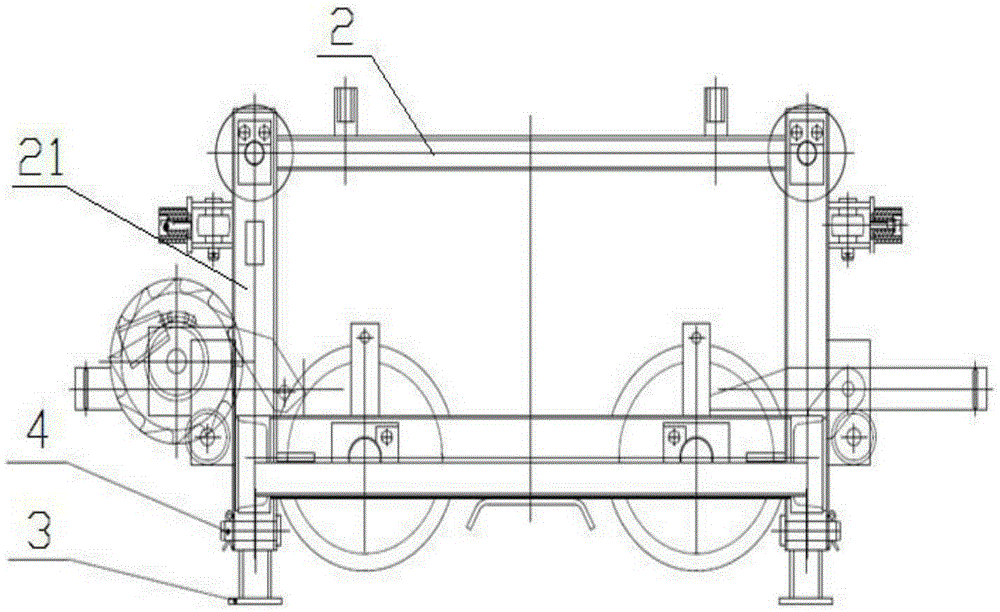

Flat-head tower crane

The invention provides a flat-head tower crane. The common tower cranes are generally provided with tower tops, and when a group of towers carry out cross operation, the common tower cranes are hard to be competent in many occasions with special requirement for height because of being limited by the tower tops. The flat-head tower crane comprises an undercarriage (1). The invention is characterized in that a group of standard sections (2) are connected on the undercarriage in order; the standard section arranged at the upper end is connected with a swivel assembly; a wrap frame (3) arranged outside the standard sections is connected with the lower part of the swivel assembly and a swivel tower body (4) is connected with the upper part of the swivel assembly; one side of the swivel tower body is connected with a boom (6) by a boom tension bar (5) and the other side thereof is connected with a balance boom (8) by a balance boom tension bar (7); the boom tension bar is connected with a speed changed trolley (9); and a hook (10) is linked with the lower part of the speed changed trolley. The tower crane serves as an elevator.

Owner:HARBIN HUATUO METAL STRUCTURE

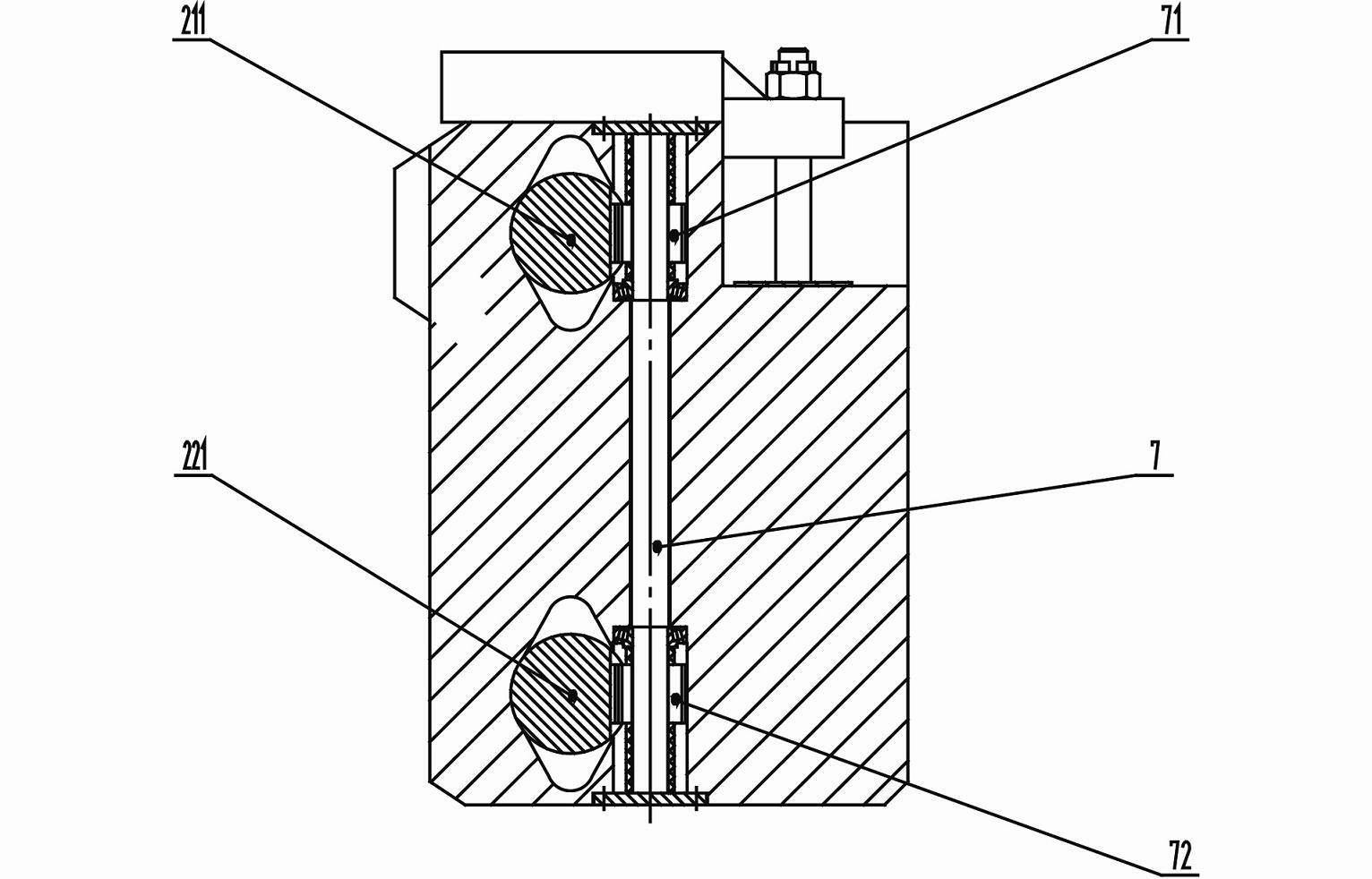

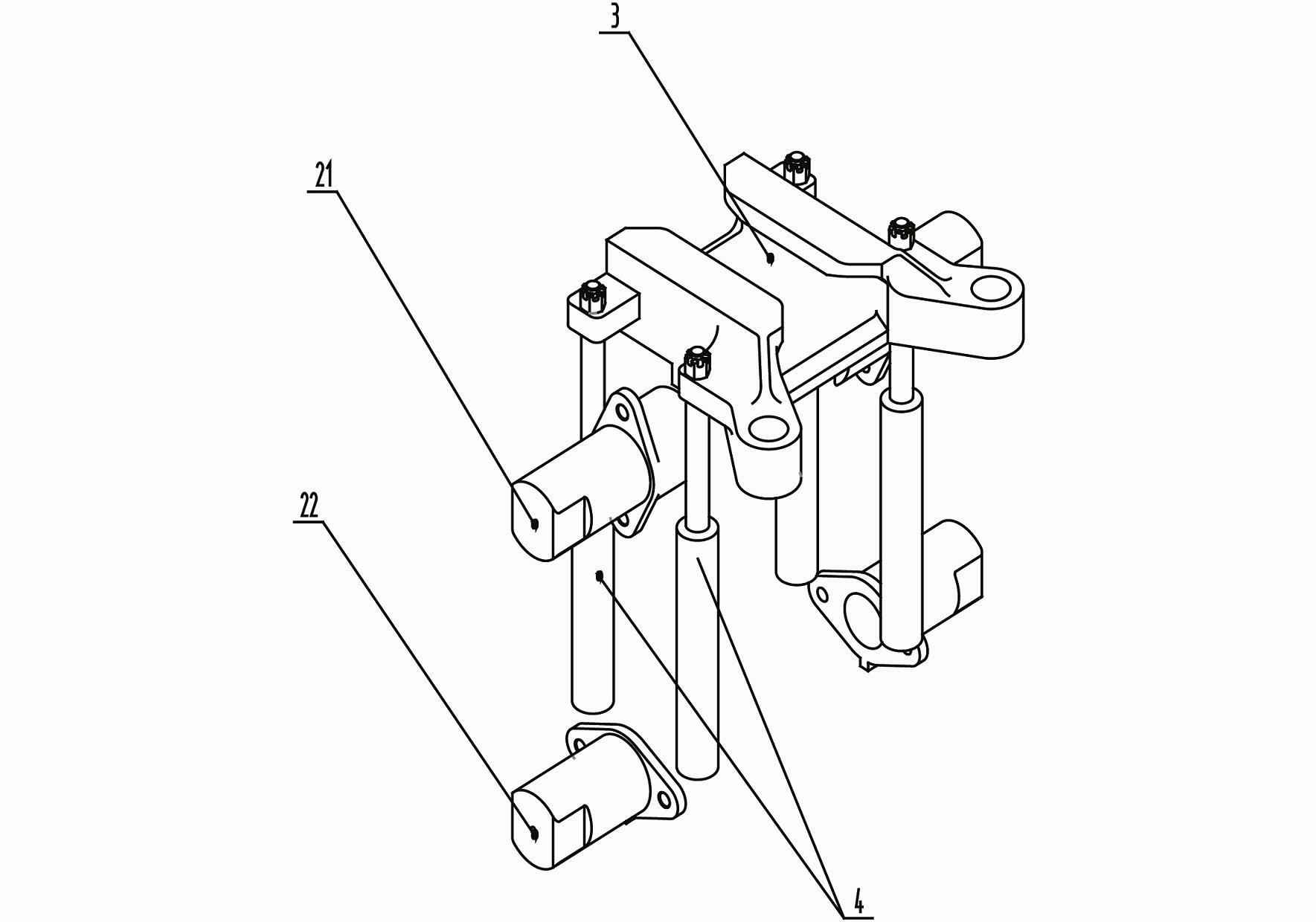

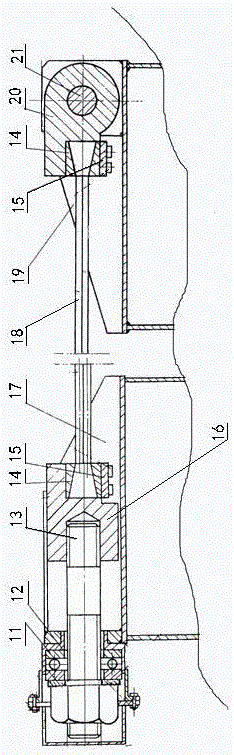

Safety pin interlocking device for crane, single cylinder safety pin type telescopic arm and crane

InactiveCN102153023ALower the altitudeIncrease the itineraryCranesStructural engineeringMechanical engineering

The invention discloses a safety pin interlocking device for a crane, a single cylinder safety pin type telescopic arm and a crane. The safety pin interlocking device for the crane comprises a pin pull device dovetail groove and a mechanical lock which is fixedly connected with the dovetail groove; the motion path of the dovetail groove is perpendicular to an axis of a cylinder pin; meanwhile, the motion path of an upper cylinder pin is intersected with the motion path of the dovetail groove, and the motion path of a lower cylinder pin is intersected with the motion path of the mechanical lock; when the arm pin moves to the unlocking position, an arm pin pulling oil cylinder drives the dovetail groove to lock the upper cylinder pin, and meanwhile, the dovetail groove drives the mechanicallock to lock the lower cylinder pin; and when the cylinder pin moves to the unlocking position, the upper cylinder pin locks the dovetail groove by a cylinder pin body, and meanwhile, the lower cylinder pin locks the mechanical lock by the cylinder pin body, thereby the arm pin is directly and indirectly locked. The single cylinder safety pin type telescopic arm and telescopic arm type crane provided by the invention comprise the safety pin interlocking device.

Owner:DALIAN UNIV OF TECH +2

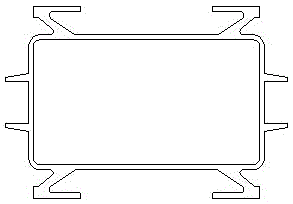

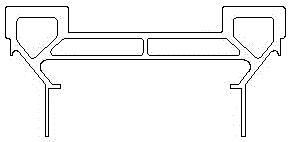

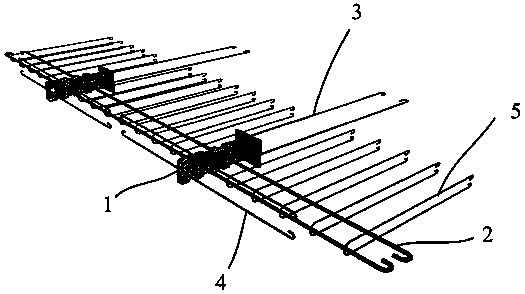

Manufacturing method of aluminum alloy mechanical arm track girder hollow profile

ActiveCN105039805AReduced risk of weakeningMeet the use requirementsUltimate tensile strengthAluminium alloy

The invention belongs to the technical field of aluminum alloy profiles and particularly relates to a manufacturing method for producing an aluminum alloy mechanical arm track girder hollow profile through an aluminum alloy replacing rolled steel. The manufacturing method comprises the steps that firstly, the intensity and the capacity of resistance to deformation of a steel cross beam are evaluated; secondly, the aluminum alloy is selected; thirdly, the structure of the aluminum alloy mechanical arm track girder hollow profile is designed; fourthly, the movement track and deformation of the aluminum alloy mechanical arm track girder hollow profile in a stressed state are simulated through a computer; fifthly, a mould of the aluminum alloy mechanical arm track girder hollow profile is manufactured; sixthly, the aluminum alloy mechanical arm track girder hollow profile is extruded and quenched online; seventhly, the aluminum alloy mechanical arm track girder hollow profile is aged; eighthly, the aluminum alloy mechanical arm track girder hollow profile is sampled; ninthly, the aluminum alloy mechanical arm track girder hollow profile is riveted; and tenthly, the aluminum alloy mechanical arm track girder hollow profile is packaged and delivered, and the aluminum replaces the steel to produce the aluminum alloy mechanical arm track girder hollow profile.

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

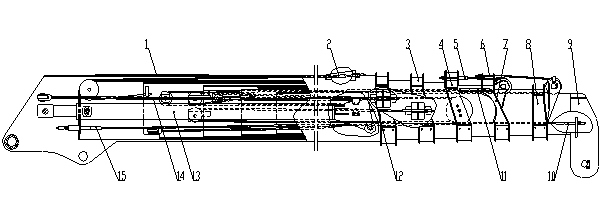

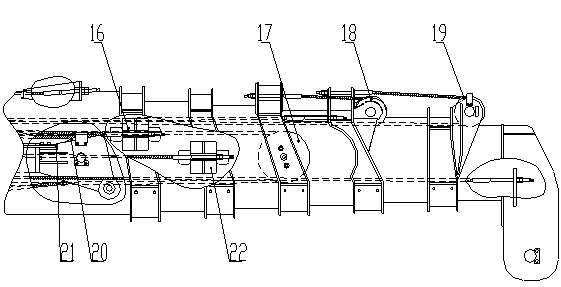

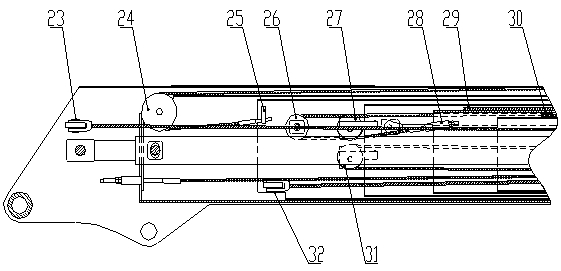

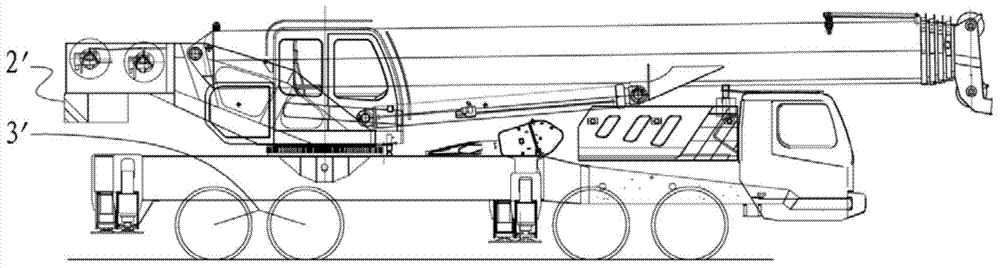

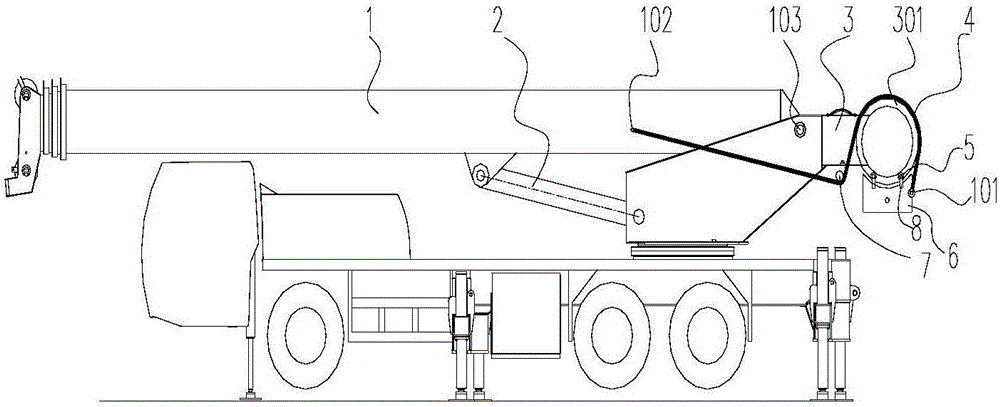

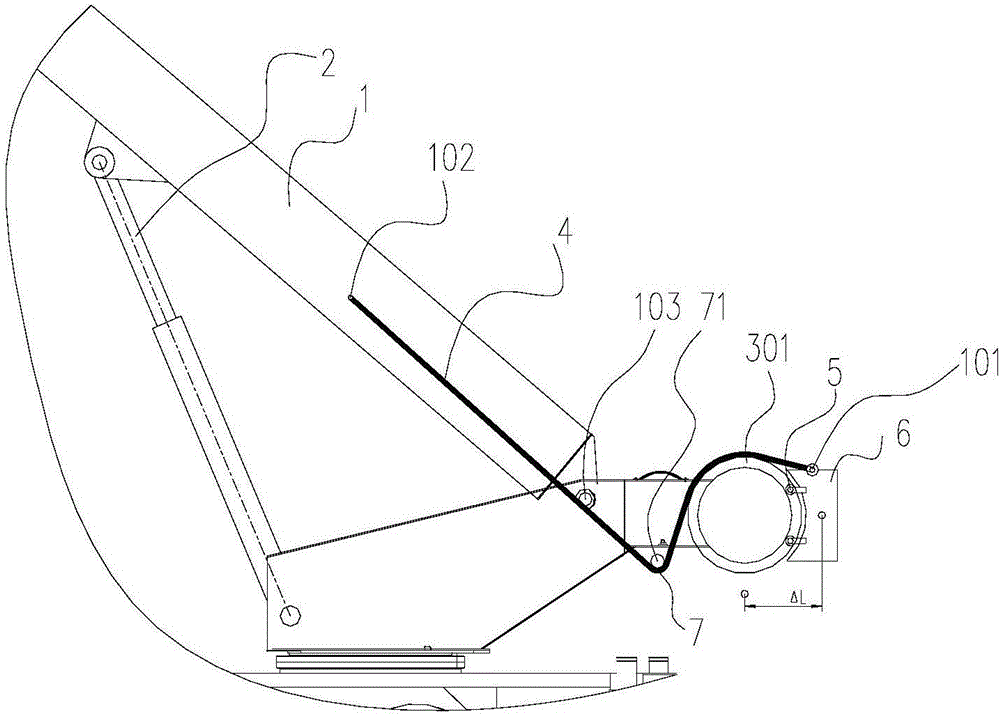

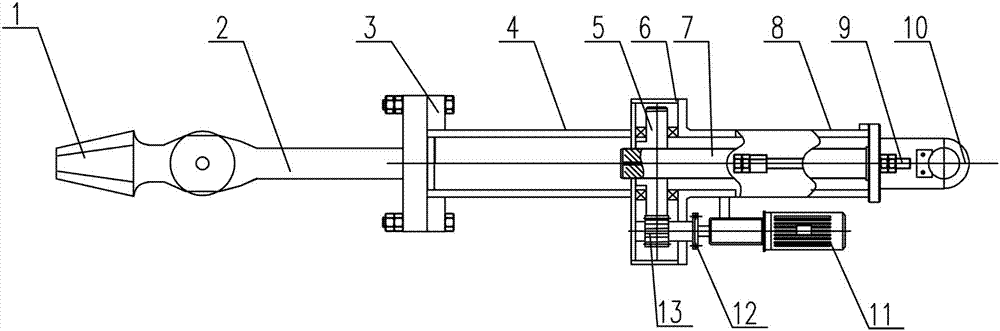

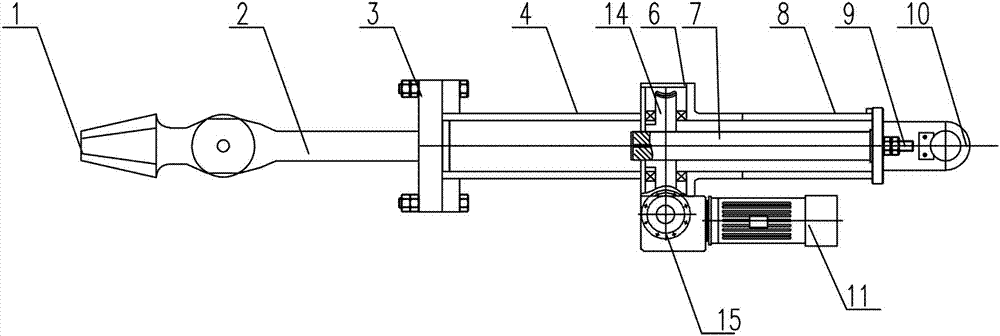

Single cylinder synchronous expansion and contraction device with multiple sets of inhaul cables for lorry-mounted crane

The invention discloses a single cylinder synchronous expansion and contraction device with multiple sets of inhaul cables for a lorry-mounted crane. The device comprises a basic arm and a plurality of telescopic arms which are overlapped and sleeved in the basic arm; a telescopic oil cylinder of which the head is fixed on the tail of the basic arm and the barrel is fixed on a first section of the tail of the telescopic arm is arranged in each of the plurality of telescopic arms; the arm body of each telescopic arm is provided with a pulley, a telescopic arm cable, and a fixed plate; a rope row is arranged in each telescopic oil cylinder; and synchronous extending or contraction of multiple sections of the telescopic arms can be realized by the connection relationship of the parts, and the operation characteristics that the conventional arm can be only extended and contracted sequentially are changed to ensure that the multiple sections of the telescopic arm bodies are extended and contracted synchronously along with the extension and contraction of the inbuilt telescopic cylinders, so that the extension and contraction speed of the arm bodies and the efficiency of the lifting operation are improved greatly. The single cylinder synchronous expansion and contraction device with the multiple sets of inhaul cables for the lorry-mounted crane has a compact structure, the mode of winding steel wire ropes is skilful, the space in the arm body is fully utilized, and the problems that the conventional five-section telescopic arm expansion and contraction system for the lorry-mounted crane is implemented by arranging two inbuilt telescopic oil cylinders are solved.

Owner:XCMG XUZHOU TRUCK MOUNTED CRANE +1

Automatic brick setting machine

InactiveCN103466334AReduce loadExtended service lifeStacking articlesDe-stacking articlesBrickPortal frame

The invention discloses an automatic brick setting machine which comprises a portal frame. A slidable lifting mechanism is arranged on the portal frame and comprises a sliding platform and a lifting platform, the lifting platform is mounted below the sliding platform, a plurality of green brick fixtures are arranged below the lifting platform, a vertical lead screw is arranged on the sliding platform, the lifting platform is lifted up and down by the aid of the lead screw and provided with a plurality of balance cylinders matched with the lead screw, the balance cylinders drive the lifting platform in auxiliary lifting, and the green brick fixtures can horizontally rotate around the axis of the lead screw. The balance cylinders bear most weight, the load of the lifting lead screw is reduced, the service life of the lead screw is prolonged, and power consumption is reduced.

Owner:赵培龙

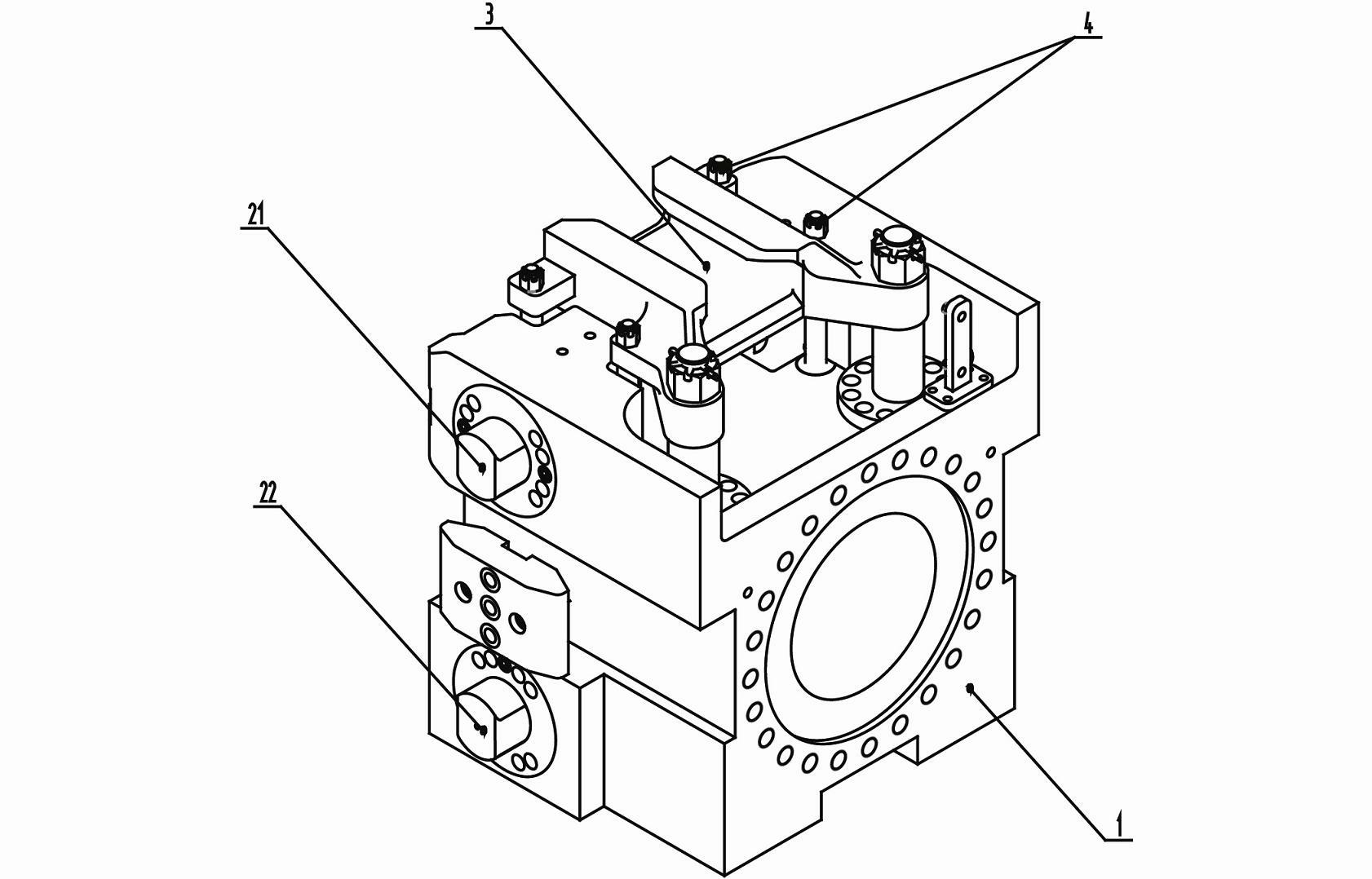

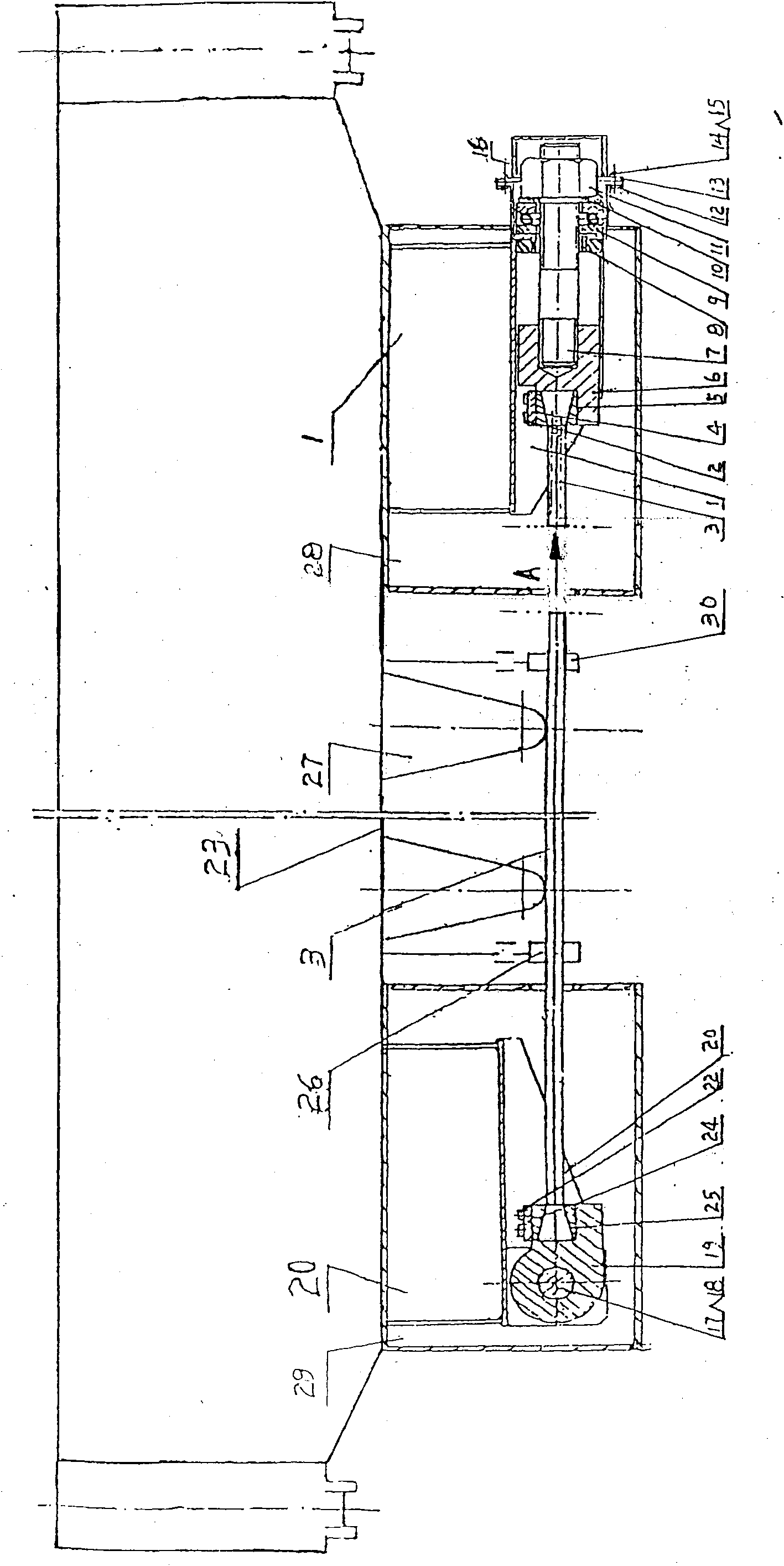

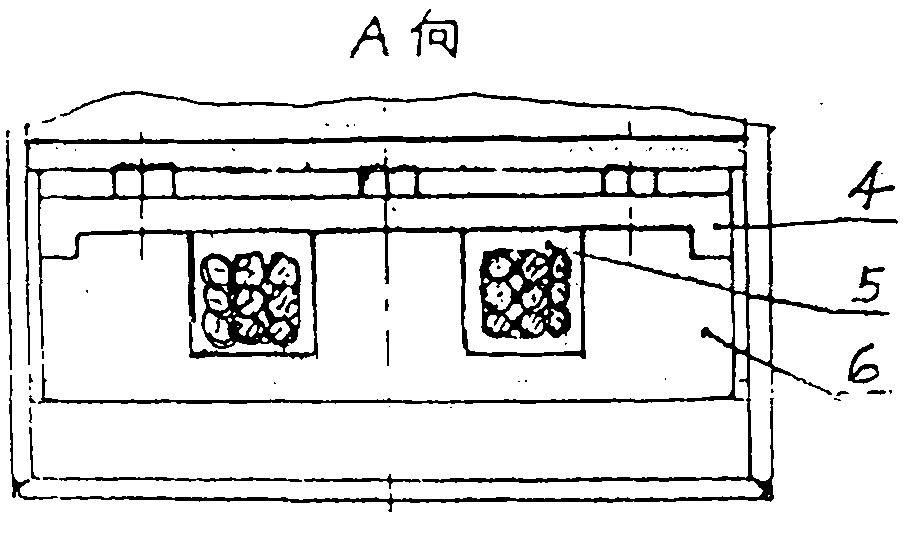

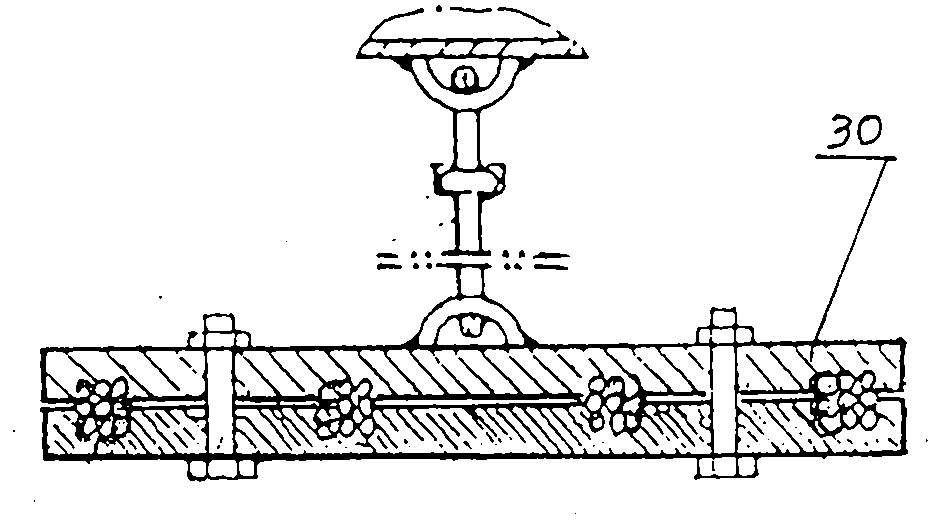

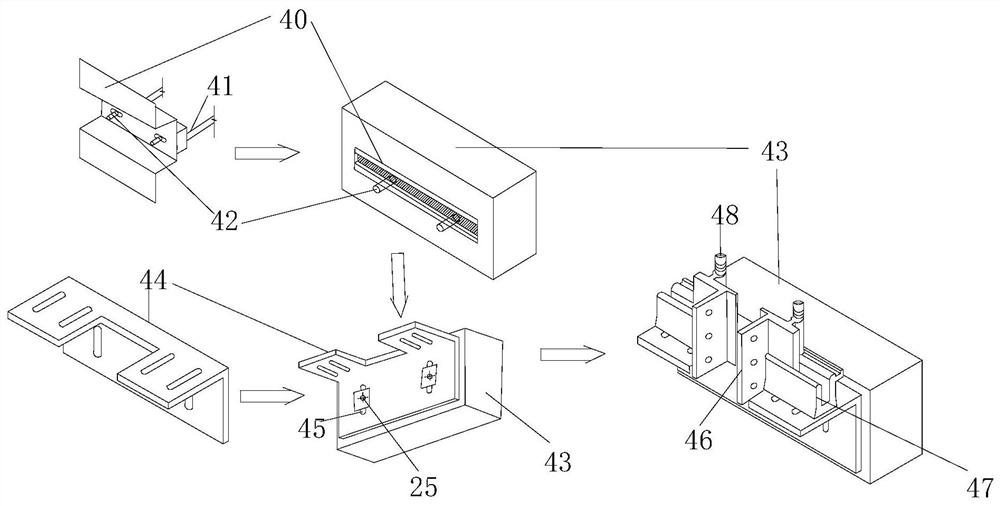

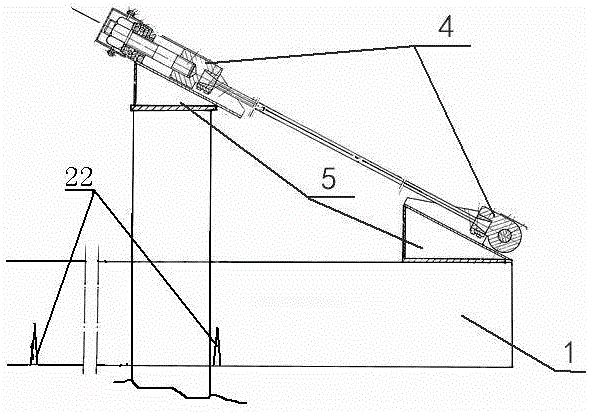

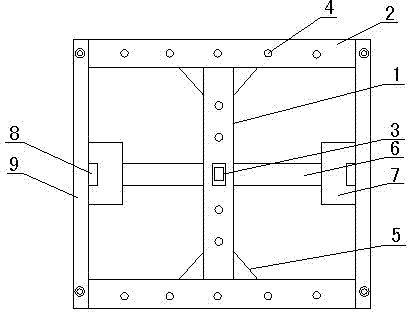

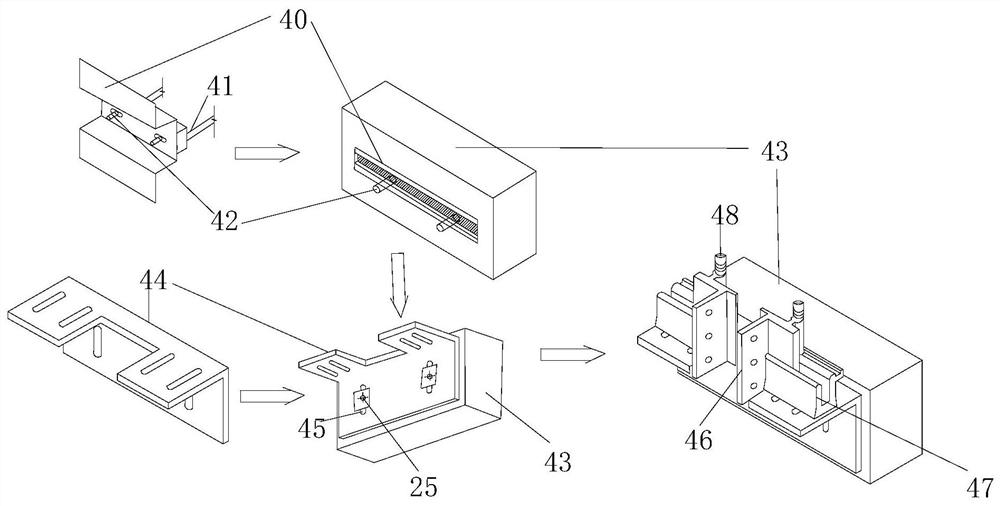

Manufacturing process of girder of overhead or gantry crane

The invention discloses a manufacturing process of a girder of an overhead or gantry crane, a threaded pull rod 7 in a box body 1 of a tensioning device is connected with a connecting seat 6, and the manufacturing process is characterized in that two wedge-shaped grooves are formed on the connecting seat 6, two rope head casting ports 5 with wedge-shaped outer shapes and square cone-shaped inner cavities are mounted in the grooves, two wedge-shaped grooves are formed on a fixed hinge 19 at the other end of a steel wire rope 3, and the rope head casting ports 25 with the wedge-shaped outer shapes and the square cone-shaped inner cavities are mounted in the grooves. The manufacturing process adopts the two groups for tensioning, the two groups are mounted on the same girder, and the ultimate tensioning force is great, thereby being applicable to manufacturing the girders of the cranes with the hoisting capacity of below 400 tons. The manufacturing process has the advantages of easy manufacturing, low cost and convenient construction, and is particularly applicable to manufacturing the gantry cranes with the span of above 60m in ports and the shipbuilding industry. The arch difference of the girder of the crane manufactured by adopting the invention can be controlled within 0-1mm, which is better than the international standard; furthermore, the manufacturing process can increase the cutting area of the girder structure, improve the strength, the static stiffness and the hoisting capacity of the girder, save steel, reduce the cost by 15-20%, be in line with the policies of energy conservation and emission reduction and prolong the service life of equipment.

Owner:傅萍 +2

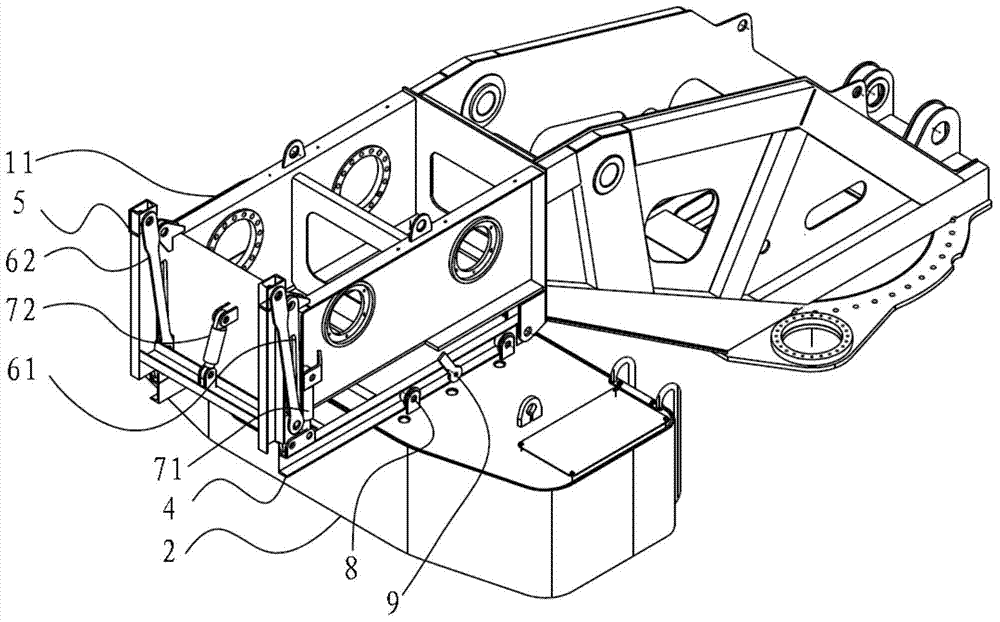

Counterweight device of crane and crane with counterweight device

ActiveCN104843599AImprove stabilityIncreased maximum lifting capacityCranesMechanical engineeringMovement pattern

The invention discloses a counterweight device of a crane and the crane with the counterweight device. The counterweight device of the crane comprises: a counterweight; a first guide rail, which is installed on the main body of the crane in a movable manner, used for supporting the counterweight and guiding the counterweight to move along the first guide rail, and capable of moving in a forward inclining state or in a backward inclining state, wherein in the forward inclining state, the counterweight moves forward along the first guide rail under the action of the gravity of the counterweight, and in the backward inclining state, the counterweight moves backward along the first guide rail under the action of the gravity of the counterweight; and a first drive unit, which is used for driving the first guide rail to move in the forward inclining state or in the backward inclining state. Since the guide rail which is capable of inclining forward and backward, the counterweight can move forward and backward along the first guide rail under the action of the gravity of the counterweight so as to adapt to different working states. In a lifting state, the counterweight moves backward, and maximum lifting weight is increased; and in a zero load state, the counterweight moves forward, and the center distribution of the whole crane is uniform, which enables the stability of the crane to be improved.

Owner:河北雷萨重型工程机械有限责任公司

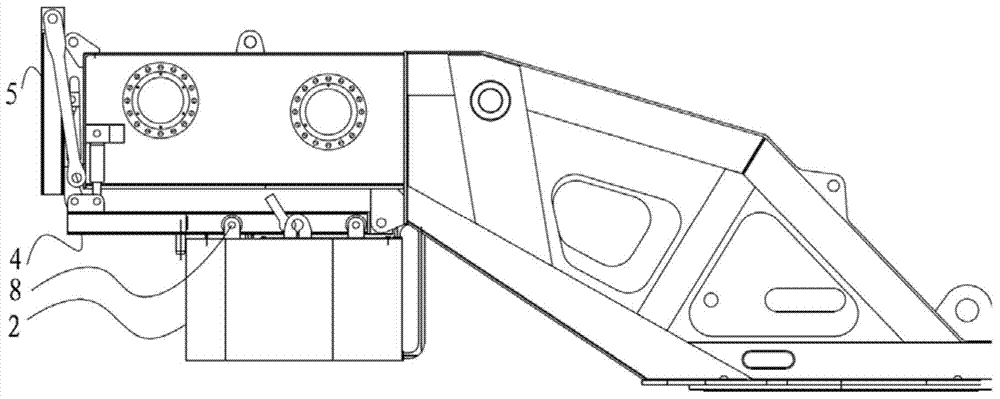

Cantilever crane counterweight mechanism and crane

The invention relates to a cantilever crane counterweight mechanism and a crane. The cantilever crane counterweight mechanism comprises a counterweight (6) arranged on a cantilever crane rotary table (3). The counterweight (6) is movably arranged on the cantilever crane rotary table (3). The cantilever crane counterweight mechanism further comprises a transmission device. The counterweight (6) is connected to a suspension arm (1) of the crane through the transmission device, so that the position of the gravity center of the counterweight (6) relative to the cantilever crane rotary table (3) is adjusted through the movement of the suspension arm (1). With the increasing of the displacement of the gravity center, the anti-tipping torque of the crane can be gradually improved, so that the elevating capacity of the suspension arm is improved under the condition that the stability and safety of the suspension arm are guaranteed.

Owner:河北雷萨重型工程机械有限责任公司

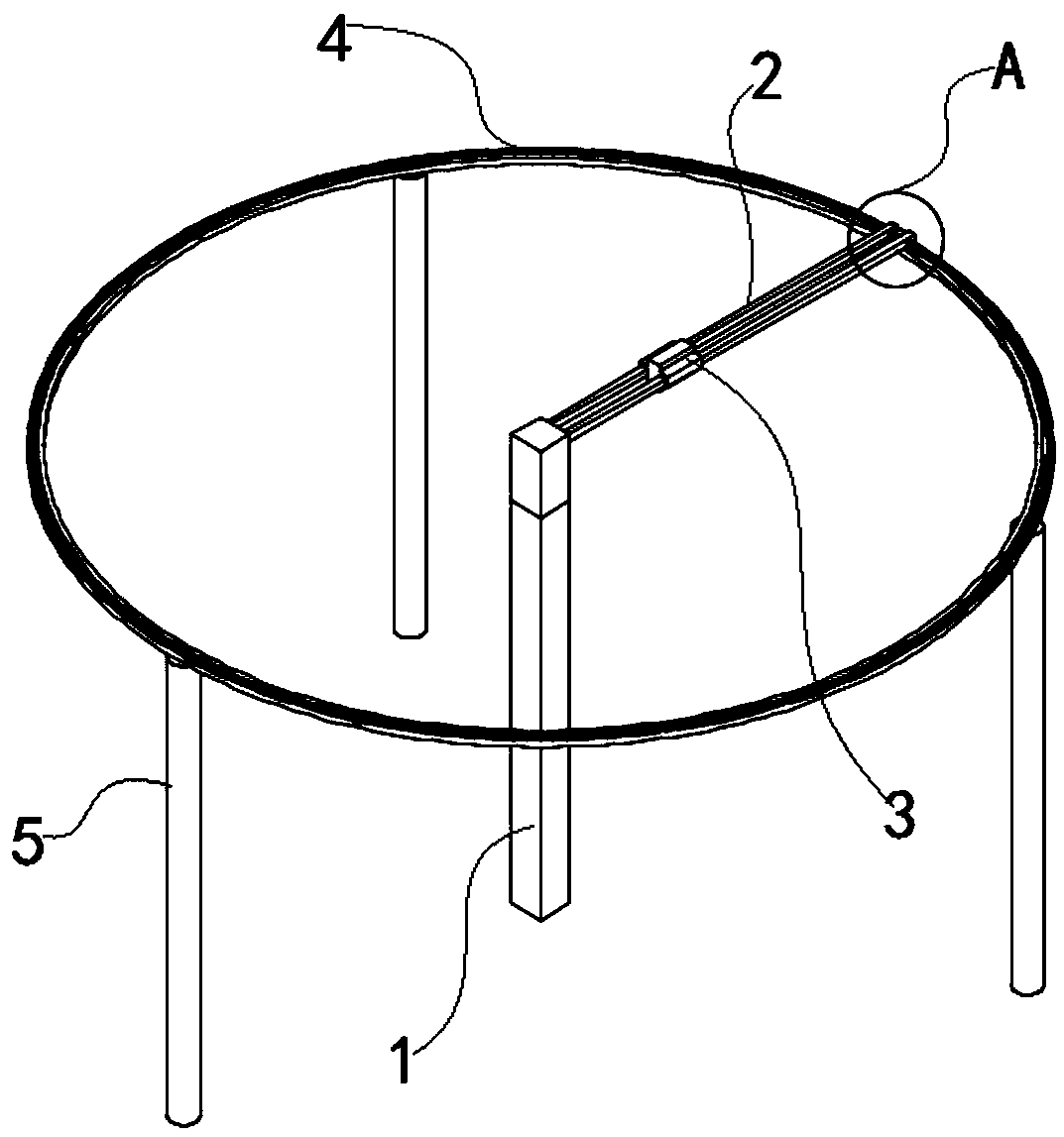

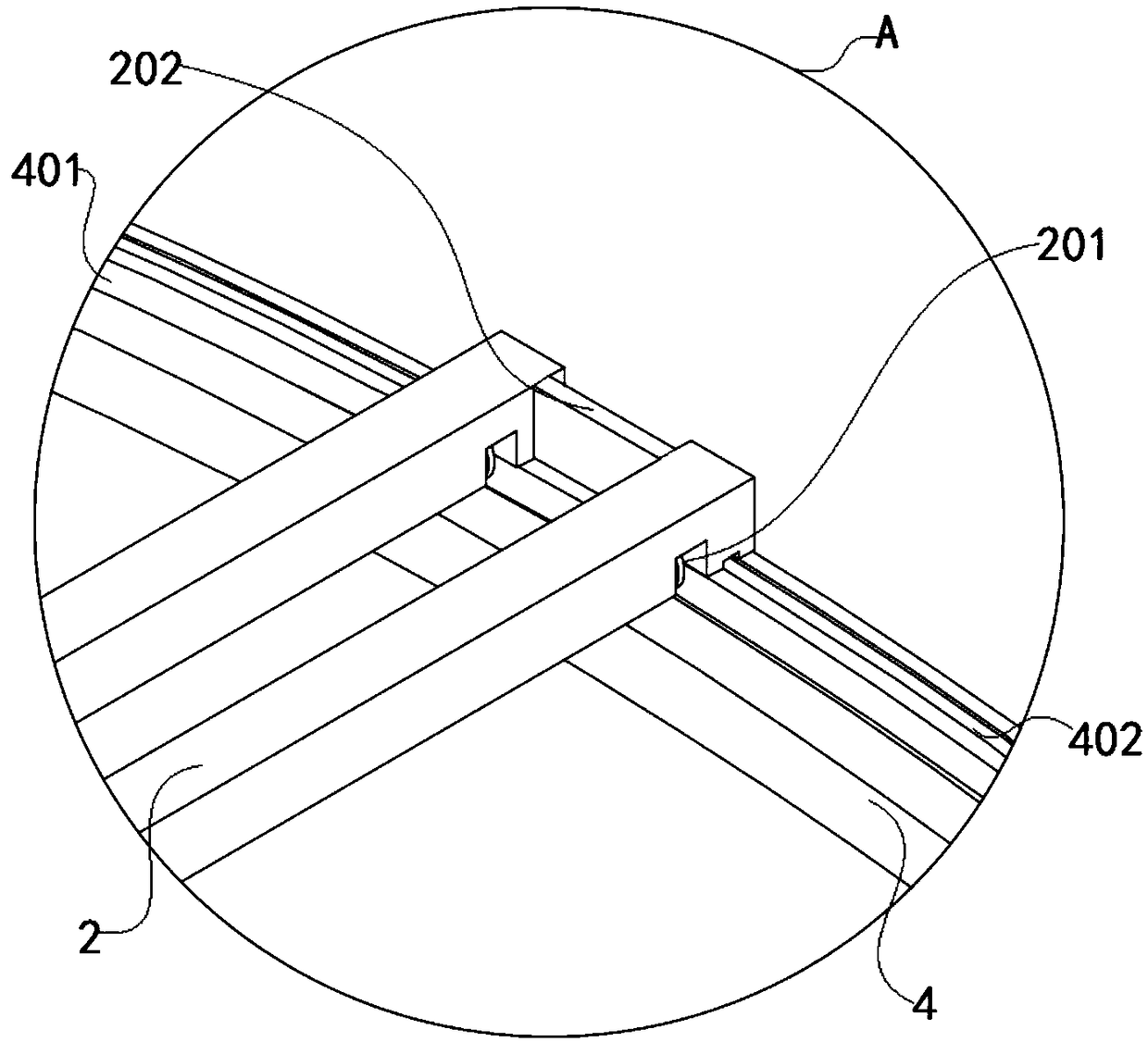

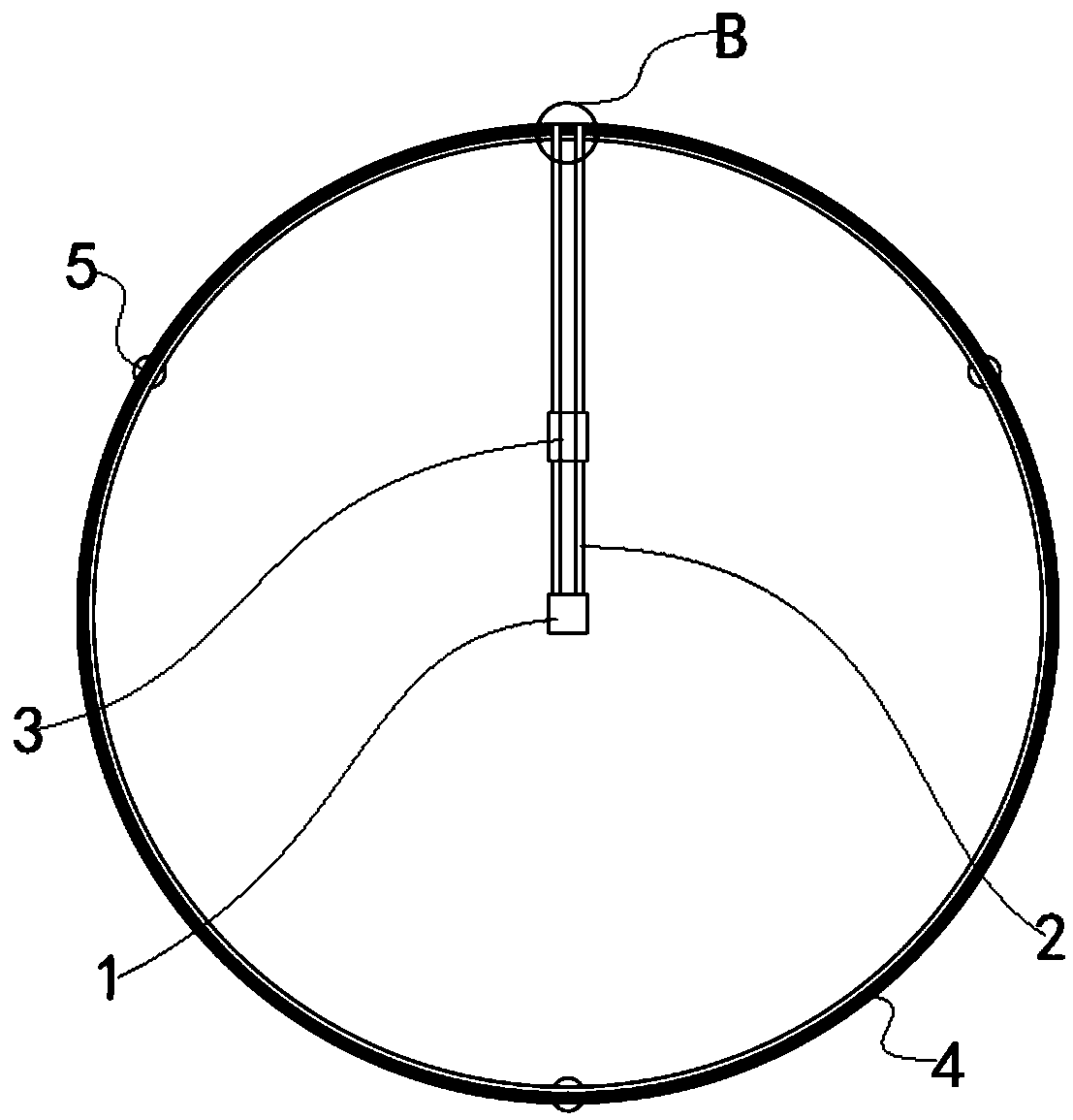

Circular high-accuracy crane and control method thereof

ActiveCN108792953AExpand the scope of workIncrease lifting weightTrolley cranesTravelling gearEngineeringWorking range

The invention discloses a circular high-accuracy crane and a control method thereof, and relates to the technical field of cranes. The circular high-accuracy crane comprises a main frame, a slide rod,an electric block, a guide rail and auxiliary frames, wherein the slide rod is connected with the main frame; the electric block is installed on the slide rod; one end of the slide rod is connected with the guide rail; one surface of the guide rail is connected with the plurality of auxiliary frames; a plurality of distance location sensors are installed on one surface of the slide rod; a baffleplate is installed on one surface of the electric block; the baffle plate is cooperated with the distance location sensors; a plurality of angle location sensors are arranged on one surface of the guide rail; a reflection plate is fixed to one end of the slide rod; and the reflection plate is cooperated with the angle location sensors. According to the circular high-accuracy crane, the working range of the crane is expanded through an annular design; the hoisting weight of the crane is increased through the cooperation of the guide rail and the auxiliary frames; and the hoisting position of the crane is accurately determined through the cooperation of the angle location sensors and the distance location sensors, so that the working efficiency is increased, and production accidents are reduced.

Owner:合肥市春华起重机械有限公司

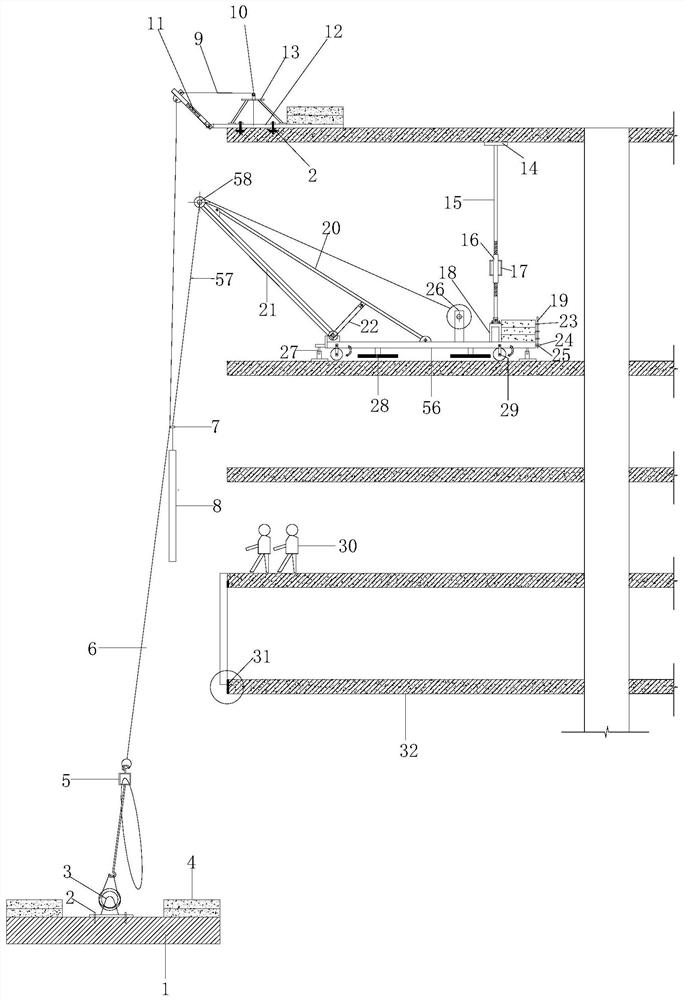

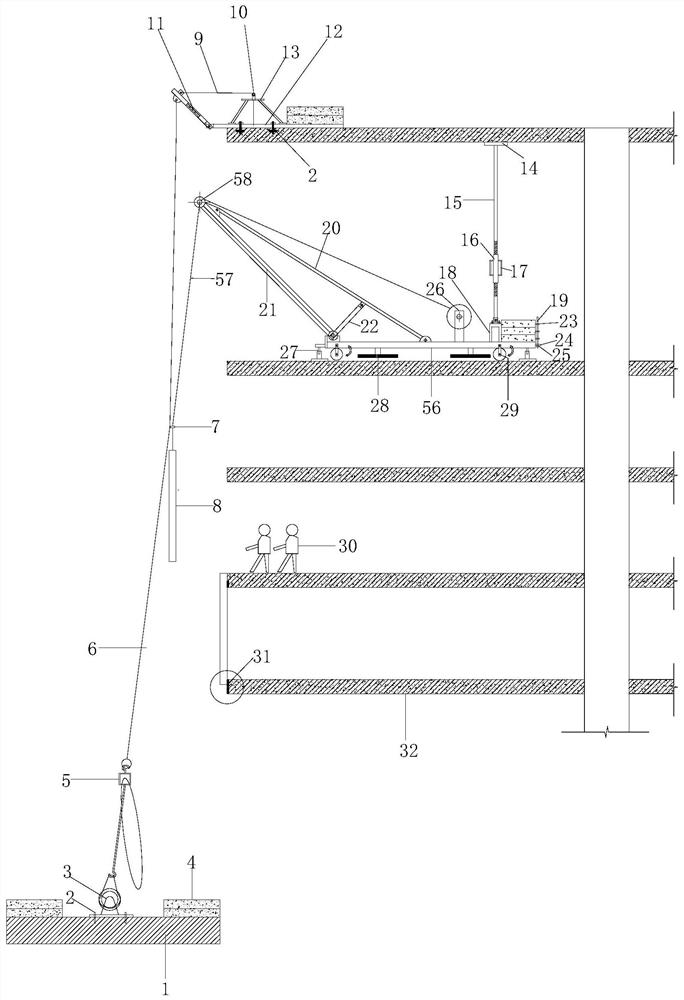

Glass curtain wall construction structure and construction method thereof

ActiveCN112196159AFast constructionImprove installation accuracyWallsBuilding material handlingArchitectural engineeringSystem construction

The invention relates to the field of housing construction engineering, and particularly relates to a glass curtain wall construction structure and a construction method thereof. The glass curtain wall construction structure is high in construction efficiency, a rigid turnover frame is transported rapidly, a moving crane is good in stability, the glass curtain wall construction quality is high, the construction speed is high, and high economic and technical benefits are achieved. The construction method mainly comprises the construction steps of (1) construction preparation, (2) surveying andsetting out, (3) embedded part embedding, (4) cable rope stabilizing system construction, (5) glass curtain wall unit plate moving crane assembling, (6) glass curtain wall unit plate transportation, (7) glass curtain wall unit plate hoisting, (8) fixed connection of glass curtain wall unit plates and three-way six-degree groove type embedded parts, (9) unit body elevation checking, (10) waterproofgland installation, and (11) curtain wall closing-in. Centralized machining, accurate positioning and rapid hoisting can be achieved, and good economic and technical benefits are achieved.

Owner:SHENZHEN JIANYI DECORATION GROUP

Method for manufacturing or transforming main beams of crane

Provided is a method for manufacturing or transforming main beams of a crane. An I-shaped steel support and reinforcing ribs are welded between a main beam midspan beam and supporting frames; tensioners are mounted at the top ends of the supporting frames and the tail end of a main beam cantilever through connecting seats, and are tensioned through a tensioning system, so that the camber of the main beam midspan beam meets the standard requirement, and the upwarping degree of the effective cantilever position of the main beam cantilever ranges from 0.9 / 350 to 1.4 / 35. According to the method for manufacturing or transforming the main beams of the crane, processing and manufacturing are easy, cost is low, and construction is convenient; the method is suitable for being used for manufacturing or transforming main beams of cranes of any tonnage, and especially suitable for manufacturing and transforming of portal cranes in the port and shipbuilding industry. The camber difference of the two manufactured or transformed main beams of the crane is kept between 0 to 1 mm, the main beams of the crane are always kept at any value within the international range, steel is saved, and cost is reduced by 15% to 20 %; the method conforms to the national energy saving and emission reducing policy, and the service life of the crane is prolonged.

Owner:傅欣荣 +7

Dolly chain driven bridge cantilever crane with balancing counterweight

The invention discloses a dolly chain driven bridge cantilever crane with a balancing counterweight. The bridge cantilever crane comprises two end beams and two main beams which form a two-beam cranespan structure, wherein a hand-pulled trolley running device is arranged between the two end beams; inverted U-shaped tracks are arranged on the two main beams; a running dolly is arranged between andconnected with the two tracks; the running dolly is provided with a chain drive unit; the central part of the running dolly is provided with a rotating mechanism; a thrust bearing is connected with the interior of the rotating mechanism; the lower end of a suspender shaft in the rotating mechanism is connected with a cantilever member; one end of a cantilever beam on the cantilever member is connected with a hand-pulled trolley, and the balancing counterweight is hung on the other side of the cantilever beam; the hand-pulled trolley can horizontally move to and fro along the cantilever beam;a hand-pulled chain hoist is hung below the hand-pulled running trolley and capable of hoisting cargos; and the cantilever beam is located below the two main beams and capable of carrying out rotation, and can stretch out of a workshop for operation.

Owner:林霞

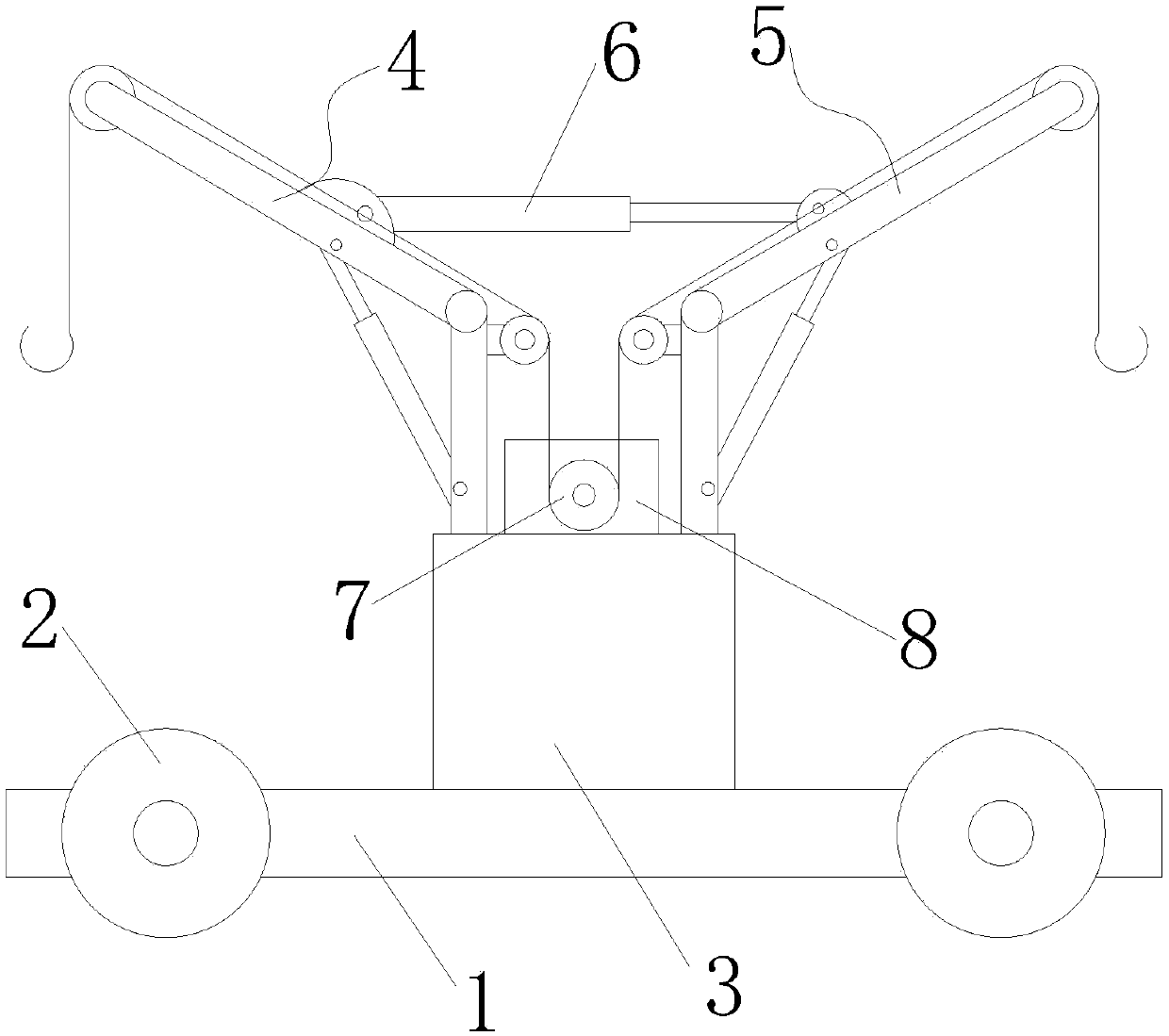

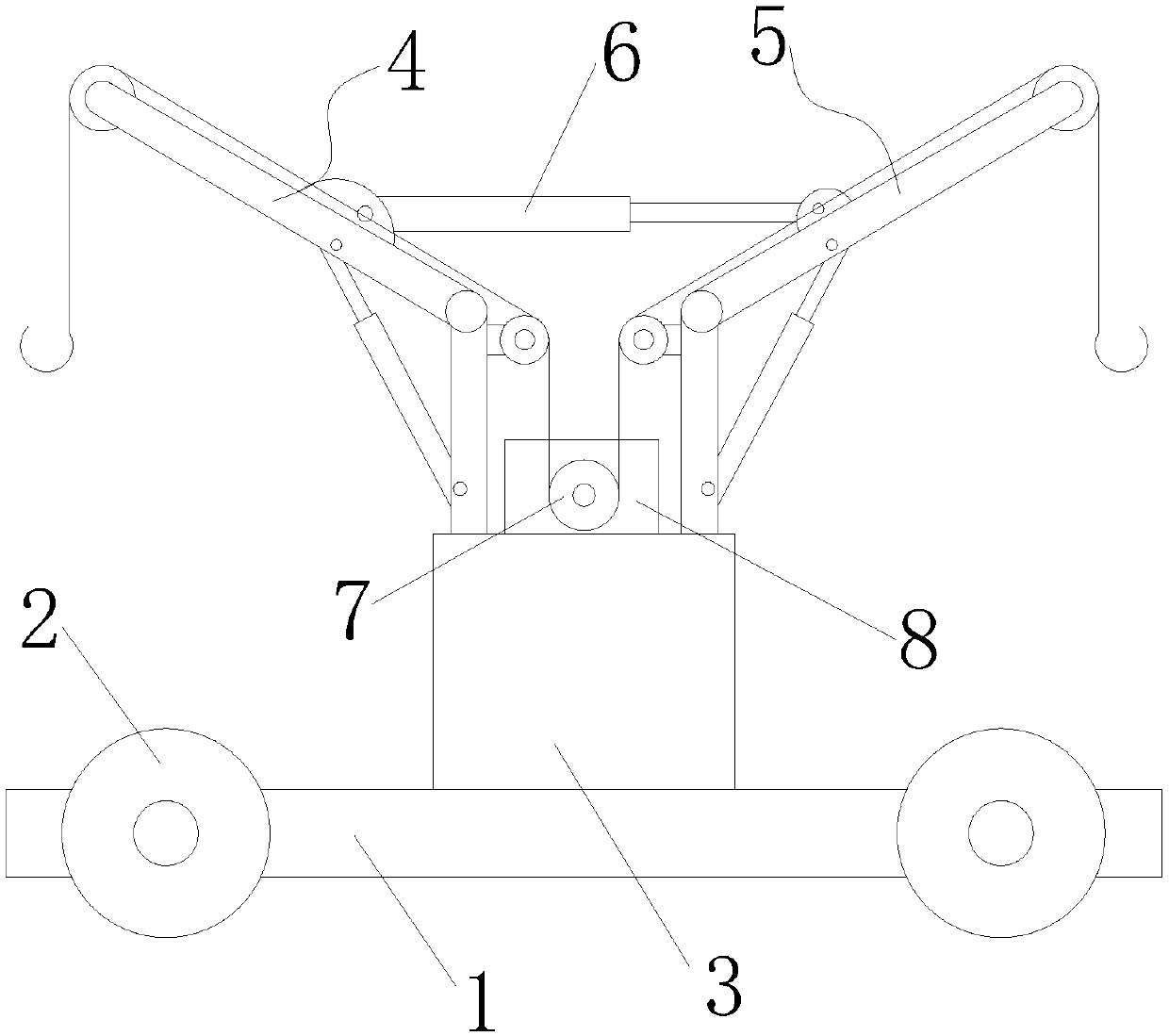

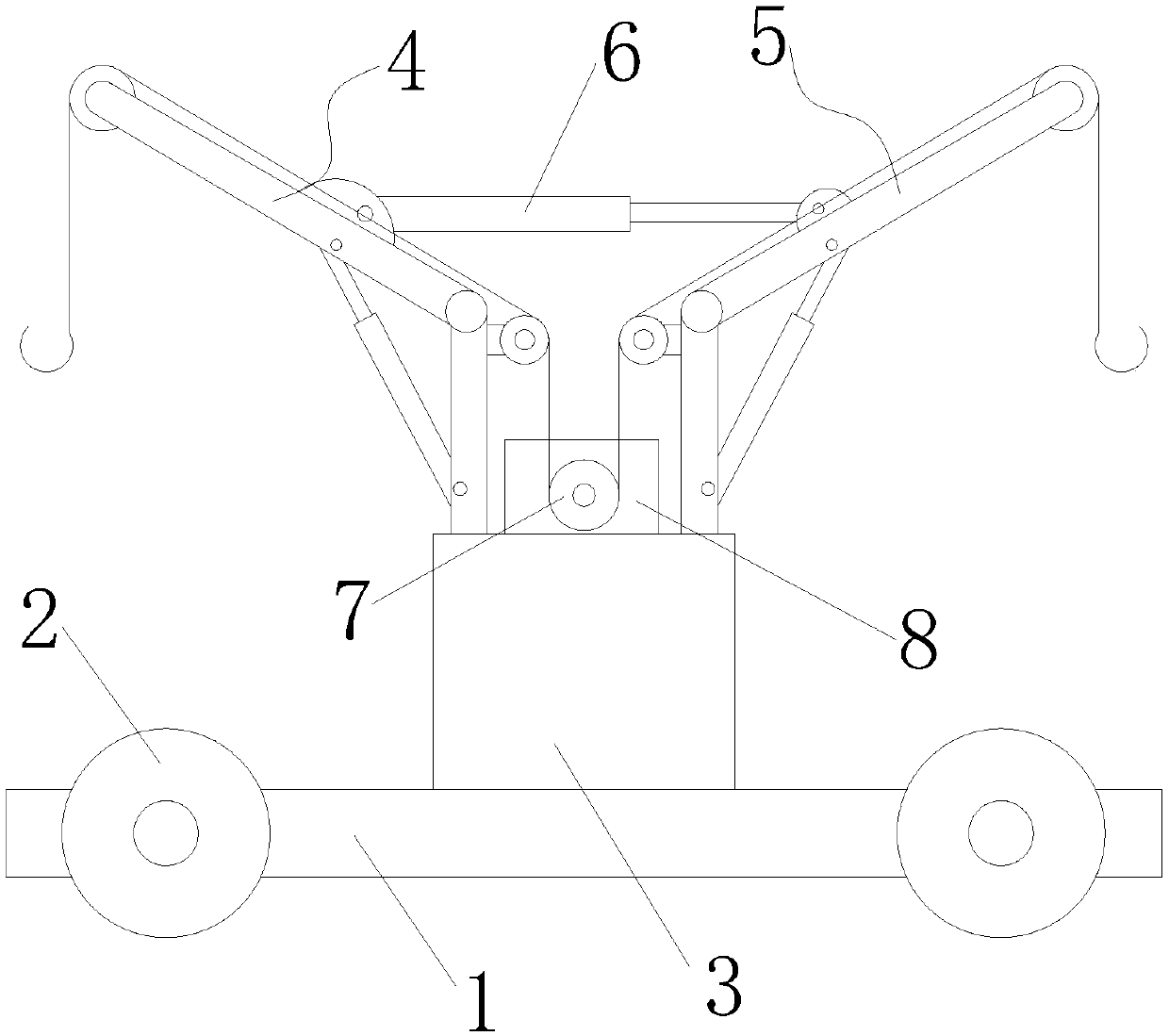

Method suitable for framework structure building underground additional storey and building

InactiveCN109835827AIncrease lifting weightSmall sizeBuilding material handlingCranesDrive motorConductor Coil

The invention relates to a method suitable for a framework structure building underground additional storey and a building. According to the method and the building, a crane bottom plate and wheels are involved, a supporting seat is arranged in the middle of the crane bottom plate, a first lifting arm is arranged on one side of the upper end of the supporting seat, a second lifting arm is arrangedon the other side of the upper end of the supporting seat, an adjusting rod is arranged between the first lifting arm and the second lifting arm, a lifting rope of the first lifting arm and a liftingrope of the second lifting arm are correspondingly connected with a winding drum, and the winding drum is connected with a driving motor. According to the method suitable for the framework structurebuilding underground additional storey and the building, during use, the crane bottom plate is moved to a proper position through the wheels, at the moment, building equipment is lifted under the action of the first lifting arm and the second lifting arm, and the distance between the first lifting arm and the second lifting arm is controlled through the adjusting rod, so that the lifting weight ofa crane is improved by the two lifting arms, and meanwhile, the size of a crane body is reduced.

Owner:田晓枫

Extensible type hoisting equipment counterweight mechanism

The invention relates to the field of hoisting equipment, in particular to an extensible type hoisting equipment counterweight mechanism. The extensible type hoisting equipment counterweight mechanism comprises an outer extending mechanism, an inner extending mechanism and a driving scissors fork assembly. The driving scissors fork assembly is arranged on a balance arm of hoisting equipment, the outer side of the driving scissors fork assembly is connected with the outer extending mechanism, and the inner side of the driving scissors fork assembly is connected with the inner extending mechanism. A counterweight is arranged at the outer end of the outer extending mechanism. The driving scissors fork assembly is driven to open and close through swinging of a hoisting boom of the hoisting equipment. The driving scissors fork assembly opens and closes to drive the outer extending mechanism to stretch out and draw back. The driving scissors fork assembly drives the inner extending mechanism to open and close. According to the extensible type hoisting equipment counterweight mechanism, the horizontal moving distance of the counterweight is substantially increased by means of the space scaling characteristic of an extensible structure, the balance bending moment of the top of a tower body is effectively reduced, the requirements for stability and static rigidity of a tower crane are met, dynamic performance is more outstanding, materials are saved, power dissipation is reduced, and the hoisting weight of the hoisting equipment is substantially increased.

Owner:韩波

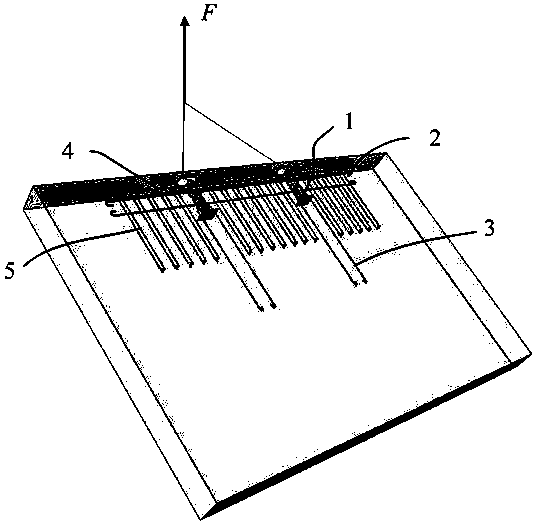

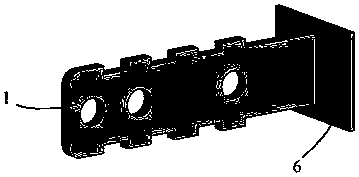

Novel prefabricated concrete member hoisting point embedded part system

PendingCN110952787AAvoid split damageIncrease the maximum carrying capacityBuilding material handlingArchitectural engineeringRebar

The invention discloses a novel prefabricated concrete member hoisting point embedded part system, and relates to the technical field of assembly type structures. The system comprises an embedded part, anti-pulling steel bars, anti-splitting steel bars, horizontal U-shaped steel bars, distribution steel bars and the like. The embedded part is made of high-strength steel, grooves are formed in theedge of the embedded part, end plates are arranged at the tail of the embedded part, and the bonding performance between the embedded part and a prefabricated member is improved. The anti-pulling steel bars penetrate through holes in the embedded part and are arranged in the longitudinal direction of the embedded part, and the anti-pulling bearing capacity of the embedded part is improved. The anti-splitting steel bars penetrate through the holes in the embedded part and are perpendicular to the embedded part, and the shear capacity of the embedded part is improved. The horizontal U-shaped steel bars are arranged around the embedded part and perpendicular to the embedded part, and the performance of the embedded part under the oblique tension is improved. The distribution steel bars are arranged around the anti-splitting steel bars and perpendicular to the anti-splitting steel bars, and the integrity between the system and the prefabricated member is improved. The embedded part systemis excellent in stress performance, suitable for various hoisting modes of large prefabricated concrete members and good in engineering application prospect.

Owner:CHONGQING UNIV

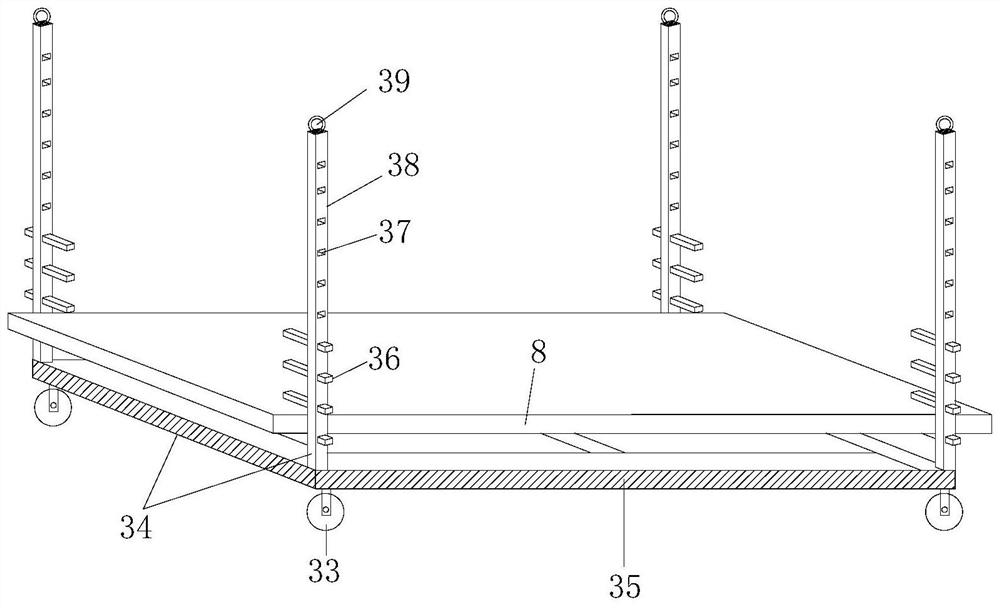

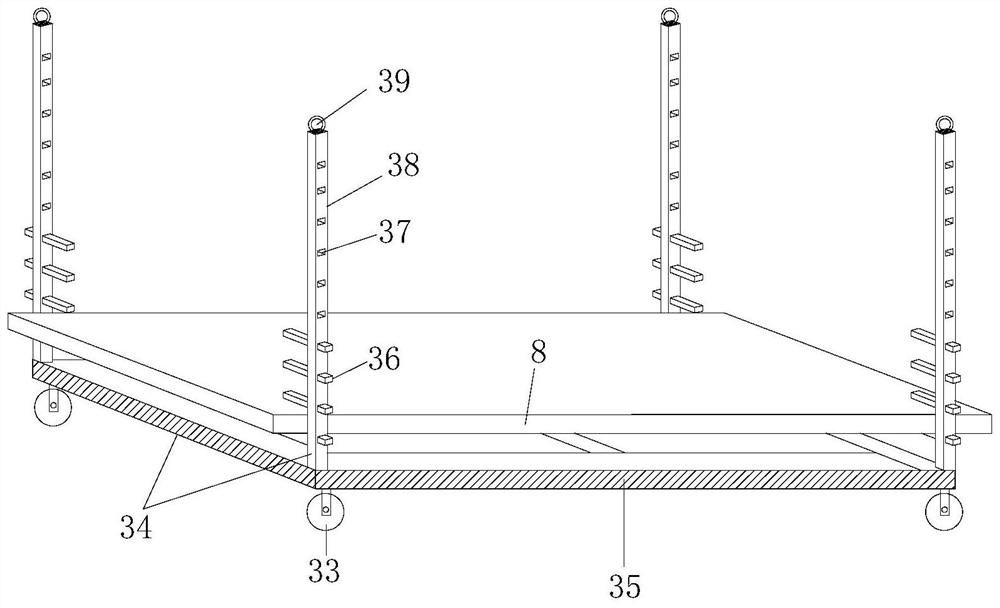

High-altitude hanging basket support convenient to dismount and mount

InactiveCN103395723AIncrease lifting weightImprove overall operating efficiencyLifting devicesWindow cleanersSteel platesFixed frame

The invention discloses a high-attitude hanging basket support convenient to dismount and mount. The high-attitude hanging basket support comprises an underframe and weighting pipes, the two sides of the underframe are respectively connected with a weighting pipe, and a middle area weighting pipe is vertically connected on the middle portion of the underframe. Rectangular supports are arranged at the two ends of the middle area weighting pipe respectively, and a fixed frame is connected on the periphery of each rectangular support. A plurality of balancing weight inserting rods which are perpendicularly downward are evenly mounted on the weighting pipes, are arranged between the fixed frames and the rectangular supports and are connected through locating steel plates. A vertical supporting pipe extending downwards is arranged in the center of the underframe, and a plurality of locating holes are distributed in the two sides of the vertical supporting pipe. The high-attitude hanging basket support has the advantages that the structure of the support can be provided with more balancing weights, can improve the lifting weight of a hanging basket, is beneficial for improving the integral operation efficiency of the hanging basket, and can meet the balancing weight operation needs under different conditions.

Owner:WUXI ACC HEAT EXCHANGER

Steel tube transporting collecting vehicle for construction site

InactiveCN109896439AIncrease lifting weightSmall sizeCranesArchitectural engineeringElectric machinery

The invention relates to a steel tube transporting collecting vehicle for a construction site. The steel tube transporting collecting vehicle for the construction site comprises a vehicle bottom plateand vehicle wheels; a supporting seat is arranged in the centre of the vehicle bottom plate; a first lifting arm is arranged on one side of the upper end of the supporting seat; a second lifting armis arranged on the other side of the upper end of the supporting seat; an adjusting rod is arranged between the first lifting arm and the second lifting arm; lifting ropes of the first lifting arm andthe second lifting arm are respectively connected with a winding drum; and the winding drum is connected with a driving motor. When the steel tube transporting collecting vehicle for the constructionsite is used, the vehicle bottom plate is moved to a suitable position through the vehicle wheels; at the moment, construction equipment is lifted under the actions of the first lifting arm and the second lifting arm, and the distance between the first lifting arm and the second lifting arm is controlled through the adjusting rod, so that the lifting weight of a crane is improved by the two lifting arms; meanwhile, the size of a vehicle body is reduced; and the steel tube transporting collecting vehicle for the construction site is convenient to operate and high in practicability.

Owner:夏永峰

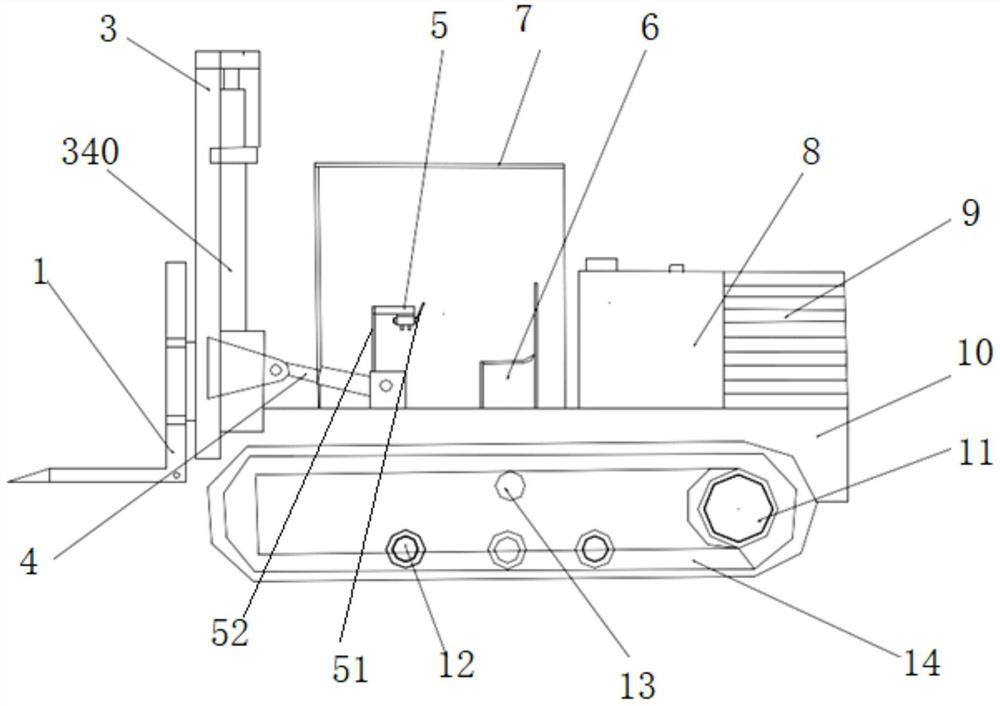

Pneumatic crawler-type forklift and method

PendingCN113184755AImprove climbing abilityReliable brakingServomotorsLifting devicesGear wheelRoad surface

The invention discloses a pneumatic crawler-type forklift and a method. The forklift comprises a walking crawler assembly, a forklift door frame assembly, a vehicle chassis and an operation table, the operation table is located above the front portion of the vehicle chassis, the vehicle chassis is installed on the walking track assembly, a pneumatic motor and a gear oil pump are installed in the vehicle chassis, an output shaft of the pneumatic motor is connected with an input shaft of the gear oil pump, an oil conveying pipeline of the gear oil pump is separately connected with a lifting oil cylinder and an inclined oil cylinder, a multi-way reversing valve set is arranged on the oil conveying pipeline of the gear oil pump, the operation table comprises a supporting frame and a multi-way reversing valve control rod, and the multi-way reversing valve control rod is connected with the multi-way reversing valve set. According to the pneumatic crawler-type forklift provided by the embodiment of the invention, a crawler-type traveling mechanism is adopted, hydraulic transmission is achieved, the gradeability is high, braking is reliable, and the pneumatic crawler-type forklift adapts to severe road surfaces of underground tunneling roadways.

Owner:陕西秦之基智能科技有限公司 +1

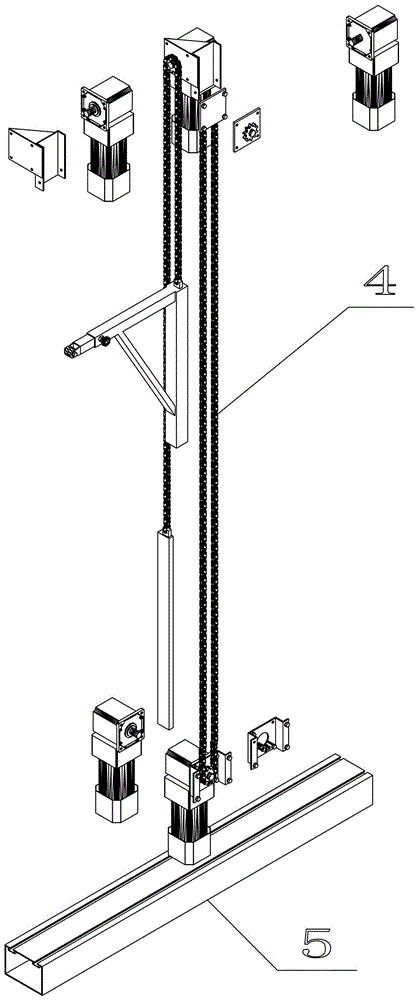

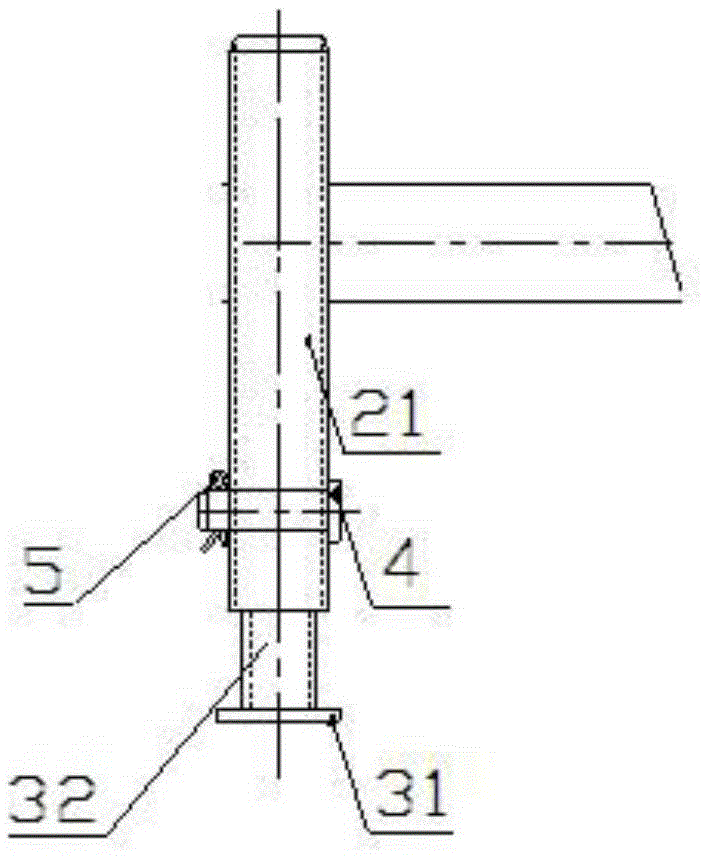

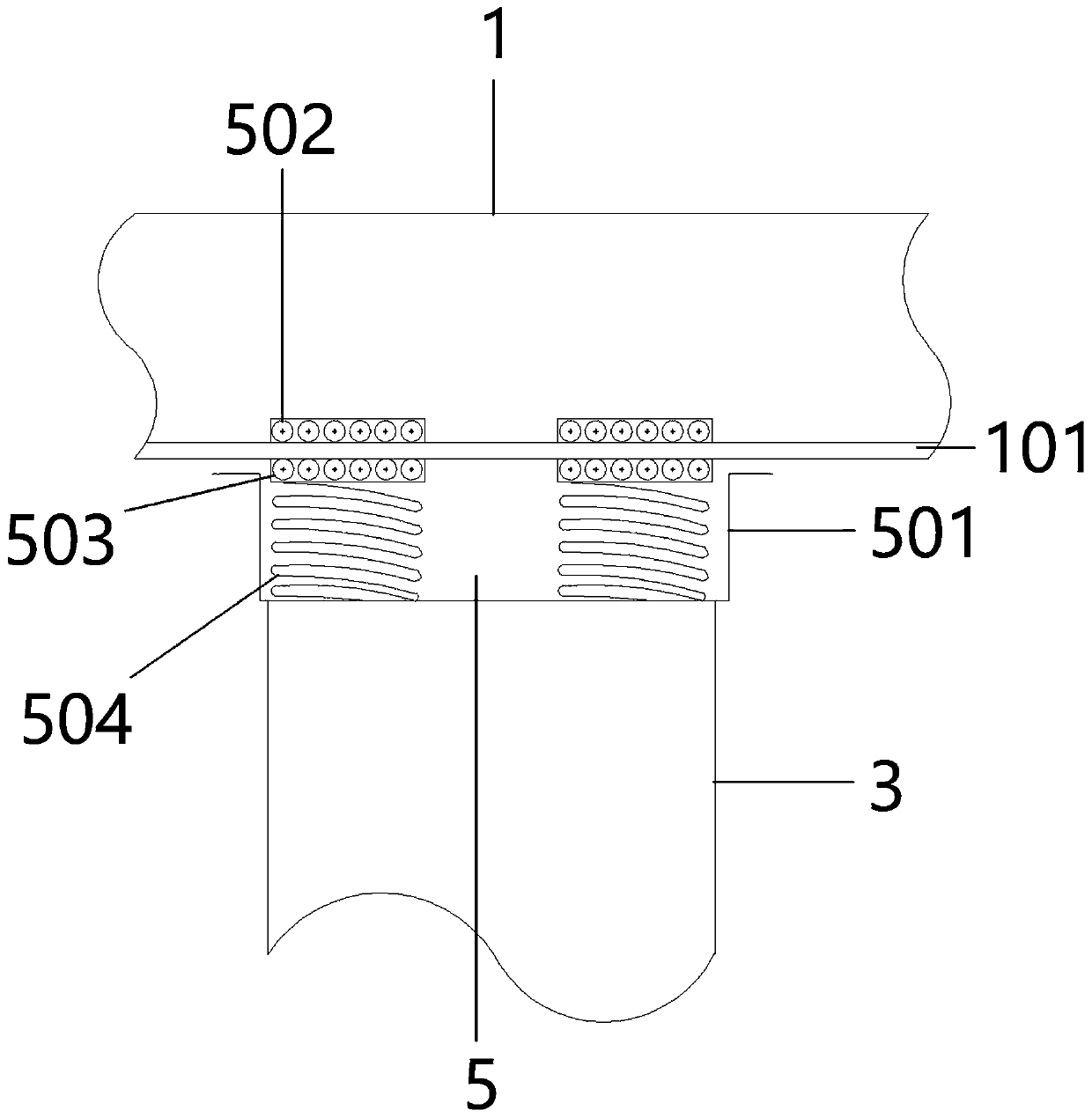

Awning mounting lift

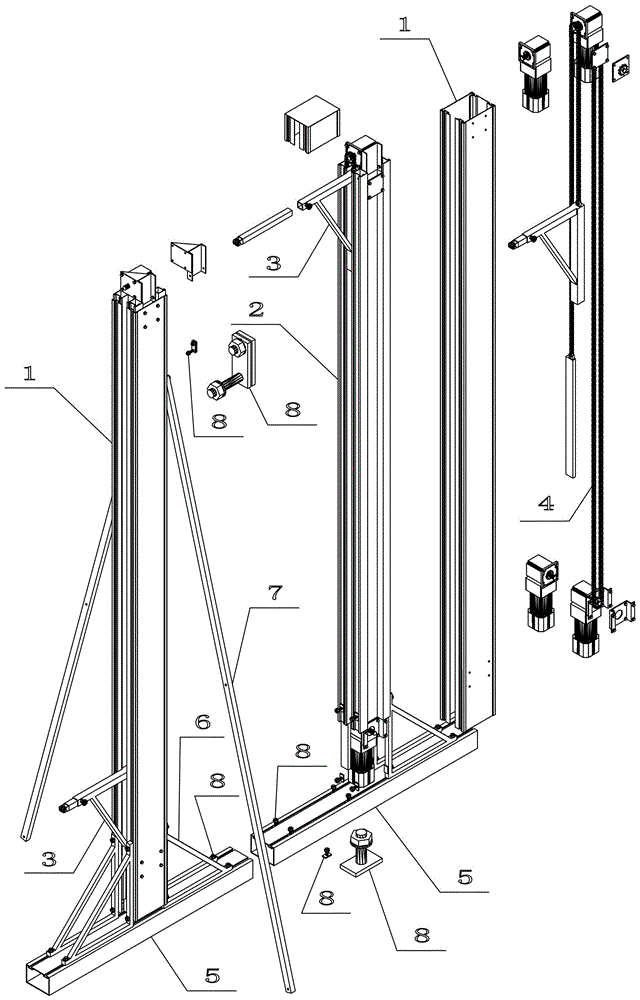

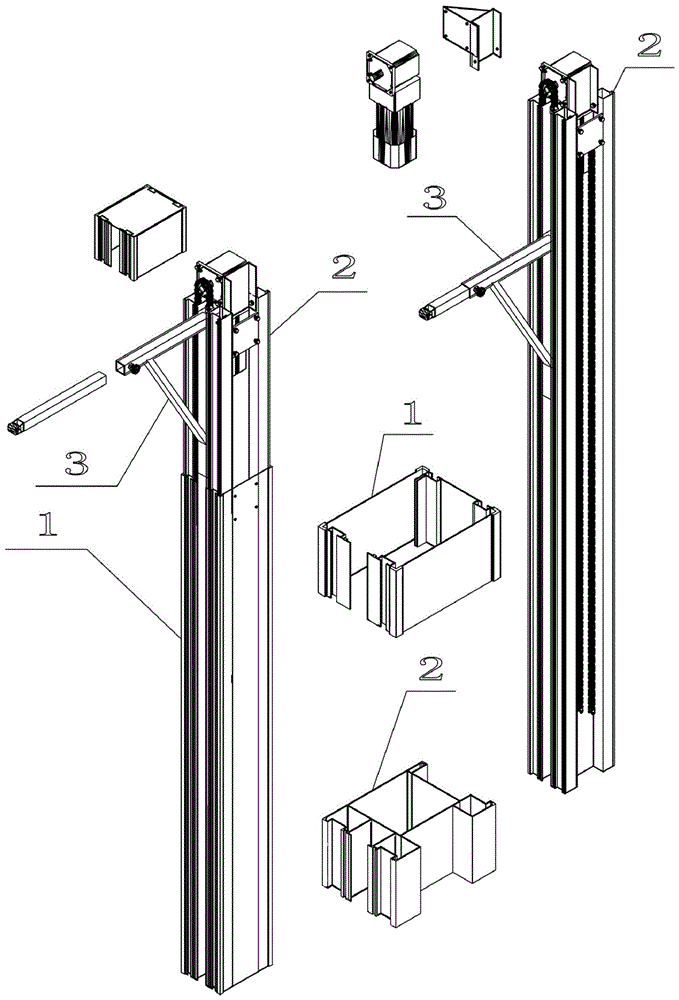

InactiveCN105752878AIncrease lifting weightImprove hoisting stabilityLifting framesGear wheelElectric machine

The invention discloses an awning mounting lift. The awning mounting lift comprises an outer tube profile (1), an inner tube profile (2), a lifting frame (3), a transmission lifting system (4), a base profile tube (5), a base supporting frame (6), a supporting tube (7), sliding blocks (8) and a power line band (9), wherein the outer tube profile (1) is connected with the base profile tube (5), the base supporting frame (6) and the supporting tube (7); a square opening for arranging a right-angle motor is formed in the inner tube profile (2), an opening for mounting a chain is formed in the side face of the inner tube profile (2), and a sliding slot for arranging the lifting frame (3) is formed in the front surface of the inner tube profile (2); the lifting frame (3) is connected with the chain of the transmission lifting system (4); the transmission lifting system (4) consists of the motor, the chain, a gear and a mounting component; a chute for mounting the base supporting frame (6) is formed in the base profile tube (5); the base supporting frame (6) is connected with the outer tube profile (1) and the base profile tube (5) through the sliding blocks (8); the supporting tube (7) is connected with the outer tube profile (1) through the sliding blocks (8); the sliding blocks (8) consist of iron plates and screws; the power line bank (9) is clamped in a notch of the outer tube profile (1) and is connected with the motor.

Owner:浙江广森休闲用品股份有限公司

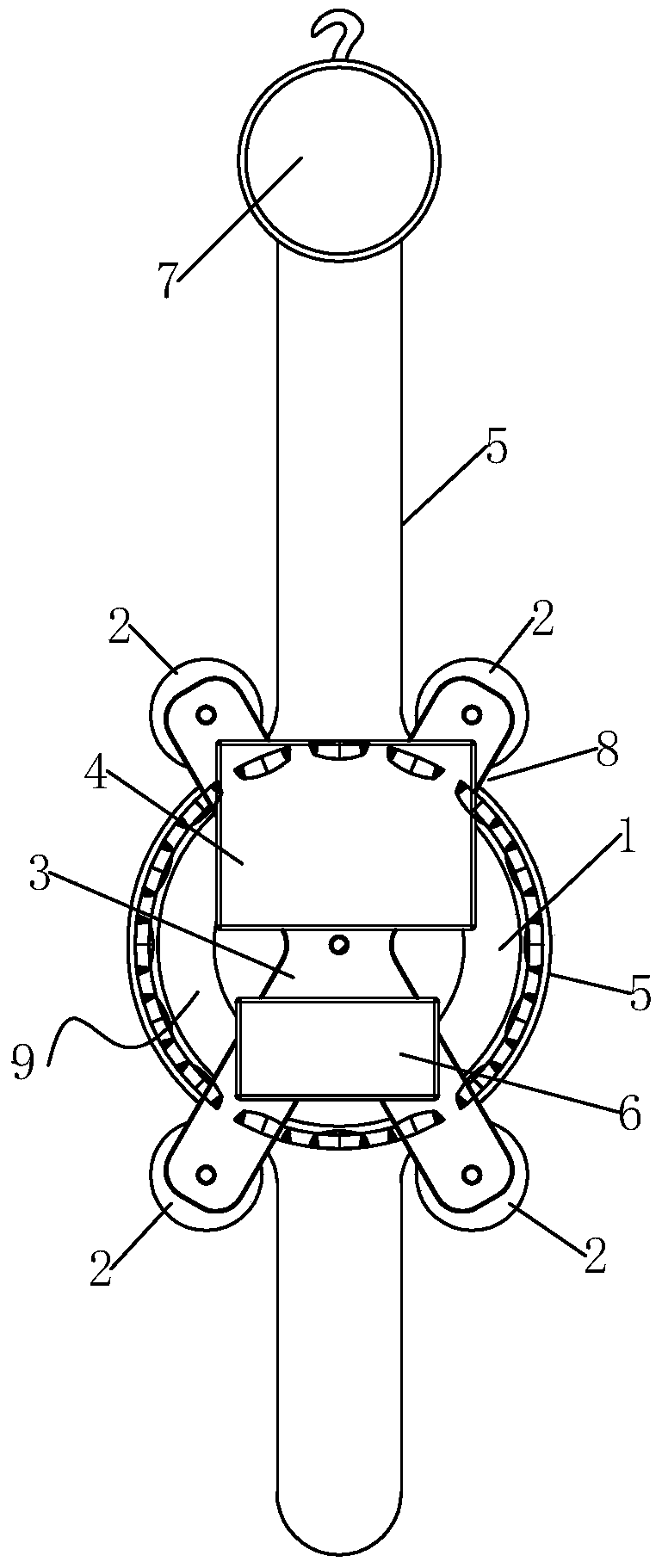

Chain hoist external power unit and chain hoist system

InactiveCN105000488BSimple structureEasy maintenancePortable liftingWinding mechanismsPower unitPetroleum engineering

The invention provides a chain block external power device and a chain block system. The chain block external power device comprises a main chain plate, four auxiliary chain plates, a support installed on the main chain plate, a motor installed on the main chain plate, and a controller used for controlling the rotation direction and the rotation speed of the motor. The support is in an X shape and comprises a first end, a second end, a third end and a fourth end, wherein the first end, the second end, the third end and the fourth end are arranged in the circumferential direction of the main chain plate and protrude to the outer side of the main chain plate; the first end, the second end, the third end and the fourth end are each provided with one auxiliary chain plate; an installation joint used for installing a chain block chain is formed between each of the four auxiliary chain plates and the main chain plate. By the adoption of the technical scheme, the chain block external power device and the chain block system are simple in structure, low in cost, durable, portable, wide in application range, high in hoisting weight, high in efficiency, safe, convenient to install and easy to maintain.

Owner:邹远琛

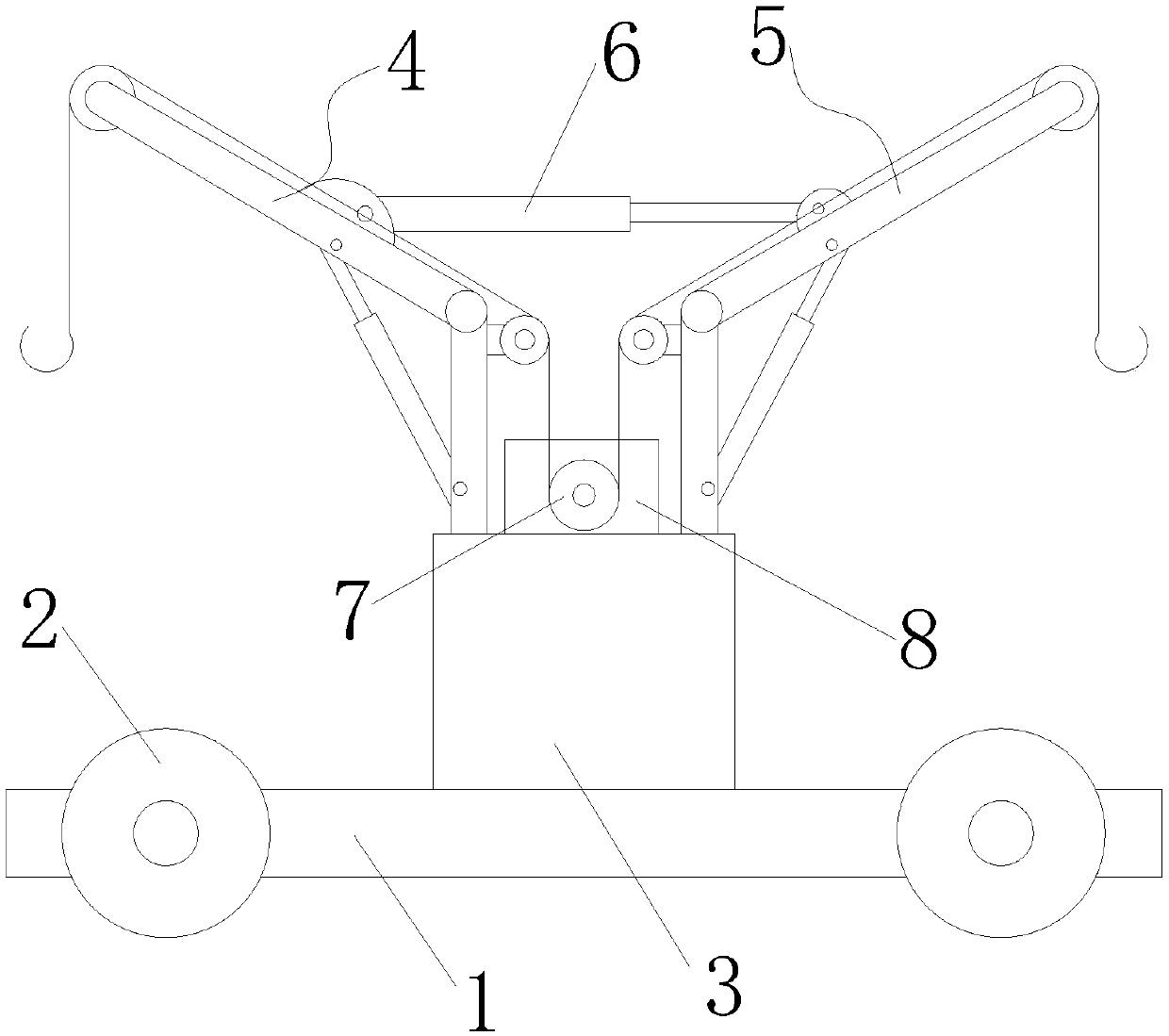

Double-arm building tooling crane

The invention relates to a double-arm building tooling crane. The crane comprises a trolley bottom plate and wheels, wherein a supporting seat is arranged in the middle of the trolley bottom plate, afirst lifting arm is arranged on one side of the upper end of the supporting seat, a second lifting arm is arranged on the other side of the upper end of the supporting seat, an adjusting rod is arranged between the first lifting arm and the second lifting arm, a lifting rope of the first lifting arm and a lifting rope of the second lifting arm are connected with a winding drum correspondingly, and the winding drum is connected with a driving motor. During use, the trolley bottom plate is moved to a proper position through the wheels, at the moment, building equipment is lifted under the action of the first hoisting arm and the second hoisting arm, the distance between the first lifting arm and the second lifting arm is controlled through the adjusting rod, so that the lifting weight of acrane is improved through the two lifting arms, meanwhile, the size of a trolley body is reduced, the operation is convenient, and the practicability is good.

Owner:田晓枫

Glass curtain wall construction structure and construction method

ActiveCN112196159BFast constructionImprove installation accuracyWallsBuilding material handlingArchitectural engineeringSystem construction

The present invention relates to the field of housing construction engineering, and more specifically relates to a glass curtain wall construction structure and a construction method thereof, which has high construction efficiency, fast transportation of a rigid turnover frame, good stability of a mobile crane, high construction quality of a glass curtain wall, and fast construction speed. High economic and technical benefits; its main construction steps include: (1) construction preparation, (1) measuring and setting out, (3) embedding of embedded parts, (4) construction of cable wind rope stabilization system, (5) glass curtain wall unit plate Mobile crane assembly, (6) transportation of glass curtain wall unit panels, (7) hoisting of glass curtain wall unit panels, (8) fixed connection of glass curtain wall unit panels with three-way six-degree trough embedded parts, (9) unit body Elevation inspection, (10) waterproof gland installation, (11) curtain wall closing can realize centralized processing, precise positioning, and rapid hoisting, which has good economic and technical benefits.

Owner:SHENZHEN JIANYI DECORATION GROUP

Variable amplitude trolley with detachable landing legs

The invention discloses a variable amplitude trolley with detachable landing legs, and belongs to the field of variable amplitude trolley equipment of tower cranes. The variable amplitude trolley comprises a variable amplitude trolley body and main chord members arranged on the variable amplitude trolley body and further comprises the detachable landing legs arranged on the variable amplitude trolley body. Landing leg sleeves are arranged at the lower ends of the main chord members and provided with through holes. The detachable landing legs comprise landing leg bodies and supporting plates arranged at the lower ends of the landing leg bodies. The landing leg bodies are provided with installing holes corresponding to the through holes in the landing leg sleeves. The installing holes and the through holes are internally provided with connecting pieces used for fixing the landing leg bodies into the landing leg sleeves, and the detachable landing legs can be installed on the main chord members through the connecting pieces. Fixing pieces used for preventing the connecting pieces from disengaging from the installing holes and the through holes are arranged at the tail ends of the connecting pieces. The landing leg bodies are fixed to the supporting plates. The detachable landing legs are arranged in the main chord members, trolley sliding wheels are protected through the landing legs, and the sliding wheels are prevented from being damaged. When a cargo boom is assembled, the landing legs can be dismounted, and therefore the elevating capacity of a tower crane can be increased.

Owner:XUZHOU CONSTR MACHINERY

Multifunctional construction tooling crane

InactiveCN109809298AIncrease lifting weightSmall sizeCranesIndustrial engineeringBuilding construction

The invention relates to a multifunctional construction tooling crane. The multifunctional construction tooling crane comprises a vehicle bottom plate and wheels. A supporting base is arranged on themiddle portion of the vehicle bottom plate. One side of the upper end of the supporting base is provided with a first hoisting arm, and the other side of the supporting base is provided with a secondhoisting arm. An adjustment lever is arranged between the first hoisting arm and the second hoisting arm. A hoisting rope of the first hoisting arm and a hoisting rope of the second hoisting arm are connected with a coiling block correspondingly. When the multifunctional construction tooling crane is in use, the vehicle bottom plate is moved to the appropriate position through the wheels, and construction equipment is hoisted under the action of the first hoisting arm and the second hoisting arm. Moreover, the distance between the first hoisting arm and the second hoisting arm is controlled through the adjustment lever. Thus, the hoisting weight of the crane is increased through the two hoisting arms. Meanwhile, the size of a vehicle body is reduced. The multifunctional construction tooling crane is convenient to operate and good in practicality.

Owner:朱东健

Turbine lifting device used for ship machining

InactiveCN110498348AIncrease flexibilityExtended service lifeTrolley cranesTravelling gearWorking environmentEngineering

The invention provides a turbine lifting device used for ship machining. The turbine lifting device comprises two walking supporting beams, a main beam connected to the upper portions of the walking supporting beams and bases fixed to the lower portions of the walking supporting beams. A sliding rail is arranged at the lower portion of the main beam, and the sliding rail is connected with walkingmechanisms fixed to the upper ends of the walking supporting beams in a sliding manner. Each walking mechanism is provided with a shell body spaced with the main beam, wherein multiple supporting springs making the shell body spaced with the main beam are fixed to the bottom of the inner side of the shell body, multiple lower walking wheels located below the sliding rail are connected to the upperends of the supporting springs, and upper walking wheels are connected to the positions, corresponding to the lower walking wheels, above the sliding rail. By means of the turbine lifting device usedfor ship machining, due to the designed walking mechanisms and wheels, the whole lifting device can be moved flexibly, meanwhile, the two walking supporting beams move along the sliding rail, and therefore the turbine lifting device can adapt to various narrow walking and working environments; the supporting springs are arranged below the lower walking wheels of the walking mechanisms, so that friction between the shell bodies and the main beam is avoided; and due to designed bearing devices, the lifting weight and flexibility of the lifting device are improved.

Owner:BINZHOU POLYTECHNIC

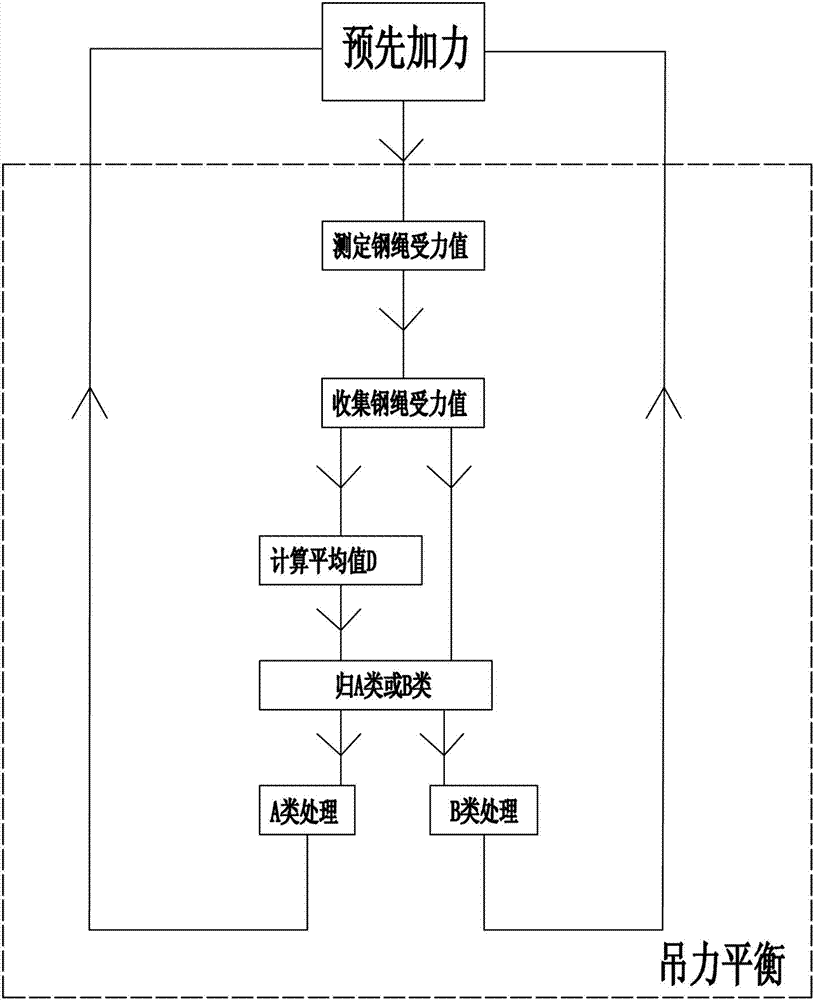

Electric steel wire rope balancing device and lifting method for vertical full-balance steel wire rope hoisting winch

ActiveCN103922210AImprove the forceEven by forceElevatorsVertical ship-liftingElectrical steelPre stress

The invention discloses an electric steel wire rope balancing device and a lifting method for a vertical full-balance steel wire rope hoisting winch. The vertical full-balance steel wire rope hoisting winch comprises winch equipment and hoisting steel wire ropes, and one end of each hoisting steel wire rope is wound on the winch equipment while the other end of each hoisting steel wire rope is connected with a to-be-hoisted article. Two disconnected steel wire ropes can be connected to form one hoisting steel wire rope by the electric steel wire rope balancing device, the electric steel wire rope balancing device can be started for pre-pressurizing the hoisting steel wire ropes, pre-stress of each hoisting steel wire rope is adjusted to balance stress of each hoisting steel wire rope by measuring stress conditions of the pre-stressed hoisting steel wire ropes. The electric steel wire rope balancing device and the lifting method for the vertical full-balance steel wire rope hoisting winch have the advantages of simple structure, convenience in maintenance, reliability in performance and capability of hoisting articles more than 4000 tons.

Owner:CHINA GEZHOUBA GROUP MACHINERY & SHIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com